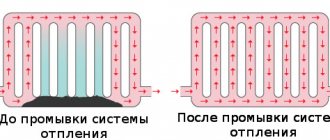

Over time, the heating system becomes dirty inside. Not only scale, but also dirt, debris, iron oxide and other deposits accumulate on the pipe walls. The thermal conductivity of the pipes decreases, and more energy is needed to warm the air in the room to a standard temperature. Corroding areas spread over a large area, which over time leads to damage to the integrity of the pipes and reduces their service life. Therefore, the internal surface of the circuit and other elements of the system requires periodic cleaning. For this, various chemical compositions are used. Here are the TOP 10 products that will help you cope with the task.

Signs of circuit contamination

The system must be flushed in the following cases:

- the temperature in the room dropped without reason while the boiler was on;

- pipes heat up slowly;

- with a hot pipeline, the radiators remain cold;

- the integrity of the pipes is compromised, fistulas appear and ruptures occur;

- The boiler is noisy.

In addition, the heating system must be flushed immediately after installation. During equipment installation, debris, oils, and other products may have gotten inside.

The heating system must be flushed immediately after installation.

Preventive actions

It is necessary to flush the heating when the lines become dirty or during preparation for operation before the heating season. Events are regulated by technical standards and require strict adherence to safety rules. The procedure includes the following steps:

- You should start flushing the heating with a visual inspection and instrumental measurements in order to identify faults and defects.

- Necessary routine repairs of parts and assemblies or replacement of failed elements.

- Washing the heating complex and its elements.

- Instrumentation testing and calibration.

- After cleaning the insides of the complex and putting it into operation, a pressure testing procedure is performed. These hydraulic tests are needed to test the reliability and performance of communications and elements.

- Laboratory analyzes of coolant fluid.

- Documentation of the preventive measures taken and delivery of the facility to the customer and supervisory authorities.

TOP 10 products and liquids for flushing heating systems

| Photo | Name | Rating | Price | |||

| Ready solutions | ||||||

| #1 | HeatGUARDEX Cleaner 808R | ⭐ 5 / 5 8 — votes | Find out the price | |||

| #2 | GEB G30 Desembuant | ⭐ 4.95 / 5 8 — votes | Find out the price | |||

| Powders | ||||||

| #1 | SteelTEX ZINC | ⭐ 5 / 5 2 - votes | Find out the price | |||

| #2 | G63 | ⭐ 4.95 / 5 | Find out the price | |||

| Concentrates | ||||||

| #1 | SYNTILOR Watesup All | ⭐ 5 / 5 3 - votes | Find out the price | |||

| #2 | YNTILOR Watesup | ⭐ 4.95 / 5 1 - voice | Find out the price | |||

| #3 | TELAKKA HEAT | ⭐ 4.9 / 5 3 - votes | Find out the price | |||

| #4 | Heat Guardex Cleaner 824R | ⭐ 4.85 / 5 3 - votes | Find out the price | |||

| #5 | ARGUS SUPER POWER | ⭐ 4.8 / 5 | Find out the price | |||

| #6 | DIXIS LUX | ⭐ 4.75 / 5 4 - votes | Find out the price | |||

Which heating system flushing product would you choose or recommend?

Take the survey

Powders

G63

The powder removes scale from the heating system. The finished solution is compatible with cast iron, metal, and aluminum surfaces. When saturated with scale, the solution turns brown. The product is used in a concentration of 25–100 g/l of water. Washing is carried out at a temperature of 30...40 °C.

Price: from 61$/2 kg.

Descaling powder - G63

pros

- with corrosion inhibitor;

- contains a scale saturation indicator;

- suitable for steel;

- The line includes an acidity neutralizer;

- contour processing in 45 minutes.

Minuses

- high price.

SteelTEX ZINC

The drug is compatible with most metals used in heating systems, enameled surfaces and zinc. Before pouring the finished solution into the system, mix it with water until a concentration of 7–15% is achieved; more powder is added during the washing process. The composition includes an indicator of residual acidity. It is recommended to use it with a neutralizer of the same line, which will enhance protection against metal oxidation.

Price: from 4557 rub./5 kg.

SteelTEX ZINC

pros

- the solution can be poured into the sewer;

- compatible with most metal surfaces;

- anti-corrosion protection.

Minuses

- No.

SteelTEX ZINC

Ready solutions

GEB G30 Desembuant

The product can be used not only in metal, but also in plastic pipelines. 1 liter of solution is designed for 100 liters of coolant.

Price: $14.

GEB G30 Desembuant

pros

- suitable for plastic pipes;

- compatible with underfloor heating systems;

- small expenditure of funds.

Minuses

- high price.

HeatGUARDEX Cleaner 808R

A product based on hydrochloric acid is designed to combat long-term deposits older than 3 years. The manufacturer promises that flushing with the drug will extend the life of the heating system by 10 years. 1 liter of the drug is designed for 100 liters of coolant.

Price: 3990 rub./l.

HeatGUARDEX Cleaner 808R

pros

- easy to use;

- effective in combating heavy pollution.

Minuses

- not identified.

Filter materials for water treatment systems HeatGUARDEX Cleaner 808R

Recommendations from experts

Most often, those sections of the pipeline that are located next to the heating unit become contaminated. It is these areas that are most susceptible to thermal influence, so they must be cleaned annually.

If the heating system has not been cleaned for 10 years or more, then it is completely dismantled and thoroughly washed. After completing the work, it is necessary to check all clamping and threaded fittings that are mounted on the line, as they also often become clogged.

If the contamination is minor, you can remove it manually. If the fittings are in poor condition, and washing does not help remove deposits, then it is more advisable to replace them with new ones.

