Increasingly, when choosing heating radiators in a house, apartment or office, preference is given to tubular radiators. The popularity of such radiators is due to their high corrosion resistance, operating efficiency and aesthetic appearance.

They consist of upper and lower collectors, between which there are jumper tubes.

Laser welding is used to connect the elements, making the seams as neat and invisible as possible.

Radiators can be made of stainless steel, aluminum, or a structure of steel tubes placed in an aluminum housing (bimetallic).

Review of manufacturers

The presented range of tubular radiators is quite large.

On the positive side, models made by Russian manufacturers have proven themselves, since such partings are produced taking into account the specifics of water quality, pressure drops and a number of other nuances inherent in our region. In the list of foreign-made goods, you should opt for radiators made in Germany, Turkey or Italy.

Heating structures from Czech companies are notable for their low cost, as well as the high level of quality of the goods sold. A distinctive feature of the product is a special system that involves installing thermostatic valves in radiators, through which the temperature is adjusted, the values of which were indicated earlier. It is worth noting the very popular Czech brand of radiators Isan Atol.

In specialized stores you can find products from Turkish manufacturers who specialize in the production of steel radiators. The products have an affordable price, in addition, most of the companies operate under the license of popular European companies, thanks to which the heating devices produced fully comply with European quality standards, which puts them on a par with Russian-made devices.

The batteries, which are manufactured in Poland, belong to the mid-price category; the production facilities, which specialize in the production of heating devices, use the latest equipment during their work, as well as many years of experience, which has a positive effect on the quality of the finished product. Most of the radiators produced by Polish companies are presented on the market with bimetallic models. Among the popular brands is Termica.

Dia Norm and Zehnder companies are popular German manufacturers of tubular steel radiators.

In addition, it is German organizations that are actively involved in the manufacture and sale of devices that should be classified as part of the model range of non-standard radiators. For example, Zehnder products are available on the market in more than 700 colors. However, the disadvantages of such products include their high cost.

There are heating products of joint production, for example, products from Arbonia are very popular. As consumers note, Swiss-German radiators have an attractive external design, good performance characteristics for Russia, and also a very affordable cost of goods.

In the list of leaders regarding the technical characteristics of heating devices, it is worth highlighting Italian products for space heating systems. The only disadvantage of this product is its full compliance with European operating standards, which is not always acceptable for the Russian consumer. However, the ease of installation and high level of efficiency of heating devices make them very popular.

Among the popular Italian brands, it is worth highlighting the products of the Royal Thermo company, which has positive characteristics regarding the quality, care and service life of the devices. The disadvantages include the high cost of Italian heating products.

Purmo are radiators from Finland, which are manufactured in a wide range of sizes, as well as connection and installation options. In addition to standard models, the company produces devices according to individual sizes and designs; the price for such devices will be slightly higher than for regular products.

Tubular radiators made in China belong to economy class products. However, the low cost does not in any way affect the quality of the goods, since the batteries are resistant to aggressive substances contained in water, and some companies specialize in producing devices that are adapted to the needs of Russian consumers.

Basic heating register calculation

If the level of heat transfer of a purchased battery can be found out from its passport, then in the case of homemade heaters you have to calculate everything yourself. Otherwise, it will not be possible to heat the room effectively and evenly.

Calculating the required radiator power to heat a room

For calculations, they use formulas that may be simple, but require certain mathematical skills. Another option is online calculators, of which there are now more than enough on the Internet. Strictly speaking, the topic is quite extensive and deserves a separate article, so we will use simple calculation methods. In any case, this issue should be given close attention, otherwise your family will complain that the radiators do not heat well and the room is cold.

A simplified method for calculating the required thermal energy is to calculate the heating area and then multiply by 100. Why is this so? Because for comfortable living per square meter you need 100 W of heat. To be more precise in the calculations, let’s take into account the number of window openings and walls:

- A room with one window and one external wall – 100 W per 1 m² of area.

- A room with one window and two external walls - 120 W per 1 m².

- A room with two windows and two external walls - 130 W per 1 m².

Important! The calculations are suitable for rooms with ceilings of no more than 3 meters, when the house is located in a moderate climate in the middle zone. If the building is located in the northern regions, then the result must be multiplied by a factor of 1.2-2.0, and if in southern latitudes - by 0.7-0.8.

Simple calculation of the thermal power of a radiator made of steel pipes

Knowing what to strive for, all that remains is to choose the design of the heating device that would satisfy your needs. How to do this?

