Warm floors come in water and electric types. The systems were originally developed to heat cold ceramic tiles and porcelain tiles, but the technology has been so successful that it has spread to other floor coverings. Any heated floor can be used in conjunction with all types of PVC tiles, however, most manufacturers impose restrictions on the surface heating temperature (28°C). There are also some features of operating infrared systems.

The information in the article is for informational purposes only and does not constitute instructions . Before laying floor coverings on heated floors, we strongly recommend that you clarify all the details with the seller. Laying any coatings other than ceramic tiles on a warm floor carries certain risks that can be avoided or at least be able to take advantage of an official guarantee if you follow the manufacturers' recommendations.

Requirements for PVC tiles under which heating can be installed

Considering the minimum heat loss (see table below), the recommended temperature limit of 28°C is sufficient for comfortable heating of the feet, but it is not enough if you plan to use a heated floor as the only source of heating. Prolonged overheating threatens to soften the polymer and deform the floor covering.

In addition, the base under the PVC tiles must be level and solid, which is not always achieved in conjunction with an infrared heated floor, under which it is necessary to lay a thermal insulation substrate. There is a technique here that is prohibited by manufacturers of film systems: you can place foil under the mats, which will do an excellent job of reflecting heat. But in this case, the warranty for the heated floor is terminated.

Elastic quartz vinyl and PVC tiles, as well as WPC laminate with a built-in backing, are combined only with a heated floor, which is mounted in a screed, and not laid directly under the floor covering (infrared heating mats).

Calculation and distribution of pipes

Pipes with diameters of 16, 20 or 25 mm are used. Using a pipe with a smaller diameter will result in impaired water circulation. By measuring the pressure in the heating pipe using a hydromanometer, you can find out the pressure in the system.

Too large a diameter of pipes for laying in a floor pie will result in a decrease in operating pressure and a drop in temperature.

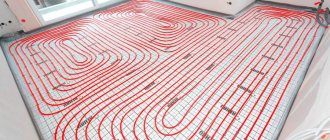

Another characteristic of the material is its need, for which the length is calculated. You can lay pipes in one of the following ways: a snake or a spiral (snail). DIY installation diagrams for a heated water floor look like this:

In the first case, significant differences in temperature are possible in certain areas of the area; the spiral provides better heat distribution. This layout method involves alternating direct and reverse supply of coolant.

On a sheet of graph paper or a squared notebook, you should draw a sketch of the room on a scale of 1:50 or 1:100 and mark the pipe routes, and the beginning should be at the riser closest to the window. The first row is laid 25 cm from the walls.

The pipe pitch is taken to be 25-50 cm (25 cm - with a diameter of 16 mm, 30-40 cm - with Ф20 mm, 40-50 cm - with Ф25 mm).

The length is measured on the sketch, a conversion factor is applied to the scale and the required size is obtained. To connect to the riser you should add 2-2.5 meters.

For each circuit, you need to buy pipe footage in one piece, since joining is unacceptable. One collector is made for several rooms, or for the entire floor.

How to calculate the heat load for heating

Immediately before laying a warm floor covering, it is recommended to clarify what temperature is comfortable for the feet. This indicator is determined by the type of surface material. For example, for heating tiles, the optimal water temperature in the heating circuit pipes is +26 °C. It is also necessary to determine the length of the circuit, based on the dimensions of the communications. So, for pipes with a diameter of 20 mm, a circuit with a length of up to 150 m is installed.

Communications are laid indoors in increments of 16-32 mm, this parameter corresponds to the diameter of the pipes. For example, if the cross-sectional size is 16 mm, communications should be laid with the same spacing. Taking into account the diameter of the pipes and the distance between them, the sufficient load (W/m²) is determined. If you plan to install a warm floor covering, you need to make a design and calculation, as with the installation of any other heating system. The main parameters that are calculated:

- calculation of heat losses;

- average circuit temperature;

- heat flux density.

After calculating the sufficient diameter of the communication, the thickness of the screed for the heated floor is determined. When choosing a boiler, calculating the power taking into account all the heating circuits of the facility is the most important criterion.

