Fireplace on a reliable support

When building a country house, the design of which includes a fireplace, many people wonder whether a foundation is needed for a fireplace. Some owners do not consider it necessary to install a solid foundation and limit themselves to installing supports, but over time, such a structure will shrink and gradually collapse. There is a technology for performing the work, according to which the foundation of the house should not be connected to the foundation for the furnace structure, since they are designed for different load-bearing loads.

Types of fireplaces

Stoves and fireplaces are used not only for heating a room. They create a comfortable, warm atmosphere in the house and are used for cooking. If you look at the flickering flame for 15 minutes, fatigue goes away and your mood improves.

The construction of such a structure must be approached with all responsibility. An obligatory step is the installation of a chimney and the construction of a reliable foundation. The room in which the fireplace is installed must be of sufficient area.

The easiest way to provide for the presence of a fireplace is during the construction phase. You can, of course, build the structure into a previously built house, but this will require additional financial and labor costs.

Types of brick fireplaces and their characteristics are presented in the table:

| № | Fireplace type | Characteristics |

| 1 | Angular | Mounted in one of the corners of the room. The firebox is located diagonally. The smoke chamber is arranged with inclined walls, the chimney is mounted inside a fire-resistant wall. It heats two rooms at once: the one in which it is located and the one located behind the wall, near the fireplace. |

| 2 | Built-in | It is erected only at the stage of building a house. Can be built into a wall, column, non-flammable thick partition. The advantage is that it does not take up much space. Not suitable for use in wooden houses. |

| 3 | Wall-mounted | It is used for large rooms, as it has significant dimensions. Typically the structure occupies the entire wall area. A chimney is installed on the outside of the wall. |

| 4 | Ostrovny | Installed in the center of the room or in any part of it, it has open approaches on all sides. This design takes up a lot of space. Do not install a fireplace near walls made of flammable materials. If the proper distance is maintained, it can be installed even in a wooden house. |

When adding a fireplace to a project, you must comply with all fire safety requirements.

Preparatory work

The first step is to build the foundation, on which the durability and reliability of the fireplace depends. The foundation for the fireplace must be separate - the building shrinks to some extent, so the installed heating unit may become deformed. When creating a foundation in a house that is already in use, it is necessary to take into account all roofing elements that may interfere with the future structure or affect the installation process.

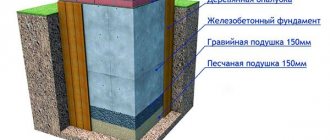

It is much easier to equip the foundation before building the house - all work will be reduced to the following sequence of operations:

- First you need to dig a pit, the depth of which is equal to or greater than the freezing depth of the soil;

- Next, the formwork is installed, and the bottom of the pit is filled with a mixture of crushed stone and sand;

- The next step is laying the selected waterproofing material;

- The foundation is reinforced with metal rods and filled with mortar to a mark located at a height of two bricks below the floor level;

- The poured foundation must be left until it hardens completely (usually this takes about three weeks).

If the foundation is poured from scratch, then there will be no special problems with it. A completely different matter is creating a foundation in an already built house, which will require dismantling part of the floor in the place where the fireplace will be installed.

The work process looks like this: first you need to mark the base of the fireplace on the floor and make indentations of about 20 cm in each direction. Using a grinder, the floor covering is cut along the marked lines. When this operation is completed, you can begin to extract the bare soil and perform the algorithm described above.

When the base of the fireplace is brought to the floor level, the gap between the stone and the floor covering must be decorated. In addition, after each stage of work, it is advisable to carry out cleaning, and immediately before building a fireplace in the house, the room should be covered with plastic film to minimize the amount of contamination of the floor and furniture.

After creating the foundation, you can begin work to ensure fire safety. If we make a fireplace with our own hands, located near the walls, it is necessary to protect each of them from exposure to high temperatures. Asbestos sheets are usually used for these purposes, but ceramic tiles are also a good option.

The last stage of preparatory work is to bring the purchased bricks into working condition. The bricks used need to be collected, sorted by size, and a small number of bricks that will be used in the near future need to be moistened - this way they will not take moisture from the mortar.

