Infrared gas heater device

Externally, the gas heater looks like a compact device that is light in weight. There is no need to use force to move it, and the dimensions of the heater allow it to be easily placed in the trunk of a car.

To operate a gas heater, which is an autonomous type of equipment, you must have a supply of liquefied gas.

A small heating device is indispensable in places far from civilization. If there is a trip to the dacha, where power outages are possible, then it is quite possible that it will become the only means of heating the premises.

A gas heater is perfect for use:

- in remote locations where builders, geologists and other specialists work;

- in country houses and small dachas;

- tourists traveling in winter;

- on vacation in natural conditions.

An infrared ceramic heater that uses liquefied gas for operation has a simple design. It consists of just a few parts:

- metal body combined with a gas cylinder;

- ceramic plates equipped with a complex system of crater-type holes;

- gas burner.

Since the use of gas can become dangerous for a person if the device is used incorrectly or if it malfunctions, any model of this type of heater is equipped with devices that ensure its safe operation. Among them are:

- a gas control system that automatically turns off the device system in the event of a sudden loss of flame;

- a carbon dioxide content sensor that turns off the device when its concentration exceeds the norm;

- power regulator.

In addition to safety devices, each model is equipped with a piezoelectric element for igniting the burner. For ease of moving the unit, the heater is equipped with wheels.

How the device works

The gas ceramic infrared heater works on the following principle:

- In the mixing chamber, gas is mixed with air.

- The gas-air mixture, passing through the holes in the ceramic plates, burns, acting as a heater for them.

- Ceramic plates heated to 900°C emit infrared heat.

A notable feature of infrared radiation is the heating of objects that find themselves in the heated zone. And the heated objects then warm the environment with their heat (for more details, see the article on the operating principle of a heater with infrared radiation). This amazing property of infrared rays allows you to significantly save energy. Sometimes savings reach 80%.

Built-in security system sensors will turn off the device if conditions that are contraindicated for operation occur. Therefore, it can be safely used in residential areas.

Causes of malfunction

Do-it-yourself boiler repair: the most common breakdowns and their elimination

Before passing a verdict on your IR heater that refuses to work, it is important to conduct an initial diagnosis of the problems and identify their cause. Typically, this type of device fails due to improper storage, falling, shock, or incorrect operation.

Experts warn: if you do not want to risk the serviceability of your heating household appliance, then you should not violate the following rules:

- the heater cannot be installed in close proximity to a window;

- storing the device in a room with high humidity levels is a serious mistake;

- the use of damaged extension cords or sockets can cause damage to the infrared heater;

- the IR heater must not be covered during operation;

- When you leave home, check that the appliance is turned off.

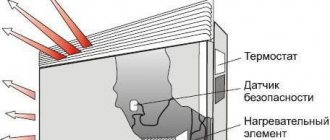

Important: according to the operating principle of the IR heater, the heat sources are all objects in the room. The thermostat will help you set a comfortable temperature for you.

The device will turn off automatically once the temperature reaches the specified value.

Safety precautions

Gas devices are devices that require unquestioning compliance with safety regulations:

- Do not remove the safety grille while the appliance is in use.

- Do not cover the device with rags or other things to dry clothes.

- It is prohibited to direct IR rays at flammable objects: light curtains, curtains, tablecloths.

- When the heater is turned on, it must be in a vertical position, unless another specific model requires a different position, as indicated in the instructions.

- The room in which the device is installed must be well ventilated.

Armed with knowledge about infrared ceramic heaters, you can successfully use them, adding comfort and life-saving warmth to your life, which will keep you and your loved ones healthy!

How to choose a heater

There are a lot of heater models you can find. It is better to choose a unit equipped with a timer. The ionization function doesn't hurt either. With it, the surrounding air does not dry out, but is electrified. This can be useful in small spaces. Professionals recommend choosing devices with a high-quality protective grille and a power reserve of 5-15%.

We also recommend reading:

Some types of ceramic heaters run on gas. This is a convenient option for using the device in the country, since it does not require either sockets or gas networks. It is enough to connect a small gas cylinder to the device. The air in the room warms up quickly enough. When choosing such a ceramic heater, you need to make sure that there is a function that turns off the heater if it falls or overturns. The device must have a sensor that indicates that the level of carbon dioxide in the room is exceeded. This is due to the burnout of oxygen in the room and the formation of carbon dioxide. If its level reaches a critical value, the heater should turn off automatically.

Similar devices are also used to heat car interiors. In a few minutes, with their help, even in severe frost, you can warm up the car windows and heat the air in the cabin. This may be necessary if the standard car heater malfunctions. The device is quite compact and does not take up much space. It is powered by a cigarette lighter, the power is 150 W, but it can be less or more. In summer, a car heater can be used as a fan.

Many consumers prefer heaters from European manufacturers. But domestic devices can be no worse than foreign products. The brands “Hybrid”, “Sikar”, “Wild Wind” and some others are very popular. But some consumers have complaints about the build quality of the devices and the heating elements. Most often, these shortcomings are observed in Chinese products. German or Italian heaters are usually very good. Don't rush when choosing. Consumers do not recommend buying a ceramic wall-mounted heater for a summer house or home. It is not very efficient; it takes a long time to warm up the air that rises. The best option is a floor sample.

