In Russia, the first effective devices for water heating of buildings were developed by the Russian scientist P.G. Sobolevsky in 1834–1841. He was the first to calculate the diameter of a heating pipe.

Nowadays, to create the most favorable living and working conditions for people, the most advanced methods of heating premises are being developed and implemented. At the same time, methods for calculating pipe diameters are being improved and simplified.

How does pipe diameter affect the efficiency of a heating system?

Calculating the diameter of the pipes will help to avoid unnecessary heat loss and energy costs for heating the room. The process allows you to determine the dimensions that should be taken into account when planning the design of the premises.

Even if during the construction of a residential building, industrial building, or structure the most modern thermal insulation materials are used, but miscalculations are made in choosing the diameter of the pipes, then maintaining the required temperature in the premises will become unprofitable for the developer. In some cases, the entire system may fail or fail.

To achieve the highest possible system efficiency, design must be approached holistically. The selection of each link - boiler, pipes, radiators, circulation pump - is carried out taking into account all the features of each individual project.

What is needed for this

To calculate the diameter of the pipe, as a rule, the following factors are taken into account:

- Total heat loss of the home.

- What power do heating radiators have separately in each room.

- The total length of the circuit pipes.

- How is the system wired?

To be able to calculate the diameter of the pipes, it is necessary to determine in advance the total heat loss, the power of the boiler equipment and batteries for each room. It is also important which method will be chosen for pipe routing. Having all these parameters in hand, a future calculation scheme is drawn up.

It is also important to remember some of the specific markings of different pipes. Thus, on polypropylene pipes for heating a private house, the outer diameter is indicated (the same applies to copper products). To calculate the internal parameter, the wall thickness is subtracted from this indicator. Steel and metal-plastic pipes are marked by their internal cross-section.

What data do you need to take into account for the calculation?

The calculation will be considered using the example of a system with forced circulation, which is ensured by the operation of a pump.

For the calculation the following data is required:

- Delta temperature of the coolant at the entrance to the system and at the return;

- coolant speed;

- heating system power;

- general heat loss of the room (house, apartment);

- pipeline length;

- radiator power in each room;

- wiring method;

- pipe material.

Boiler power

In a country house, rooms are heated using gas or electric equipment, less often - solid fuel models. Based on the size of the heated space, the power is calculated. For high-quality home heating you need 0.1 kW of thermal energy per square. Parameters may change due to climatic conditions or gentle regime up to 1.3.

The power of the boiler is affected by the material from which the walls are made and the presence of thermal insulation. Increased thermal conductivity, combined with the thinness of the partitions, increases the heat loss of a country house. Even the most efficient model will not cope with heating the building.

What to look forSource eco-kotly.ru

The quality of heating is affected by the presence of a second circuit in the boiler. When hot water is turned on for domestic needs, the performance in the utility system decreases. Designs with this option should have higher parameters than their single-circuit counterparts.

The boiler power depends on the type of fuel. Gas equipment is considered the most practical. The most expensive are electric, the most inconvenient are solid fuel. Pumps are used to optimize coolant circulation and solve the problem of air locks.

Formula for determining pipe diameter

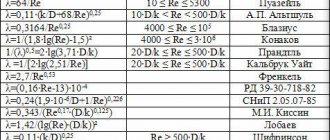

Professional calculation of pipe diameter is quite complex and is only accessible to heating specialists. Nowadays, a wealth of experience has been accumulated in using certain pipes in one case or another. The result was the systematization of data and its entry into standard tables.

Diameter correspondence table for the most common types of pipes.

| Nominal diameter (Dy) of the pipe, mm | Thread diameter (G), in inches | Outer diameter (Dh), mm | ||

| Steel seam, water and gas pipes | Seamless steel | Polymer | ||

| 10 | 3/8″ | 17 | 16 | 16 |

| 15 | 1/2″ | 21,3 | 20 | 20 |

| 20 | 3/4″ | 26,8 | 26 | 25 |

| 25 | 1″ | 33,5 | 32 | 32 |

| 32 | 1 1/4″ | 42,3 | 42 | 40 |

| 40 | 1 1/2″ | 48 | 45 | 50 |

| 50 | 2″ | 60 | 57 | 63 |

| 65 | 2 1/2″ | 75,5 | 76 | 75 |

| 80 | 3″ | 88,5 | 89 | 90 |

| 90 | 3 1/2″ | 101,3 | 102 | 110 |

| 100 | 4″ | 114 | 108 | 125 |

| 125 | 5″ | 140 | 133 | 140 |

| 150 | 6″ | 165 | 159 | 160 |

For those situations when you need to independently calculate the diameter of a heating pipe, there is a simplified calculation formula:

