How to insulate a heating battery?

To do this, it is best to use food-grade aluminum foil, tightly wrapping the radiator. This fairly simple operation alone will significantly reduce the amount of heat entering the room. Next, lay a layer of thermal insulation material on top of the foil.

Interesting materials:

How to properly wash colored items in a washing machine? How to properly wash felt boots? How to properly wash a cotton blanket? How to properly wash a velor robe? How to properly wash clothes for a newborn? How to properly wash cotton items? How to properly wash items made from camel hair? How to properly wash things that fade? How to wash clothes using a semi-automatic machine? How to properly wash things with down?

Scope of application

Reflective thermal insulation is applicable to all surfaces without dirt and dust, suitable for complex structures with corners, bends and differences. Insulating walls from the outside can achieve maximum effect by creating an air gap of 20 mm on the foil side.

The material is effective for multi-story and single-story frame houses, and it will increase the resistance of the walls without increasing their volume. Installation is carried out end-to-end without overlaps, and the seams are taped with foil tape.

Application from inside

If you want to insulate the room from the inside, then there are two options. The first option is to make 2 air gaps between the external wall and the material, between the insulation and the cladding (for example, drywall). In this case, TIM with double foil is used.

The second option is to create one gap between the external wall and the insulation, for which material foiled on one side is used. The foil is turned indoors.

Roof insulation

Reflective TIMs mounted on the roof provide not only thermal but also vapor insulation. The under-roof space is also protected from moisture.

Reflective film is especially effective when insulating the ceiling of a bathhouse.

Piping and ventilation

Pipes require insulation with double-sided foil. If the pipes have a diameter less than 159 mm, then there is no need to create an air gap between the TIM and the pipe. If the pipes have a larger diameter, then a gap is required. The air gap is arranged as follows:

- The first option is to attach rings made of foil film to the pipe with a distance of 300-400 mm from each other. And on top of the rings the pipe is wrapped with insulation;

- the second option is to lay wooden blocks with a cross-section of 10 by 10 mm or 20 by 20 mm along the pipe, after which insulation is wrapped on top of them.

The joints must be sealed with aluminum tape. Insulating ventilation ducts will eliminate heat loss and provide sound insulation.

Where does the heat go?

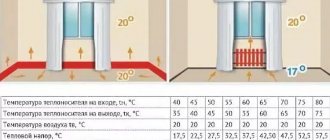

Heating devices in buildings are installed under the windows.

The goal is to warm the air inside and create a thermal curtain that prevents the penetration of cold from the street.

Heat spreads from a heated object to a cold one.

The wall temperature is lower than that of the radiator.

In the cold season, the surface behind it heats up to 35-40 °C.

Instead of heating the air inside a warehouse or office, some of the energy is used to heat the external walls.

Important Features

By choosing modern material, the owner of the premises receives certain advantages. They are largely due to the high characteristics of the insulator itself.

Gaps between the film can be sealed with aluminum tape

When using this solution during the cold season, heat loss is eliminated. In summer, there is no excess thermal energy in the rooms of the building. As a result, a small amount of resources has to be spent on maintaining an optimal microclimate. Reflective insulation works on the principle of a thermos, preventing the penetration of thermal energy along a given vector.

One of the features of foil insulation is its complete waterproofness. This statement is especially true for models made from polyethylene foam. Aluminum foil is not subject to combustion. Therefore, the use of such a layer together with foam plastic or foamed polyethylene provides increased fire safety.

Read also: about non-flammable fireproof insulation.

In terms of physical parameters, reflective insulation has the same properties as the base layer. The material that is created on the basis of foamed polyethylene has the smallest thickness. Models made from mineral wool with the addition of a layer of foil are thicker.

How reflective insulation behaves in fire:

Advantages and disadvantages

Any material used in the construction industry becomes popular if it has a set of unique positive qualities that are in demand among consumers. In the case of reflective type insulation, there is no shortage of them.

Experts highlight the following advantages:

- The material meets hygienic standards, since the main components in its production are polyethylene and foil.

- This solution is able to reflect up to 97% of thermal energy.

- Polyethylene foam, which contains air bubbles in its structure, allows for additional thermal resistance.

- High fireproof properties. Experts classify the material as highly flammable.

- Rolls of reflective insulation are lightweight and compact in size. Therefore, there are no problems with storage, they are convenient to transport.

- When using material to insulate surfaces, heating costs are reduced. The cost savings for the owner of the structure are much higher than with other solutions.

