Engineering systems › Heating

Receive a commercial offer for heating system repair by calling +7(495) 745-01-41.

To receive a commercial offer

, write a request to e-mail [email protected] or send a quick request

The heating system is an engineering component of a building designed to ensure comfortable and cozy human life. Like other engineering components, this system has its own operational period, after which high-quality repair work is required. In addition, throughout the entire period of use, the heating system requires careful and timely maintenance. This is necessary to extend its service life.

There are planned and major heating repairs. The type of work is determined depending on the nature and size of the defect that appears. During a major overhaul of a heating system, its main components are re-equipped, the boiler equipment or energy source is partially or completely changed, the foundation is strengthened or the functionality of heating units is improved through process automation. It is also possible to modernize the installed equipment.

Planned repair operations are carried out based on a pre-developed schedule. During such repairs, the heating system as a whole is washed, specific non-working appliances are repaired, leaks are eliminated, loose fasteners are tightened and equipment is painted.

First of all, the normal and efficient operation of the heating system depends on the availability and frequency of scheduled repairs. This allows you to maintain the system in optimal operating condition and prevent a defect at the stage of its development.

Often relatively new heating systems undergo major overhauls. It may be required due to a trivial undetected defect in heating equipment, violation of functional requirements and freezing of thermal energy sources (heating systems of private households often suffer from such defects). Serious breakdowns also occur when the maintenance team is forced to completely replace one or another heating element.

When repairing a heating system, the following work is performed:

- heating devices are removed;

- the wiring and risers of the central heating system are repaired (if present);

- the internal part of the pipelines is being restored;

- small heating components are repaired;

- the functioning of the heating system is restored.

In addition, a major overhaul involves improving the system aimed at better heating of the premises. During modernization, the following activities are carried out:

- pumping equipment is installed, which improves the transportation of the system source of thermal energy;

- modern control devices with temperature sensors are installed;

- additional equipment such as heated towel rails or a “warm floor” system is installed.

Overhaul of the heating system

The main indicators of a heating system are stability and reliability, which directly affect the living conditions of people in the building. Stopping the system or malfunctioning of certain of its components forces professional repairs to be performed to restore operating condition.

specializes in major repairs of heating systems. Our specialists guarantee the quality and efficiency of the work performed. This allows the building owner to be fully prepared for the onset of the heating season. Regardless of the complexity of the problem, we are ready to help everyone who comes to us. The company has official documents giving the right to carry out repair work. Thus, the customer can be confident in the qualifications and experience of our specialists.

Specifics of major repairs

- Major repairs involve the implementation of a whole range of measures. The work can be simple (for example, thermal insulation of pipelines or installation and dismantling of shut-off valves) or complex (for example, laying pipelines or troubleshooting equipment). Our team of technicians works not only to restore the defective heating system, but also to improve it, thereby increasing the efficiency, reliability and economics of heating.

- At the initial stage of a major overhaul, the heating system undergoes a visual inspection. Initially, EuroHolod specialists assess the situation taking into account all the customer’s comments. The client receives information with a proposal to replace specific equipment so that the system begins to function better. A detailed inspection is accompanied by drawing up a overhaul plan, after which the customer is given the opportunity to familiarize himself with the estimate for maintenance.

- When performing repair operations, the specifics of the heating system, as well as the structural characteristics of the serviced object, are taken into account. It is recommended to draw up a preliminary application for performing these operations in order to timely complete all repair stages and prepare the heating system for seasonal operation.

Description of repair measures

During a major overhaul, valves and other shut-off valves are changed, the working condition of pipelines is restored, and their specific elements are changed (if necessary). In addition, air collectors are installed and a sludge separator is installed.

The overhaul carried out by the company’s specialists will reduce heat loss during the operation of the heating system and increase its reliability. The operation of the equipment will be long and uninterrupted.

Hydraulic tests

Pressure testing is carried out within 2 - 3 days at elevated pressure.

Hydraulic tests of the heating system (pressure testing) are planned and control measures designed to check the reliability of heat exchange equipment. This action is carried out in order to detect components, equipment and communication sections that are potentially dangerous in terms of leaks. Hydraulic tests should be performed before the start of the heating season, after completion of planned or major repairs of the system.

