A bimetallic radiator is a heating device in which coolant circulates through a steel core placed inside an aluminum casing. Batteries of this type belong to sectional heating devices and operate on the principle of combined (convective and radiant) heat exchange.

The technical characteristics of bimetallic heating radiators include a number of parameters and design features that allow you to evaluate the heating device and compare it with other models of a similar size.

How to correctly compare bimetallic radiators with each other?

Anyone who carefully approaches the choice of heating batteries for their home or apartment strives to purchase products with optimal performance and technical characteristics. To correctly select the most suitable radiator, the models being compared must be of the same size. In the reference data, the parameters are given for one section, so you need to compare not the devices as a whole, but their structural parts. The main parameter by which the division into standard sizes occurs is the interaxle distance.

Radiators with different center distances.

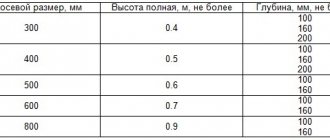

The center distance is the size between the axis of the upper and lower collector. Like all-aluminum models, bimetallic heating radiators are mainly produced with a center distance from 200 to 800 mm. Models with a large center distance, and as a consequence, with an increased section height (but a smaller width of the entire radiator), are rare. They are used if the interior features of the room do not allow placing a horizontally located device.

The device of a bimetallic radiator.

Geometric parameters

The main geometric characteristics of a bimetallic radiator are its height, as well as the width and depth of the section. The height, as a rule, is 60 - 80 mm higher than its center distance.

Most manufacturers produce models with a section width of 80 mm. Knowing the number of sections, you can easily determine the total width of the device.

The depth of the section is 80 – 100 mm. The radiator can be either constant depth or varying in height, like the stylish and elegant DreamLiner series device from Royal Thermo.

Installation of a heating radiator on a wooden wall.

Thermal power

This parameter allows you to determine how many radiator sections of a particular model are needed to heat a room of a certain area. Thermal power is measured in Watts and is at an interaxial distance:

- 500 mm – from 170 to 200 W;

- 350 mm – from 120 to 140 W;

- 300 mm – from 100 to 145 W;

- 200 mm – about 100 W.

In their information and technical materials (instructions, manuals, catalogs), manufacturers indicate tables showing the number of sections optimal for heating rooms of various sizes.

The steel core is the basis of the structure.

Volume (capacity) of one section

In bimetallic radiators, coolant circulates through steel cores. The core is an H-shaped welded structure consisting of an upper and lower collector connected to each other by a vertical tube (heat pipe). Each manifold has two side holes with internal threads, thanks to which the sections can be connected using steel nipples. This design completely eliminates contact of the coolant with aluminum.

Unlike aluminum radiators, where the heat pipe has an oval cross-section, the steel cores of bimetallic models use exclusively round tubes, which provides for a smaller capacity of each section. Thus, the bimetallic Rifar Base 500 has a section capacity of 0.20 liters, while the aluminum Rifar Alum 500 model of the same size has a volume of 0.27 liters.

Section of the device in section.

Section weight

Bimetallic radiators have more mass than similar models of aluminum radiators. This is explained by the use of steel cores in their design, the density of which (and therefore the mass) exceeds that of aluminum. For example, the bimetallic radiator Varmega Bimega 500/80 weighs 1.75 kg, and the aluminum radiator Almega 500/80 from the same manufacturer weighs 1.2 kg.

Pressure

The operating pressure of bimetallic radiators is 16 – 40 atm (1.6 – 4.0 MPa). According to regulatory documents, devices must be tested by pressure testing the heating system with a pressure 1.5 times higher than the operating value. The documentation also indicates the value of the maximum pressure, upon reaching which it can begin to collapse.

Connection of sections.

Which is better: monolith or section

When choosing bimetallic equipment for your heating, you need to think about the design of the radiator itself. It has several varieties:

- sectional;

- monolithic.