It produces good devices. They cost relatively little and last a very long time. Bork heaters have a beautiful appearance, a good safety system, and high efficiency. It is difficult to find anything more suitable for a summer residence. “NVA” is a device for heating medium-sized rooms. After switching off, it remains warm for a very long time.

Those interested can try to make a small heating device from ceramic pots with their own hands. To work, you need to take 3 flower pots of different sizes. The largest can be 18 cm in diameter and 23 cm in height. These dimensions are approximate. The remaining pots are inserted inside the large one according to the matryoshka principle. The most convenient way to fasten them together is with a metal bolt of sufficient length, washers and nuts. The holes in the pots are already made by the manufacturer. This heater will work on a candle. It is not able to completely heat the room in the winter cold, but it is quite suitable as an additional source of heat. A wax candle weighing 4.5 g is enough for a day of continuous use. Paraffin burns even longer.

Application area

Gas ceramic heaters can use not only autonomous gas sources for operation, they can also be connected to the main network. Devices connected to the main network successfully cope with heating:

- spacious living quarters;

- sheds, outbuildings;

- production premises.

Autonomous heaters are used to heat:

- garages;

- tents;

- open areas of restaurants;

- country houses and dachas.

Outdoor gas heaters are used as a thermal umbrella for heating gazebos, barbecue areas, trees during severe frosts, and any open areas.

Gas heater for small utility rooms, garages

Since utility rooms and garages can often be storage for things or various fuels and lubricants, a heater with an open fire source cannot be used in it. A gas ceramic heater is perfect for this purpose as a safe device equipped with automatic control systems.

To heat the garage, small compact models with low power are produced. Both a floor-mounted and portable option will be convenient. The portable heater is equipped with a convenient handle, so this model can also be used to thaw frozen locks.

Gas ceramic tent heater

During hikes, people traditionally warmed themselves by fires. But it is not always possible to light fires if there is no dry wood. A gas heater is not afraid of any weather, and it can warm people not only in the evening, but throughout the night if installed in a tent.

Ultra-compact models have been developed especially for tents that easily fit in a backpack.

Variants of devices have been developed whose designs allow them to also be used as a gas stove.

Gas infrared heater for cottages and country houses

To choose the right heater for a country house, you need to consider how you are going to use it: for a long time or occasionally?

From an economic point of view, it is not advisable to use a gas appliance as the main source of heat. Of course, if there are no other sources of energy, then there is no choice.

For short-term heating of a country house during a winter holiday, using a gas appliance will be the optimal solution.

When choosing the optimal heater power, you do not need to take into account the total area of the entire room, because it is capable of heating only a certain area. You can also use it to heat an open space:

- summer terrace,

- picnic areas,

- children's playground.

Types of IR heaters

Do-it-yourself thermopot repair in 3 stages

When going to the store for an infrared heater, be prepared for the variety of representatives of this product group - from simple models powered by electric current to gas ones, which are used to heat large areas. Let's take a closer look at each variety to consider their features.

Electric infrared heaters are divided into several subcategories depending on the heating element they use. They are compact, convenient, have a long service life and rarely fail.

A non-conducting resist cable is placed in the ceramic IR heater as a heating element. It is located inside a ceramic panel that transmits infrared waves well. Externally, the device is a thin hinged panel with a remote thermostat.

In carbon IR heaters, the role of the “first violin” is played by a sealed quartz tube, inside of which there is carbon nanofiber. Such heaters consume less energy than previous ones and even have a therapeutic effect, so they are often used as a device for physiotherapy. Their disadvantage is their rather high cost. However, judging by the reviews of the owners of this device, such heaters are worth the money spent.

Film infrared heaters operate by using a flexible resist cable that heats the outer metal film. They are easy to install on a prepared base. The surface of the IR film is heated to 75°C. The clear advantage of this type of heaters is flexibility, which means that the range of their applications in everyday life is extremely wide.

The operating principle of gas models is exactly the same as that of electric ones. Only they do not use current as an energy source, but gas fuel. They are usually installed in workshops, stadiums or on the street. They have impressive sizes (up to 15–20 meters in height) and serious power. True, there are also more modest models that have the shape of an umbrella. They can be seen on open terraces and verandas of catering establishments during the cold season. They are “powered” from a gas pipe or from a liquefied gas cylinder.

Criterias of choice

The choice of a suitable heater is made based on the size and configuration of the premises. Each model has certain capabilities, the ability to heat a given area. At the same time, it is necessary to take into account the shape of the room - the device has a directional effect and cannot cover a room with a complex configuration.

You should not choose a heater “for growth”. It should be kept in mind that excess power will not be used for future use. It will heat the surfaces too much, which can cause damage to floor coverings or furniture. In addition, direct radiation directed at people or animals can cause deterioration in health.