The feasibility of using heated floors with vinyl tiles

PVC tiles have a very low thermal conductivity coefficient: 0.15-0.25 W/(m*K). Thanks to this, the surface of the flooring takes on the temperature of the air in the room and is never cold. In addition, thermal conductivity also determines how well a material retains heat and, accordingly, how efficiently electricity is used.

Based on this, the conclusion suggests itself: the use of heated floors with PVC tiles, although allowed by all manufacturers, is in most cases redundant, because the surface of a vinyl floor covering, unlike porcelain stoneware or tiles, does not cool down to an uncomfortable state.

However, for the bathroom, in the nursery or on an insulated balcony, especially in winter, you want to feel the warmth under your feet and be able to walk barefoot. And here the possibility of operating energy-efficient and comfortable heating seems to be a clear advantage.

Tips for choosing

You can lay any of the materials recommended above on a warm water floor in a private home, however, in order for the coating to last as long as possible and without destruction, you must consider the following tips for their use:

- Ceramic tile. Suitable for rooms with increased load, changes in air temperature and humidity. At the same time, in the kitchen it is better to choose light-colored material to visually expand the room. In the hallway, preference should be given to dark colors so that dust and dirt brought from the street are invisible. In a bathtub, shower room, or toilet, it is better to lay tiles with a structural anti-slip surface.

Types of vinyl floor coverings for heated floors

Optimizing the use of heated floors is one of the key factors in the development of vinyl flooring, in particular, the emergence of stone-polymer SPC laminate and wood-polymer WPC tiles with a density of 2000 kg/m3 and 1050 kg/m3, respectively. Learn more about the evolution of vinyl flooring and the role of heating systems.

Stone SPC laminate

◈ Details about SPC laminate.

SPC laminate with a thermal conductivity of 0.18-0.25 W/(m*K) is the flooring closest to porcelain stoneware. Due to the high content of compressed stone (up to 80% calcium carbonate), the surface heats up quickly and evenly, with virtually no heat loss. But at the same time, thanks to the binding polymer, the floor cools down much more slowly. In addition, you cannot use film flooring with ceramic tiles, but you can with SPC vinyl.

Only two brands of stone-polymer SPC tiles - Fargo, Stone Floor - officially allow heated floor heating to 40°C. There is also a collection of Art Stone Armor with two heat-stabilizing layers: it is interesting that in the presentation the manufacturer states 45°C, but in the instructions he repeatedly warns against overheating above 28°C.

Vinyl WPC Tile

◈ Details about WPC tiles.

WPC tiles with a high content of wood flour and a foamed structure are also suitable for all types of heated floors, but the density is 2 times lower than that of SPC and the minimum content of stone chips greatly increases heat loss, the floor takes a long time to heat up and at 40°C micro-expansion of the planks is observed ( see comparison table below).

Resilient Vinyl Flooring

◈ Details about quartz vinyl tiles and PVC tiles.

Adhesive PVC or quartz vinyl tiles are compatible only with built-in systems: water and electric heating up to 28°C. Film systems can also be used in conjunction with the locking installation method, however, only elastic underlay materials or foil recommended for vinyl should be used as a thermal insulation substrate (not recommended by manufacturers of heated floors).

Interlocking quartz vinyl or interlocking LVT tiles with a thickness of 3.5 mm and thinner are a poor choice for any type of heated floor: when heated, the interlocking joints soften, which leads to a violation of the tightness and integrity of the entire flooring.

Rigid Vinyl covering

◈ Details about Rigid Vinyl floors.

Interlocking flooring with a thick vinyl layer is also compatible with heating systems. Thanks to a thickness of 5 mm or more, Rigid Vinyl can be used with infrared heated floors and with increased surface heating. As with the vast majority of vinyl flooring, Rigid Vinyl manufacturers also declare a heating limit of up to 28°C.

PVC tiles - what is it, structural features

Quartz vinyl is easy to install, just like laminate, but its performance is equal to that of ceramic tiles. Based on the installation method, there are two types of coatings – adhesive and locking.