The main disadvantage of reflective insulation is its softness. After installation, finishing work is not carried out using plaster and ordinary wallpaper. Another disadvantage is that easy fastening is only possible when using materials with an adhesive backing.

Other models must be installed using a suitable fastening compound. When a material is nailed to a surface, it reduces its thermal insulation properties. When insulating facade walls, it can only be used as an additional layer, acting as a protection against moisture and reflecting heat.

Installation of films behind radiators is a simple sequence of actions

From a technological point of view, the foil behind the heating battery is installed without any difficulties. You will complete all the work efficiently and quickly if you listen to some advice.

First, don't buy matte metallic material. Use only polished foil.

Second, don't buy double-sided films. One air gap is quite enough to ensure high-quality heat reflection.

Thirdly, leave a gap of about 1.5–2 cm on both sides of the insulator layer. It is necessary to obtain the optimal thermal resistance of the reflector (1.15 sq.m*°C/W).

Prepare liquid nails or standard adhesive used for installing wallpaper, as well as directly reflective foil, and proceed to install it. The procedure is as follows. First, carefully measure the dimensions of the wall areas where you plan to install the screen or niches.

The parameters of the film must correspond to the projection of the heating radiator onto the wall. Add about 10% to the result obtained. In this case, the heat-reflecting potential of the foil will be slightly greater. Some masters say that extra centimeters are not needed.

The effect from them will be insignificant, but the edges of the screen sticking out from behind the radiator will greatly spoil the aesthetics of the room. See for yourself, choose the option that suits you personally.

Then make sure that there is a gap of at least 1.5 cm between the heating device and the film that you will mount. When there is not enough free space, you will have to adjust the radiator suspension to provide the missing centimeters.

Next, remove the radiator. Mark the places where its mounting brackets are located. Dismantle them. Inspect the brick or concrete masonry of the wall surface.

If there are gaps, cracks, or other defects, plaster them (or putty). Level the wall, glue the screen (coat its back side with wallpaper or polymer composition).

Instead of glue, as noted, it is allowed to use liquid nails. In some cases, it is permissible to use staples or small nails to secure the foil (if they fit into the wall material without any problems and are firmly held in it). Carefully return the pendants to their place and install the battery.

Additionally, we will give some useful recommendations to home craftsmen who are installing heat-reflecting products for the first time. If during installation of the screen you damage its outer covering, the cut site can be masked with LAMS or LAS films.

They are made of foil and do not reduce the efficiency of heat reflection. Don't try to find screens that are too thick. Practice shows that five centimeters is enough to effectively save heat in the house.

Recommendations for the installation process

- Installing a heat-reflecting screen behind the battery is technologically simple, but will be done faster and better if you take into account the following practical recommendations:

- the maximum effect when using penofol and similar materials is achieved if there is an air gap of 15-20 mm on both sides of the insulating layer. In this case, the thermal resistance of the insulating structure is achieved up to 1.1-1.2 (m∙°C)/W. Installation is carried out on wooden slats, and penofol must be double-sided foil (type B);

- in most cases, to create a reflective screen for batteries, one air gap is enough - between the radiator and the insulating material. Double-sided foiling is not necessary in this case;

- When choosing a reflector, it should be taken into account that the foil must be polished (not matte).

Product design

A reflective screen for a metal stove can be made of stainless steel

The reflective screen for the heating radiator is made from materials whose main property is low thermal conductivity, not exceeding 0.05 W/m*C. All screens have a layer of insulation. The sheet consists of foil and a layer that retains heat.

Foamed polyethylene is often used as insulation. It has good thermal insulation properties, technical characteristics and is low in cost. For thermal protection of furnaces, basalt cardboard is mainly used.

Front reflectors for heating radiators in bathhouses are a good replacement for brickwork. They allow you to increase the temperature and heat adjacent rooms. The thickness of the steel sheet must be at least 0.8 m. Organosilicon paint is used as a coating.

When installing screens under a wooden covering on the wall in a steam room, the safety of the room increases. Aluminum foil acts as a screen, the joints between the sheets of which are sealed with special metal tape. It is used if the temperature of the outer walls of the furnace is not higher than 400°C.

Special fire-resistant materials to protect buildings from fire

The main advantages of heat-reflecting screens:

- Wide scope of application. They are suitable for installation at home, in shopping centers, bathhouses, factories and other residential and non-residential premises.

- Achieving energy savings by retaining heat in the room.

