Brick is a classic building material designed to last for decades. The thermal conductivity of brick walls depends on their thickness - the number of rows of masonry.

If a brick wall freezes in the first winter after building a brick house, this means that the construction technology was violated or the thickness of the house wall is insufficient. In this case, it is necessary to solve the problem of thermal insulation of brick walls from the inside.

External thermal insulation should be a priority, but its installation is not always possible. Let's look at how to insulate a brick house from the inside with mineral wool, which one is better to use, and how to properly carry out the installation of thermal insulation.

About insulating brick walls

Human activity is associated with a large release of heat and moisture. Heat radiates from the body, from household appliances. Moisture is released when breathing, cooking, using water for hygiene, washing dishes, and watering flowers. And the warmer the air, the better it retains moisture.

If the brick walls are not insulated enough, then when the heated, humid air cools, condensation will form on them. This will lead to the growth of fungus and the appearance of dark spots on the surface of walls and ceilings.

Mold spores are harmful to human health by entering the respiratory system and causing asthma or allergic reactions. In addition, mold has a destructive effect on the materials from which the walls are built and irreversibly damages the finish.

Before insulating the walls of a brick house from the inside, it is advisable to understand how this will affect the condition of the external walls and the indoor microclimate.

Main types of mineral wool

There are three such types.

Glass wool

This product is produced by melting broken glass and quartz (sand). When a molten mass is obtained, glass fibers are pulled out of it, the length of which is 15-50 mm, thickness - 5-15 microns.

Considering what this mineral wool consists of, it can be argued that this material:

- chemically absolutely inert;

- cannot become a medium for the development of any forms of biological life (neither microflora, nor rodents, nor insects will grow in glass wool);

- not subject to rotting.

The disadvantage is the causticity and fragility of the elements that make up glass wool. When styling it, you need to work using special protective equipment, otherwise the skin will be completely irritated. Also, glass wool particles should not be allowed to get into the respiratory system or eyes.

So it is not advisable to use glass wool when arranging thermal insulation in residential premises. After all, microparticles will still be released from the laid mats and spread throughout the room. Residents will begin to inhale them along with dust particles and suffer from allergic reactions.

Slag

This mineral wool is also not suitable for thermal insulation of housing. There are many reasons that can be cited, including:

- causticity and fragility of particles;

- high hygroscopicity (ability to accumulate moisture);

- significant shrinkage (as a result, the insulating properties of the insulator layer are lost).

And the designated material cannot be classified as absolutely environmentally friendly. It is produced from blast furnace slag. Their composition is heterogeneous; they can even show increased background radiation. In addition, steam may be highly acidic, and moisture absorption contributes to the formation of an aggressive environment. Metal elements deteriorate first.

Basalt (stone) wool

This insulation is excellent for furnishing residential premises, that is, for internal insulation of houses. This material, when compared with all others, is considered the most elastic and durable. The fibers are less brittle and therefore do not cause irritation to the mucous membranes and skin. At the same time, reducing negative qualities does not in any way reduce the insulating properties. Basalt wool has a thermal conductivity coefficient almost the same as glass wool.

A negative property of stone wool can be considered its ability to absorb moisture. However, its hygroscopicity index remains the lowest when compared with other similar compositions. Complete polymerization of the binder occurs when such a mass is produced. So this mineral wool does not pose a significant danger to human health. You just need to purchase certified products supplied by reputable manufacturers. Laying basalt wool is easy. Such mats (cords):

- hold their shape well;

- easily cut;

- If necessary, they are fixed to the wall with glue.

Features of internal insulation

It is clear that insulating a brick house from the inside is not the best solution. However, you should resort to it if:

- The building is an architectural monument and the appearance of its facade should not be changed.

- The walls of an apartment in a multi-story building freeze. According to current standards, it is forbidden to install structures that change the appearance of the building.

- The buildings are located close to each other, which makes it impossible to carry out work on insulating the external walls.

- Exterior brick houses made of expensive facing bricks are a pity to cover with new finishing, and laying a new outer layer of decorative brick after installing the insulation requires additional serious financial investments.

The disadvantages of insulating internal brick walls include the reduction of space in the room due to the installation of insulation and a base for finishing. The thickness of the insulating “pie” is usually at least 10 cm.