Therefore, it is necessary to choose a device based on the area of the room. Manufacturers indicate how much area a particular device can cover. You can be guided by the ratio - 1 kW of power per 10 m2 of area. However, you can make a calculation taking into account the high efficiency of gas ceramic heaters and use a different formula - 1 kW per 15 m2.

Which brand of gas heater should I choose?

DIY floor fan repair

Various companies are fighting for global leadership in this field, but among them there are clear favorites, whose equipment is distributed in many countries.

Among the best representatives of the segment are:

1. Ballu

2. Timberk

3. Kovea

4. Pathfinder

5. Siabs

The first company has its headquarters in Hong Kong, but its branches are spread all over the world. Large offices are located in Japan, Lithuania, Korea, Poland and China. The main specialization of this corporation is climate control equipment. Her department has a large design bureau and experimental design laboratories.

Another concern originating in Asia is Timberk, which has existed since 2004. The marketing network covers all of Eastern Europe, Russia, and CIS countries. The range includes more than 120 types of climate control products, including split systems and heaters.

It acts as a highly specialized company with domestic production and export to neighboring countries. In business since 1991, it has focused its activities on outdoor equipment and gear, of which compact gas heaters are an integral part.

The Italian company Siabs also actively uses innovative technologies, whose models have no analogues and are reliable in operation.

Gas radiant heating is a radical solution to improve the energy efficiency of enterprises.

Publications

Author: S. Zolotarevsky, Ph.D., General Director of NPF RASKO LLC

Edition: Boiler houses and MINI-CHP No. 6. Year: 2017

26.01.2018

A significant reserve for improving the quality and competitiveness of products manufactured by enterprises and services provided is to reduce the cost of heating production premises while simultaneously increasing the comfort of stay of production personnel in them. Recently, autonomous industrial heating systems (IHS) have become especially relevant. Autonomous heating has a number of significant advantages, including: complete independence from the work of city utility organizations; independent choice of temperature depending on your needs; simplicity and ease of operation of the equipment.

Based on the type of thermal energy output, PICs can be divided into: radiant (infrared) ; convective ; radiative-convective .

The use of traditional convective heating systems in high industrial premises (workshops, warehouses, sports facilities, agricultural facilities, with heights of 6 m or more) is extremely ineffective, because as a result of convective heat exchange (Fig. 1), warm air will concentrate in the upper part of these rooms, while in their lower part it will be cold.

Rice. 1. An example of a convective heating system.

At the same time, radiant (infrared) heating (Fig. 2) provide heating of objects (floors, equipment) and heating of people (the heat is felt on the skin and clothing) exactly in the necessary areas. In fact, such a system is a complete analogue of the warming effect of sunlight, with the only difference being that the emission spectrum of radiant heating systems (gas, electric or water) is in the range of infrared radiation, i.e. it completely lacks harmful ultraviolet radiation.

Rice. 2. An example of a radiant (infrared) heating system.

In terms of economic indicators, namely the cost of fuel required to heat the relevant premises and maintain the required temperatures in them, the undisputed leader is gas radiant heating systems. This is determined, firstly, by the fact that the cost of natural gas required to generate a unit of thermal (in this case, radiant) energy is significantly lower than the cost of electricity required to generate the same amount of heat, and secondly (in comparison with water radiant heating systems ), there is no need to build a boiler house (even a gas one) to heat water, as well as pipelines and pumping equipment for its circulation from the boiler house to the corresponding radiant energy emitters and back.

Modern gas radiant heating systems are not only the most cost-effective among all heating systems, but also successfully destroy the established stereotype that gas is dangerous. Equipped with a built-in flame-out protection system in gas infrared emitters (GII) and equipped with a gas contamination control system, they have been successfully used for many decades in many countries of the world, primarily in the most developed ones (Molka V. Three “Es” in heating industrial premises. – Kiev, 2005), for heating all types of industrial premises (workshops, logistics warehouses, aircraft hangars, railway depots, large garages), agricultural facilities (greenhouses, farms, etc.), stadiums, gyms, exhibition complexes, entertainment and cultural - educational institutions.

In Russia, heating systems with GII, according to the Code of Rules SP 60.13330.2012 SNiP 41-01-2003 “Heating, ventilation and air conditioning”, approved by order of the Ministry of Regional Development of the Russian Federation dated June 30, 2012 No. 279, are allowed to be used in premises with category explosion and fire hazard B2, B3, B4, G and D and buildings I, II, III, IVСО degree of fire resistance in accordance with the Technical Regulations on Fire Safety Requirements Federal Law No. 123 of July 22, 2008 (Federal Law of July 22, 2008 No. 123-FZ (as amended) dated July 13, 2015) “Technical Regulations on Fire Safety Requirements”).

The economic effect of equipping these industrial facilities with gas radiant heating systems is more than obvious: heating costs are reduced by 3–5 times or more, and the payback period of projects in the vast majority of cases does not exceed 0.5–2 years.