There is an elementary solution - use a table. It already calculates the heat transfer rates of rolled pipes. The values take into account the temperature regime, in which the supply temperature of the coolant is +90℃, and the return temperature is +20℃.

So, the table below allows you to find out the thermal power of one linear meter of register pipe per square meter of heated area.

| External section of the pipe, mm | Heated room area, m² |

| 25 | 0,5 |

| 32 | 0,57 |

| 42 | 0,69 |

| 57 | 0,94 |

| 76 | 1,19 |

| 89 | 1,37 |

| 108 | 1,66 |

| 133 | 2,0 |

| 159 | 2,43 |

Important! Keep in mind that calculations based on square footage alone are fairly rough estimates. It is advisable to use special formulas that use the temperature conditions of the system and the linear parameters of the radiator.

What other quantities do you need to know?

So, we have decided on the option - all that remains is to draw up a drawing. At this stage, such a parameter as the distance from section to section – h – is often forgotten.

When assembling a coil-type radiator from steel pipes, this value is determined by the dimensions of the bends used. Here it is worth paying attention to the value of F - this is the so-called outlet height. Without a doubt, the intersection distance here will be expressed by the formula:

h = 2F-D

If you decide to assemble a simple sectional radiator, then the gap between the pipes can be set independently, but with one condition:

H = D+50 mm

The same principle applies when working with rolled profiles, only instead of the diameter the height of the square or rectangular profile is used. Of course, the design features of the device are taken into account.

Decorative possibilities of tubular heating devices

Tubular radiators look very elegant and light.

There are non-standard versions available for sale. For example, semicircular. True, such models cost three times more than those that have a regular shape. An interesting design solution can be called tubular bench radiators. The color range of tubular steel devices is very wide. Most often you can find dark and light batteries on sale. Dark options improve heat transfer. But many consumers prefer more interesting color solutions. For example, bronze, metallic, lacquered wood, mother-of-pearl, aged bronze, etc. Chrome plated products also have good efficiency.

Such fashionable interior styles as vintage and loft have given rise to other interesting designs for radiators. For example, there are models in which the metal surface is treated with special means to increase anti-corrosion properties, and the top is coated with a transparent varnish.

Battery grilles are often used as design decoration. Such elements add aesthetics and also protect the radiator from various mechanical damage. The nets are sold in different shades. At the same time, the price of grilles for heating radiators does not depend on color.

Subtleties of connection

The choice of installation method for tubular radiators is determined by the device model. There are several device options:

- universal devices - most of the tubular radiators sold have special holes for connecting to any type of heating system pipes;

- models of devices with a bottom connection method, in which all outlet and inlet communications are located outside the viewing area;

- the side type involves connecting the radiator to vertical heating risers;

- radiators with a cross connection type - in this option, the pipe supplying coolant is located at the top, and the outlet pipe is on the opposite side.

Heating devices are mounted on brackets suitable for the type; after completing all actions related to the installation of the radiator, it is imperative to perform pressure testing to eliminate the risk of leaks at the junction of pipes and the heating system. For tubular radiators, the most acceptable coolant temperature is considered to be not exceeding +120 C.

How to choose heating pipes

Deciding which pipes are needed for heating is not easy, so to maximize the efficiency of the selected materials, it is necessary to comprehensively consider their characteristics in relation to a particular system.

When choosing pipes, you need to consider the following factors:

- The power of the system and the pressure created in it;

- Pipeline installation method (external or internal);

- Type of heating system (natural or forced);

- Limit temperature of the coolant in the system;

- System configuration (simple or complex).

These factors provide most of the information necessary for selecting the optimal materials, but not all of it - for example, the coefficient of linear expansion of a pipe when exposed to temperatures depends specifically on the pipes. For the information to be complete, you need to know exactly which pipes are used for heating.

Previously, only metal pipes were used to lay heating system pipelines. This is not surprising, because there was no alternative, and it was impossible to think about what was better - steel pipes or polypropylene. Now there are many good analogues that are worth paying attention to.

Chinese

The most budget model of a metal tubular radiator can be called Oasis batteries made in China. Despite its low cost, the device is characterized by good durability, resistance to aggressive influences and the absence of operational restrictions. A number of models are manufactured taking into account the specifics of domestic heating networks. Oasis tubular heating radiators have the most positive reviews. The company also specializes in the production of standard bimetallic heating radiators, characterized by excellent thermal characteristics and affordable cost.