When installing thermal insulation inside the house, it is important to remember that insulating the internal surfaces of brick walls is fraught with the formation of condensation, which should not be allowed.

Where to place thermal insulation?

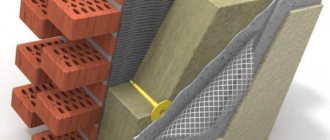

Insulation of buildings should be carried out correctly from the outside, otherwise condensation cannot be avoided upon contact with a cold front (dew point). Let's consider three types of brick walls:

- There is no thermal insulation . The dew point is located in the thickness of the brick wall, so it accumulates moisture during the winter months, dries out and eventually collapses.

- Thermal insulation is located on the room side . As the brick wall freezes, the dew point moves towards the room, towards the inner surface of the enclosing structure. As a result, moisture condenses between the heat insulator and the brick wall. To avoid the appearance of moisture in the wall, it is necessary to ensure effective ventilation of the room .

- The insulation layer is laid on the street side . The wall does not freeze, so it remains dry and freely allows water vapor to pass through. It is important that there is a ventilation gap between the insulation layer and the brickwork to remove moisture from the room.

Pros and cons of mineral wool

Mineral wool has some advantages over other insulation materials:

- low thermal conductivity;

- reduced fire level;

- stability of characteristics under mechanical influence;

- soundproofing;

- resistance to temperature changes;

- biochemical resistance;

- convenience and ease of installation.

But there are also disadvantages:

- heavy weight, very heavy construction;

- not hard and durable enough;

- higher cost;

- increased safety requirements;

- the highest labor costs.

Despite many advantages, building regulations do not recommend insulating rooms with ordinary mineral wool. This is due to the presence of phenol in the composition, which has a negative effect on the human body. When insulating a brick wall from the inside, you can use ecowool or stone wool.

If mineral wool is installed incorrectly, hazardous substances will enter the air through the ventilation.

When working with mineral wool, it is mandatory to use gloves and a respirator!

Varieties of mineral wool

Mineral wool is the general name for a thermal insulator, indicating its origin. But, there are several types of products that differ from each other. They are:

Glass wool. It has been used for a long time, but with the advent of new analogues, it is losing relevance

When working, it is important to protect the respiratory tract, mucous membranes and skin, since the insulation releases small particles of glass. Slag

Made from blast furnace slag. Rarely used in private housing construction. Suitable for non-residential premises, warehouses or temporary structures. Capable of oxidizing metal and strongly absorbing moisture. Stone wool. It is made by melting rocks (gabbro-basalt). Suitable for both insulation of facades and thermal insulation inside. Basalt wool. They prefer to insulate a house with mineral wool using this particular heat insulator. In all respects, basalt materials are better and of higher quality, they have a longer service life, and are easy to work with.

If you need to insulate a frame house using mineral wool, then the scheme involves the use of basalt wool

It is dense, does not shrink and does not burn, which is important for safety reasons.

Estimated prices for insulation

The cost of a heat insulator and their installation depends on the area of insulation, the size and price of the slabs. With a total insulation area of 109.9 m2, a thickness of the slab layer of 0.1 m, the volume of the heat insulator will be 11 m3.

Since most insulation materials are sold in m3, knowing its cost, you can determine the total cost of purchasing slabs:

- Basalt wool, 1500 RUR/m3, total 16500 RUR.

- Mineral wool, 1070 rub./m3, total 11770 rub.

- TechnoNIKOL basalt wool, 2270 RUR/m3, total 24970 RUR.

- Glass wool Isover Warm House, 1250 rub./m3, total 13740 rub.

- Stone wool Mat Teploroll, 1280 RUR/m3, total 14080 RUR.

- Slag wool, 860 rubles/m3, total 9640 rubles.

- Ursa GEO Facade, 975 rub./m3, total 10,725 rub.

Factors influencing the cost of thermal insulation work for a house with brick walls:

- type of material;

- wall area;

- height of the house;

- finishing method;

- technical condition of the surface;

- season.