During the inspection process, water is pumped into the pipes and air is released. Then, using a pump with a pressure gauge, a pressure of 2-6 atm is created in the circuit, which is higher than the nominal one. Signs of a malfunction are leaks and drops of water at the joints. After eliminating the defects, the test is repeated. A prerequisite is the use of hot water, the temperature of which is equal to or higher than the calculated one. The thermal test shows the true readiness of the circuit for operation.

Autonomous heating repair rules

A breakdown of an autonomous heating system cannot always be identified immediately. Emergency repair of the heating system is required only if there are obvious malfunctions - leaking radiators, pipes or boiler failure. But it is more difficult to determine a malfunction based on indirect signs.

There are several factors that indicate the need for heating repairs in a private home. First of all, a constant decrease in pressure in the system. The reason for this is a small leak. Another sign is the deterioration of the heat supply - a decrease in efficiency, uneven heat distribution. Timely repair of heating systems in a country house will help eliminate these problems.

Before restoring the functionality of the autonomous heat supply, the following actions must be performed:

- Turn off the boiler. For solid fuel models, it is recommended to limit the air flow into the combustion chamber to reduce heat transfer to a minimum level.

- Determine the breakdown area and block the access of the coolant in this area.

- Choose the optimal technology for heating repairs in a private home. It depends on the type of failure - depressurization of pipes or radiators, failure of the boiler, expansion tank, circulation pump.

- Carrying out repair work on the heating system in a private home.

- Checking the functionality of the system, starting the heating.

This is a general scheme that has a number of nuances depending on the type of restoration measures. All influencing factors should be taken into account - the temperature outside, the type of coolant in the system (water or antifreeze), and the heating supply package. In some cases, it is better to make an initial emergency repair of the heating system, and then call specialists to professionally solve the problem.

To promptly repair heating systems in a country house, it is recommended to purchase kits for eliminating leaks in pipes and radiators in advance.

Improving room heating

The speed of movement of the coolant can be increased with a circulation pump.

Quite often, property owners have to deal with insufficient levels of heating of premises in severe frosts.

You can increase the efficiency of your heating system by installing the following products:

- Centrifugal pump. It must be installed at the outlet by inserting into the feed.

- Copper pipes with better heat transfer.

- Electric or water heated floor.

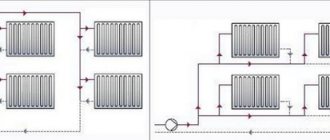

In some cases, you should change the piping scheme, using a two-pipe option.

Heating repair in an apartment

Restoring the functionality of centralized heating differs from the technology described above for autonomous heating. In many cases, you cannot repair the heating in an apartment yourself, as this may affect the heat supply parameters of the entire house.

First of all, it is necessary to notify the utility services with which the heat supply contract has been concluded. It is advisable to record the fact of the accident on a photo or video camera. Then, after consultation with representatives of the management company, try to make temporary repairs to the heating supply in the apartment. It is strictly forbidden to block common risers yourself.

Upon arrival of utility services, a report is drawn up, which indicates the following points:

- Possible causes of the accident;

- Measures taken for emergency restoration of the heating system in the apartment;

- The consequences of an emergency are damage to walls, flow, interior items. An inspection of the apartment below is required.

It is important to remember that independent heating repairs in an apartment can only be carried out with the consent of the Management Company. Exceptions are those situations when a heating supply component is replaced with similar ones without affecting the heating of the entire house.

A copy of the accident report must be kept by the owner of the apartment until the issue of compensation for the consequences of heating failure is resolved.

Gas appliance under pressure: column

With proper care and operation, the column will save gas, electricity, and automatically heat water to a preset temperature. Repairing geysers yourself can break the tightness of the units, which is dangerous due to gas leakage. There are a number of malfunctions that require specialist intervention:

- The smell of gas appears in the apartment. Do not attempt to detect and repair leaks yourself. It is better to ventilate the room and turn off the gas valves. Leave the lighting fixtures in the condition they were in when the smell appeared.