German

It is especially worth noting the high quality of tubular steel radiators from the German company Zehnder. The products of this company are distinguished by significant technological diversity, with the ability to connect to hot water pipes, open water heating systems and electrical circuits. German plumbing companies specialize in non-standard heating devices. Such models can be very high or super low, with a very rich range of colors (700 shades). The high cost of Zehnder products should be taken into account.

Speaking about German radiators, it is worth mentioning the Swiss-German enterprise Arbonia. These products are distinguished by excellent design, high technical characteristics and quality. At the same time, the cost of Arbonia heating appliances is quite acceptable for domestic buyers.

Cast iron heating radiators

Conventionally, they can be divided into conventional or modern-style radiators and retro-style radiators.

Cast iron radiators in a modern style

The oldest type of radiators. These radiators are distinguished by simplicity and severity of form, flat facade, and neat design. They take a long time to warm up, but they withstand all the hardships of central heating with honor. They are durable, cheap, and last for 50 years. Therefore, when deciding which types of heating radiators to choose, many choose cast iron ones.

Manufacturers: Budget cast iron radiators are produced by Ukrainian, Russian, and Belarusian factories. But foreign products will be of better quality and prettier in appearance. Let us note the companies Konner, Viadrus, DemirDöküm, Roca.

Adviсe

Before installing aluminum systems, it is recommended to wash them, the main thing is not to use alkali for this. The wall on which the battery is hung is additionally reinforced. In addition, it is necessary to additionally finish it with fire-resistant material, for example, apply special plaster. This type of finishing will increase the fire resistance of the surface, but will not increase its thickness.

The attachment points must be evenly distributed over the entire surface of the battery, be strong, without defects or damage. Oil models can only be installed in places where the risk of fire is minimized. Such systems cannot withstand mechanical damage, so it is better to protect them with a special mesh.

See the next video for more details.

Subtleties of installing homemade registers

Actually, the procedure is not much different from installing factory heating devices. The only difference here is the weight and dimensions of the structure. However, keep in mind a few simple rules:

- The distance between the battery and the wall should be at least 25 mm, and the same to the floor. From top to window sill - at least 50 mm.

- When assembling threaded connections for sealing, use paronite gaskets, FUM tape or tow with sealant.

- The slope of the underwater pipes in relation to the register should be 5-10 mm per meter in the direction of the coolant movement. When the line length is less than 500 mm, it is not necessary to make a slope.

- The installation part of the work should be carried out before the onset of the heating season - this way you can do a test run of the heating system, check its tightness and design power.

Pros and cons of tubular batteries

Before you buy tubular heating radiators, you need to consider what advantages and disadvantages they have.

Among the advantages of using these heaters are:

- Resistant to the negative effects of hard water. Corrosion plaques practically do not form on such batteries.

- Variety of colors and shapes. This allows you to choose a model that will ideally suit the design of the room.

- Safety. The device has no sharp corners. An excellent option for families with children. Such radiators are less dangerous.

- Easy to use and maintain. Due to their design, tubular batteries do not accumulate dust. They are very easy to wash.

- Modern models can be connected both via the bottom and side circuits.

- Only modern materials and the latest technologies are used for production.

The reviews for steel tubular heating radiators are very good. Many users note the following advantages of tubular batteries: ease of regulating the water supply, the ability to install on drywall, optimal price-quality ratio.

But heating devices also have some disadvantages:

- Low power. Because of this, tubular steel batteries can only be installed in small buildings and the private residential sector.

- The level of heat transfer is low.

- Expensive. Since this type of heating device appeared on the market relatively recently and new materials and technologies are used for its production, prices for steel tubular heating radiators are still quite high.

- Leaks may occur in areas where tubular welding has been carried out.

Copper pipes

Copper pipes are a rather unusual and very rare phenomenon. They seem to have a lot of positive qualities, but there is one serious drawback - too high a cost. It is because of this that copper pipes are practically not used when laying heating systems.

If we talk about the advantages, then their list will look like this:

- Ability to work in a wide temperature range - copper can withstand temperatures up to 500 degrees and can easily survive negative temperatures;

- Good resistance to high pressure (copper can even withstand water hammer);

- Durability - copper pipes can work without problems for more than a hundred years;

- Excellent visual qualities that only improve over time.

Of course, copper pipes can be used for heating, but this will be very expensive, so first you should consider all types of pipes for heating a private home - perhaps there is a more affordable material whose characteristics will be sufficient to solve a specific problem.

Positive and negative qualities

Choosing a tubular heating radiator involves first of all studying all its qualities. Both advantages and disadvantages must be taken into account, only then the choice will be competent.