On the Russian market, gas radiant heating systems are represented by products from a number of well-known manufacturers, such as Sibshvank JSC , GoGas Goch GmbH, Carlieuklima Spa, Fraccaro srl, Adrian Group sro, etc. The most preferable in terms of price/quality, delivery time, The level of service and technical support at all stages from the design of the PIC to its subsequent operation is the product of JSC Sibschwank , Tyumen - a subsidiary of Schwank GmbH (Germany) - the world leader in the field of gas radiant heating. Sibshvank production has a high degree of localization in Russia. Accordingly, its application is fully consistent with the policy towards import substitution taken in recent years. In addition, as a result of a significant weakening of the ruble exchange rate in relation to leading world currencies, prices for products of Sibshvank JSC compare favorably with the prices of the mentioned foreign ones. It produces “light” and “dark” GII , as well as control and regulation devices for POS control of the specified type.

Rice. 3. Design of the Schwank GII “light” type.

The “heart” of the “light” type GII (Fig. 3) is the Schwank ceramic tile, which has no equal in the world. When a mixture of gas and air burns, the temperature on the surface of the tile reaches 950 °C, and it begins to emit infrared radiation, which, upon reaching the heated surfaces, is converted into thermal energy. The heated surface of the tile glows orange, which is why infrared heaters of this type are usually called “light”. Emitter reflectors direct radiant heat to the surface to be heated.

Light-colored HII "Sibshvank" is used for heating production workshops, hangars, warehouses, gyms and churches (5-6 m or more in height). In addition, it offers special (windproof) models of light-colored GII for heating the stands of football stadiums, terraces, open areas of restaurants, cafes and other establishments.

Consumers are offered three types of “light” type infrared heaters (Fig. 4) : supraSchwank – premium model; termoSchwank (2100 series) – industry standard; ecoSchwank (series 2000) – basic model.

A distinctive feature of the supraSchwank HII is its uniquely high radiant efficiency (up to 81%) and therefore exceptional efficiency, as well as two-stage or stepless thermal power control.

Rice. 4. GII Schwank “light” type

The scope of application of the “dark” type GII (GII-TM) is premises with a height of no more than 6–10 m with insignificant air exchange: exhibition halls, warehouses, service stations, workshops, car parks. Removal of combustion products from each emitter is carried out using chimneys. The use of ceramic tiles allows you to increase the length of the flame, which ensures uniform heating of the radiating surface. The use of a blower fan eliminates the interaction of combustion products with the environment (Fig. 5).

Rice. 5. Design of the Schwank GII “dark” type.

The appearance of the “dark” type GII is shown in Fig. 6.

Rice. 6. GII Schwank “dark” type.

Rice. 7. Options for dark GII: L-shaped, U-shaped

For ease of installation of gas pipelines and chimneys, Schwank “dark” type GIIs are available in linear and U-shaped versions ( Fig. 7 ).

To control gas radiant control systems, specialized controllers are used that receive information from temperature sensors located in the heating zones of heated premises. In systems using emitters, temperature control in the room, turning on and off the GII is performed automatically by the “Thermal Control” temperature regulator ( Fig. 8 ). When the room temperature drops, the temperature controller turns on the GII. The heat generated by burning gas in a gas incinerator is directed in the form of a stream of infrared radiation to the working area of the room, heating the floor and equipment. As a result, the indoor temperature rises.

When the set air temperature in the room is reached, the temperature controller turns off the GII.

Rice. 8. Temperature regulator “Thermal control” with temperature sensor.

For example, the “Thermal Control Plus M” modification has up to 8 control loops, i.e. can provide control of 8 temperature zones (each zone has its own temperature sensor). Heating modes can be programmed for a long period in advance, taking into account the operating mode in the room where this PIC is installed. The special “chimney sweep” function allows for preliminary purging of the system to remove combustion products from “dark” emitters.

As already noted, operating costs when switching to a radiant heating system with GII are several times lower than when heating using traditional convective systems. As an example in table. 1 shows a comparison of the indicated costs for a plant in the Chelyabinsk region.

From the data presented in it it follows that operating costs only for consumed energy resources when switching to a gas radiant heating system are reduced by 3.3 times compared to the heat supply option from a combined heat and power plant and more than 2.9 times compared to the heating option using our own gas boiler room.

Real savings in practice are even greater. It is further increased due to:

— low inertia of gas-radiant heating systems, allowing to reduce the temperature in the premises not only during non-working hours, but even during the lunch break; - the ability to maintain the required temperatures only in work areas, and not in the entire room as a whole; — absence of heat loss and elimination of coolant leaks in heating mains from the boiler room to the heated room; — a sharp reduction in labor costs for starting the heating system, which even allows you to completely turn off the heating on days of sudden warming, and then quickly turn it on; — eliminating the cost of repairing heating mains; — a sharp reduction in the cost of maintaining heating equipment (the costs of chemical water treatment, replacement of circulation pumps and many others are completely eliminated), etc.

Naturally, the question arises: why have such highly efficient heating systems not been widely used in Russia until now? Why is it that until now, unlike most countries in Europe and North America, where not only the majority of industrial facilities are heated in this way, but also many shopping centers, exhibition complexes and sports facilities, the number of such facilities in Russia does not exceed a few percent of the potential?