Why do you need a foundation for a fireplace?

Building a foundation for a fireplace will extend its service life and protect residents from the threat of fire as a result of sparks entering through cracks in the walls of the structure.

You can use the fireplace without installing a reliable base under it, provided that it weighs no more than 500 kg. When using a structure of greater weight, shrinkage will occur over time. This will lead to the appearance of cracks and gradual destruction of the structure.

The foundation must be strictly level and ensure the level position of all elements of the system. It should be wider than the base of the stove or fireplace by at least 10 cm on each side.

The floor level should be 8-10 cm higher than the base under the fireplace.

It would be correct to lay the foundation for the fireplace during the installation of the foundation of the house. You first need to know the dimensions and weight of the heating structure, perform all the necessary calculations, and only after that proceed to constructing the base.

To protect against moisture, which is always present in the soil, waterproofing measures are carried out. To protect against moisture, roofing felt with a bitumen coating is used, laid in two layers so that the joints of the upper and lower rows do not intersect.

A distance of at least 5 cm is provided between the foundations of the house and the fireplace; it is covered with sand and compacted well.

How to tie to the floor

The first step is to decide what material the foundation will be made of, then decide on the location, then carry out mathematical calculations and start laying the foundation. If the traditional type of concrete is chosen for the construction of the foundation, then temporary formwork is performed and the building mixture is poured.

Within 24 hours, hardening occurs, the base becomes hard and gains strength, which means that such a fireplace can be used for a long time.

It is important to know: for safety reasons, flammable objects should not be installed near the fireplace. It is best to place them at a distance of at least a meter from the fireplace, which will protect your home from fire. Watch the video, which explains the main features of the foundation for the fireplace:

Watch the video, which explains the basic features of the foundation for the fireplace:

Calculation of foundation dimensions

To correctly calculate the parameters of the base for a fireplace, you need to take into account the characteristics of the soil, the size and weight of the fireplace itself.

Foundation for the combustion structure

The foundation is laid 20 cm below the freezing point of the soil, so that during frost heaving of the soil it will not be pushed out. The depth of underground sources is also taken into account.

Clay soil with moisture in it is not able to withstand loads; it shrinks unevenly throughout its entire service life.

On sandy soil, shrinkage occurs over a short period. Under the pressure of weight, the sand is compacted and subsequently serves as a reliable basis for construction.

The width of the pit should be 5-15 cm larger than the size of the fireplace.

The minimum laying depth is 50 cm; if necessary, the base can be deepened by 1 m or more.

Brick finishing

If you are looking for an answer to the question of what is the best way to decorate a fireplace, then you don’t have to think long and leave the exposed brickwork without decorative decorations. But you still have to work hard. Firstly, you need to more clearly highlight the coating by applying a hydrochloric acid or sulfuric acid solution.

And secondly, it is advisable to carefully sew the seams. To do this, a space of up to 7 mm unfilled with mortar is left on the outside of the masonry. They need to be treated with grout, but only after the glue mixture has dried. It is advisable to sand the surface of the brick. The originality comes from chamfering the edges.

Basic moments

What to consider when installing a fireplace:

- the hole for the firebox should correspond to 1/50 of the area of the room;

- the height of the portal should be 2 times greater than the depth of the firebox;

- the chimney diameter is made 10-15 cm, it should be 10-15 times smaller than the firebox area;

- the fireplace is not installed in the path of drafts or near steps;

- The length of the chimney pipe is made at least 50 cm.

Foundation layout diagram

The total length of the smoke exhaust system is 3-4 m, sometimes it is increased to 7 m.

The structure must be protected from moisture. To do this, vertical and horizontal waterproofing is carried out using roll or coating materials.

Chimney installation

If the chimney is not assembled according to all the requirements and rules, then it will be impossible to ensure the operation of even the highest quality fireplace. There are a few simple rules that are best followed in any case:

- First of all, the chimney cannot be built into external walls.

- It is better to place the chimney pipe as close to the ridge as possible. It is better if the section of pipe sticking out on the street is as small as possible.

- Brick is the best material for making chimneys.