Here are what are most often considered to be the advantages of tubular options:

This type of radiator is resistant to corrosion and is not destroyed by hard water.

An extensive range of design solutions for Russian and foreign tubular heating radiators allows you to choose any model.

No sharp corners that can lead to injury, which is very important for families with children

Caring for such radiators is easy, because they do not accumulate dust.

Although this variety has a lot of advantages, it is not without its disadvantages. The most annoying thing on the list of shortcomings is the high price of tubular heating radiators.

In addition, they have low power and poor heat dissipation. And also in some cases, leaks were noticed in places where pipes were welded.

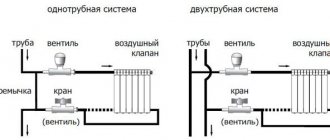

Connecting a radiator at home

Before direct installation, you should make sure that all the elements necessary for installation are available. If a single-pipe connection method was chosen, it is recommended to purchase a bypass, which will allow you to remove the radiator being installed without the need to shut off the entire system.

Also, according to the size and connection method, connecting elements are selected if they are not included in the radiator kit. This also includes shut-off valves and drains, which are also selected according to size.

It is highly desirable to install a Mayevsky valve in the structure, which will allow the accumulated air to be periodically released from the system.

There are a large number of photos on the Internet demonstrating the connections of heating radiators, for choosing the optimal configuration of components.

It is worth noting that when installing any types of radiators with the exception of cast iron, you should not remove the packaging until the installation work is completed.

Design features of tubular batteries

In their design, tubular batteries are a bit like cast iron ones.

You can read more about cast iron heating radiators here. They just look thinner and much more elegant. Such equipment consists of lower and upper collectors connected by steel tubes. The elements are connected using universal laser welding. Thanks to this, the seam is neat and almost invisible. All tubular steel radiators have a very durable design. Thanks to the variety of sizes, shapes, and color shades, such a heating device will fit into any apartment interior.

Where can tubular radiators be installed?

Steel tubular radiators are usually installed in private houses or in apartments of five-story buildings.

Because water hammer often occurs in the central heating network. And the working pressure of a steel tubular battery is only 6-10 atmospheres. In the event of serious pressure surges, no specialist can guarantee the tightness and safety of the installation. In private homes, the operating pressure ranges from 6 to 8 atmospheres. Even if a water hammer occurs, the steel device will withstand such a load.

Tubular steel heating radiators are often used in medical institutions. This is explained by the fact that the batteries have excellent hygienic properties and are not hazardous. The device is characterized by the absence of corners and smooth bends. Dust does not accumulate on such radiators. And their wear resistance is much higher than that of their cast iron counterparts.

Characteristics of Tubular Steel Batteries

Tubular heating radiators are most often made of steel. Steel tubular heating radiators are very popular, because steel is a strong and reliable metal.

The main technical parameters of steel tubular radiators include:

- Height. Located within 30-300 cm.

- The number of tubes is not limited. There are options with one tube. And there are also with a much larger number.

- Depth is about 22.5 cm. There can be from 1 to 6 elements in a row in depth. For tubular steel radiators, the price depends on the working volume and parameters of the tubes.

- Sectional distance. Available in two versions: 6.5 and 4.5 cm. Batteries with a step between sections of 6.5 cm are more often used in hospitals, schools and other institutions where the requirements for the absence of dirt and dust are very high.

- The wall thickness varies from 0.1 to 0.2 cm. For imported models, the standard thickness is 0.1-0.15 cm. For domestic analogues, this parameter is slightly larger - 0.2 cm.

- In the classic version, the section section is round. The diameter is about 2.5 cm. However, pipes with flat, rectangular, oval and triangular cross-sections are also found on sale.

Types of tubular batteries

Depending on the location of the tubes, the equipment can be of two types: horizontal and vertical.

Horizontal ones are more often used in spacious office spaces. But vertical tubular heating radiators are actively installed in private homes, hospitals and schools. Thanks to their design features, vertical models visually raise the ceiling and do not accumulate dust. Depending on the shape, the heating device can be angular, flat, radius or designer. The corner model involves dividing the radiator into two sections, which are located at an angle relative to each other. You can choose any angle. With the flat version, the tubes are arranged in one row. This is the most popular form among buyers. The radius device has the shape of an arc. Quite an interesting solution. The designer type heating device is particularly original. Vertical pipes can be bent to create a wave-shaped structure.

