What pressure should be in the heating system on the supply and return?

The operating pressure in the heating circuit of the top and bottom floors should not differ by more than 10%, and the pressure test pressure by 20%. Most often, in an average urban multi-storey building, the working pressure on the coolant supply pipe is 6 a - 4 ÷ 4.5 atmospheres.

Interesting materials:

What car color is the least easily soiled? Which color is closest to white? What color goes best with blue? What color goes best with gold? What color attracts men the most? Which color attracts the most attention? What color will be in fashion in 2022? What color to print? What façade color goes with a brown roof? What lipstick color suits brown eyes?

Main menu

Good day, dear readers! If you have at least a little experience with the operation and maintenance of central heating systems, then you have probably heard about such a thing as return overheating. What is it, why does it occur, and how to deal with it?

Return overheating is when the temperature of the water leaving the house exceeds the temperature that should be according to the temperature schedule. That is, according to the schedule, let’s say the return should be 63 °C, but in fact it is 67 °C. Moreover, overheating according to the temperature graph should not be looked at by the outside air temperature, since the heating network is inertial, and the temperature changes during the day. You need to compare by temperature t1, that is, the supply temperature.

We first look at the thermometer readings for supply t1, then at the temperature graph to see what the corresponding temperature t2 should be. Then we look at the actual t2 on the thermometer and compare it with t2 according to the graph. It’s good when t2 matches or is slightly less than t2 according to the temperature graph. And it’s bad if in fact the return temperature is too high against the schedule. According to clause 9.2.1 of the “Rules for the technical operation of thermal power plants”, “the average daily temperature of the return network water should not exceed the temperature specified by the temperature schedule by more than 5%.”

Nowadays, cunning power engineers include this clause from the Rules in heat supply contracts. That is, if your overheating jumps beyond 5%, then you will additionally be fined for exceeding the return flow. If the overheating falls within this 5%, there will be no penalty, but it’s better for you to eliminate the overheating anyway. The ideal option is when the return is on your schedule, or a little lower.

There are basically two reasons for overheating. The first is the flow through various jumpers between the supply and return, that is, from supply to return. This mainly occurs either through the hot water line or through the vent. Therefore, if you experience overheating, first of all, look to see if there is a flow from the supply to the return. But in fact, this happens rarely.

The main and main reason for overheating, in 95% of cases, is increased consumption of network water

. That is, when network water overheats, more water passes through your heating unit than you actually need. Why do power engineers struggle so much with overheating? An increased consumption of network water indicates that the coolant consumption is not the calculated one, that is, the consumption is overestimated and more than the calculated one. And this is an increased circulation, which causes an increase in energy consumption to drive network pumps at the heat source. Electricity costs money, so excessive return flow is a direct loss for the heat supply organization.

I have heard the opinion that increased return flow is beneficial to the consumer. They say that if you return T2 from home with overheating according to the schedule, then the heat consumption will become less, because the difference T1-T2 will decrease. However, it is not. The amount of heat Qinput, Gcal, is generally considered as follows. Amount of heat supplied Q 1 = G1* (t1- tх.в.)*0.001 where G1 is the water consumption in tons per hour; t/hour; t1 – supply water temperature; th.v. – temperature of cold water, which is prepared and heated at the heat source, usually tx.w. 5 °C is accepted.

The amount of heat in the return is calculated similarly: Q 1 = G2*(t2- tх.в.)*0.001. The heat consumption is determined by the formula: Qinput = Q1— Q2= G1*( t1- tх.в.)*0.001- G2*(t2- tх.в.)*0.001. So it turns out that although the difference t1-t2 decreases in case of overheating, the increased consumption G ultimately outweighs the formula, and the amount of heat Qinput is still greater. In general, the conclusion is this: for the consumer, overheating in the return means overheating of the entire building and an increase in the amount of heat consumed, and it is definitely not economically profitable for the consumer.

How to eliminate overheating? To do this, in the ITP (heating unit) at the supply, before the elevator, it is necessary to adjust the pressure regulator (or flow regulator), depending on what is installed. What is a pressure regulator RD, I wrote here. By adjusting the pressure through the RD, and looking at the readings of the heat meter, or thermometers and pressure gauges, you can set the required pressure at which the flow rate will not exceed the calculated one. It’s better, of course, to let the experts do it. If the heating unit is automated by modern automation, then during normal operation of the equipment, overheating is impossible in principle.

Most recently, I wrote and published a book entirely devoted to heating return, overheating by return. It’s called “Everything you wanted to know about return overheating!”

