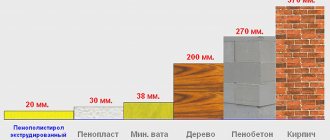

Penoplex - a material with a low level of thermal conductivity - is a good heat insulator, which is also used for insulating floors. Let's figure out how to insulate a floor with penoplex, what are the features and specifics of working with this material. Let's consider its properties, main advantages and disadvantages, as well as the technology for laying such slabs. There are many options for such floor finishing, but among them 4 main methods stand out - they are the ones used most often in construction.

Floor insulation with penoplex Source remont-max.by

Features and specifics of working with penoplex

Penoplex is often used for floor insulation. Thanks to its thermal insulation properties, the material copes well with its task. Before working with it, you need to know what thickness of penoplex is needed to insulate the floor.

On a note ! Most often, penoplex 600 mm wide and 1200-2400 mm long is used to insulate floors. The packaging from the manufacturer contains 4-20 sheets of material, each thickness from 100 to 200 mm.

Penoplex sheets at the factory Source lestnitsygid.ru

7 advantages of a thermal insulation layer made of penoplex:

- waterproof - the material rejects moisture and always remains dry;

- vapor permeability – foam floors “breathe” and do not sweat;

- thermal conductivity is low, which allows you to retain heat inside the house;

- environmental friendliness - absolutely clean and non-toxic;

- mold and fungi - the manufacturer guarantees their absence;

- sound insulation – prevents the penetration of extraneous noise.

The material also has 2 drawbacks. The first one is on fire. The second disadvantage is the reaction with solvents. Penoplex is “afraid” of them.

How to work with penoplex correctly

The technology for working with penoplex differs depending on the chosen installation method, but they are all united by the need to create a concrete screed.

Penoplex goes under the subfloor Source pol-exp.com

4 main options for laying penoplex on the floor :

- Laying material on top of the ground.

- Insulation on floor slabs.

- Laying under heated floors.

- Thermal insulation of wooden covering.

According to builders, penoplex is most often used for warm water floors. Due to its waterproof properties, the material becomes an ideal basis in this regard.

Penoplex insulation on top of the ground

Before starting work, you need to prepare the necessary materials in advance. You will need gravel and sand, cement and small crushed stone, reinforcing mesh and a level, a tamping tool and metal beacons. You also need to purchase alabaster, moisture-proofing material and metallized tape.

The main rule when laying penoplex on the ground is to reduce the level by 500 mm in relation to the height of the floors. We also recommend that you ensure that the surface is uniform and free of cracks. It must be taken into account that without additional support after installation, the material may sag. If there are voids underneath, the floor will collapse.

If you do everything correctly, the floor will be perfectly flat Source 2proraba.com

See also: Catalog of companies that specialize in insulation and insulation of houses

8 steps on how to properly insulate a floor with penoplex :

- Leveling and compacting the soil (if the surface is saturated with moisture, you cannot work with it - you should let the soil dry, then level it).

- Adding gravel (in the process it is important to use a level and compact the material according to the measured parameters - the layer should not exceed 400 mm; you can also replace the material with crushed stone).

- Compacting sand to a thickness of 100 mm (if desired, you can use other material - granotsev).

- Laying foam sheets with a 50 percent offset (meaning the next row relative to the previous one).

- Water-repellent layering (here a special material is used or a regular film with overlapping edges and sizing with tape).

- Secure the floor with a reinforcing mesh (you need to ensure that a distance of about 2-3 cm is maintained from the walls).

- Installation of beacons 180 cm from each other (it is important to correctly measure the distance from the wall of 20 cm, and for the solution here you need to use alabaster).

- Leveling the surface (at this stage you need to fill the floor with cement mortar or self-leveling mixture, then do the external finishing).

If the floors of non-residential premises are thermally insulated (warehouses, garages, etc.), then the technology changes slightly. Penoplex sheets are laid last (that is, the fourth point becomes the eighth), then secured.

Laying foam sheets in non-residential premises Source ad-cd.net

How to lay penoplex on floor slabs

Similar to the previous method, this will require the use of plastic film to protect the internal space from water. For evenness, a building level is used. You also need to purchase polymer putty, polyurethane glue, a puncher and a primer. At the final stage you will need cement or a self-leveling compound.

5 steps on how to properly lay penoplex on the floor under a screed :

- Checking the floor slabs for evenness and then cleaning the surface (if there are defects, they must be eliminated using putty or a hammer drill).