Aluminum heating radiators

As the name suggests, these are radiators made entirely of aluminum. There are two types of radiators - injection molded and extruded. Both of them are best used for autonomous heating - they are not suitable for a centralized system due to pressure and corrosion, which is caused by poor-quality coolant in the central heating network.

Molding radiators

Radiators made by injection molding are distinguished by wide channels for hot water and durable thick walls.

The radiator is made up of several sections, which, if necessary, can either be added or removed.

Extrusion radiators

With this production method (which is cheaper), the vertical parts of the battery are extruded from an aluminum alloy using an extruder. The collector is cast from silumin. The whole product cannot be changed - you can neither add sections nor remove them. This is the main disadvantage of this type of radiator.

Manufacturers: These are mainly companies from Italy. In particular, we can name FARAL Green HP, ALUWORK, Sira Group (ROVALL batteries), Fondital.

+ Pros:

- These radiators are very light, so they are easy to install, without requiring the use of durable brackets.

- In terms of heat transfer, they occupy one of the first places among all heating devices.

- They can heat up a room very quickly.

- They are economical and can be equipped with a temperature controller.

- The product design is modern and attractive.

- Minuses:

- The service life is not very long - about 15 years.

- Aluminum is chemically active, therefore it suffers from corrosion and requires a high-quality coolant.

- When air is displaced, hydrogen is formed.

- Weak convection.

- Leaks between sections are possible.

- Aluminum radiators are not able to withstand water hammer and pressure surges.

Main characteristics:

- Pressure (working) – on average 6-16 bar.

- Thermal power (1 section) – 82-212 watts.

- Hot water temperature (maximum) – 110 degrees.

- Water pH is 7-8.

Decorative benefits

Tubular radiators are characterized by special elegance and lightness. If desired, you can find models of non-standard configuration (semicircular sections, bench radiators, etc.), the cost of which is an order of magnitude higher. It is especially worth noting the wide range of colors of tubular steel appliances.

The most popular are light and dark solutions. Dark radiators have better heat transfer. Bronze, metallic, lacquered wood, mother-of-pearl, and aged bronze are considered more interesting color options. Good efficiency is observed in chrome-plated products.

In such popular interior styles as vintage and loft, you can also find more original designs of heating devices. In some cases, special anti-corrosion substances are applied to the metal surface.

Transparent varnish is used as a finishing touch. An example of design is the use of grilles, which makes the radiator more aesthetically pleasing. In addition, this creates additional protection against mechanical influences. You can choose a mesh of almost any shade: the price remains stable.

Calculation of power parameters

To carry out calculations, the temperature indicator for heating the coolant is useful. It is determined by the area of the room and the heating mode of the rooms.

For simplicity, the formula Q = St x K xt is used, where:

- Q is the design power of the heat pipe;

- St (m2) – heat exchange area;

- K – heat transfer coefficient of a steel pipe, the default indicator is 11.63 W/m2 x C;

- t – thermal pressure.

And now the calculations themselves - first determine the length of the pipe along the outer edge, multiply the indicator by the length of the section, then find half the sum of the temperatures in the supply and discharge pipelines - this is the thermal pressure parameter. Subtract the room heating temperature from the final result.

Important! Considering that the pipes are connected in parallel, water is transported sequentially through all registers, the heat transfer in each subsequent section of the pipeline will decrease by 10%, therefore it will be necessary to make adjustments and reduce the power of each subsequent section by 10%.

Tubular radiator design

Unlike the old cast iron versions of tubular batteries, modern designs are much nicer and better made. They represent two functional compartments: upper and lower.

These compartments are connected to each other by special steel pipes. Tubular steel radiators of modern models look very miniature and cute.

Despite their strength, steel tubular radiators are not able to withstand large pressure drops. For this reason, their installation is recommended only in private houses or five-story apartments.

In large high-rise buildings there are often unexpected power surges that exceed 10 atmospheres.

Tubular steel radiators are very popular in medical institutions. This is easily explained, because tubular batteries do not contain any corners that can cause injury.

In addition, tubular radiators do not attract dust and do not require special cleaning. For hospital and outpatient facilities, these qualities are most important.

Stainless steel pipes

Stainless steel pipes are a very good replacement for expensive copper pipes, having most of the same positive qualities at a relatively low price.

The advantages of this material are as follows:

- High resistance to pressure (maximum performance is demonstrated by seamless products with thick walls);

- Long service life;

- High thermal conductivity;

- Ability to work at high temperatures (stainless steel pipes can transport even heated steam);

- Excellent strength properties;

- Low cost (relative to copper products).