- Ease of installation. There is no need to call a technician to install the screen behind the battery.

- No specialized care or complex maintenance is required.

- Light weight and flexible. No special conditions are required for transportation.

- Wide selection of materials from any price range.

- Low thermal conductivity.

- It is easy to cut into pieces of the required size using a regular construction knife.

- Moisture protection.

- Possibility of insulation of internal surfaces.

- Ensuring the reflection of thermal waves with an efficiency of 97%.

You can purchase the screen in specialized stores.

Why do you need foil?

The coefficient of reflection of thermal radiation of polished aluminum is higher than that of other metals.

This means that maximum heat will return inside the room.

You should not use screens with a double-sided metal backing.

The layer of foil on the side of the cold wall does not carry a functional load - it simply has nothing to reflect.

Unscrupulous sellers in construction markets deceive customers by talking about new metallized coatings with fantastic characteristics.

These are fairy tales.

Any polished metal refracts heat rays, but the reflection coefficient is negligible and does not affect thermal efficiency.

The cost per square meter of a thermal reflective screen with aluminum foil is more expensive than with a metallized film.

The difference is small - 5-10 rubles.

Pros of a heat reflective screen

Is it worth the candle: pros and cons of installing a screen

On forums dedicated to home heating issues, there is a constant debate between supporters and opponents of installing reflective screens behind radiators. Some participants in such debates say that screens provide a real increase in temperature and savings in heating costs. Representatives of the other camp are confident that screens have more of a psychological effect.

I have collected the main arguments of both sides in a table:

| Pros | Cons |

| The cost of a reflector (if you do the installation yourself) is low. With the cost of a roll of insulation being 18 sq. m 1.5 thousand rub. You can equip an entire house with screens for 2–3 thousand rubles. | Due to the low efficiency of the screen, the cost of creating it is money thrown away. |

| It’s easy to build a screen; a person without special skills can handle it. | If you do not understand what and how to do, you can disrupt the air flow and reduce the efficiency of the heating radiator. |

| The screen saves 5–7% of the energy emitted by the radiator. | The screen only protects 5% of the external wall of the room. Through the rest of the area, not protected by a reflector, the street is still heated. |

| The temperature in a room equipped with a heat reflector will be 2–3 °C higher, all other things being equal. | Often there is no objective evidence of savings, and all talk about effectiveness is based on the “placebo effect.” |

We recommend: Saving neighbors from flooding - simple ways to eliminate leaks in pressure pipes

Taking into account the ratio of the costs of making a screen and the cost of paying gas bills for a boiler in a cottage, the option of creating reflectors behind the batteries seemed promising to me. Therefore, I decided to spend money on one roll of insulating material, make screens in one or two rooms, and then evaluate the effectiveness of the idea.

Advantages and disadvantages of heat-reflective insulation

We have figured out the operating principle of this insulation, now we will consider the advantages that sellers and advertising agents give it. These include the following.

Easy to use. It’s impossible to disagree with this statement - what could be simpler than attaching rolled material? I rolled it out over the surface and pinned it with a stapler or nails. And some types of this material are generally made on a self-adhesive basis. Compactness. This point is also beyond doubt, since unlike other insulation materials (the same mineral wool), isolon has a small thickness, which allows it to be placed even in the shallowest cavities. Wide scope of application. In general, I agree, but some aspects and abilities attributed to this material do not correspond to reality. More on this a little later, but for now you only need to know that this material is used to insulate any surface under any operating conditions. Safety and environmental friendliness. By themselves, polyethylene and foil do not pose any threat to humans. But the issue of harmlessness and environmental friendliness should not be removed from the agenda - you need to understand the dangers of a thermos, which is obtained as a result of the circular use of heat-reflecting insulation. At a minimum, these are comfortable conditions for the growth of fungal microorganisms - and needless to say, this problem can be solved with the help of high-quality ventilation. Try to ventilate the space between the floor screed and the floor slab. And so it is with walls and ceilings (although the latter are a little easier). High thermal conductivity. Here, as they say, if you try, you won’t know. You can write anything you want on paper

Judging from actual practice, such thermal insulation copes with its tasks quite well, but, again, if we take into account its vapor non-conductivity, then cheaper polyethylene film can be used with the same success. Low degree of flammability. This statement does not inspire confidence at all - it immediately begs the question, how low is this degree? And I remember how polyethylene burns with a clear flame and drops molten particles onto the floor, spreading the fire further and further. Durability

It is difficult to disagree with this - under natural conditions, polyethylene decomposes for a very, very long time. But here you should look not at this moment, but at the operating conditions. For example, reflective thermal insulation for underfloor heating. Salt, contained in abundance in cement mortar, and foil are bad neighbors - after a year, the first will simply corrode the second and only a small and ineffective layer of isolon will remain.