Produced by pressing several layers:

- UV layer protects the next PU layer? Including from light.

- Polyurethane layer, protection against abrasion, mechanical damage, stains.

- PVC layer, additional protection against abrasion. Creates a feeling of real surface texture, thanks to embossing in wood or stone register.

- Decorative layer imitates natural materials.

- The fiber optic layer reflects light, which makes the decor more realistic. Absorbs vibrations.

- Double reinforcing fiberglass is responsible for the flexibility and strength of the structure, resistance to deformation and changes in geometric shapes during operation.

- The quartz vinyl layer takes on the main loads. Thanks to quartz, it is resistant to temperature changes and maintains geometry.

- Another double reinforcing fiberglass.

- PVC layer, stabilizing.

This structure provides a number of advantages:

- resistance to changes in humidity and temperature;

- 100% water protection;

- elasticity;

- antistatic properties;

- fast warm-up.

You can find out more about the pros and cons of PVC tiles in our article.

Comparative table of heat loss and thermal expansion

| The basis | Heating up to 28°C* | Heating up to 40°C** | ||

| Thermal expansion | Heat loss | Thermal expansion | Heat loss | |

| SPC | No | 0.5°C | 0,04% | 0.5°C |

| WPC | No | 6.5°C | 0,21% | 6.5°C |

| LVT, quartz vinyl | No | 1.5°C | — | — |

| Rigid Vinyl | No | 1.5°C | 0,21% | 1.5°C |

* - Up to 28°C. Heating floor.

** - Up to 40°C. Enough to heat the room, the maximum permissible temperature for comfortable walking on the floor.

Installation methods for selected elements

Installation methods vary significantly depending on the composition and shape of the underfloor heating elements. All cases have one thing in common - high-quality leveling of the base and its primer to improve adhesion.

Tiles and porcelain tiles are laid on glue, the basis of which is cement. It is possible to use mortars packaged in tubes; it is faster, easier, but more expensive. Laying is done in even rows, offset or diagonally. Alignment is achieved using plastic crosses. After the solution hardens, they are removed and the seams are rubbed down.

Polymer fragments are fixed to the slab on an adhesive base end-to-end or attached in a floating manner directly to the screed. In this case, gluing is performed only along the chamfers on the edges of the products.

Recommendations for the installation and use of heated floors with PVC coatings

- All types of heated floors can be used together with SPC laminate, WPC and Rigid Vinyl tiles.

- Together with adhesive PVC and quartz vinyl tiles, only water and cable systems built into the screed are allowed.

- It is not allowed to use heated floors with elastic interlocking vinyl up to 3.5 mm thick.

- When using flexible vinyl tiles, as well as WPC and Rigid Vinyl together with heated floors, it is necessary to provide expansion gaps at the walls of 8-10 mm so that potential thermal expansion does not deform the flooring.

- The recommended heating temperature for heated floors under vinyl is 28°C. Prolonged overheating can lead to softening of the polymer. In practice, the restriction does not apply to SPC laminate, which is based on up to 80% mineral filler.

- It is not recommended to use heated floors as the main and only source of heating.

- Under carpets and some types of furniture, heat accumulation and spot overheating are possible, which is unacceptable.

Advantages and disadvantages

The following other points count in favor of underfloor heating:

- savings during operation up to 45%;

- the ability to avoid installing radiators, which allows for better use of room space;

- The finishing coating is suitable from any material;

- the air warms up more evenly, there are no drafts;

- The comfort of being in a space heated by thermal radiation is much higher than with radiator heating.

However, there are also disadvantages, which include a drop in pressure in the heating system due to the coolant diverted to heated floors, as well as the inability to quickly find and repair a leak in the event of an accident.

In any case, the main argument in favor of underfloor heating is the ability to increase living comfort while saving significant money.

Typical installation patterns

All types of vinyl flooring are suitable, including adhesive quartz vinyl tiles. Before laying the adhesive floor, the plywood base must be puttied and sanded along the seams and on the screws.

Scheme 1. Water-heated floor on a wooden floor

Pattern 2 is suitable for interlocking and glue-down vinyl floors on any substrate.