- Triggering of the automatic protection system (the column goes out immediately after ignition). In the absence of draft (the effect of deflecting the flame from the column into the room), the cleanliness of the chimney is checked. This is done by special services.

DIY battery repair

Most often, emergencies occur with batteries and heating radiators. This is due to the peculiarities of their operation. Timely repair of heating radiators will not only help eliminate the accident, but will also make it possible to use this heating element in the future.

There are a number of reasons why a radiator fails. The main one is the rusting process - the reduction of pipe walls. They cannot withstand the pressure of the system, and a gap forms. To quickly resolve the problem, you can perform a temporary repair of the heating radiator yourself. It is best to use cold welding for this. You must first check whether it is designed for use with the radiator material.

Below is the procedure for self-repairing heating batteries:

- Disconnect the radiator from the general heating system.

- Determine the location of depressurization and clean it of dirt, paint and grease.

- Prepare hot welding solution. If it is two-component, you should act strictly according to the instructions from the manufacturer.

- Repairing a heating radiator with your own hands - apply cold welding to the fabric base and wrap the leak area.

- For better sealing, it is recommended to secure the patch with a mounting clamp. If this is not possible due to the design of the battery, we apply an additional layer of cold welding.

After repairing the heating battery, you can reconnect it to the general heating system. But this should be done only after the cold weld has completely dried.

Carrying out such a repair of a heating radiator with your own hands will only temporarily solve the problem. The best option for restoring the functionality of the radiator is to replace the section or use electric (argon) welding.

After completing the restoration work, remove the air plugs from the radiator by opening the Mayevsky valve.

Before the start of the season

Before the start of the season, it is necessary to regulate the system according to a certain algorithm. First, the valves at the heating system inlet are opened. Then water from the heating network is supplied to the pipelines - this happens with all equipment intended for heating.

When there is water inside the pipes, experts examine the lines for heating the lower sections of the risers. If any of the system elements gets very hot, the taps are closed. The main objective of the measures is to create the same temperature conditions for all risers operating within a particular system.

Following the risers, uniform heating must be ensured for heating equipment on each floor of the house. As in the previous case, taps in very hot areas are covered. The required temperature is controlled in the central section of the device section, which is furthest from the riser.

The study of the system is considered successful if the temperature conditions in the premises deviate from the specified value by 1-2 degrees. Otherwise, you need to carry out troubleshooting work.

When starting a system after a long period of inactivity, it may take a couple of days to a week to balance.

Heating pipe repair

Thanks to its convenient design, repair of heating pipes in an apartment or house can be carried out in several ways. The only complication is a temporary lack of coolant circulation. In an apartment building, this requires turning off the central riser. For an autonomous system, it is enough to deactivate the heating boiler.

The first thing to do when a heating pipe breaks is to protect the floor covering from moisture. You can use rags and containers for this. Then you can repair heating pipes without welding using available materials and tools. To do this you will need the following components:

- Clamps. Their diameter must correspond to the cross-section of the pipe.

- Rubber gasket. You can use an old bicycle tube for this.

Before performing independent repairs of heating pipes without welding, you should shut off the flow of coolant in this area. Then the depressurization area is cleaned. The next step in repairing heating pipes in an apartment is installing a rubber gasket. It is wound in several layers. The pressure should be tight and tight. Mounting clamps are used for fixation.

More efficient repair of heating pipes without welding can be done using a special kit. It includes a clamp and a rubberized gasket. It differs from homemade ones in the speed of installation and service life.

It is purchased in advance, as it is designed for pipes of a certain diameter. If the cross-section of the line is different, it is recommended to buy several different sets.

Repair of polymer heating pipes in an apartment can be carried out using a welding machine. A set of mounting fittings and a piece of pipe of this diameter must be available. To carry out restoration work, the following actions are performed:

- The pipeline section is disconnected from the general pipeline;

- Using special scissors, the defective area of the pipe is cut out;

- A new pipeline is welded using a welding machine.