D = √ ((314 × Q) / (V × ∆t))

Where:

- D is the required pipeline diameter, mm;

- ∆t—temperature delta (difference between inlet and return), C°;

- Q is the required thermal power, kW. A certain (formula below) amount of heat required to heat the room;

- V—coolant speed, m/s. Selected from a specific range.

Temperature delta calculation

At the supply, the standard water temperature should not be less than 90°C, and at the outlet the coolant cools down to 65–70°C. As a result, the value of ∆t is 20–25°С.

Coolant velocity threshold:

- The minimum level is 0.2–0.25 m/sec. At lower speeds, air begins to be released from the coolant. This leads to the formation of air pockets. The consequence is a partial or complete loss of functionality of the heating system.

- The upper level can reach 0.6–1.5 m/sec. As it approaches the maximum value, hydraulic noise increases.

Calculation of the minimum required thermal power

To determine the minimum required power of the heating system, you can use the following simplified formula:

Qt = V × ∆t × K: 860

The symbols represent:

- Qt is the required thermal power, in kW/hour;

- V is the volume of the heated room, in m²;

- ∆t—temperature difference between outside and inside the room, °C;

- K is the heat loss coefficient of the building;

- 860 - conversion to kW/hour.

Simplified values of heat loss coefficient for various types of buildings

Calculating the heat loss of a house is the most important factor for the effective design of a heating system. It will help predict the estimate for installation and heating costs in the planned building.

Heat loss in any room depends on three basic parameters:

- Volume of the room - you need to find out the amount of air that needs to be heated.

- The temperature difference between inside and outside: the greater this parameter, the faster the heat exchange occurs and the faster the room cools.

- Thermal conductivity of enclosing structures is the ability of walls, windows, roofs to retain heat.

In this case, you can use the following values of the coefficient (K) for various types of buildings:

- 3–4 - a building that does not have additional insulating protection (a simplified structure made of wood or metal sheets).

- 2–2.9 - low degree of thermal insulation (buildings with single brick masonry, uninsulated log house).

- 1–1.9 - average level (classic building design: double brickwork, log house with single insulation, a small number of windows, standard roofing).

- 0.6–0.9 - high degree (the structure of the building is improved, the brick walls have double thermal insulation, a small number of windows have double frames, the base of the floor and the roof are insulated).

Sometimes there is a possibility that the diameter will be narrowed against the calculated or tabulated value. This is highly undesirable. When wiring around the house, it is recommended to use the same size pipes. An increase or decrease in diameter can cause a malfunction of the entire heating system.

In this video, a specialist gives practical advice on calculating pipe diameters.

Prices for different types of heating pipes

heating pipes

Tips for choosing

They must meet the following requirements:

- satisfy the power of the heating device,

- correspond to the total load of the system as a whole.

The first thing you need to do is decide what kind of pipes you want to use for heating in your home. If you say that the choice is difficult, it means saying nothing.

It will be quite difficult for the average person to navigate the range of products offered by the modern construction products market.

As for alternative options for selecting pipes for heating a private home, a lot depends on various factors.

In this case, calculations must be made according to the standards established in the general order.

The scheme by which the heat supply of a country house is calculated will look completely different.

You will not be able to achieve a comfortable temperature in all rooms if there is disproportion:

- sections of pipe products,

- total housing area,

- rated boiler performance,

- type of fuel (read about the internal heating cable for water supply here).

All heating products for the needs of private buildings must comply with established standards. This is due to the type of heating system.

It can be performed in one of two variations:

- hidden,

- closed.

Depending on the chosen option, the temperature load and susceptibility to microclimate fluctuations will be different.

The installed pipes are located according to:

- the outer perimeter of the building,

- inside the house,

- under the base of the floor.

