The construction market is filled with many types of insulation materials. They come in rolls, slabs, backfill and sprayed. Since the assortment is very large, it can be difficult to make the right and informed choice. What can I say if there are more than 6 types of foam materials alone? We are talking about Ravaterm, Polyspen, Stirex, Penofol, Penoplex and Technoplex. The materials are used for internal and external insulation. Which material is better? To do this, you need to understand the features of each material, its advantages and disadvantages. Most experts recommend using Penoplex or Technoplex.

Why are they so good? Technoplex or Penoplex, which is better? What if you compare them with other materials? This is exactly what we will do.

Venerable rival

Insulation materials are essentially extruded polystyrene foam. This is a new generation of thermal insulators that can effectively retain heat. Today in the assortment of large stores you can find a number of such building materials that are used for similar purposes, but still differ in their characteristics. Let's look at and compare the most popular of them.

Penoplex competitors

Penoplex is one of the most popular foam materials , the properties of which have been improved as a result of additional processing - extrusion. Use of penoplex: attics, facades, roofs and foundations of buildings. For each of these objects there is a separate, most suitable type of slab.

Wide use of the product is possible due to a number of properties:

- Minimally absorbs water, which is important for heat insulators. A series of experiments were carried out, during which the product was left in water for several days - moisture penetrates only into the outer layers, and the internal closed cells remain dry.

- It has a low thermal conductivity coefficient (0.03 W*m*°C), and the value does not change significantly even in a humid environment. This expands the scope of application and allows the product to be used in conditions of increased dampness.

- Low vapor permeability – protects the surface well from moisture evaporation. Due to this property, a 2-centimeter layer of material can replace a layer of roofing felt.

- Long service life. During the experiments, it was established that the properties of the product do not change even after a significant change in external conditions - it was frozen and thawed, and also tested with water. The manufacturer indicated that the plates last about 50 years, but tests indicate a longer period of use.

- Compressive strength. Thanks to the production technology, the board has a homogeneous structure with evenly distributed small cells, which improves strength and resistance to mechanical stress.

- Easy installation. The material can be cut even with an ordinary knife. Self-installation is possible without the involvement of specialists.

- High level of environmental friendliness. The manufacturer used a type of freon that does not burn, is not poisonous and does not harm the environment.

- Minimal chemical activity. Does not react with most chemicals often used in construction: ketones (acetone, methyl ethyl ketone), formaldehyde, kerosene, gasoline, oil paints, etc.

- High biostability - the boards are not subject to rotting and decomposition.

It is also worth noting the following pros and cons of penoplex: materials of this type require maintaining a certain, not too high temperature. If this condition is violated, they will become deformed and may even ignite.

There are a number of foam-type slabs for insulation. They are made using similar technology, therefore they are similar in structure and properties, but, as a rule, they have different areas of application.

Foamed polystyrene - what is it?

Penoplex is produced by the company of the same name. It creates insulating material using a special technology: extruded polystyrene is foamed under high pressure. The same applies to the technology for creating Technoplex, according to open sources. It is produced by TechnoNIKOL. As for the remaining details of the process of creating Penoplex and TechnoNIKOL insulation, nothing is reported about them. True, fragmentary data leads us to the following thoughts:

- Polystyrene granules, which act as the main raw material, are mixed with the gasifier. The mixture is heated to a high temperature and pressed through small holes. In this case, polystyrene granules must be highly purified.

- As the mixture passes through the micro-hole nozzle, the flow begins to break up into microscopic threads. In this case, the polymer molecules are pulled out and form a connection with each other. And thanks to pressure, they begin to harden.

- When the polypropylene comes out of the nozzle, it begins to foam and forms a porous material with thousands of small bubbles.

Important!

In the future, we will denote Penoplex as the first, and Technoplex as the second. It turns out that based on the technology of creation, it cannot be said that Penoplex or TechnoNIKOL is better. They are almost the same, the difference lies in composition and strength. According to the TechnoNIKOL company, the composition of their products, namely Technoplex, is enriched with amphora carbon or graphite. In this case, the rolling rollers can better form the material into its final shape and thickness.

So, Penoplex is made by extrusion. And Technoplex, thanks to the inclusion of graphite nanoparticles, increases the strength of the material, and its thermal conductivity coefficient decreases even more. Both the first and second materials are environmentally safe. They are safe and non-flammable. The materials will not dissolve in water or soil.

Note! There is a big difference between well-known and cheap manufacturers.

Conventional production technology involves the use of light freons mixed with carbon dioxide as a vapor-forming gas. As for new creation methods that are much better. For their implementation, liquid and powder gas-forming agents are used.