Stainless steel pipes are available in two forms - seamless products and products with a welded seam. The latter are made by welding and are sheet steel rolled into a pipe. The price of such products is lower, but you have to pay for it with a shorter service life.

Understanding which steel pipes are better for heating, you can come to a clear conclusion - these are seamless pipes that demonstrate the best qualities. Products with thin walls are almost equal in performance parameters to copper ones - and the difference in price is more than noticeable.

Heating market overview

The range of tubular steel batteries is very wide. You can buy either a radiator with a conventional design or a model that is a real work of art. The choice of companies and models is large and varied. It is best to buy Russian-made tubular heating radiators: domestic models are manufactured taking into account the climate, the quality of local water, frequent pressure changes and other important factors.

Among imported models, it is better to give preference to German, Czech, Turkish, Polish and Italian manufacturers.

Czech radiators

When considering Czech heating radiators, one should note the good quality of the products and relatively low cost. A feature of Czech-made batteries is a patented system for installing integrated thermostatic valves. Thanks to the valve, the temperature is adjusted according to preset parameters. Among Czech-made tubular radiators, Isan Atol products are in demand.

Turkish radiators

Turkish batteries are also of good quality. But it should be noted that Turkey produces mostly steel heating radiators of the panel type. The prices are quite affordable. Many models are manufactured under license from well-known European manufacturers. Therefore, the products generally comply with European quality standards.

Polish radiators

Inexpensive batteries are also available from Polish manufacturers. It should be noted that Poland has been producing bimetallic heating radiators for a long time. Thanks to many years of experience and improved production technology, prices for heating equipment are low. At the same time, the technical characteristics and quality are quite good. Among the Polish companies that specialize in the production of bimetallic radiators is Termica.

German radiators

Zehnder tubular heating radiators from a German manufacturer are of high quality. Depending on the type of connection, such batteries can be of different types: connected to hot water supply pipes, for open water heating systems and electric.

The German company specializes in the production of non-standard heating devices.

There are extremely high and super low models. The color range is varied - more than 700 shades. True, the cost of Zehnder heating radiators is very high.

The Swiss-German company Arbonia also produces durable, reliable products. Despite the remarkable design, high technical characteristics and excellent quality, the price of Arbonia heating radiators is quite acceptable for Russian buyers.

Finnish radiators

Purmo radiators made in Finland are also distinguished by their attractive design and good quality. Prices for Purmo heating radiators depend on the specific model and size. But, as a rule, the cost is quite affordable. The products are available in a large number of standard sizes and installation methods. You can choose the appropriate option for any room. It is possible to order a non-standard battery option. True, the price for such Purmo heating radiators will be slightly higher than for the standard model.

Chinese radiators

A more budget-friendly option is Oasis batteries made in China. Despite its availability, the product is very durable, resistant to aggressive substances and has no restrictions on use. Some models are manufactured taking into account the characteristics of Russian heating networks. Reviews for Oasis heating radiators are usually good. The company also produces bimetallic heating radiators, which we wrote about. Many note the excellent heating and affordable price.

https://youtube.com/watch?v=r0jbGAs22l8

Which material is more suitable for underfloor heating pipes?

Metal-plastic pipes

Metal-plastic pipes are the first and most popular, until recently, polymer pipes for heated floors. If you look in section, such a pipe consists of two polymer layers, between which there is a layer of aluminum foil 0.2 millimeters thick or more. The most famous pipe for underfloor heating is the Henco pipe. It hasn't been very popular lately, because... the cost of the pipe is quite high. Through the use of cross-linked PEX polyethylene and high-quality adhesive for gluing the layers. Unlike Henco, other European manufacturers have switched to the production of metal-plastic pipes made of heat-resistant polyethylene PE-RT. The elongation of this material when heated is several times less than that of PEX cross-linked polyethylene ; therefore, the reliability of such a pipe during sudden temperature fluctuations is higher. So, many Chinese manufacturers use cross-linked polyethylene, and taking into account the savings on other materials, the overall quality of the pipe turns out to be quite low, which is why there are a lot of bad reviews on the forums about delaminating pipes and a cracking outer layer (they are afraid of ultraviolet radiation).

The presence of aluminum foil in the composition of a metal-plastic pipe allows you to completely avoid the ingress of oxygen into the coolant and reduce the linear elongation by up to 5 times.