Scheme 2. Cement-sand screed and water heated floor

Pattern 3 is suitable for interlocking vinyl floors on any substrate.

Scheme 3. Cement-polymer screed and cable heated floor

Scheme 4 is only suitable for interlocking vinyl floor coverings on any substrate with a thickness of 4mm or more.

Scheme 4. Cement screed and film heated floor

Subscribe to the mailing list of new articles and reviews from Doctorfloor.ru

The editors do not claim to have the only correct and correct opinion regarding vinyl floor coverings. If you think that you have more professional, complete and reliable information, contact us by e-mail or through the feedback form in the Contacts section. We will be grateful for your help in filling the resource!

Similar articles

Vinyl wall tiles: choice in…

PVC tiles for the nursery: comfort and…

Quartz vinyl for the kitchen: a universal choice...

Quartz vinyl tiles in the bathroom: finishing with…

Quartz vinyl tiles on the balcony: a stylish area…

Main components of a water floor

The design of a water heated floor is multi-layered; before we begin to study the installation and installation scheme, we will consider each layer in the system separately.

Waterproofing

If there was one material for everything, then there would be no need to study the building materials market, choosing something better and most suitable for your needs.

To waterproof the floor under the heated tiles, use polyethylene or roofing felt if the installation is done on the ground.

Reflectors

A reflector is a foil layer or metal plates. If you purchase the latter option, it makes sense to immediately buy products with channels for pipes.

Insulation materials

For insulation, it is optimal to purchase extruded polystyrene foam rather than basalt wool. Mineral wool is highly hygroscopic in its properties, and since the underfloor heating system is water-based, any leakage will ruin the insulating layer, which will result in a major repair.

Pipes

Now we come to the main layer of the warm “pie” - the pipes. Water moves along them, which will heat the floors under the tiles. Pipes can be made from various materials. This affects their price, technical characteristics and conditions of use. Pipes for water heated floors

| Photo | Material |

| Polypropylene products are capable of significant expansion when exposed to high temperatures. It would be better to purchase pipes based on polypropylene with reinforced fiber. | |

| Metal-plastic models for warm systems are durable. | |

| Copper pipes are elastic and last a long time, although they cost an order of magnitude higher. | |

| Steel models are very durable and of excellent quality, although they can be damaged by corrosion over time. |

Base

Since we are talking about tiles, we need to take into account that the base is made solid. If you do not use a screed, you can use moisture-resistant plasterboard, plywood and wood.

There are three main ways to install water heated floors:

- under the screed;

- flooring system;

- on a wooden base (joists).

Installation on subfloors with built-in underfloor heating

Instructions for laying VINILAM, Allure, VINILPOL, CERAMO VINILAM floor coverings on bases with a built-in floor heating system.

All collections of floor coverings from the Vinylam company work perfectly on heated bases, subject to building codes and recommendations.

Recommended underfloor heating systems for vinyl interlocking and adhesive floor coverings are hydronic underfloor heating and electric cable underfloor heating, which are filled with thick or thin screeds. For free-lying interlocking coverings, it is not recommended to install heating elements in local areas that do not coincide with a single mass of floor covering, since heating a free-lying modular covering requires uniform heating of the base. Laying of flooring on subfloors with underfloor heating systems must be carried out in accordance with international standards DIN 18365 and EN 1264.

It is not recommended to install vinyl flooring on a film infrared “warm floor”. The reason is that in this floor heating system a thick foam substrate is recommended, there is direct contact between the heating elements and the floor covering, it is easy to make a mistake when installing a temperature sensor, so sudden heating of the floor surface is possible, the film “warm floor” is not installed under furniture throughout room area. As a result of the combination of these factors, local overheating, deformation of the planks and the appearance of cracks can occur. In order to still use film technology for vinyl coverings correctly, it is necessary to lay a free-lying dry Knauf screed on top of the film “warm floor”, and the film should heat the entire flooring evenly over the entire area. (the heating sensor is mounted in a layer of dry screed). When laying vinyl on such a film “warm floor”, the buyer takes on all possible risks of damage to the floor covering in the future.