Comparative characteristics of such devices can be seen in the table below:

| Sectional | Monolithic |

| Service life 20-25 years | 50 years |

| Working pressure 20-35 bar | 100 bar |

| Thermal power of one section is 100-200 watts | 100-200 watt |

Manufacturers accompany their products with a variety of technical materials. These include operating instructions, user manuals and product catalogs. In the tables presented, you can understand how many sections are needed to heat a room of a certain area.

Sectional systems are significantly inferior in their performance characteristics to monolithic bimetallic radiators. Leaks can form at joints.

The main disadvantage of monolithic structures is their cost. It is much higher than the price of sectional devices.

Monolithic bimetallic radiators must be installed in multi-storey buildings. The fact is that the coolant is always supplied under very high pressure. Only monolithic structures can easily withstand it.

Comparative technical characteristics of bimetallic radiators

For convenient comparison of different models, tables 1-3 contain data on the main characteristics of products from 11 manufacturers. The information is provided both for the most common standard size of 500 mm, and for radiators with center distances of 350, 300 and 200 mm, which are present in the model range of only some manufacturers.

Table 1 - Comparison of characteristics of models with an interaxial distance of 500 mm.

| Manufacturer and model | Overall dimensions, mm | Section volume, l | Section weight, kg | Pressure, atm | Thermal power, W | |||

| height | width | depth | working | test | ||||

| Bilux plus R500 | 563 | 80 | 85 | 0,21 | 1,82 | 20 | 30 | 182 |

| Industry Pasotti Elegance Wave Bimetallico | 565 | 80 | 100 | 0,19 | 2,06 | 35 | 52 | 176 |

| Global Style Extra 500 | 566 | 81 | 80 | 0,21 | 1,87 | 35 | 52,5 | 170,7 |

| Conner Bimetal 80/500 | 563 | 80 | 80 | 0,40 | 2,18 | 30 | 45 | 190 |

| Rifar Base 500 | 570 | 79 | 100 | 0,20 | 1,92 | 20 | 30 | 204 |

| Royal Thermo BiLiner 500 | 574 | 80 | 87 | 0,205 | 2,01 | 30 | 45 | 171 |

| Tenrad BM500 | 550 | 80 | 75 | 0,22 | 1,45 | 24 | 36 | 161 |

| Varmega Bimega 500/80 | 565 | 80 | 80 | 0,3 | 1,75 | 30 | 45 | 190 |

| Santekhprom RBS-500 | 560 | 80 | 95 | 0,23 | 2,34 | 16 | 24 | 185 |

| Sira Industry RS Bimetal 500 | 572 | 80 | 95 | 0,199 | 2,03 | 40 | 60 | 201 |

| Scola JB-SA 500 | 565 | 78 | 80 | 0,28 | 1,85 | 30 | 40 | 188 |

Variety of standard sizes.

Table 2 - Comparison of characteristics of models with an interaxle distance of 350 mm.

| Manufacturer and model | Overall dimensions, mm | Section volume, l | Section weight, kg | Pressure, atm | Thermal power, W | |||

| height | width | depth | working | test | ||||

| Global Style Extra 350 | 416 | 81 | 80 | 0,17 | 1,42 | 35 | 52.5 | 119.6 |

| Conner Bimetal 80/350 | 413 | 80 | 80 | 0,30 | 1,28 | 30 | 45 | 140 |

| Rifar Base 350 | 415 | 80 | 90 | 0,18 | 1,36 | 20 | 30 | 136 |

| Royal Thermo BiLiner 350 | 424 | 80 | 87 | 0,175 | 1,52 | 30 | 45 | 118 |

| Tenrad BM350 | 400 | 80 | 75 | 0,15 | 1,18 | 24 | 36 | 120 |

| Varmega Bimega 350/80 | 412 | 80 | 80 | 0,22 | 1,43 | 30 | 45 | 140 |

Curved radiator for bay windows.