There are several reasons for this. The main ones:

- During the Soviet years, no one thought about energy efficiency and did not invest money in improving it. Accordingly, there is a serious lag both technically and in the way of thinking of those responsible for this (government officials, heads of enterprises, regulatory authorities);

- One of the forms of this technical backwardness is the imperfection and inconsistency of the existing regulatory framework. Even on the question: “In which rooms and which GIIs (light or dark) can be used?” there is no consensus of opinion. This not only complicates the process of coordinating the use of PIC with GII, but also makes enterprise managers fear that in the event of any force majeure situations (for example, a fire or explosion), they could potentially be blamed for the fact that the installation of GII was carried out in violation of some regulation (although, of course, any such project, before its implementation, must undergo an examination by Rostekhnadzor for compliance with industrial safety requirements);

- financial problems of most industrial enterprises. With the highest energy efficiency and extremely short payback periods, which no one disputes, to implement the project of switching to gas radiant heating, the enterprise needs significant funds, which, as a rule, are not available. Loans are very expensive. But the main thing is that many enterprises do not have confidence in successful development in a tangible future. In such a situation, investing in energy efficiency seems risky to most managers and owners. So they continue to “patch up” the existing convective heating system, which is sucking the last juice out of the enterprise and worsening its already difficult situation;

- and finally the last one. The well-known principle “the neighbor already has one,” due to the insignificant number of gas radiant heating systems in Russia, has also not yet worked. As soon as their number increases, the “neighbors” will definitely fuss, and even those who did not have them before will “find” funds. But for such a transition from quantitative changes to qualitative ones, as philosophy teaches us, we must reach a certain critical level!

Whoever overcomes these difficulties and stereotypes first, who is the first to increase the energy efficiency of his production, and, therefore, reduces production costs and production costs (i.e., actually increases his competitiveness), he, other things being equal, will not only strengthen his position on market, but will also receive a new, powerful impetus for development.

LLC NPF RASKO 125464, Moscow, st. Mitinskaya, 12 E-mail: This email address is being protected from spambots. You must have JavaScript enabled to view it. Website: packo.ru Tel/fax (multi-channel)

A significant reserve for improving the quality and competitiveness of products manufactured by enterprises and services provided is to reduce the cost of heating production premises while simultaneously increasing the comfort of stay of production personnel in them.

Types of heaters

The variety of modern heaters can amaze even a specialist in this field. However, the most popular are:

- oil;

- ceramic;

- infrared.

Oil-based models are considered classic heaters. Sections of these devices are characterized by a ribbed design. Externally, they are very similar to central heating radiators. In addition, they have a similar operating principle. Oil is supplied through the pipe to the heater, which transfers heat to the section. Then the oil flows back to the heating element.

Due to the relatively high costs associated with purchasing a high-quality infrared emitter, it is worth conducting a thorough comparison between different makes and models. All relevant information can be found in the respective product descriptions.

Infrared heaters, also called thermal energy heaters, are extremely decorative and efficient. We recommend additional heating where you need more heat. Comforting radiant heat is absorbed, stored and released by surfaces in the room. This creates a comfortable indoor climate. Enjoy the calming effect of heat wave heaters.

Often the control panel of such a device includes only three keys. The first two are responsible for turning on a separate heating element, the third (wheel) serves as a temperature regulator. These heating elements differ in power, which allows expanding the adjustment possibilities.

The main advantages of an oil heater include:

- heating the air through convection;

- high mechanical strength;

- impeccable environmental cleanliness;

- democratic price.

The next type of work - ceramic heaters - is based on the principle of forced convection. The main feature of these devices is the material of the heating element, which is made of ceramic. A ceramic heater consists of many tiny particles through which air passes. Its main elements are the heating element itself, the fan, the blind motor, the control unit (electronic) and the control panel.

Good heating with infrared heater

Infrared heating systems are optically invisible as heating. No matter how the image is heated with your own motif, heated mirrors in the bathroom, the possibility of recording on the heating panel in the kitchen or how heated glass, large, small or round, no other heating offers you so many design possibilities with a compelling design and better functionality. With electricity from renewable energy sources, for example.

Pleasant, measured indoor climate without dust formation due to air circulation without dry air healthy and stable heat no formation of moisture or mold in the masonry flexible installation on the ceiling, wall or freely in the room various designs - round, rectangular, ball-like high-quality surfaces - enamel , glass or coating. We all know how warm the sun's rays feel. It gets under the skin and warms the body from the inside. This type of warmth is especially noticeable when standing in the blazing sun on a beautiful day.

The main advantage of ceramic elements lies in the very large heat transfer area. Also, it is worth noting the almost unlimited service life, the ability to maintain the volume of oxygen in the room and high safety. Some models have the ability to ionize air.

The main component of this equipment is a quartz infrared tube. It is able to heat surrounding objects, which subsequently “throw” heat into the room. Essentially, all objects become sources of heat. Maintaining the required temperature level is carried out using a thermostat. When a specific temperature is reached, the device turns on or off.

