All about steel radiators Lideya, Buderus, Arbonia, AXIS, Korado, Vogel&Noot, Oasis, Terra teknik, Konrad and Rosterm, as well as Ukrainian, Russian and Turkish manufacturers of panel heating radiators.

Taking into account the fact that every year an increasing number of old cast iron radiators installed in Soviet times are breaking down, the heating equipment market is unlikely to be oversaturated soon.

Today it presents products from both domestic manufacturers and from Europe, Belarus, Ukraine and Turkey.

Conrad

The Russian manufacturer produces all types of panel radiators with side and bottom connections.

Each device includes additional parts: brackets, Mayevsky tap, plugs, pipes.

Conrad produces batteries that are suitable for use in closed heating systems.

Dimensions of panel radiators

The depth of these radiators depends on the type:

- single-panel type 10 and 11, depth 60 - 65 mm;

- two-panel depending on type: type 21 - 63 - 67 mm;

- type 22 - 100 - 106 mm;

It has a wide range in height - from 300 mm to 900 mm. The change step is usually 100 mm, but some companies produce special models. For example, Kermi has vertical panel radiators Verteo Plan and Verteo Profil. They are tall and narrow. Height 1600 - 2400 mm, width 400 - 700 mm. The Plan model has a smooth front panel, the Profil has a regular ribbed one. But according to their characteristics, they are only suitable for individual heating (working pressure 6 Bar). Read about other types of tall radiators here.

Vertical models of panel radiators have low operating pressure - they can only work in individual heating

Width has even more options. In the standard version, you can be offered a radiator with a length from 400 mm to 3000 mm. Perhaps only tubular radiators have such a range. No one else has. There are about a thousand modifications in total, taking into account types and sizes. So there is plenty to choose from.

Kermi

A manufacturer from Germany, existing and actively conducting its production activities for more than 50 years. In their structure, Kermi panel radiators are very similar to conventional ones.

Kermi steel radiator

The panels are constructed of two plates with a recess between them. This is where the coolant circulation process takes place. All produced radiators are characterized by the highest quality, meeting European standards.

The latest equipment is used in the production process. The batteries have good heat dissipation, being 20-30% ahead of their competitors in this indicator.

The company has developed its own Therm X2 technology.

The batteries produced are more suitable for closed heating systems.

The manufacturer Kermi offers a wide range of radiators with both side and bottom connections. And the variety of designs allows everyone to choose the most suitable option for their home.

Thermal power

The power of a panel radiator depends on the type and size. Due to the large number of options, manufacturers create tables in which they enter data determined experimentally. Often such tables have several columns for different temperature conditions. The fact is that according to the standard, the thermal power of a heating device is determined for high-temperature conditions: supply 95oC, return 75oC and maintaining a temperature of 20oC. But today such a regime, especially in individual heating, is rare. Lower temperatures are used more often - this is more economical, especially with automated boilers. It is for modes with medium and low coolant temperatures in the network that the power is indicated. To make selecting equipment easier.

The power of a panel radiator depends on its type and dimensions

How to choose the power of a panel radiator? The required heating power is influenced by many factors: from the material and thickness of the walls and climate zone, to the number, size and type of glazing of windows. In order not to make a mistake and to be 100% sure, you need to order a thermal engineering calculation. Then you will be given the required radiator power in each room.

If it is not possible to make a professional calculation, you can read about how to do it yourself here. Well, the most approximate calculation can be made based on average standards. It is believed that in central Russia, heating one meter of area requires 100 W of heat. To help you understand how approximate these calculations are, let’s say that in reality both 40 W and 190 W may be required.

So, knowing the area, you find the required amount of heat: multiply the area by the norm of 100 W. Then figure out how tall the radiator you need. And look at the tables for suitable options. In the row or column with the desired height, look for the appropriate power. You shouldn't expect a 100% match; take the closest value. Usually there are several options: there will definitely be two or three. These will be batteries of different depths and lengths. Based on these parameters, you choose which one attracts you more.

Read more about calculating power and choosing the type of radiator here.

Korado

A Czech company that has achieved good results in the production of steel radiators. Users leave a lot of positive reviews about Korado products and note their high quality and durability.

The batteries can be installed in both single-pipe and two-pipe heating circuits with closed and open coolant circulation.

Radiator Korado Radik Klasik

All produced radiators are presented in 4 series: Radik Hygiene, Radik Klasik, Radik Plan, Radik Ventel Kompakt.

Features of operation of steel panel radiators

Steel is quite susceptible to corrosion, which is why all manufacturers prohibit draining water from the system at the end of the heating season. If this can be done, then only for a short time to repair or reconstruct the network. Moreover, short-term drains and fillings have a very bad effect: these are almost ideal conditions for corrosion. Therefore, if you are planning repairs or reconstruction, do everything at once.

At the same time, it is prohibited to disconnect metal batteries using taps. The fact is that when steel comes into contact with water, chemical reactions occur with the release of gases. Therefore, a Mayevsky faucet must be installed on each radiator.

The Mayevsky valve is a manual air vent valve. And you have to bleed the air manually. If this is not done on time, the radiators will stop heating. And in the summer, when the ball valves on the radiator are closed, such a quantity of gases can accumulate in it that it simply ruptures. In order not to monitor the amount of air in the system, you can install an automatic air vent. Then, by the way, you can close the taps for the summer - if the air valve is open, it will release the resulting gases. Read about the types of air vents and their installation here.

Any steel radiator must be equipped with air vents

How often should I bleed manually? If the system is designed normally and operates normally, then several times after the start of the heating season. If airing occurs regularly (the tops of the radiators become cold, and after deflating everything returns to normal), then consultation with a specialist is necessary - somewhere there is a “leakage” of air, and this is very bad for metal batteries: they quickly rust.