- Covering the slabs with a primer for the second and higher floors or laying the floor with plastic film for the first (in the second case, do not forget about gluing the joints with tape).

- Laying the tiles themselves (here you need to coat them with glue to bond them to the base).

- Re-layering the film for waterproofing.

- Pouring the floor under the screed (using cement or self-leveling mixture).

After drying, finishing work is carried out for the finished floor.

Finishing work after insulation with penoplex Source postroy-prosto.ru

Method 3 – penoplex under heated floors

This method uses already familiar materials - cement (self-leveling) mortar, glue, tape, waterproofing film, building level. The process will also require damper tape.

5 steps on how to lay penoplex under a heated floor system:

- preparing the concrete base (here it is necessary to clean the floor and cover it with a primer, but if the concrete base has many defects, a cement screed should be used for leveling);

- applying penoplex boards in a staggered manner (the reverse side is lubricated with pre-prepared glue, and after laying the sheets are pressed down level);

- sealing the surface (for this, waterproofing film and tape are used at the joints, and damper tape must be used near the walls);

- placement of a heated floor system;

- pouring the coating with a self-leveling mixture (can be replaced with cement).

Before installing the finished floor, be sure to wait until the surface is completely dry.

Penoplex under a warm floor Source strojdvor.ru

Specifications

They may differ slightly for different types of PPP. The table below shows the main average technical indicators of the characteristics of extruded polystyrene.

| Insulation characteristics | Meaning |

| Water absorption during the day | 0.5% of the total volume |

| Vapor permeability coefficient | 0,005 |

| Fire resistance | Group G4 |

| Density | From 20 to 50 kg/m3 |

| Specific heat | 1.45 kJ |

| Coefficient of thermal conductivity | 0,034 |

| Standard sizes | 1185 x 585 x (20 - 100) mm |

Penoplex under floor screed - general information

Due to its high strength, penoplex is a universal material - it is suitable for thermal insulation of absolutely any surface. The big advantage in this regard is its ideal flatness, which makes it easy to clean the external floors.

It is important to know ! If you are choosing which penoplex to use for the floor screed, it does not matter - you just need to have enough thickness for the required level of thermal insulation. And the main thing here is the waterproofing layer.

The sheets themselves are stacked at a short distance from each other. Subsequently, the resulting void seams are eliminated. For this purpose, special construction foam is used, and sometimes adhesive tape is used.

Foaming voids with polyurethane foam Source sdelaysam-svoimirukami.ru

Correct installation of insulation

How to attach penoplex to the wall after completing the preparatory work? The whole process can be divided into several stages:

- Installation of the starter scarf. It is attached along the lower contour of the insulated zone and is necessary to support the sheets from below. Thanks to it, the insulation boards will not slip during installation, which will significantly simplify the installation itself. The plank can be a specially purchased factory one or made independently (for example, from a wooden beam of the same thickness as the thermal insulation sheets used).

- Preparing to attach penoplex to the wall. It consists in the fact that the side on which the material will be adjacent to the base needs to be rolled with a needle roller to create roughness. This is only required when attaching with adhesive to ensure a stronger connection.

- The installation itself. Its features depend on how the slabs are attached (glue, dowels, something else), but there are no difficulties or special techniques. The only thing is that each subsequent horizontal row is recommended to be installed with an offset of half the slab to improve the quality of thermal insulation and the overall strength of the structure.

- Sealing of seams. You can seal the seams between the plates with polyurethane foam or special mastics.

Not everyone knows which side to attach the penoplex to the wall, and whether it is important at all. In fact, this does not matter at all, since this insulation is double-sided.

In conclusion, it is necessary to list how penoplex is attached to a brick wall, as well as to other hard surfaces. The most popular mounting options are mounting methods using (listed in order of decreasing popularity):

- bitumen-polymer mastic;

- disc dowels;

- dry cement mixtures;

- polyurethane foam;

- glue-foam;

- "liquid nails"

Knowing how to attach penoplex to a brick wall and other surfaces correctly, you will be able to install high-quality and durable thermal insulation yourself or effectively supervise the craftsmen hired for this work.

Video description

Watch in this video how to mix the solution yourself:

It is also important to remember about the beacons - without them you cannot start the pouring process. Otherwise the surface will be uneven. The filling technique itself involves working from the far corner (here we will work with a level). After leveling the previous layer and before pouring the next one, a reinforcing mesh is placed.

It is important! Before carrying out work, you should consider the further use of the room, since the thickness of the screed depends on this. Thin slabs are suitable for an ordinary living room. For heavy structures, it is better to give preference to dense sheets.