If you decide to use a metal-plastic pipe, it is better to focus on European manufacturers

- Uponor (PE-RT/AL/PE-RT) Germany

- SANHA (PE-RT/Al/PE-HD) Germany (Application up to operating class 5)

- HENCO (PEXc/AL0.4vmm/PEXc) Belgium

- APE, STOUT (PEXb/Al/PEXb) Italy

- COMPIPE (PEXb/Al/PEXb) Russia (Application up to operating class 5)

- Valtec, Altstream, etc. Russia-China

XLPE pipes

Cross-linked polyethylene is the most popular material for underfloor heating pipes at present. We will not dwell on the description of this material, because... There’s enough information to fill an entire article, but we’ll tell you which pipe options are best to choose.

The highest percentage of crosslinking (from 75%) in the peroxide crosslinking method is PEXa pipes. The most expensive method used by European manufacturers. The silane crosslinking method of PEXb is the most common, the level of crosslinking is quite high, but for example in the USA such pipes are prohibited for use due to the presence of harmful chemical compounds. It is also believed that a PEXb pipe gains its strength properties only during operation of the pipe with coolant.

By exposing the material to charged particles, 60% cross-linked PEXc polyethylene is obtained. The product is irradiated in the solid state. The main disadvantages of the method are the heterogeneity of the material as a result, but there are also advantages - cross-linked polyethylene gains increased elasticity.

As the degree of crosslinking increases, strength, heat resistance, and resistance to aggressive environments and ultraviolet rays increase. However, along with an increase in the degree of cross-linking, the fragility of the resulting pipeline increases and the flexibility decreases. If you increase the degree of crosslinking of polyethylene to 100%, then its properties will be similar to glass.

The biggest problem in choosing a specific manufacturer and pipe is the low quality of stitching in Chinese-made pipes, as well as in some Russian representatives. Another disadvantage of such pipes is the rigidity of the pipe; it does not hold its shape well and after bending it tries to take its previous shape and therefore it is more difficult to work with it than with a metal-plastic pipe, especially for an inexperienced installer.

The disadvantage of PEX material is that it is oxygen permeable. Water in pipelines without oxygen protection becomes saturated with oxygen after a certain time, which can lead to corrosion of system elements. To reduce the oxygen permeability of PEX, a thin layer of polyvinylethylene (EVOH) is used. The PEX base layer and the EVOH layer are joined together with glue. It is worth noting that the EVOH layer does not completely prevent oxygen emission, but only reduces oxygen permeability to 0.05–0.1 g/m3 day, which is acceptable for heating systems. In a PEX-EVOH pipe, the anti-diffusion layer is made on the outside, i.e. The pipe has a three-layer construction: PEX-adhesive-EVOH. Five-layer (PEX-adhesive-EVOH-adhesive-PEX) pipes are also available on the market, but tests have shown that the three-layer design is more reliable. The belief that the outer layer of EVOH in a three-layer construction is susceptible to abrasion is erroneous.

Another disadvantage of PEX pipes is their large linear elongation, so such pipes are practically not used for external installation, but only for hidden ones.

One of the advantages of pipelines made of cross-linked polyethylene is the presence of a memory effect. The shape memory effect is very useful during installation. If a kink, compression or other deformation occurs during pipeline installation, it can be easily eliminated by heating the pipeline to a temperature of 100–120 °C. (However, in the passport for the Russian-Chinese Valtec pipe it is written: “If there is a “break”, the damaged section of the pipe must be removed.”)

Wrinkles form on pipelines coated with an anti-diffusion layer after restoration. In these areas, the anti-diffusion layer peels away from the PEX layer. This defect has virtually no effect on the characteristics of the pipeline, since the main load-bearing capacity of the pipeline is determined by the PEX layer, which has been completely restored. A slight peeling of the anti-diffusion layer does not significantly increase the oxygen permeability of the pipeline.

Pipelines made of cross-linked polyethylene, and especially PEXa produced in Europe, are better suited than other polymer pipes for use not only in underfloor heating, but also in radiator heating, using the hidden method.

What pipes can be found on sale:

- UPONOR COMFORT PIPE PE-Xa EVOH Germany (use up to operating class 4)

- UPONOR COMFORT PIPE PLUS PE-Xa EVOH Germany (use up to class 5, underfloor heating and radiators)

- STOUT PEX-A Spain (use up to operating class 5) BEST CHOICE for PRICE-QUALITY

- SANEXT “Warm floor” PE-Xa Russia-Europe (use up to 4th class of operation)

- Valtec PE-Xb EVOH Russia-China (use up to operating class 4)

Heat-resistant polyethylene PE-RT

Very often, heat-resistant polyethylene PE-RT is called cross-linked polyethylene. But the production technology of such polyethylene is as follows. In the chemical reaction, “flat” butene is replaced by octylene (formula C8P16), which has a spatially branched structure. Subsequently, it forms side branches near the main chain, which are mutually intertwined monomer chains. They are connected to each other due to the mechanical interlacing of branches, and not due to interatomic bonds.