Purmo

A well-known Finnish company that uses cold-rolled 1.25 mm steel for the manufacture of almost all panel radiators.

The batteries are painted using cataphoresis, so they are resistant to corrosive processes.

You can find out what paint to use to paint batteries in this article

The model range is presented in the following line:

- Purmo Compact C - side connection;

- Purmo Ventil Compact VKO - models with both bottom and side connections and are equipped with a thermostat;

- Purmo Hygiene P - side connection, no convection elements;

- Purmo Ventil Hygiene PV - without convection elements, but the kit includes a thermostat, two connection options: bottom and side;

- Purmo Planora Plan DF has side and bottom connections and is characterized by a smooth radiator screen.

Steel radiators PURMO Compact

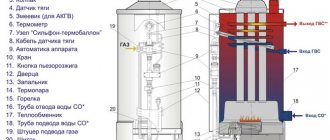

Construction and types

Structurally, this heating device consists of one, two or three heating panels connected to two horizontal collectors: one that supplies coolant at the top and collects cooled water at the bottom.

Convection plates can be welded between the panels. They are thin steel sheets corrugated in the shape of the letter “P” (0.4-0.6 mm thick), which are attached to the heating panels by spot welding. The presence of convective plates significantly increases heat transfer - by about 40-50%.

To increase heat transfer, “U”-shaped convective fins are attached to the heating panel

The reliability of a panel radiator is determined mainly by the quality of manufacturing of the heating plates. They are welded from two steel sheets, in which two horizontal (upper and lower) and many vertical channels through which the coolant moves are formed using a press.

When assembling the heating panel, the two sheets are first connected along vertical channels. Spot welding is used, the seams are on the back side. Then a robot welder passes along the perimeter, using a continuous seam to hermetically connect them into a single structure.

Modern production is mostly robotic

Then a leak test is carried out. The panel is lowered into a vessel with water, air is pumped inside under excess pressure (this is the factory test pressure). Sealed elements are used for the assembly of radiators; non-sealed elements are rejected.

Depending on the number of heating and convection panels, flat radiators have different thermal power and depth. The designation shows the composition of the radiator:

- 10 - one heating panel without convective elements;

- 11 — heating element + fins to increase heat transfer;

- 21 (or 12) - two panels along which the coolant runs + a convective element between them;

- 22 - two heating planes + two fin plates;

- 33 - three plates with coolant + three convective elements.

This is how the different types look schematically

Most often, radiators are hung on the wall, but there are special mounts for installation on the floor. For installation on the wall, brackets are welded on the rear panel, with which the battery is hung on fixed brackets.

Prado

A Russian manufacturer that produces batteries with side and bottom connections.

The products are characterized not only by high quality, but also by a reasonable price.

Radiators are characterized by high heat transfer rates, they are quite durable and, with proper care, can last for many years.

Prado products are presented in two lines: Classic and Universal.

Radiator Prado Classic

The entire model range of the Universal series is equipped with thermostats and devices can be connected both from the side and from below.

Radiators of the Classic series are not equipped with a thermostat and have only a side connection method.

Conclusion

Everything that we have described to you is theoretical knowledge that will help you understand and choose the most suitable model for your living space. At the same time, we advise you, after reading this article, to study the models with your own eyes, to consult with sellers, because a lot depends on certain features of the room in which the radiators will be installed.

Cast iron radiators are quite heavy, so it is better to purchase floor-standing units with legs instead of wall-mounted ones

In the video presented in this article you will find additional information on this topic.

Did you like the article? Subscribe to our Yandex.Zen channel

Comparison

Let us consider in the table the main technical characteristics of some of the described manufacturers of heating radiators.

| Manufacturer | Working pressure, atm. | Max. t coolant, °C | Power, W | Water volume, l | Weight, kg | Connection method |

| Kermi (Germany) | 10 | 110 | 965 | 2,7 | 17,07 | Side - thread 4 x 1/2" (internal) Bottom - thread 2 x 3/4" (external) |

| Lideya (Belarus) | 8,6 | 110 | 1080 | 3,3 | 15,1 | Side - 4 connecting pipes with internal thread ½ Bottom - 2 connecting pipes with internal thread 1/2″ |

| Korado Radik (Czech Republic) | 10 | 110 | 914 | 2 | 15,6 | Side - thread 4 x 1/2" (internal) Bottom - thread 2 x 3/4" (external) |

| Purmo (Finland) | 8,7 | 110 | 929 | 2,6 | 13,6 | Side – internal thread 1/2″ Bottom – internal thread 2 x 1/2″ |

Not as many companies are engaged in the production of tubular radiators as panel ones. They are expensive and mostly such products can be found from German manufacturers Zehnder Charleston, Arbonia, Kermi, Charleston.

An article about radiator manufacturers from Turkey, Finland and the Czech Republic is here

AXIS from Serbia

Although the domestic market is represented by a huge selection of steel radiators from foreign and local manufacturers, consumers are primarily interested in the price of the product, and then its quality. When there is a manufacturer who has managed to harmoniously combine both in his products, he is immediately noticed. Axis steel panel radiators have only recently entered the market, but they have already managed to impress customers.

Their distinctive features are:

- large “range” in standard sizes;

- high level of heat transfer with low inertia;

- equipped with thermostats;

- working pressure 10 and 13 atmospheres;

- heating the media up to 120 degrees;

- operation in low temperature mode;

- warranty period is 10 years.

This is quite a lot for a young brand from Serbia.

Drawing a conclusion, we can say that the domestic market of thermal technologies today offers such a range of products that the average consumer is unable to understand it. As a rule, you need to determine your choice based on the technical characteristics of steel radiators, and then use them to select manufacturers whose quality meets the required standards.