Economic Advantages of Infrared Heater

The generated heat is released evenly into the room over several hours as moderate radiant heat. Just like in the past with tile slabs. Room air is not dried out or overheated. The temperature is controlled by a thermostat. The cost of an infrared heater consists solely of the initial cost, installation cost and monthly energy costs. You don't have to worry about space for boilers or anything like that. You don't need space for oil or pellets. Infrared heater "radiators" consist of non-moving parts and are therefore very durable with low maintenance requirements.

What it is

This is a specialized device that provides a comfortable temperature in the room. It is highly efficient - the efficiency of infrared gas heaters reaches 80%.

Externally, IR gas ceramic devices look very respectable - they can be made in different configurations or sizes. The operating principle of heaters allows you to change the shape of the working element without loss of performance.

There are powerful models designed for heating large production areas. There are also compact household appliances designed for use at home. These types of devices are used to heat a dacha.

They are highly efficient and economical, allowing you to create a comfortable temperature in the room in the shortest time periods.

Principle of operation

Infrared heaters have a specific operating principle.

They radiate thermal energy into space, and all surfaces and objects in the radiation zone interact with this radiation. This means that it is not the air that is heated, as happens with convector-type devices, but the objects placed in the room.

A clear example of such an effect is the Sun - it heats the surface of the Earth, and the air is heated by it.

The device of a gas IR heater includes the following elements:

- mixing chamber where gas is combined with air;

- ceramic plates with holes through which the air-gas mixture passes. It burns and heats the plates to 800-900 °C;

- a reflector that reflects radiated heat waves in a certain direction.

Only the main structural components are listed. Many manufacturers are constantly developing and making their own amendments to the design, which makes the devices more efficient and economical.

Varieties

Ceramic gas heaters are available in different modifications, used in certain conditions.

The range of specialized stores includes:

outdoor heater

camp stove

converter

heat gun

fireplace

tiles, etc.

Only the most common design options are listed. It must be taken into account that all heaters are designed to implement the same basic tasks. Their names refer to configuration features rather than functional features.

Manufacturers are constantly developing new models and designs, expanding their range and producing devices with increased functionality.

For example, some models, in addition to heating rooms, can be used for cooking.

Ceramic

The operation of this heating device is based on forced convection. The heating element of the device is made of ceramics. Since the heating element consists of many plates, the device has a significant heat transfer area. This is its undoubted advantage.

Repair issues

The “weak link” of ceramic structures is the fan heater. Sometimes it simply won't turn on. The reasons for this can be completely different:

- When diagnosing, check the serviceability of the fuse and its contacts, as well as the resistance of the transformer windings. If these components turn out to be serviceable, check the voltage of the stabilizer.

- A typical malfunction for “ceramics” is the lack of response to commands from the control panel. As a rule, the breakdown is associated with a quartz resonator. Repair consists of replacing this component.

Instructions for modifying a ceramic heater with your own hands

Do-it-yourself integration of electronic automation into a ceramic heater / Thermoregulator W1209

Ceramic heater

The purchased ceramic heater had three operating modes - fan, heater mode 1 and heater mode 2. The instructions strictly state that when you turn off the heating mode, you must leave the fan on for some time until the massive heating element cools down. This posed the main obstacle to quickly finalizing the heater’s operation scheme. If this condition is not met, there is a serious risk of damaging the plastic case over time. But there are no insurmountable obstacles, especially since life in 2022 has forced us to save on everything; in short, we managed to start the heater in safe mode with our own hands.

Disassembling a ceramic heater

This heater has a reasonable design and to access the main electrics, you just need to unscrew the 4 screws securing the leg cover with your own hands. We unscrew them and gain access to the display board. The heater circuit is simple. Look at the photo. Indication circuits are connected in the power supply circuit of the fan and two heaters. The operation indicator has been carefully removed as unnecessary. Only two decorative red LEDs were left, which had never lit before; it turned out that the polarity of their activation was reversed. After dismantling the display board, gaps appeared in the power wires of the fan and heaters along the neutral wire, which will be used to connect to the control circuits.

Possible causes of failure

Before you begin inspecting and repairing the heater, be sure to disconnect it from the power supply by unplugging the plug. To understand how to carry out repairs, the first step is to find out the cause of the breakdown.

If the IR heater suddenly stops functioning and the lamp on the power indicator does not light up, then first you need to check the voltage in the outlet. Perhaps due to a voltage drop, the circuit breaker at the input of the wiring to the house was activated, thereby turning off the electricity. The contact at the point where the device is connected to the socket could also be broken, or the socket itself could be faulty. It also happens that the heater simply overheats, and shutting down is the work of its protection systems.

If all the checks did not lead to the desired result, and the IR heater still does not work, then it is necessary to undertake repairs.

Review of the KOVEA Fire Ball heater. Video

An overview of the advantages and disadvantages of the KOVEA Fire Ball KH-0710 gas heater is presented in the video below.