Characteristics of the technoplex

The slabs are made using similar technology and have been produced in Russia since 2006. They do not shrink, are resistant to chemical influences, but are resistant to gasoline and solvents, and are also used inside buildings. Let's compare several parameters:

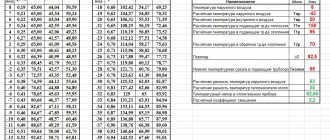

| Penoplex | Technoplex | |

| Use of buildings | roofs, facades, roads | inner part |

| Density, kg/m3 | 25-47 | 26-35 |

| Flammability group | G4 | G4 |

| Water absorption,% | 0,2-0,4 | 0.2 |

| Vapor permeability | 0,012 | 0.01 |

| Price, rub/m2 | 90-250 | 100-290 |

The main types of insulation used to reduce heat loss

To carry out thermal insulation measures of any type, the following types of insulators are used:

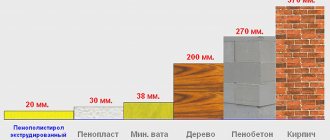

- extruded polystyrene foam (XPS), refers to polystyrene derivatives (represented by various manufacturing enterprises, has many brands);

- polystyrene foam, its production also involves the processing of polystyrene, but using a different technology (it has a sufficient number of manufacturers, the breakdown by brand is not clear, it is positioned as “foam plastic”).

- mineral or basalt wool is fundamentally different from polystyrene products and acts as the main competitor of foamed polystyrenes (represented on the insulating goods market by a large number of manufacturers).

The number of manufacturing companies, both domestic and foreign, is measured in dozens. When choosing products, you need to rely on the physical properties of each individual product.

Styrofoam or penoplex

A line of materials used for insulating three-layer walls, flat and pitched roofs, plinths, and underground parts of a building. Also used in the manufacture of sandwich panels, on highways and airfields.

Strength – 250-500 mPa;

Flammability group – G3 or G4;

Vapor permeability – 0.006 mg/(mh*Pa).

Comparison

The main technical characteristics of insulation are its thermal conductivity, water absorption and operating temperature.

The flammability group for both insulation materials is G4 (highly flammable). Their prices differ by 10% (Technoplex is more expensive).

After comparing them, it is clear that there are no significant differences between these insulation materials.

Yes, Technoplex has slightly better characteristics, but the cost is also higher. Despite the fact that Penoplex is cheaper, with individual construction the savings are insignificant.

Penoplex and expanded polystyrene: choosing the best insulation

If the insulation absorbs water, then over time its thermal insulation qualities will inevitably decrease. Extruded polystyrene foam differs from other heat-insulating materials in its minimal moisture absorption, high strength, durability and monolithic structure.

PENOPLEX is extruded polystyrene foam, the production of which is established at factories located in many cities in Russia and abroad. The most modern equipment from the world's leading manufacturers allows us to guarantee the highest quality of products under the PENOPLEX brand.

PENOPLEX insulation is chemically inert (does not emit harmful chemical compounds when used within the permissible temperature range (from -50 ° C to +75 ° C), is not subject to rotting and biodegradation. You can work with it in any weather conditions without any means protection from atmospheric precipitation.The slabs are easy to process (can be cut well using a regular knife) and are extremely simple to install.

The durability of the thermal insulation material is confirmed by NIISF protocol No. 132-1 dated October 29, 2001 (Russian Academy of Architecture and Construction Sciences) and is more than 50 years.

PENOPLEX COMFORT - specially designed for low-rise construction. The balance of technical characteristics of the universal material PENOPLEX K0MF0RT, such as: strength, zero water absorption, high thermal protection, biostability and environmental friendliness, allow it to be used effectively in all structures without overpaying for the enhanced properties of professional brands.

PENOPLEX WALL - optimal for insulating external and internal vertical enclosing structures (walls, partitions, facade systems); minimal water absorption, absolute biostability, low thermal conductivity (1.4 times more effective than mineral wool, and 1.3 times more effective than ball foam) provide reliable protection for your facade throughout its entire service life. The flammability group of PENOPLEX WALL is reduced, and the presence of special fire retardant additives makes it possible to prevent spontaneous combustion.

PENOPLEX ROOF - optimal for insulating roofs of any type; The compressive strength of this type is 25 t/m2. The flammability group of PENOPLEX ROOF is reduced, and the presence of special fire retardant additives makes it possible to prevent spontaneous combustion.

Heat conduction and moisture absorption

The thermal conductivity coefficient is one of the main parameters for insulation. The thermal conductivity parameter of the first is on average in the range from 0.028 to 0.031 W/mK, it all depends on the operating conditions. The second has an identical thermal conductivity parameter of 0.031 W/mK. It turns out that the effectiveness of materials in this area is the same.

The same applies to water absorption of materials. The first has an indicator of up to 0.2% of the volume per day, just like the second. This is truly surprising and shows that each of the materials copes well with moisture and resists it. Therefore, if anyone asks whether Penoplex or mineral wool is better, then we can confidently say that the first option. When wet, mineral wool loses its properties.

Note! The same applies to the frost resistance of the material. Its properties are not lost during frequent freezing and defrosting.

Scope of application of the material

Traditionally, extruded polystyrene foam boards are used in industrial, civil and road construction. They have been used for a long time and very successfully in facade heat-insulating compositions with external plaster, in multi-layer panels, successfully combined with other materials: cement-bonded particle boards, for example, and analogues.

Thermal insulation of floor coverings

When insulating a floor using a wide variety of heat- and sound-insulating foamed polymer materials, specialists, as a rule, give preference to XPS boards, which is justified by their strength. When working, it is important to keep in mind that they must be placed on any flat and hard surface.