- It is better not to place reflectors and umbrellas at the chimney outlet.

- The fireplace will not work if there is no air supply.

- Compared to closed structures, open ones benefit.

By creating the necessary draft, the chimney serves to remove air and gases from any smoke structures and remove combustion products. Among other things, the chimney must be resistant to the effects of an aggressive mixture of condensate and soot, withstand the temperature of the exhaust gases, and comply with operational, fire and building standards.

For each chimney, in principle, processes such as fastening the smoke exhaust structure and its assembly, installation, installation and construction are considered individually. For a brick chimney, the process is as follows:

- Foundation

- Order

- Composition of the solution

- Mopping

- The head and the need for a chimney.

If the chimney is made of ceramics, then the following must be done:

- Foundation and fastening of modular elements

- Audit

- Connection tee.

Most actions are performed for stainless steel chimneys:

- Mounts and brackets

- Pipes “for smoke” or “for condensate”

- The use of bends or elbows to deflect the channel from the vertical

- Passages through floors and roofs

- The head and the need for an umbrella

During the installation process, it is necessary to take into account the thermal expansion that occurs during operation. It is unacceptable to violate the tightness of the installed channel. At the design stage of the fireplace design, the order of installation of the chimney, the correspondence of the component elements, cross-section and height are calculated.

DIY fireplace foundation

After all the calculations have been completed and the materials have been prepared, we begin to construct the base for the fireplace. As stated above, the foundation for the house and the fireplace should not be common.

Step-by-step installation instructions:

- Mark the location of the base; it should be 10 cm wider than the dimensions of the structure, taking into account the finishing materials.

- They dig a pit 20 cm deeper than the freezing point of the soil, but not less than 50 cm. The bottom is leveled and the soil is well compacted.

- Sand and crushed stone are poured in layers, 150-200 cm thick.

- Rubble stone, 200 mm thick, is poured and filled with prepared cement-sand mortar with the addition of crushed stone. Sand and cement are mixed in a ratio of 6:1.

- Following the same scheme, subsequent layers are poured until the desired height is reached.

- Upon reaching the floor level, the formwork is installed and filled with concrete so that the top layer is located 150 mm below the floor covering.

- Fill in the leveling screed.

- Start installing the fireplace.

Be sure to ensure that all structural elements are located strictly level.

Creation Rules

Work begins with digging a pit, the dimensions of which will be 10-15 cm larger than the size of the foundation. The depth of the pit varies between 60 centimeters for a one-story building and 70-100 cm for a two-story building. There should be no irregularities on its bottom. The laying should be carried out in layers: for these purposes, small crushed stone or stone is used. The solution is poured to a depth of 20-25 cm. The distance between large stones should be 3-5 cm. The upper part of the base can be made:

- level with the floor;

- near the floor;

- lower by 15 cm with the goal of subsequently leveling it and making the first layer of brickwork.

The laying is done in two rows along with two layers of waterproofing. If everything was done correctly, the level of the finished foundation and the subfloor should coincide and be at the same height.

Rubble concrete base

As in the first case, first they make markings and dig a pit of the required size.

Then the formwork is installed, placing its walls strictly level. Coat the wooden form with bitumen mastic or cover it with roofing felt so that concrete milk does not seep into the sand cushion.

Reinforced concrete base

Stones of at least 15 cm in size are not placed tightly on the bottom. The layer thickness should be 150 mm. The gaps between them are filled with crushed stone.

Prepare a cement-sand mortar in a 1:3 ratio and fill it with rubble stones.

If the solution is mixed by hand, lay one row per day. If you have a concrete mixer or construction mixer, you can get the job done much faster.

Preparatory work

Work on arranging a corner fireplace begins with the construction of the base. It is strictly forbidden to connect the foundation of the structure under construction with the base of the main building - this will lead to very unfavorable consequences.

To determine the optimal width of the foundation, add about 50 mm to the width of the front plinth row. Determine the length in accordance with the dimensions of the side row of the plinth. In general, the dimensions of the base should be slightly larger than the dimensions of the future fireplace.

When choosing a place for arranging the foundation and the fireplace itself, make sure that in the future the smoke exhaust pipe does not pass through the elements of the roof rafter system and beams.