In general, not all that glitters is gold

With this kind of building materials you need to be quite careful and, first of all, pay attention not to their advantages, but to the disadvantages that emerge when they are used in certain conditions. And they mostly prefer to remain silent about shortcomings

Reflective thermal insulation for walls photo

Disadvantages of the material

Energy-saving film is not a source of heat and does not affect the heating of the room. Retains heat produced by central heating sources. The material maintains the existing air temperature.

Through a window covered with athermal protection, heat from the street does not penetrate

Disadvantages of the material:

- The protection does not allow UV radiation to pass through and is not recommended for use in rooms with indoor plants. Not suitable for tinting glass in greenhouses and greenhouses in the local area. Plants need ultraviolet light to grow. If there are plants in a room with energy-saving coating, you can use phytolamps. However, you can forget about saving energy - for normal plant growth and compensation for the lack of sunlight, lighting must work at least 12 hours a day.

- The effectiveness of the film coating depends on proper gluing. It is better not to cover large areas of glazing - for example, panoramic windows or portals - by yourself.

- The coating prevents the penetration of natural solar heat from outside into the room; in spring and autumn the apartment will be uncomfortable - damp, cold. Mobile heating devices must be turned on.

- Ability to reflect radio signals. Radio waves from the outside going to the indoor antenna or mobile phone are reflected by the coating. There may be interruptions in cellular communications.

- If the room has window systems with two or three-chamber double-glazed windows, it is not necessary to use film.

Wooden screens

The simplest screen to make is a panel in the form of a lattice made of wooden slats mounted on a wooden frame. The position of the slats can be any - vertical, horizontal, diagonal.

If desired, you can make a cellular lattice by placing the slats at an angle to each other, and using two opposite directions of the layout. Moreover, the angle between them does not have to be right. But in order for the lattice to be flat, you will have to make grooves at the connection points, and, given the thickness of the slats and the manual manufacturing method, it will definitely not be easy to do everything.

Another type is a screen-blind. This screen is reminiscent of classic wooden window shutters. In order for the slats in the frame to be at the same angle to the plane, identical parallel cuts are made on the side posts using a miter box. Since the thickness of the wood hacksaw blade is less than the thickness of the slats, two cuts are needed for each of them, and the excess must be removed with a narrow chisel.

Both the timber for the frame and the slats must be dry. Considering the proximity of the screen to the battery, it is necessary that their own humidity should not exceed 12% (these are general requirements for wood intended for carpentry). There is a simple home way to check - if you try to tie thin shavings into a knot, it should break.

When making both types of screens, each rail must be carefully sanded before attaching it to the frame. After they are fixed in place, the grille is primed and coated with two layers of varnish, paint or enamel.

As a decorative finish, you can attach platbands made of wood or MDF around the perimeter of the frame. If these are wooden platbands, then they must be treated in the same way as the grille, but their finishing coating does not have to be the same - the perimeter may be of a different shade.

When the battery is in a niche, the screen can either completely cover it or hang on hooks, leaving small gaps at the top, bottom and sides.

When attaching the screen to the frame, the side surfaces are sheathed with laminated fiberboard or chipboard. The ends of the sheathing do not need to be trimmed with a decorative edge if the screen trims will cover them.

Another common type of wooden screen is using plywood as a panel. If you know how to work with a jigsaw, you can cut out an openwork lattice with any pattern transferred to the surface of the plywood using a stencil. The finishing process for such a panel is no different from a grille: sanding, priming and painting.

Important! When choosing chipboard or plywood for a screen, you need to pay attention to their class. For plywood it should be E1, for chipboard - E0

Manufacturing technology

Before you start making a fence for the battery, you should choose a suitable design: hanging or resting on the floor in the room.

Then a drawing is made, and tools and materials are selected.

Materials and tools

For manufacturing you will need the following materials and tools:

- Chipboard sheet.

- Special edge for finishing with a thermal adhesive layer on the back side.

- Metal screws and angles.

- A stapler with staples or small nails with a hammer.

- Iron.

- Knife.

- Sandpaper.

Marking and measurements

First you need to mark the location on the wall and take the necessary measurements. We mark the mounting points for placing the panel. We make a simple schematic drawing with important dimensions.