All joints of laid slabs must be glued with construction tape, and after that the surface is reinforced with a special mesh. An indispensable condition is the presence of an expansion joint 2 cm wide around the perimeter. If installation of a “warm floor” is planned, at this stage the installation of its system is carried out.

The next step is to apply a reinforced screed 4–5 cm thick and eliminate small cracks and irregularities, and then lay the floor covering. It is important to keep in mind that it takes at least 28 days for the screed to dry completely.

Roof insulation

The technology of roof insulation using slabs of extruded polystyrene foam depends on its shape - pitched or flat. In both the first and second cases, in order to avoid the accumulation of condensate, it is recommended to additionally use hydro- and vapor barrier materials. Increased humidity over time will inevitably lead to a decrease in thermal insulation boards and wood rotting.

There are several ways to insulate a roof using such slabs:

In practice, as a rule, several methods are combined at once.

A pitched roof is usually insulated by installing sheet material between the rafters. Most often, at the design stage, the distance between them is selected based on the size of the slabs. To ensure more reliable fastening and sealing, dowels and sealants are used.

When insulating a flat roof from the outside, the slabs are laid, glued or secured with dowels, ensuring a tight fit.

Before this, the surface is cleaned, waterproofing and a vapor barrier membrane are laid. Then expanded clay is poured onto the slabs and cement mortar is poured.

Such a roof can be insulated from the inside without dismantling the existing structure. For this, as in previous cases, dowels or glue are used for fastening, and sealant is used to fill voids.

After installing the sheets, the ceiling is sheathed with finishing material.

Insulation of walls inside a building

In the construction of individual houses, XPS boards are successfully used inside frame walls, installing them between the internal and external cladding.

Thermal insulation of walls in apartment buildings is considered the most problematic. To avoid shifting the location of condensation to the inner surface, sealing is used. In this regard, experts recognize XPS boards as the best material. Installation of insulation includes several stages:

Insulation of facades

To insulate external walls, as a rule, XPS boards with a thickness of at least 80 mm are used. Before starting to lay the heat insulator, the surface is carefully prepared - putty is applied, leveled, cleaned and primer is applied.

The heat insulator is secured using dowels and glue. The outside of the sheets is covered with mastic and primed. If plaster is to be applied in the future, then an additional layer of mastic is applied to the slabs, into which a special mesh is pressed.

The final operation is decorating the walls. For this purpose, fiberboard and particle boards, siding and other similar materials are used.

Insulation of foundations

With proper use, high-quality XPS boards can last in soils for up to 50 years. When getting started, it is important to consider some nuances:

Before starting work on insulating the foundation, you should prepare the surface: clean concrete particles from adhering dirt, rub cracks and chips with a cement-sand mixture. The slabs are fastened differently in different cases.

The insulation is attached to the vertical wall of the foundation, which has a waterproofing layer, using a special spike with teeth. The use of dowels here is unacceptable, as the waterproofing will be damaged. Additionally, special mastic or adhesive foam is used. It is applied, retreating from the edge at least 2 cm, and then wait 10 minutes. Gaps larger than 2 mm must be foamed.

When insulating a monolithic slab foundation or the sole of a strip base, the XPS slab is laid loosely on a sand bed. In some cases, adjacent insulating boards are fastened together, but most often it is enough to just foam the seams.

Safe for me, safe for you

It is impossible not to compare both materials in terms of their impact on the environment and interaction with it. Who to give preference: penoplex or technoplex?

The fire hazard of the materials is the same. They belong to the category of substances that support and spread combustion. When they burn, a gas that is unsuitable for breathing is released into the atmosphere. Because of this, they are not recommended for use as insulation without taking additional measures to ensure fire safety, for example, treating them with thermite.

The chemical and biological activity of these insulation materials is the same due to the use of the same source material: they are not afraid of contact with most building materials and solutions, are not attacked by insects and rodents, do not rot or spread fungus.

Environmental safety is ensured by the extremely stable position of the components. During the entire service life, there is no release of substances and compounds harmful to humans into the environment.

Both materials are destroyed under the influence of ultraviolet radiation, so their use without shelter is not recommended.

Installation subtleties

Insulation using technoplex is not a complicated procedure that requires special skills and knowledge. Such work can be performed by anyone, even those not familiar with the basics of finishing work. The slabs are glued or fixed with plastic dowels, which greatly simplifies the installation process. However, for high-quality wall insulation, experts recommend following the following rules:

- The insulation is laid only on a flat surface. Therefore, before starting work, it is necessary to knock off all mortar protrusions from the walls.

- To ensure that the row lies evenly, it is recommended to mark the starting line on the wall using a laser level. Further slabs will be placed more simply - the technoplex is characterized by ideal geometry.

- The first slab must be aligned strictly along the marked line, and a through hole for the dowel must be drilled in the center. Having achieved absolute symmetry, the corners are also fixed with fasteners.

- The seams between the insulation elements can be filled with silicone sealant.

- Before finishing the walls, the insulation is covered with a reinforcing fiberglass mesh and a layer of plaster.