General characteristics

The product is sold in two forms: slabs and rolls. The dimensions of the sheets are established by GOSTs. In the rolled version, the length of the mat can reach 10 meters, the width - from 1 to 1.5 meters. Slab parameters: 1250*610 mm. Thickness varies from 2 to 15 cm. Density is another important indicator, which indicates the number of fibers per 1 m³. On the packaging it is indicated by the letter P. Values from 35-150 are suitable for working with walls. The higher the value, the greater the load on the base.

Photo: Instagram @ooo_prosk

Photo: Instagram @rockwool_russia

What you need to do DIY insulation work

To perform insulation you may need the following tools and materials: Tool kit for insulating brick walls from the inside:

- hammer drill with a set of drills;

- screwdriver;

- level;

- roulette;

- furniture stapler;

- hammer;

- scissors;

- putty knife;

- brush;

- the insulation itself;

- adhesive solution;

- polyurethane foam;

- lathing material;

- deep penetration primer;

- antifungal impregnation;

- polyethylene film;

- mushroom dowels;

- nails.

Some construction equipment may not be needed. It all depends on what you plan to use to insulate the brick wall.

What is a vapor barrier and how to install it

The process of internal insulation of brick walls has one important stage - installation of a vapor barrier. Economic activities in the house lead to the constant release of moisture (steam).

Mineral wool, in turn, absorbs this steam and because of this, dampness and mold occur. Therefore, it is very important to isolate the insulation from moisture and steam with a special membrane. It is installed on top of a frame with insulation. A vapor barrier can be created using a membrane film.

It is vapor permeable, which has a positive effect on the quality of insulation. The membrane film “works” only in one direction. This must be kept in mind when installing it. The entire partition is covered with film. The membrane film must be laid overlapping, and the joints must be glued with mounting tape.

Insulation of brick walls from the inside with mineral wool, consider 2 options

It is important to note that thermal insulation of internal surfaces is the last thermal insulation solution, which should only be considered if it is not possible to insulate a brick wall from the outside.

Ignorance or recklessness in this case may worsen, but not improve, living conditions.

Frame method

The first option is quite complicated, and not everyone can do it with their own hands. Most experts recommend insulating walls from the inside using a metal frame onto which plasterboard sheets are attached.

- The material (for example, mineral wool slabs) is laid in the middle between the sheathing strips. After that, a vapor barrier is attached over the insulation, forming a sealed layer. The vapor barrier serves to protect the insulation from moisture.

- Between the insulation and, in our version, drywall, we leave a gap of several centimeters for ventilation of our system. As a result, we will have a system in several layers (membrane insulation, air layer for ventilation and all this is covered with plasterboard).

Installation of insulation using fastening brackets

In order to insulate brick walls from the inside with mineral wool using this technology, follow the following sequence:

- Install special holders for attaching plasterboard profiles to the wall.

- Screw them vertically at a distance of 50-60 cm from each other.

- Give the bracket the shape of the letter P. Such fastenings are reliable enough both for installing the profile and for fixing mineral wool.

- Unpack the roll or bale of mineral wool sheets.

- Measure and cut slabs and sheets of the required length with a margin of at least 10 cm. If you do not take into account the margin in length, then if the mineral wool is slightly deformed, it may simply not be enough to insulate the entire height of the wall.

- Place the measured strip of cotton wool onto the mounting holders. Mineral wool can be easily pierced with a staple, so it will hang vertically without any problems. The bracket is necessary to ensure that the insulation covers the entire wall tightly and without breaks.

- Install the next strip lightly with an accordion.

- Secure the drywall to the profile.

Some good tips

- To avoid mistakes, you must follow the instructions exactly;

- For high-quality installation of the material, the slab must have a width of more than one meter;

- In order for mineral wool for wall insulation to last longer, it is necessary to create a high-quality vapor barrier;

- The material should lie tightly and evenly on the surface. When filling the grate with insulation, it is important to avoid gaps;

- Insulating walls with mineral wool slabs is much easier than using mineral wool in rolls;

- The wall on which the insulation is applied must not have cracks or defects.

Well, I would like to hope that this article will help the reader understand and understand what mineral wool is, what properties it has, and how to use it correctly to save heat in the house. Let insulating walls with mineral wool seem like an easy job with a positive result for everyone!