General recommendations when designing floor heating systems.

- Consider the mandatory ventilation of the room and its direction.

- Consider the direction and strength of convection from the heating elements.

- Consider the dependence of dust movement on convective currents.

- Take into account the recommendations of Sanitary and Building Codes on the temperature conditions of air and house structures in different seasons and in different climatic zones

- Take into account the recommendations of the Building Regulations regarding the operating temperature of free-standing coatings.

- Consider the purpose of the room (living room, bedroom), the temperature regime depends on this.

- Consider the constant effect of high floor temperature on the blood vessels of the legs and internal pressure in the body.

For professional calculations of complex heating and underfloor heating systems, contact independent heating engineers to obtain results that meet your needs.

Basic Rules:

!!! All floor coverings and building structures suffer from overheating. Therefore, in a “warm floor” project there must be a temperature control system installed in the screed so close to the heat source (at the coolant inlet) that the heating system turns off without inertia when the base is heated no higher than 28 degrees Celsius. In the absence or incorrect installation of temperature control sensors in the “warm floor” system, it is impossible to clearly control the temperature; in such cases, changes in the shape, size and other characteristics of vinyl floor coverings that could not be taken into account by the manufacturer are possible. In cases where there is no temperature control sensor on “warm floor” systems, if any problems arise, claims will not be accepted.

!! The recommended base temperature for a vinyl modular covering on a base with a floor heating system is not higher than +28 C. If the free-lying floor covering has a temperature of less than 10 degrees Celsius, then the increase in floor temperature to room temperature should occur smoothly, without sudden jumps.

!!! The recommended (SNiP, SanPiN) comfortable temperature on the floor surface is 24-25 degrees Celsius in residential interior spaces.

!!! It is not recommended to install any free-standing coverings on foundations with a built-in heating system in a house with a heating temperature of more than 28 degrees Celsius.

!!! Heating over the entire surface of the base, on which a single array of free-lying interlocking covering is located, must be uniform.

!!! When laying vinyl laminate flooring on fresh screeds with built-in floor heating systems, a prerequisite is a base humidity of no more than 5%. All fresh screeds must be given time to dry thoroughly. Fresh concrete bases - drying time is at least 30 days. Self-leveling mixtures - drying time is at least 10-15 days.

Laying flooring on a heated base.

The technology for laying loose flooring on a base with a built-in heating system is the same as in the installation instructions for each VINILAM collection.

Before installing the floor covering, it is imperative to test the “warm floor” in heating operating modes and make sure that the heating is uniform and that the temperature on the regulator corresponds to the actual temperature on the base.

Before installing the floor covering, the floor heating system (water or electric) built into the screed must be turned off 48 hours before laying the floor covering. If it is impossible to turn off the “warm floor”, then during the acclimatization period of 48 hours, during installation and for 48 hours after installation, a constant temperature of the base and air in the room must be ensured between 18 and 24°C. It is better to set a temperature that will be closer to a constant temperature during further operation.

NECESSARILY !!! When installing free-standing interlocking vinyl covering, it is necessary to maintain compensation CLEARANCES of 10 mm between the floor covering and the wall, along the perimeter of the room. It is recommended that built-in heavy furniture be placed on separate floor coverings and ensure that the covering can expand and contract freely. The covering should not be pressed against heavy furniture, baseboards, door frames or otherwise restricted by movements that occur during expansion and contraction.

When installing adhesive modular “quartz vinyl”, the material is completely fixed on the base with glue; when installing it on a heated base, you need to take into account not the expansion and contraction of the floor covering, but the expansion and contraction of the base slabs. During continuous installation, if a compensatory gap is made in the screed between rooms, then the movement of the screed in this place must be taken into account. The gaps with the walls for adhesive tiles can be 5 mm. You also need to take into account that the glue works up to 50 degrees Celsius and it is also impossible to overheat the adhesive floor covering.