Here is the content of this book:

1. Introduction

2. What is heating return?

3. What causes return overheating?

4. Penalties from the heat supply organization for overheating of the return.

5. How to adjust the heating system and eliminate overheating in the return pipeline?

6. Conclusion

You can view it using the link below:

Everything you wanted to know about return overheating!

I will be glad to receive comments on the article.

Calculation of the diameter and size of heating pipes

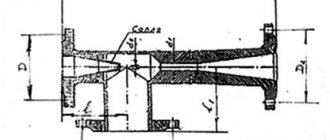

D — DN (outer diameter); d1 - nominal diameter (inner diameter)

The question of what the diameter of heating pipes should be in a private house and apartment never ceases to arise among those who plan to assemble the circuit themselves. In this article you will find a calculation of the diameter of a heating pipe. We will not dwell on the operating principle of both types of circuit; this is material for another article. Here we will simply compare the advantages and disadvantages of each of them. As a result, some myths will be debunked, and based on the facts, you will be able to draw your own conclusions.

Adjustment

How to adjust the pressure in the elevator unit?

Support washer

To be correct, when using a retaining washer, it is not necessary to adjust the pressure, but to periodically replace the washer with a similar one due to abrasive wear of the narrow metal sheet in process water. How to replace the washer with your own hands?

The instructions are generally quite simple:

- All valves or valves in the elevator are closed.

- One vent on the return and supply is opened to drain the unit.

- The bolts on the flange are loosened.

- Instead of the old washer, a new one is installed, equipped with a pair of gaskets - one on each side.

Tip: in the absence of paronitis, washers are cut from a dilapidated car inner tube. Don't forget to cut an eyelet that will allow the washer to fit into the flange groove.

- The bolts are tightened in pairs, crosswise. Once the gaskets are pressed, the nuts are tightened until they stop, no more than half a turn at a time. If you rush, uneven compression will certainly lead to the gasket being torn off by pressure from one side of the flange.

Heating system

The difference between the mixture and the return flow is normally regulated only by replacing, welding or drilling out the nozzle. But from time to time it becomes necessary to remove the difference without stopping the heating (in most cases, with important deviations from the temperature schedule during the peak of cold weather).

This is done by adjusting the inlet valve on the return pipeline, thereby eliminating the difference between the direct and return lines and between the mixture and the return.

- We measure the supply pressure at the end of the inlet valve.

- Switch the hot water supply to the supply thread.

- We screw the pressure gauge into the vent on the return line.

- We completely close the input check valve and then slowly open it until the difference decreases from the initial one by 0.2 kgf/cm2. Manipulation with subsequent opening and closing of the valve is necessary so that its cheeks descend as much as possible on the stem. If the valve and cheeks can sag in the future, the price of ridiculous time savings is at least defrosted access heating.

- The return temperature is monitored at daily intervals. If it is necessary to lower it further, the difference is removed 0.2 atmospheres at a time.

What is return in plumbing?

Return

- this is the coolant (water or antifreeze) in the heating system, which, after passing through all the radiators, loses temperature and is supplied again to the boiler for heating.

Interesting materials:

How to replant daffodils in summer? How to replant raspberries in the fall? How to transplant a geranium shoot? How to transplant Primrose into a pot? How to transplant a cedar sprout? How to replant Sansevieria after purchase? How to transplant a plum to another place? How to replant an old cactus? How to replant a flowering Kalanchoe after purchase? How to replant a blooming azalea?

Data: how to calculate the diameter of a heating pipe

To calculate the diameter of the pipeline, you will need the following data: this is the total heat loss of the home, the length of the pipeline, and the calculation of the power of the radiators in each room, as well as the wiring method. The outlet can be one-pipe, two-pipe, have forced or natural ventilation.

Also pay attention to the markings on copper and polypropylene pipes of outer diameter. The internal one can be calculated by subtracting the wall thickness. For metal-plastic and steel pipes, the internal size is indicated when marking.

Unfortunately, it is impossible to accurately calculate the pipe cross-section. One way or another, you will have to choose from a couple of options. This point is worth clarifying: a certain amount of heat needs to be delivered to the radiators, while achieving uniform heating of the batteries. If we are talking about systems with forced ventilation, then this is done using pipes, a pump and the coolant itself. All that is needed is to drive the required amount of coolant over a certain period of time.

It turns out that you can choose pipes of a smaller diameter and supply the coolant at a higher speed. You can also make a choice in favor of pipes of a larger cross-section, but reduce the intensity of the coolant supply. The first option is preferable.