To prevent cracks from appearing in the frozen surface, you need to water it with water for three days. Drying takes several days. Only after all these procedures is the facial finishing performed.

Self-leveling mixtures

To understand what thickness of penoplex to choose for insulating a floor with a screed made from a self-leveling mixture, it is necessary to take into account the type of room. The greater the load on the floor, the thicker the slab should be.

In this case, it is important to take into account the thickness of the layer of the mixture itself under the screed - in this case it is no more than 2 cm Source remstroidomufa.ru

3 advantages of self-leveling mixture:

- does not require manual alignment;

- distributed with a needle roller;

- dries faster than cement.

On a note! The leveling of such a surface is carried out under the influence of gravity. The kneading process itself is described on the packaging of the material. This base polymerizes in just a few hours.

The importance of leveling the underlying base should be kept in mind. If any defects remain, there will be a difference in height, and, as a result, an uneven screed.

Attention ! Waterproofing must be installed as close to the finished floor as possible. Some people put it under penoplex - this is a mistake. If water penetrates into the floor, it will not be possible to dry it. The surface will remain wet for a long time, since the slabs have a water-repellent effect.

The finishing itself can be anything - from ceramic tiles to wooden parquet. If the technology has been followed, the result will be excellent.

Insulation on top of the ground

To carry out the work we will need:

- gravel or small crushed stone;

- sand and cement;

- building level and rule;

- tamping device;

- reinforcing mesh;

- metallized tape;

- moisture-proofing material;

- metal beacons;

- alabaster;

- penoplex.

To install this type of thermal insulation, you need to lower the ground level by 500 mm from the finished floor. There should be no voids in the soil, otherwise the future foundation will shrink unevenly, which will cause destruction of the floor.

Briefly about the main thing

Penoplex is characterized by two properties. The first is its low thermal conductivity, due to which it has good thermal insulation. Secondly, the slabs are not susceptible to mold and mildew; they create a good soundproofing layer, while rejecting moisture.

Another advantage is that penoplex is universal in use - it can be used regardless of the base flooring. But here it is important to understand what thickness of penoplex to use for the floor under the screed. The further load on the surface (purpose of the room) has a huge impact. If this is, for example, a warehouse or a garage where a car will be stored, it is better to choose denser slabs.

The type of finishing does not matter. It all depends on the preferences of the owner of the premises. You can choose laminate, tile, plywood or parquet.

Another mandatory point is waterproofing. If this layer is skipped or installed incorrectly, spilled water may accumulate under the finish coat. Penoplex does not absorb moisture, and it will be quite difficult to dry it.

Methods of laying heating systems

Warm floors can be equipped with or without a concrete screed. Which method is better to choose depends on the technical features of the room.

Into a concrete screed

For a concrete screed, the building must have reliable floors.

The construction of a concrete system assumes that all heating elements are located under the screed layer. This technology is used for water and electric floors. In the latter case, only a separate heating cable can be covered with a layer of screed. Do not place a layer of concrete on heating mats. They can only be covered with ceramic tiles.

Concrete floors, due to their thickness, cannot be used in buildings with weak floors. The base should be a rough covering or monolithic slabs.

Advantages of concrete screed:

- Possibility of uniform heat distribution over the entire surface. Thanks to this, the room will warm up more efficiently.

- The concrete layer warms up slowly, but at the same time cools down slowly.

The disadvantages of the system are the complexity of the installation work. The concrete structure is made in layers:

- base;

- waterproofing;

- insulation;

- reflective foil;

- reinforcing mesh;

- heated floor pipe;

- pipe-cable.

Finishing materials are laid out as the top layer.

The heated floor screed is floating, so it must be separated from the walls by a gasket. If a semi-dry screed is used, panels with “barrels” are used to secure the pipes.

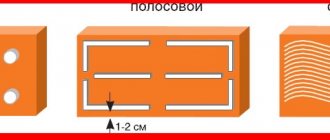

Into heat distribution plates without the use of concrete screed

Heat distribution plates in penoplex

When it is impossible to make a concrete screed due to its weight, heat distribution plates will help. They are made from aluminum or galvanized. Installed directly on the thermal insulation layer. The structures are equipped with gutters into which pipes are inserted. The plates make it possible to create warm floors in buildings with any ceilings. They perfectly reflect heat and distribute it evenly over the entire surface of the floor covering.

Unlike concrete screed, the plates heat up instantly. After turning off the heat supply, they remain warm for a long time.