We make four walls for the frame from chipboard. You can purchase already manufactured parts. We connect the walls together using metal corners.

We make a lattice from the edge and fix its parts on the frame using small nails and a furniture stapler. The length of the edging material is calculated by the formula L(edge length)=(a (product length)*b(width)*1.3)/c(edge width).

The holes on the grill must be the same size; for this you need to make preliminary markings on the frame or a special template. The front side of the grate must be heated with an iron at high temperature. As a result of this procedure, the heated glue will connect the lattice elements at the intersection points and give it greater rigidity.

The same edge must be used to finish the end parts of the frame. We apply the edge to the end and smooth it with an iron. Using a knife, cut off the protruding edges of the edge. Protruding edges are sanded with sandpaper.

Consolidation

If the screen is supposed to be located close to the wall, then we simply insert it. If a hanging option is planned, then you need to perform a few more manipulations.

- We make recesses in the frame at the junction points with the heating pipes. Then the decorative fence is placed on the pipes using special grooves.

- You need to attach metal corners in the marked places.

- Then we bend the edges of the corners 10 mm upward and hang the made panel on the resulting hooks.

The enclosing screen is an excellent solution for various heating devices. If you do everything correctly and choose high-quality material, you can create a wonderful decorative element yourself.

Alternative methods

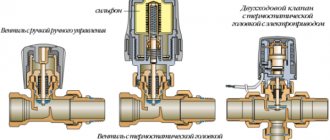

One of the alternative ways to protect against excessive heat in a living space is to purchase and install a special valve. Such a simple device allows you to regulate the level of thermal energy supplied to the battery and save its value in ruble equivalent. The principle of saving becomes important for apartment owners, since heat distribution will be possible depending on atmospheric conditions.

The current state of the market for plumbing fixtures and fittings makes it possible to purchase a special protective screen that operates on the principle of blinds. One turn of the flaps of such a screen helps to reduce the amount of thermal energy distributed throughout the apartment, as well as minimize the risk of burns from an excessively hot radiator. Another advantage of placing a louvered screen is the simplicity of its design, which allows you to avoid complex installation work. Installing this type of device will not take more than 10 minutes of your time.

The most radical way to limit the heat supply to your apartment is to contact the office of the management company. Such treatment will reduce the thermal effect from the apartment radiator by covering the corresponding common house valve. This method is not a panacea if limiting the heat supply to the apartment is necessary exclusively for you. Using this option will also affect your housemates who may not be feeling hot.

The simplest way

Widely used in standard apartments, cast iron radiators are the best way to heat residential premises. However, such heating devices also have their drawbacks, mainly associated with the lack of a thermostat and an excessively high output of accumulated energy. You can consider ways to optimize the operation of cast iron radiators, if any are present in your apartment.

The simplest and most effective material for eliminating excessive heat transfer from a cast iron battery is a regular blanket placed on the planes of the radiator. Closing the battery with it will be a matter of seconds for you. The possible predicted skepticism of many Internet users is associated, first of all, with poor knowledge of the physical processes described in the school curriculum.

Reduced indoor humidity will be a minor side effect. It can be easily eliminated by purchasing an air humidifier (its average consumption in a typical apartment is up to three liters of water per day) and a psychrometer - a device that controls the level of humidity in the room.

Advice

Do not use the windows as a way to lower the room temperature; they can only be opened for natural ventilation of the room. Otherwise, the presence of very dry air in the apartment can lead to unpleasant consequences for the nasopharynx and skin. The heat escaping from the room will not significantly reduce the heating temperature.

The rationale for such advice lies in the physical processes that occur when cold street air enters the apartment. This air, which has a low level of humidity, heats up as it passes through the window into the room and reduces the absolute value of humidity. Accordingly, an increase in the humidity of the apartment atmosphere will occur with the help of your breath and skin, taking away the water it needs from the body.

We recommend: 9 useful things that can be sewn from old jeans

Principle of operation

To understand the principle of operation of such insulation, consider the main methods of transferring heat from one coating to another:

Thus, heat loss is inevitable. It turns out that to create the effect of thermal insulation, it is necessary to minimize heat loss from radiation. But traditional TIMs are not able to protect a building from this type of heat transfer. And the optimal material was found - foil insulation, known for its reflective and low-emissivity properties.

Reflective thermal insulation works across all heat transfer processes: radiation, convection and conduction, inhibiting heat loss.