For temporary repairs of plastic heating pipes without welding, you can use a special putty. It is important to ensure that it is suitable for this type of pipe.

In copper pipelines, depressurization most often occurs at the joints. To solve this problem, you can re-solder or replace the entire section of the line.

Trust the professionals

Under no circumstances should repairs to central heating systems be carried out on your own - entrust this concern to professionals. When ordering work from us, you can be sure that the systems will serve you well for many years. We understand the responsibility that falls on us to our customers, so we do not involve third parties. We provide a 100% guarantee on our work.

Reviews about the company

Heating boiler repair

Heating boilers are the most complex element of heat supply. It is almost impossible to restore their functionality in the event of a breakdown on your own. Therefore, before repairing diesel heating boilers or their other analogues, you should analyze all possible consequences.

First you need to check whether the warranty on the equipment is still valid. If this is indeed the case, you need to call specialists to fix the problem. Self-repair of electric heating boilers may result in premature voiding of the warranty.

But primary knowledge about the cause of the malfunction will help the specialist. You can describe the emergency situation over the phone. The company representative will take with him the optimal set of tools and components necessary for replacement.

Repair of electric heating boilers may be necessary in the following cases:

- A sharp decrease in heating of the coolant;

- Failure of the control unit;

- Heat exchanger failure – leakage;

- The influence of third-party factors that led to the breakdown - a sharp surge in voltage in the network, overheating of the coolant.

Often the reason for the repair of diesel heating boilers can be the quality of the fuel used. In this case, you can clean the injector yourself and check the primary fuel heating unit. If these actions do not solve the problem, you will have to call a specialist.

But there are a number of breakdowns that cannot be eliminated by repairing electric heating boilers. First of all, this concerns the destruction of the housing and the lack of maintainability of the heat exchanger. In these cases, it is more advisable to purchase new equipment than to repair diesel heating boilers.

After the repair is completed by specialists, a note about this fact is made in the warranty card. If the breakdown is due to a manufacturing defect in the equipment, you can request an increase in the warranty period.

Our advantages are your guarantees

The company employs employees who have experience in providing this type of service. In the process of work, the company's employees use advanced technologies and high-quality materials. All work is carried out in accordance with the regulatory requirements of GOST and international quality standards. All staff have the necessary education.

Each applicant has undergone a pre-qualification screening prior to being hired. We constantly improve the qualifications of our employees by participating in international trainings.

Repair of circulation pumps

To increase the speed of movement of the coolant in the heat supply, a circulation pump is installed. Its breakdown will not only worsen heat transfer, but will also negatively affect the performance of the entire system.

Despite the apparent complexity of the design, you can repair the heating pump yourself. To do this, first determine the cause of the problem and develop the optimal scheme to eliminate it. Before repairing the heating circulation pump, you should turn off the system and wait until the coolant cools down. This can be avoided if a bypass is installed on the pump unit. It is enough to redirect the movement of hot water along the spare circuit.

Self-repair of heating pumps is carried out only after detailed familiarization with the design features of a particular model. Then the device should be dismantled to further restore functionality. There are several causes of malfunctions, after identifying which repair work on the heating pump is carried out with your own hands.

Let's look at the most common of them, as well as ways to solve the problem:

- The power plant does not work. First you need to check the condition of the terminals - the fuse on them often blows due to power surges in the network. The solution is to replace the fuse;

- Increased noise during operation. To repair heating pumps in this case, it is necessary to remove air from the pipe. It is best to install an automatic air vent in advance;

- Strong vibration during operation. Most likely the bearing on the shaft has failed. To repair the heating circulation pump, you will need to replace it;

- Incorrect blade rotation. The connection phase should be checked, as well as the correct installation of the pump;

- A little pressure. Most often this is due to a clogged filter. In this case, it will not be necessary to repair the heat supply pump, but to clean the filter.

After long-term operation, some pump components lose their hermetic properties - the geometry of the impeller and shaft changes. To repair a heating circulation pump, the condition of these elements is first checked. Almost all models are designed to replace components. But before purchasing, you need to select the right components, writing down the brand of the pump and its model.