PE-RT pipes are mainly used for underfloor heating, where the temperature and pressure are lower than in water supply and heating systems. Although the manufacturers of PE-RT pipes, when pursuing their marketing policy, claim that the properties of their pipes are the same as those made from PEX cross-linked polyethylene. However, this is questionable because PE-RT is a conventional thermoplastic with limited overall resistance to elevated temperatures and pressures in hot water systems, as evidenced by hydraulic testing and subsequent practice.

A comparison of regression curves obtained by the independent Bodycoat Polymer Institute (Belgium) suggests that the durability of PE-X pipes is higher, and the regression curve, showing the loss of ability to perform work functions over time, for heat-resistant polyethylene PE-RT has a characteristic break (loss of strength during long-term operation) already at 70 °C.

- BioPipe (PERT) Russia

- RosTurPlast 16×2.0 PE-RT (type 2) (Russia) The most affordable option with high quality

Stainless steel and copper pipes

These types of pipes are practically not used in the installation of heated floors, and the main reason is the high price. Due to the fact that polyethylene pipelines from the best German manufacturers are 2 times cheaper than metal pipes, and their service life is more than 50 years (in a heated floor), there is no need for such pipes. Installation of a copper pipe floor is more expensive and the installer of such floors must have extensive experience and qualifications.

Installation

The installation of steel tubular batteries is in many ways similar to the installation of traditional models and is not very difficult if you have theoretical knowledge and practical skills.

List of tools required for work:

- screwdriver;

- impact drill or hammer drill;

- adjustable wrench;

- pliers;

- roulette;

- building level;

- pencil.

Installation steps:

- Removing the old battery.

- Marking and installation of mounting brackets. Steel tubular radiators are heavy, so it is necessary to use brackets with appropriate load capacity.

- Tubular radiator canopy and installation kit assembly.

- Installation of a shut-off valve, a valve for a thermal head and a Mayevsky valve.

- Connection to heating system pipes.

- Crimping.

Connection method

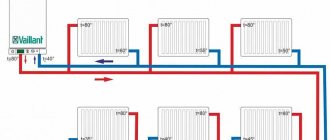

Most models are connected to the heating system using the bottom or side method. The choice of connection method is influenced by the characteristics and features of a particular model, as well as the features of the distribution of heating pipes in the premises.

The bottom connection method is that both the supply and return pipes are connected to the radiator from below. With a side connection, the supply and return pipes are connected to the left or right side of the battery, depending on the model.

Conditions for correct installation

Regardless of the characteristics of the radiator, for its effective operation during installation it is important to ensure the following conditions:

- Distance between the top edge and the window sill (for horizontal models): 5-10 cm.

- Distance between the bottom edge and the floor: 9-12 cm.

- Distance between the wall and the radiator: 2-5 cm. In the case of installing a reflective heat-insulating layer, mounting brackets of increased length will be required.

Number of sections of bimetallic radiators

How many sections there will be on a bimetallic radiator has a direct impact on the choice of connection method. A battery of up to 8 sections can be connected with a side, bottom saddle or diagonal connection. If there are more than 8 sections, it is better to use a diagonal connection.

When using side switching, a flow extender will be required. This refers to a tube inserted into the supply manifold. It helps out in situations where the side connection provides heating only for the first sections. Thanks to the tube inserted inside, the coolant flows further than the inlet, heating the surface of the device more evenly.

Flow extension length options:

- 2/3 batteries.

- To the center of the last section.

Different cases show the effectiveness of both the first and second options. The main thing is that a noticeable optimization of radiator heating is achieved. Sometimes it happens that installation to the middle of the last section provokes a decrease in the heating level of the first sections. In this case, it is recommended to shorten the tube. But such situations rarely occur, which is influenced by the pressure in the riser and the cross-section of the liner.

As practical experience suggests, it is better to install a long tube, because You can always shorten it (but you won’t be able to lengthen it). Another way to distribute the coolant more evenly is to equip the flow extension tube with a series of holes. Thanks to this, the coolant flows into nearby vertical collectors. However, in general a single tube is sufficient.