Table 3 - Technical characteristics of bimetallic radiators with center distances of 300 and 200 mm.

| Manufacturer and model | Overall dimensions, mm | Section volume, l | Section weight, kg | Pressure, atm | Thermal power, W | |||

| height | width | depth | working | test | ||||

| Center distance 300 mm | ||||||||

| Bilux plus R300 | 365 | 80 | 85 | 0,17 | 1,29 | 20 | 30 | 142 |

| Santekhprom RBS-300 | 360 | 80 | 95 | 0,178 | 1,67 | 16 | 24 | 121 |

| Sira Industry RS Bimetal 300 | 372 | 80 | 95 | 0,165 | — | 40 | 60 | 145 |

| Scola JB-SA 300 | 365 | 78 | 80 | — | 1,45 | 30 | 40 | 106 |

| Center distance 200 mm | ||||||||

| Bilux plus R200 | 550 | 80 | 75 | 0,22 | 1,45 | 24 | 36 | 161 |

| Rifar Base 200 | 565 | 80 | 80 | 0,3 | 1,75 | 30 | 45 | 190 |

Materials used

The core of the bimetallic radiator section is made of steel pipes. For batteries of normal strength (working pressure 16 - 20 atm), the core is made of carbon steel grade St.3 or its foreign analogues (for example, Tenrad radiators). The core (frame) of high-strength models is welded from stainless steel pipes. High-strength devices with a stainless steel core (for example, Biliner from Royal Thermo) can withstand burst pressures of more than 100 atm.

The outer part of bimetallic radiators is made of aluminum by injection molding. The extrusion method used in the production of some aluminum models cannot be used in this case, since a core must be placed inside the workpiece before forming begins. O-rings are made from heat-resistant silicone rubber.

Profiled fins.

And now about the disadvantages of bimetal radiators

The most significant disadvantage of these batteries is their high cost. They are much more expensive than conventional cast iron radiators. However, bimetal products look much neater, fitting well into a modern interior. And in terms of lifespan, they are ahead of other types of batteries.

It is also not good that when exposed to both water and air at the same time, corrosion can begin to “eat” the steel pipes of the core. And this happens when water is drained from the heating system during repairs or an accident. Pipes also rust from antifreeze, which is often present in heating systems of small houses. In this case, bimetallic sectional batteries must be abandoned - it is better to take either solid or all-aluminum ones.

Another acceptable option is radiators with a copper core and an aluminum body. The oxide film on copper pipes is quite strong - it will save them from corrosion. You can use a stainless steel one instead of a copper core - that’s also a good option.

Fins

The fins serve to increase the total heat transfer area of the heating device. Modern models use various design solutions that make fins more efficient.

The efficiency of heat transfer is increased by introducing additional fins into the structure, as well as by profiling convection channels between the ribs. In Tenrad radiators, the channels form a confuser, due to which the air flow speed increases, which increases the intensity of convective heat transfer. The outer edges of the ribs are rounded to increase injury safety.

Six-section radiators.

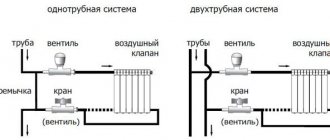

Method of connecting sections

In bimetallic heating radiators, the sections are connected to each other using steel threaded nipples. In the manufacture of Monolit series radiators from the Rifar company, another type of connection is used - welding. This model of heating devices can withstand increased pressure (operating up to 100 atm) and temperature (up to 135°C versus 110°C for nipple models).

Diagram of a monolithic radiator.

Bimetallic radiators are the most technically advanced heating device for water heating systems. Combining high efficiency and good performance indicators, devices of this type are optimal for use in domestic conditions. Knowing the technical characteristics of bimetallic heating radiators of various models, you can choose a heating device that best suits the operating conditions in a particular room.

How to calculate the number of sections

The instructions supplied with the device must indicate its power. Based on this value, the number of sections is calculated.

The main indicators are calculated using the formula A = B x 100/C:

- A is the number of required sections.

- B – area of the heated room.

- B – thermal power.

For example, we need to heat a room whose area is 12 square meters. meters, and the ceiling height reaches 3.5 m. We calculate the power of one section using the formula. Result: A = 12 x 100/200 = 6 sections.

Sometimes when calculating the final number is not an integer. Rounding is done upward. Manufacturers produce bimetallic batteries in a variety of sizes, so it will not be difficult to create a combination of them.