Today there are a huge number of options for heating a home or cottage. One of the main types of fuel is gas. An important advantage of this type of fuel is that if there is no main gas pipeline in the area, its presence can be compensated by liquefied gas in cylinders. Gas heaters have a high degree of efficiency and relatively low operating costs. An online forum where consumers leave their reviews about a particular type of product will help determine which heater will be the most effective for a particular case.

Gas equipment repair and possible malfunctions

During the operation of gas equipment, it may need to be repaired. Repair of gas equipment is necessary for the following main reasons:

Regulatory requirements for the room for installing a gas boiler.

- Manufacturing defect.

- Incorrect installation.

- Everyday use is done incorrectly.

- Blockages in the supply ventilation or flue.

- Voltage surges that prevent the piezoelectric element from working.

- Gas is supplied, but the burners do not light.

- Automatic shutdown of equipment that occurs immediately after it is turned on.

- During operation of the gas device, an unpleasant odor appears.

Such malfunctions of these devices can occur for various reasons. For example, in the case when gas flows, but the fire does not burn, the cause of the malfunction may be the supply of low-quality gas. The reason for turning off the heater may be carbon dioxide, or rather, its increased content. The smell of gas may mainly indicate the end of the gas in the cylinder. In rare cases - about a panel malfunction.

You can only change the cylinders yourself after refilling them. Also tightening the clamps and adjusting the flame power jets. All other types of work to troubleshoot gas appliances should be done by professionals with specialized training and experience. They must have a certificate to carry out such work classified as hazardous.

The certificate is issued only after completing special training. Such preparation will allow you to determine the true cause of the malfunction. A mistake in such a matter can lead to very serious consequences. These include suffocation, fire or explosion.

Calling specialists for inspection and possible repairs should be done in the following cases:

- Malfunction of the ignition system.

- Clogged internal heater systems.

- The unpleasant odor does not disappear after airing the room.

Before starting repair work, you should carry out a comprehensive diagnosis of the boiler and determine its malfunction. After identifying the cause of the malfunction, an estimate is drawn up and the price of the work is determined.

Questions and answers

Let's look at the most common questions that inexperienced users have. The answers will provide significant time savings and eliminate the possibility of errors.

Is it possible to sleep with the heater on?

Manufacturers claim that the devices are completely safe and do not require constant attention. However, experienced users recommend turning off or at least setting the heating mode to minimum, as well as opening the windows or setting the shutters for micro-ventilation.

How long does it take from the moment the heating is turned on until the temperature rises?

As a rule, the effect of heaters begins to be felt from the very moment they are turned on. However, if the room is large, you will have to wait from a few minutes to half an hour.

Can I connect a regular propane tank to the heater?

This depends on the type of connector installed on the connecting hose. Different models may have their own design features, however, all the necessary adapters are commercially available.

If the room is large, is it possible to install two heaters?

There are no fundamental objections to the use of several devices in one room. You just need to take into account the specifics of the device’s operation and direct the heaters to different points. If they radiate to one point, there is a danger of overheating the floor covering or furniture. This can cause swelling and deterioration of finishes.

How dangerous are such heaters in terms of gas leakage?

Any gas equipment creates a certain danger and requires compliance with certain rules. Before starting use, you must carefully study the manufacturer's instructions and strictly follow its points. Then the danger from using the devices can be reduced to a minimum.

Pros and cons of the device

Gas infrared heaters with ceramic plates have a number of advantages that have made this type of heating device in demand and popular.

Advantages

All the best ceramic infrared heaters are energy efficient, as they consume 50% less fuel than heaters that run on liquid fuel or electricity. In addition, the cost of gas is incomparably lower than electricity, which makes heating less expensive. Experts estimate that IR devices save up to 40% of electricity.

Infrared heaters are reliable due to their design simplicity; the average lifespan of the device is 30 years.

Important! IR structures are made in such a way that they can quickly heat a room, while the heat flow can be directed, and the heaters themselves can be placed on the floor, wall or ceiling. Such heat does not dry out the air, does not affect human well-being and does not raise dust.

Modern models allow you to program the indoor microclimate.

You can install the device yourself without spending a lot of time and effort. Autonomous devices are lightweight and durable, their size does not exceed 20x20 cm.

Are there any disadvantages?

There are few disadvantages to this design, and the main one is related to the fact that the device, which runs on gas, is quite unsafe in terms of fire. Hence the increased requirements for compliance with operating rules. Failure to comply with the rules can lead to a gas explosion or fire.

To prevent such troubles, it is necessary to thoroughly ventilate the room where the heater is installed, and if the device runs on natural gas, a chimney must be made for the house. It is a good idea to install a gas analyzer in the room, which will give a signal if there is a leak.

It must be said that manufacturers take safety requirements seriously, so many models are equipped with various protective systems, such as:

- turning off the gas supply if the burner goes out;

- shutting off the fuel supply if the carbon dioxide concentration exceeds 1.5%;

- turning off the gas supply if the device has fallen or tilted;

- from splashing water;

- shutdown when the device overheats.

The more advanced the model of a ceramic gas heater, the more built-in protective mechanisms are in the design.