The installation method should be chosen depending on what type of pipes you decide to give preference to.

Whether you can carry out the entire process of heating your home yourself or decide to invite specialists is up to you to decide at a family council.

If you have confidence in your abilities, then feel free to take on a difficult and very responsible task.

- carried out on the principle of gravity or compulsorily,

- a light or ornate scheme is provided,

- house one or more floors,

- pressure is assumed to be insignificant or maximum,

- the liquid will flow through the pipes hot or warm (this article describes shut-off valves for a toilet with a side connection).

Pipes for private and apartment buildings

There are various heating systems, and in each specific case the pipes must correspond to the individual characteristics of the designed structure.

Individual construction

In Russia and the CIS countries, three types of heating systems are used, each of which has its own characteristics.

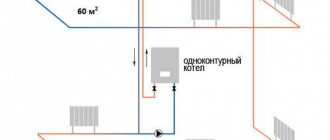

Leningradka

With its help, you can perfectly organize the heating of any home, significantly save on the purchase of materials and reduce the cost of installation work. This scheme allows you to regulate the temperature in each individual room, creating optimal living conditions.

The Leningradka heating system uses the following pipe diameters:

- Trunk: 20–25 mm (one-story house) and 30–40 mm (two-story house and above).

- For radiator connection: 13–16 mm.

To regulate the heat supply to each radiator, you can install a valve on the connection pipe.

Tichelman loop

This system is characterized by the following positive features: stability during operation and uniform heating of all radiators. This diagram for connecting heating devices is also called associated. The coolant supply ends at the last radiator. The return starts immediately from the first battery. The Tichelman loop can be used with equal effectiveness on large and small areas.

Dead end

In this system, the radiator closest to the boiler heats up more, and the latter receives less coolant than the others. For a dead-end circuit, the number of radiators in each arm is limited. The pipes used are the same as in Leningradka.

Heating system of an apartment building

Nowadays, a central heating system is usually used for an apartment building. Water comes into it from thermal power plants (or other suppliers). The system is designed in such a way as to ensure the same coolant pressure in the main pipes on all floors of the house .

Diameters of heating pipes in an apartment building:

- At the entrance, in the basement - 100 mm.

- Loungers that distribute the coolant along the entrances - 50–76 mm. The parameter depends on the size of the building, the distance to which the coolant is transported and how many branches the pipeline will have.

- The diameter of the risers is 20 mm.

The return is performed in increasing order - 20–50–76–100 mm. Various water circuits are used: single-pipe and double-pipe.

According to SNIPs and GOSTs, the heating system of an apartment building must ensure that the air inside all residential premises is heated to 20-22 degrees Celsius in winter.

Heating system: varieties

Heating systems can be with natural (gravity, without a pump) or with pump (forced) circulation, and are made according to a two-pipe, one-pipe and collector (beam) scheme. The latter is shown in the subheading picture.

Water heating systems are also classified (regardless of the method of coolant circulation) according to the following parameters:

- With top and bottom connection types.

- Double-pipe and single-pipe.

- With horizontal and vertical risers.

- With the passing movement of water and a dead-end circuit.

We recommend watching a wonderful video that talks about the nuances of using a particular heating system:

Heating manifold calculation

To ensure balance and stable operation of the heating system, all its elements must match each other in their throughput. The latter depends on the correctly selected pipe cross-section.

The reservoir calculation is based on this principle. It must have a cross-sectional value equal to or permissibly larger than the sum of the cross-sectional areas of all outlet branches. The cross-sectional size of the prefabricated comb must be no less than the sum of the areas of the supply pipelines.

This condition is described by this formula:

S = S, + S,, + S,,, + … + Sn

Where:

- S is the cross-sectional area of the collector or comb;

- S, ... - Sn - cross-sectional areas of outgoing or incoming branches.

Formula for calculating cross-sectional area

The basis is the formula for calculating the area of a circle, and in this case, the cross-section of the collector (comb). The sum of the cross-sectional areas of the outgoing pipes gives the desired result - the size of the heating collector.

Scall = π × Dcall²/4, then the calculation formula takes the form:

π × Dcol²/4 = π × d,²/4 + π × d,,²/4 + π × d,,,²/4 + …+ π × dn²/4,

Where:

- Dcol — collector diameter;

- π—pi number;

- d, — dn – internal diameters of outlet branches.