Example of heating system calculation

As a rule, a simplified calculation is performed based on such parameters as the volume of the room, the level of its insulation, the flow rate of the coolant and the temperature difference in the inlet and outlet pipelines.

The diameter of the heating pipe with forced circulation is determined in the following sequence:

- the total amount of heat that needs to be supplied to the room is determined (thermal power, kW), you can also rely on tabular data;

Thermal power value depending on the temperature difference and pump power

- Having set the speed of water movement, the optimal D is determined.

Calculation of thermal power

As an example, a standard room with dimensions of 4.8x5.0x3.0m will be used. The heating circuit is with forced circulation; it is necessary to calculate the diameters of the heating pipes for distribution throughout the apartment. The basic calculation formula looks like this:

The following notations are used in the formula:

- V is the volume of the room. In the example, it is equal to 3.8∙4.0∙3.0 = 45.6m 3 ;

- Δt is the difference between the temperature outside and inside. In the example, 53ᵒС is taken;

Minimum temperatures by month for some cities

- K is a special coefficient that determines the degree of insulation of the building. In general, its value ranges from 0.6-0.9 (effective thermal insulation is used, the floor and roof are insulated, at least double-glazed windows are installed) to 3-4 (buildings without thermal insulation, for example, change houses). In the example, an intermediate option is used - the apartment has standard thermal insulation (K = 1.0 - 1.9), K = 1.1 is accepted.

Calculating the diameter of a heating pipe is an important stage in the design of a heating system.

When it comes to installing a heating system, quite often the pipe is chosen simply based on the advice of friends or the recommendations of store salespeople. Calculating the diameter of a heating pipe is not always done.

By choosing a size at random, there is a risk that the heating system will not work efficiently.

Selecting the diameter of heating pipes

What could be the consequences: narrowing the diameter of the heating pipe

Narrowing the pipe diameter is extremely undesirable. When wiring around the house, it is recommended to use the same standard size - there is no need to increase or decrease it. The only possible exception would be a large length of the circulation circuit. But even in this case you need to be careful.

Many experts do not recommend narrowing the diameter of the pipes, as this can have a detrimental effect on the entire heating system

But why does the size become smaller when replacing a steel pipe with a plastic one? Everything is simple here: with the same internal diameter, the outer diameter of the plastic pipes themselves is larger. This means that the holes in the walls and ceilings will have to be expanded, and seriously - from 25 to 32 mm. But for this you will need a special tool. Therefore, it is easier to pass thinner pipes into these holes.

But in this same situation, it turns out that the residents who made such a replacement of pipes automatically “stole” approximately 40% of the heat and water passing through the pipes from their neighbors in this riser. Therefore, it is worth understanding that the thickness of pipes that are arbitrarily replaced in a heating system is not a matter of private decision; this cannot be done. If steel pipes are replaced with plastic ones, no matter how you look at it, you will have to widen the holes in the ceilings.

There is such an option in this situation. When replacing risers, you can pass new pieces of steel pipes of the same diameter into the old holes; their length will be 50-60 cm (this depends on such a parameter as the thickness of the ceiling). And then they are connected with couplings to plastic pipes. This option is quite acceptable.

Heating system

Why do you need an expansion tank?

Accommodates excess expanded coolant when it is heated. Without an expansion tank, the pressure may exceed the tensile strength of the pipe. The tank consists of a steel barrel and a rubber membrane that separates air from water.

Air, unlike liquids, is highly compressible; with an increase in coolant volume by 5%, the pressure in the circuit due to the air tank will increase slightly.

The volume of the tank is usually taken approximately equal to 10% of the total volume of the heating system. The price of this device is low, so the purchase will not be ruinous.

The correct installation of the tank is with the hose facing up. Then excess air will not get into it.

Why does pressure decrease in a closed circuit?

Why does pressure drop in a closed heating system?

After all, the water has nowhere to go!

- If there are automatic air vents in the system, the air dissolved in the water at the time of filling will escape through them. Yes, it makes up a small part of the coolant volume; but a large change in volume is not necessary for the pressure gauge to register the change.

- Plastic and metal-plastic pipes may be slightly deformed under the influence of pressure. Combined with high water temperature, this process will speed up.

- The pressure in the heating system drops when the temperature of the coolant decreases. Thermal expansion, remember?

- Finally, minor leaks are easy to see only in centralized heating through rust marks. Water in a closed circuit is not so rich in iron, and the pipes in a private house are most often not made of steel; therefore, it is almost impossible to see traces of small leaks if the water has time to evaporate.

Why is a pressure drop in a closed circuit dangerous?