The foundation is made extremely simply - a pit of the required size is dug, the bottom of the pit is covered with waterproofing, a layer of a mixture of sand and crushed stone is poured on top, reinforcement is laid and mortar is poured.

Building a foundation for a fireplace

Building a foundation for a fireplace

Allow the foundation to gain strength and cover it with a double layer of roofing felt.

While the foundation hardens, begin preparing building materials for upcoming use. So, the clay must first be soaked in water for a couple of days. Soak the bricks for the same amount of time.

Fireplace foundation laying diagram

Pre-calibrate the bricks you have. Elements with significant deviations from the previously mentioned size cannot be used for masonry.

To prepare the solution, use a standard and proven recipe. Pour the dry sifted sand into the clay pulp, and then mix the resulting mixture thoroughly. Determine the required amount of water individually. The finished mixture should have the consistency of jelly.

Fireplace mortar

Check the finished solution. To do this, roll a sample out of it into a “sausage” about 1.5 cm in diameter. If the sample does not stick to your hands, holds its given shape normally and does not fall apart, everything is fine.

Also check how the solution you prepared behaves directly on the brick. To do this, place the mixture on the building element. It is necessary that the solution does not stick to the trowel, does not fall apart and does not spread over the brick under its weight.

Reinforced concrete slab foundation

Foundation in a wooden house

Prepare a foundation pit and install formwork. Lay metal reinforcing mesh or steel rods at a distance of 15-20 cm from each other in the longitudinal and transverse directions. The intersections of the rods are connected with wire.

Prepare a solution of cement and gravel mixed in a ratio of 1:4. pouring is carried out in layers of 20 cm. The second and subsequent layers are poured after the previous ones have hardened.

When laying deep, a reinforcing structure of 4 piles is used, connected to each other by a reinforced concrete tie. Then carry out the work as described above.

Cladding an outdoor stove with bricks and making a smoke extractor (with photo)

The surface of the cornice is usually covered with clinker slabs, and its edges are decorated with facing bricks cut to the size of the end.

During facing work, it is necessary to ensure that the seams between the bricks are of the same width. After completing the masonry, use a narrow trowel to press the mortar into the seams so that they are completely sealed. Then smooth out the solution, let it dry, and then remove the seams.

After completing work with the fireplace, you can proceed directly to the manufacture of the smoke extractor. Blanks made of sheet copper 1 mm thick should be pre-cut. The width of all allowances for creating the sides should be 29 mm, and the height of the pipe should be 50 cm. To make it, you will need four blanks, each 25 cm wide. On the two outer blanks on the left and right, you need to carefully bend the edges 25 mm wide at a right angle. After this, you need to attach the smoke eliminator hood to the fireclay insert guard. Instead of copper, you can use other sheet metal (stainless steel or galvanized iron) for the smoke eliminator.

To create the edges of thin sheet metal, you need to fix the workpiece between two pieces of hardwood, then use a rubber mallet and a mounting block to carefully bend the protruding edge. Then, on the workpieces at equal distances from each other, you should first make markings, and then drill holes with a diameter of 4 mm for the rivets. For a fastened smoke extractor, it is recommended to strengthen the edge of the hood using brass corners.

On top it is necessary to install a square chimney with a weather vane. You can simply put it on the cap, but it is still recommended to attach it using rivets. In this case, the pipe will definitely not be blown away by the wind.

The smoke extractor must be fixed to the furnace fence using galvanized steel brackets. Before this, they need to be bent and attached to the cap with rivets 12 mm long. In order to correctly mark the points for drilling holes for dowels, the cap with the pipe must be attached to the fireplace, determine the future location of the brackets, only then make the markings, remove the cap and drill the holes. The cap can then be placed and screwed on.

In the hearth there is a frame for hanging the grill grate and installing an ash pan. To make it you will need steel corners. They must be connected to each other with screws or welding. As supports for the grill grate, it is recommended to attach two vertical elements made of strip steel to the rear transverse element of the frame.