To simplify the formula, you need to reduce the number pi and take everything to the square root:

Dcall = 2 × √ (d,²/4 + d,,²/4 + d,,,²/4 +…+dn²/4).

Using this formula, you can calculate a reservoir of any complexity and configuration. If all outgoing heating branches have the same diameter, the formula takes the following form:

Dcall = 2 × √ (dtotal²/4 × N),

Where:

- N is the number of pipes leaving the comb;

- dtotal – diameter of each outlet pipe.

If the calculation results in a fractional number, it should be rounded up. This is necessary to avoid narrowing the cross-section of the collector and reducing the power of the system.

Additional requirements for collector design

When calculating all parameters of the collector, two conditions must be met: the distance between the input and output groups of branches is equal to six diameters, and the heating circuit outlets are three sizes apart from each other.

Scheme for connecting the collector to the cottage heating system.

Equation method

Although pipes made of different materials are marked with different values (internal or external), in some cases they can be equated. This applies to situations where it is not possible to find data on a specific pipe: in such a situation, you can use information on a similar cross-section of a product made of a different material.

Let's say you need to calculate what diameter of a metal-plastic pipe is needed for heating, but the necessary information on this material has not been found. As an alternative, a table of coolant speed in the heating system for polypropylene products is used. Using the appropriate dimensions, the appropriate parameters for the metal-plastic pipe are selected. In this case, it is impossible to avoid inaccuracies, but in forced-type circuits they are not critical.

Mounting sleeves

Installation of the heating system is impossible without the use of mounting sleeves. When laying a pipeline through walls and ceilings, the walls of the products come into contact with an aggressive environment.

Due to physical laws, pipes during operation will undergo periodic contraction and expansion. This will lead to mechanical stress on the surface, guaranteeing faster wear at the contact points. To avoid this, SNIP building codes provide for the supply of pipelines with additional structural parts called sleeves.

The sleeves are designed to:

- prevent the leakage of liquids from adjacent rooms or the street;

- prevent the passage of unnecessary gaseous substances;

- maintain sound insulation;

- ensure the integrity of the structure when dismantling or replacing the pipeline;

- prevent unwanted insects from entering the premises.

The pipeline can pass through any building in two planes: vertical (floors, floors, ceilings) and horizontal (internal and external walls, ceilings).

The sleeve consists of:

- Covers (standard or cut from steel or polymer pipes).

- Packings (filling the cavity between the pipeline and the cover), which can be a soft, non-combustible material. It is possible to use special cement or clay mixtures.

The size of the sleeve assembly is determined by the outer diameter of the pipeline and the thickness of the wall or ceiling: the size of the sleeve and the length of the product should be 10–20 mm larger.

This video will briefly introduce you to the installation of a heating system in an apartment.

General information about heating pipes

All pipes for heating systems can be divided into two types: metal and polymer.

Metal:

- copper;

- metal-plastic;

- bronze;

- metal corrugated;

- steel.

Copper pipes are superior to all others in the following parameters: long service life, smoothness, which increases the speed of coolant movement, and resistance to ultraviolet radiation.

Polymer:

- polyvinyl chloride (PVC);

- polyethylene terephthalate (PET);

- metal-plastic;

- polyurethane;

- propylene;

- polypropylene.

The cross-sectional diameter in which propylene and polypropylene pipes are offered can be in the range of 16-110 mm. The advantages of this material include: relatively low weight, ease of processing and installation work, low price. Long-burning wood stoves for home heating you will find the answer in the link.

Conclusion

Using a not very complex and branched scheme to organize the heating of your home, you can calculate the optimal pipeline diameter on your own. To do this, you need to arm yourself with information about the heat loss of your home and the power of each battery. Next, using special tables and reference books, the optimal value of the pipe cross-section is selected, which can ensure the transportation of the required volume of thermal energy to each of the rooms.

If complex schemes with many elements are used, then it is advisable to invite a professional plumber to calculate them. If you have confidence in your own abilities, it is still recommended to consult with a specialist. There are cases when, due to mistakes made, it is necessary to undertake an expensive reconstruction of the entire circuit.