There should be a sealing lubricant on the gaskets and pipes of the pump. If it is missing, it must be reapplied.

Problems and solutions

Emergency repairs

Let's take a look at the most common problems faced by emergency locksmith teams and their typical solutions.

- There is no heating through the riser. The work begins with checking the condition of valves and discharges: often the cause is uncoordinated repair work carried out by residents and hired workers. If they are in working position, the risers are moved to discharge in both directions to localize the problem.

The cause is often a piece of slag in a pipe bend or a stuck screw valve. Finally, if water passes freely through the riser, you just have to go up to the top floor and bleed the air there.

- Fistula in the heating pipe. If there is no threat of complete destruction of the riser or liner, the emergency crew simply applies a bandage, eliminating the leak. Welding work is carried out by a maintenance team.

- The locknut in front of the radiator is leaking. When the riser is dropped, the threads are rewound. If it is destroyed by corrosion, the connection on the liner is replaced by welding or manual threading.

- Heavy leakage between sections of radiators. Its cause can only be a burst nipple. After resetting the risers, the radiator is dismantled and rebuilt.

- The flush valve does not close after flushing the radiator. The riser is reset, after which the gasket on the tap is changed.

- The entrance heating has been defrosted and hot water is supplied to the entrance. After disconnecting the riser, the damaged sections are dismantled, and the remaining part of the radiator is started. If necessary, the emergency service performs welding work to restore connections, registers, etc.

The legislative framework

Legislation on heat supply issues consists of the Constitution of the Russian Federation, as well as. The latter establishes the legal basis for relations related to the production, transmission and consumption of thermal energy.

Certain aspects are regulated by by-laws and decisions of local authorities.

Find out what the standard air temperature standards are for an apartment during the heating season.

Which radiator is better?

Among all the radiators that are sold in the store, choose the one that you would like to see in your room. It should fit into the interior, perhaps even be its exclusive part. Next, consider its characteristics.

The choice of radiators can be based on the following indicators:

- where are you going to install;

- radiator type;

- material;

- power;

- operating pressure;

- sectional or monolithic panel;

- exotic appearance;

- price.

You can choose such a radiator to suit your interior

Cast iron radiators last a long time, but they are heavy, initially require overhaul and replacement of gaskets, take a long time to heat up and have poor heat transfer. They cost not much less than bimetallic ones.

Bimetallic and aluminum radiators make no difference from a practical point of view. The operating pressure, even in high-rise buildings, does not exceed 10-12 atm and such radiators can easily withstand it. Look in the passport - the manufacturer indicates the working pressure and testing pressure, which is not less than 15 atm. This applies to houses with a riser system.

How can I do this for free through the management company or housing office?

The problem of replacing a heating riser can arise for many technical reasons. In this case, routine repairs are necessary.

This issue is regulated by the following documents:

- rules for the maintenance of apartment buildings adopted at the general meeting of residents;

- norms and rules for the technical operation of housing stock (SNiP and VSN);

- Methodological recommendations MDK 2-04.2004.

If, according to the specified documents, the heating riser does not meet the requirements and creates a lot of problems, then homeowners have the right to demand a free replacement (on account of monthly payments). There is a certain procedure for this. First of all, a general meeting of residents is held, at which a decision is made on the need for the event. If it is not possible to convene a meeting, then a collective appeal is written.

Where to contact?

If the apartment building is owned by the residents, then the issue of major or current repairs is the responsibility of the management company, where the corresponding application is submitted. In case of preservation of municipal property, responsibility for carrying out repairs lies with the local executive power. You should contact the housing office that is in charge of the house.

Required documents

The following documents must be attached to the repair application:

- Riser inspection report. To draw it up, a specialist plumber is called in to determine the type and extent of damage.

- A certificate confirming the absence of arrears in payments for the maintenance of the house and payment for other utilities.

- Technical passport of the house.

Work to replace the riser will affect the interests of residents through whose apartments it passes. That is why the consent of all interested residents is necessary (in a collective application). If there is a decision of the general meeting, then separate consent is not required.