In addition, you will need a weather vane, which is a cap that crowns the chimney. It is necessary to prevent precipitation and birds from entering the mouth of the pipe and to protect it from moisture.

You can purchase a ready-made grill for cooking roast, but you can save money and weld it yourself from pieces of steel rod with a cross-section of 8 × 8 mm and a length of 540 mm each, having previously bent them. Do not forget that two pieces of such a rod will be needed for the grille frame, which is made first, and then the remaining rods (about 18 pieces) are welded onto it. Screws can be used instead of welding. After assembly, it is recommended to chrome plate the grille. Two similar pieces of rod must be attached to the longitudinal elements of the frame from above, which are used as guides for the retractable ash pan. The distance between them should be slightly larger than the width of the ash pan. The retractable ash pan itself is best made from black sheet metal 1.5 mm thick.

Watch step by step how to make an outdoor fireplace in the video below on this page:

Features of a fireplace in a wooden house

A foundation for a fireplace in a wooden house is mandatory. When performing calculations and installation work, you need to take into account the specifics of operation in a wooden house:

- The fireplace cannot be placed directly on the floor or ceiling; not only is the material flammable, it does not have sufficient strength to withstand significant load-bearing loads.

- When installing a large heating structure in a small room, the air will be too dry. This will lead to cracking of walls, ceilings, and wood floors.

- You cannot install the stove opposite windows and doors, as a draft will form, which can cause the almost extinct coals to ignite.

It is better to choose an island fireplace arrangement. When installing it next to a wall, it will overheat, which may result in a fire.

For the installation of brickwork, a lime-sand mortar is used; minimal gaps are left between the elements.

How to build a foundation for a stove with your own hands can be seen in the video: A foundation for a fireplace weighing more than 500 kg is necessary to avoid uneven shrinkage and the formation of cracks through which a fire can occur. Before erecting a supporting structure, you need to correctly calculate all its parameters; the safety and service life of the fireplace will depend on this.

Combustion chamber

There are open and closed combustion chambers. The closed structure must necessarily include additional components - a gate and transparent doors made of fire-resistant glass. The simplest option would be to purchase a ready-made combustion chamber - this will significantly simplify the installation work, and cast-iron closed fireboxes look very good.

Arrangement of the fuel chamber is one of the most problematic and difficult stages of installing a fireplace. The firebox located under the chimney must have a chimney tooth, which is necessary for the efficient operation of the entire structure. To extend the service life of a metal firebox, it is advisable to line its internal walls with fireclay bricks, which will minimize the contact of open fire with the chamber material.

Since the main working process takes place in the firebox, it is worth considering it now:

- The fuel is removed from the fuel basket, which is usually located under the firebox, and placed on a grate located in the chamber;

- The ignited firewood is set on fire, and the intensity of its combustion is regulated using a slide valve, which provides oxygen access to the working area (if the fireplace has an open firebox, the combustion process can only be changed by adding firewood);

- The burned fuel becomes ash and ends up in the ash pan, located directly under the grate (collected ash must be removed periodically, so the best option would be a retractable ash pan);

- The gas released during combustion goes outside through the chimney (for maximum efficiency, it is worth equipping the chimney with a forced draft, which will also allow you to regulate the heat transfer of the fireplace).

The second option is somewhat more difficult to arrange - it involves installing the back wall at an angle of 30 degrees towards the inside of the fireplace. If you make a fireplace with your own hands using such a scheme, the advantage will be increased reflection of thermal energy into the room.

Finishing

In absolutely all cases, the resulting fireplace will have to be decorated from the outside. It can simply be coated with a layer of glossy or matte paint. Here you need to remember the elementary laws from the physics course. Dark bodies emit more energy, and since our task is to remove energy, black colors will be a priority.

Good to know: What kind of fireplace can be installed in an apartment and how to do it

The fireplace can be finished with special fireproof materials. These include tiles made of ceramics, artificial and natural stone. When gluing tiles, you should remember the thermal expansion of the metal, so the seam gap should be slightly increased.

With the possibility of making your own fireplace, a lot of opportunities open up for you to realize your old dream exactly in the form in which it interprets itself. Desire and work in a certain sequence will ensure an excellent result.