Assessing the need to use built-in base heating systems when laying vinyl flooring:

Due to the limitation of heating the base for free-lying coverings to 28 ° C, approximately 25-26 ° C reaches the surface, which is only 3-4 degrees more than the usual room temperature of the floor. If the heating system is planned in the bathroom, in the nursery, on an insulated loggia, in living rooms above cold rooms, then its use is completely justified. If heating is planned in the living room, in the kitchen, in the corridor, while the residents wear slippers and do not lie on the floor for long periods of time, then you need to weigh the ratio of financial costs and the real thermal effect.

You need to understand that without additional heating, vinyl flooring is quite comfortable in terms of thermal sensations in ordinary heated apartment buildings, where the screeds are insulated and the heating is on during cold seasons.

The coatings of the VINILAM PARQUET, VINILAM CHEVRON, ALLURE ISOCORE, VINILAM CORK collections should be especially highlighted, their thermal conductivity coefficient is 0.16 V/m*K., That is, heat from the room is not transferred through the vinyl to the cold base. These floor coverings retain our heat very effectively and are very comfortable in terms of thermal sensations. To enhance thermal comfort, aluminum foil (without foam backing) can be applied underneath these floorings to reflect wave heat back into the room.

Table.1 Thermal parameters of VINILAM floor coverings.

| Collection name | Recommended maximum floor surface temperature | Thermal conductivity coefficient / reduced | Resistance to heat transfer through the thickness of the floor covering | Coefficient of linear expansion of the material from t0. |

| Vinilam Click 3.7 mm. | +28 0С | 0.27 W/m* 0С | 0,0167 sq.m* 0С/W | 0,000075 |

| Vinilam CERAMO 4.5 mm. | +28 0С | 0.22 W/m* 0С | 0,027 sq.m* 0С/W | 0,000085 |

| Vinilam Cork 7 mm | +28 0С | 0.16 W/m* 0С | 0,043 sq.m* 0С/W | 0,000075 |

| Allure ISOCORE 7.5 mm. | +28 0С | 0.16 W/m* 0С | 0.043 sq.m*0С/W | 0,000075 |

| Vinilam Parquet 6.5 mm. | +28 0С | 0.16 W/m* 0С | 0.043 sq.m*0С/W | 0,000075 |

| Vinilam Chevron 8.5 mm. | +28 0С | 0.16 W/m* 0С | 0.043 sq.m*0С/W | 0,000075 |

Calculation of thermal expansion of a free-lying array of interlocking floor coverings.

Thermal expansion is calculated using the formula:

L = K * T * L1, where

L is the total change in the length of the laying array due to temperature changes.

K - coefficient of linear thermal expansion of the material (PVC 0.000075)

T is the temperature difference from the initial (room) temperature to the final temperature (increased or decreased). For example, from 20°C to 40°C the difference is 20°C.

L1 - initial laying length (for example 10,000 millimeters)

Calculation example:

The expansion of a 10-meter-long flooring array is 0.000075* 20°C * 10000 mm = 15.0 mm.

That is, the gap with each wall must be at least 7.5 mm. In this case, we recommend making the temperature gap larger, for example 10 mm.

!!! If you somehow fix one edge of the flooring (heavy furniture, kitchen, closet), then expansion when heated will lead to the expansion of the flooring only in one direction and a decrease in only the opposite gap by the entire 15 mm. (for this example). It is recommended not to place heavy and built-in furniture on a single array of loose flooring. It can be installed on your flooring area. Gaps between sections of flooring can be made invisible in various ways.

Optimal coolant temperature depending on coating

A water heating system is often installed in a concrete screed, and it has a high degree of heating. If the screed is thick, the floor surface will warm up worse. In addition, different flooring materials have different degrees of thermal conductivity.

The optimal temperature for a heated floor when laying laminate or parquet heated by water heating is considered to be +28 degrees. Excess may deform the material.

If the hydrofloor is located under the tiles, then the permissible value is + 33. When laying carpet, the maximum heating of the coolant is +27 degrees. When using linoleum, overheating is not recommended, and the temperature should not exceed more than + 26°C.

In any case, it is necessary to choose a material that is intended for heating systems, otherwise toxic substances may be released.