Drawing up an application

After identifying defects and inspecting damaged elements, an application is submitted to the head of the management company (ZhEK). It is written in free form, but should contain the following main points:

- information about the owner of the property;

- reasons for contacting, description of damage and confirmation of irreparability;

- essence of the request (repair or replacement, scope of work).

The application is drawn up in 2 copies.

One of them is sent to the management company. The applicant's copy is marked with a date and signature confirming receipt. We do not recommend completing the documents yourself. Save time - contact our lawyers by phone:

8 (800) 350-14-90

Duration of the procedure

The period for consideration of the application is regulated by clause 40 of the Decree of the Government of the Russian Federation of August 13, 2006 No. 491 , the management company is given 5 days for this. It has the right to send its representatives to conduct its own inspection.

For this, experienced specialists are usually involved, giving an expert opinion on the extent of damage, the causes and culprit of its occurrence. After this, a deadline for the work is agreed upon that satisfies both parties.

To carry out the work, the management company enters into an agreement with a specialized organization. An estimate of repair costs, incl. for the purchase of materials, dismantling, installation and testing. For his part, the owner must ensure free access to the work area and normal working conditions. Control of execution remains with the management company.

It's clogged and clogged.

Every heating system must have a coarse filter. A very small device with a fine mesh and a sump (installed downwards! or at least to the side) saves equipment, pumps, and the boiler from coolant contamination that will be present in any system. Wood shavings, broken threads, rust, water sediment…. everything is retained by the mesh in the filter.

The sedimentation tank must be periodically untwisted and the mesh cleaned.

If the circulation in the heating system of a private house is disrupted, then the first thing you need to do is check the filter, which should be installed on the return line in front of the boiler.

What difficulties with the law may arise if you carry out the work yourself?

The legislation of the Russian Federation does not prohibit apartment residents from changing the risers located in their premises. However, according to Articles 44 and 46 of the Housing Code, they are considered common property, and any changes without approval are considered a violation of property rights. In practice, there will be no problems if the system operates reliably and no one has any complaints.

Everything changes when a defect is discovered on the installed pipe. Further, serious problems and punishments will appear:

- the management company will refuse to repair the system with an unauthorized change;

- If neighbors are flooded, the blame will fall entirely on the citizen who committed the unauthorized action.

The owner, represented by the management company, may demand new repairs at the expense of the tenant. For example, if you install a plastic riser without authorization, you may be required to return the metal pipe.

Types of materials for making radiators

- Radiators made of cast iron

. The biggest advantage of cast iron is its low cost; moreover, it is highly durable, which will increase its service life for many decades. The features of this design are designed for the purchase of radiators with a large number of sections in order to heat the room quickly and efficiently. - Batteries made of steel

. Such structures are characterized by a high level of heat transfer, and are also able to withstand high loads and corrosion; moreover, they are easy to install indoors and ensure maximum efficient operation. Steel radiators can be sectional or panel. Sectional radiators in appearance resemble cast iron batteries. Steel radiators are able to withstand a working pressure of 16 atmospheres and also have a long service life. The main disadvantage is the risk of damage due to water hammer or external mechanical impact, due to the relatively thin steel - 1.5 mm. - Bimetal batteries

. This type is considered the most innovative and modern, in addition, they are light in weight and have a pleasant appearance. Such a heating system can be installed independently and without the help of specialists, and the combination of two types of metals increases resistance to external and internal influences and ensures maximum heat transfer (read: “The best heating radiators for an apartment: classification”). Bimetallic batteries with a steel core and aluminum fins have 4 important properties: high mechanical strength, thanks to the high level - 16 atmospheres - working pressure and test pressure - up to 30 atmospheres; - the chemical stability of the core has the ability to form a galvanic couple with copper pipelines;

- high efficiency;

- the modern look is quite presentable. Aluminum radiators are lightweight, so battery installation can be done by one person. The positive qualities of radiators lie in the large number of product options that differ in functionality and form, as well as an immediate response to changes in water temperature. Disadvantages include the need for air removal and unacceptable contact of the coolant with other metals. If this rule is not followed, the radiator may be destroyed by chemical attack.