Boiler failure. In older models without thermal control - up to an explosion. Modern older models often have automatic control of not only temperature, but also pressure: when it falls below a threshold value, the boiler reports a problem.

In any case, it is better to maintain the pressure in the circuit at a level of approximately one and a half atmospheres.

How to slow down the pressure drop

In order not to recharge the heating system over and over again every day, a simple measure will help: install a second expansion tank of a larger volume.

The internal volumes of several tanks are summed up; the greater the total amount of air in them, the smaller the pressure drop will cause a decrease in the volume of coolant by, say, 10 milliliters per day.

Where to put the expansion tank

In general, there is no big difference for a membrane tank: it can be connected in any part of the circuit. Manufacturers, however, recommend connecting it where the water flow is as close to laminar as possible. If there is a tank in the system, the tank can be mounted on a straight section of pipe in front of it.

Why is the return diameter not equal to the supply diameter?

#1 BuTeK

- Colleagues

- 88 messages

- Gender: Man

- City: St. Petersburg

The program produced the calculation result.

Below is only a part. According to the table of branches, it turns out that I supply Du20 from the main line to the riser, and discharge Du15 (riser 1). But at the same time, the diameter of the last section of the main line is DN20 (riser 1). PS After analyzing it, I realized that the diameter of the liner is equal to the diameter of the fittings installed on it (MSV-C). It seemed to me that the balancer is installed regardless of the diameter of the riser.

#2 Sailor

- Gender: Man

- City: Potok

Conventionally, this phrase is about “riser legs” - the body of the riser (floor riser) stands with one foot on the hot pipe, the other on the cold one! Why are the legs different diameters?

Why is the diameter of the pipe of the riser connection unit to the supply (hot) inter-riser main not always equal to the diameter of the pipe of the riser connection unit to the return (return) inter-riser main?

The program initially implemented the desire to use 70% of the available pressure in risers and 30% in mains. This means that in the most remote one, you should initially assign a loss share of 0.7 from that available at the input.

In those closest to the heating point, the share of losses will already be more than 0.7 (by the value of the resistance of the inter-riser pipes from the riser in question to the most distant one) and therefore this share increases for the next more distant risers. The reason for the increase is the resistance of the inter-riser lines.

If their diameters are selected in such a way that the pressure drop in the inter-riser pipes is close to zero, then all risers would have the recommended 70% and are already automatically linked - the desired hydraulic equality has been created for them and there is no need to install a balancing valve (valve) on each riser. 30% could simply be spent on the way from the input to the nearest riser.

But such a solution significantly increases the cost of pipes and it is cheaper to install smaller diameters of inter-riser pipes and buy balancing valves for each riser. Hydraulic equality of the risers will be ensured, but the metal consumption (material consumption) of the system will be reduced.

To implement the idea in the program algorithm, when entering data, each riser has its own share of pressure losses in it. In total, the pressure drop in the riser elements when choosing diameters should not exceed the planned proportion.

For this reason, there may be different diameters of the connection points to the supply and return pipes. The final “linking” is ensured by the settings of the balancing valves. But by calculation we have “design settings”. The final ones are set by the “system start-up and adjustment” service when it is put into operation.

The goal of the project is to ensure start-up and commissioning without changing diameters or replacing fittings. Moreover, after a year and a half or two, any operating system, as practice shows, requires flushing and clarification of the valve settings. The fittings should be selected with some adjustment margin - avoid “extreme” settings, so that later you can “tighten / loosen” the riser.

True, BUT, as a rule, you should try to match it to the diameter of the pipe and do without “muff adapters”

Source

Ways to reduce heat loss

The above information will help to be used to correctly calculate the coolant temperature norm and tell you how to determine situations when you need to use a regulator.

But it is important to remember that the temperature in the room is affected not only by the temperature of the coolant, street air and wind strength. The degree of insulation of the facade, doors and windows in the house should also be taken into account.

To reduce heat loss from your home, you need to worry about its maximum thermal insulation. Insulated walls, sealed doors, and metal-plastic windows will help reduce heat loss. This will also reduce heating costs.

Two-pipe circuit in a private house

First, let's generalize a little. Let’s take, for example, calculating the diameter of polypropylene pipes for heating in a private house. Basically, products with a cross section of 25 mm are used for the circuit, and bends to radiators are set to 20 mm. Due to the fact that the size of the heating pipes in a private house, used as pipes to the batteries, is smaller, the following processes occur:

- the coolant speed increases;

- circulation in the radiator improves;

- The battery warms up evenly, which is important when connected at the bottom.