Consumers also include the high cost of devices and the need for preventative maintenance every year as disadvantages.

Advantages and disadvantages

The advantages of a ceramic heater include:

- Fast heating.

- Compared to heating boilers, fuel savings reach 50%.

- Installation of heaters is possible at a height exceeding 60 m.

- Possibility of changing the direction of heat flow.

- Autonomy, independence from electricity.

- Compact, easy to transport.

- Easy installation.

Among the shortcomings, users noted:

- High cost.

- The need for equipment cleaning and annual maintenance.

Types of infrared radiation sources

The simplest sources of IR radiation include the familiar incandescent lamps that operate at low voltage. Under such conditions, they mainly emit infrared streams. The share of light electromagnetic waves is insignificant, but it is still determined optically.

Nowadays, private consumers, construction and production organizations have many different types of IR emitters at their disposal.

The scope of their application is determined by:

- operating temperature;

- maximum wavelength value;

- zone in which the infrared flux is distributed evenly.

Taking into account the listed characteristics, a radiating device is selected that is designed to solve specific problems.

The most common types of IR emitters include:

- Lamps with mirror reflecting devices. At maximum radiation, their wavelength is 1.05 microns.

- Quartz tube lamps. Their wavelength at maximum radiation is in the range from 2 to 3 microns.

- Rod non-metallic heaters. Structurally, they are supplemented with reflectors, the maximum wavelength is from 6 to 8 microns.

- Tubular electric heaters. Widely used in everyday life, used in production are devices with heating elements.

- Infrared burners. They are equipped with ceramic or metal perforated nozzles. They are used in construction for heating open and closed areas during the construction of a building and finishing work.

Sources of infrared rays have found application in farming. With their help, young birds and newly born pets are heated. Emitters are installed in greenhouses to stimulate the growth of cultivated varieties, in barns and granaries for drying.

Sources of infrared fluxes are divided into:

- Infrared lamps. These are “light” emitters and devices that supply thermal radiation.

- Heaters. Devices used for heating confined spaces and open spaces. These include models that run on electricity, liquid or gaseous fuel. The heating element can be either a heating element or a spiral made of a high-resistance alloy.

According to the classification by wavelength, infrared sources are divided into two main groups: dark and light. The former work by releasing long waves into space, the latter - short ones.

Infrared heaters

IR heating elements are used in a wide variety of devices. They are mainly used to equip infrared heaters for heating rooms and open areas. IR heaters create comfort in homes, industrial workshops, offices and other areas without drying out the air. IR heaters are also used in process equipment for uniform and high-precision heating of materials and surfaces.

A striking example of installations for technological use include IR soldering stations, laboratory cabinets and heating furnaces. In modern soldering, IR heaters are used to solder group printed circuit boards with SMD components.

What is infrared radiation and how does it work?

In nature, IR radiation belongs to one of the components of the solar spectrum. Infrared rays belong to the lowest frequency zone of sunlight. It is thanks to this spectrum that our planet receives thermal energy. The IR stream of rays penetrates the airspace without any obstacles, without wasting energy on heating the atmosphere. All physical bodies can be heated, including the earth and various objects that get in the way. The air space, in turn, receives heat secondarily, that is, from already heated surfaces. There is a law of physics involved here, which states that warmer bodies give up energy to colder ones. This is why the air at night is much cooler than during the day. Therefore, IR heaters that are part of household and industrial installations also work on the same principle.

Naturally, the spectrum of individually produced IR heaters is not as wide as the IR rays of sunlight and is located in the region of infrared waves with a length of λ = 50-2000 microns. The fact that the lower the temperature of the heated body, the longer the wave is also taken into account. In total, the range of infrared radiation is much wider and is divided into three categories depending on the wavelength:

- short waves: λ = 0.74—2.5 µm,

- medium wavelength: λ = 2.5—50 µm,

- long waves: λ = 50-2000 µm.

IR heaters perform their tasks efficiently only in the long-wave spectrum. Different types of IR devices are the basis for the production of IR heating equipment. Since thermal energy from infrared heaters is often transmitted by radiation, they are classified as emitters.

IR heater design

In essence, the design of an infrared heater is simple: the heating element - the emitter is placed in a housing (its design can be different), inside the housing there is a reflector - a reflector, terminals for connecting the heating device to the network, and outside there is a terminal for external leads.

A heater of this design is very similar to a spotlight for halogen lamps used to illuminate advertisements, building facades, porch steps, and part of the yard near the house. Simply put, such heaters are used for relatively small areas for local lighting. IR heaters are convenient to maintain certain temperatures in individual areas without wasting energy on heating the entire area of the room.

Spot IR heating

Using such a heater, you can create a directed heat flow. For example, in a cafe, such a device can be used to heat local zones at individual tables. Attach the IR emitter to the ceiling like a lamp.

Full heating

There are a large number of such devices, because with their help you can heat fairly spacious rooms: workshops, warehouses, workshops, and small areas in open space. An example of outdoor heating is verandas and gazebos, restaurant terraces, etc. Full heaters use a carbon lamp.