Comparison of consumption and cost of different heating system cleaning products

| Type | Name | How to breed | Cost per 1 liter (kg), rub. |

| Concentrates | DIXIS LUX | 1 liter per 10 liters of water | 153 |

| ARGUS SUPER POWER | 1 liter per 10–15 liters of water | 300 | |

| Heat Guardex Cleaner 824R | 1 liter per 30 liters of water | 6400 | |

| TELAKKA HEAT | 1 liter for 5–10 liters of water | 450 | |

| SYNTILOR Watesup | 1 liter for 5–15 liters of water | 480 | |

| SYNTILOR Watesup All | 1 liter for 5–15 liters of water | 320 | |

| Powders | Descaling powder - G63 | 25–100 g/l | 2250 |

| SteelTEX ZINC | 1 to 15 | 911 | |

| Ready solutions | GEB G30 Desembuant | 1 to 100 | 975 |

| HeatGUARDEX Cleaner 808R | 1 to 100 | 3990 |

How to choose a liquid for flushing the circuit?

It is necessary to select a means for flushing the circuit taking into account the material from which the pipes and radiators are made. This information is indicated in the instructions for the drug.

The type of coolant also matters - water or antifreeze (propylene glycol, ethylene glycol, glycerin). Thus, systems operating on “anti-freeze” systems are characterized by the deposition of sludge and glycol residues formed during the decomposition of the coolant. Other active ingredients are used to dissolve them.

Ideally, before flushing the circuit, regardless of the type of coolant, it is recommended to analyze the composition of the coolant and, depending on the substances contained in the circulating medium, select a product. But it is clear that at home no one will burden themselves with unnecessary complications. Therefore, masters use the product they trust the most.

Means and liquids for flushing heating systems

Dosage forms

Reagents for flushing the heating system are divided into three types according to the dosage form:

- powders;

- concentrates;

- ready-to-use formulations.

Powder and concentrated forms are diluted with water before use. The third type is immediately poured into the system.

Active substance

Circuit cleaning products are usually based on acids - citric, phosphoric, hydrochloric, acetic, citric. Alkali-based detergents are also produced. The second ones clean more delicately. But they are usually used only in certain areas - for example, to clean the membrane.

Flushing the boiler circuit with a special liquid

Attention! Acidic products must be used with extreme caution on old metal pipes. If pockets of corrosion have formed on the inside, then under the influence of acidic agents, a leak may occur in these places after cleaning.

Other components

In addition to acids and alkalis, the composition includes surfactants - surfactants that wash away the dirt accumulated inside the circuit and prevent it from re-settling on the pipe walls. The rinses also include components that prevent metal corrosion.

Some manufacturers add color indicators to indicate the chemical activity of the product. If the color changes at the very beginning of the wash, this means that the concentration is too low and needs to be increased.

Attention! Spent products are often prohibited from being discharged into the sewer system. First it must be neutralized with a special solution.

But some manufacturers add additives to their products that make the cleaner biodegradable. This point should always be clarified in the instructions or with the seller.

Video - What is better for the heating system: water or anti-freeze

Method for performing centralized battery cleaning

To clean cast iron batteries properly, you will have to contact a utility service or a special construction company. In this case, the hydropneumatic method is used for flushing. At the same time, water is supplied to the riser under strong pressure. Compressors operating intermittently supply air to the system, which is mixed with water. The air-saturated liquid is fed into the system, where microbubbles hit the walls of the batteries and break off microparticles of debris and dirt. Thus, blockages are gradually washed out of the batteries and channels.

Although this method is considered quite effective, it requires some preparation. However, before washing cast iron batteries, they will not need to be dismantled. However, some owners prefer not to waste time and effort on coordinating with neighbors and ordering services from the utility service, but simply remove the radiator and clean it themselves.

Flushing technology

To flush with chemicals you will need:

- the remedy itself;

- a container into which the liquid will be drained;

- pump;

- hoses.

Important! When working with substances, you need to wear personal protective equipment. If a chemical reagent gets on the skin or mucous membranes, you need to rinse the area with plenty of running water and see a doctor.

Washing with solutions is carried out in the following order:

- Water is drained from the heating system.

- Mix the powder or concentrate in the proportions specified by the manufacturer.

- Pour in the cleaning solution. 1 liter of the drug usually corresponds to 1 liter of the volume of the heating system element. That is, a pipeline volume of 100 liters will require the same amount of liquid.

- Connect the pump and pump the chemical through the circuit for several hours.

- Drain the detergent.

- Refill the system with water.

When using ready-made solutions, drain the coolant from the system in a volume corresponding to the amount of cleaning agent and replace it with a cleaner. In this case, washing may take longer - up to 5 days. After this, the contents of the circuit are removed, the system is washed, and then water or “anti-freeze” is poured into the pipes.

Attention! It is recommended to carry out flushing every 2–3 years.

Timely flushing will extend the life of the heating system. In addition, you will not have to overuse energy resources to ensure a comfortable microclimate in your home.

Video - Do-it-yourself flushing of a heating battery using a vibration pump

What will you need?

To flush your heating system yourself without disassembling the radiators, you will need specialized equipment (CIF), which is called cleaning in place. It is necessary for the pump to give direction to the movement of fluid in the system. The installation is a plastic container with a pump. In addition, you will need a cleaning solution. It will be poured into the tank and the system will be filled using a pump.

Such equipment is selected based on several factors.

- The cleaning system must be automatic with pulse control for flushing.

- The product body must be resistant to the use of various disinfectants.

- Size and weight are important, because with large dimensions it will be difficult to use the equipment. The optimal option will weigh 7-8 kg.

- It is desirable that the device has an indicator of water pressure and flow, and a flow reverse.

- The container should hold between 10-20 liters.

If you plan to mechanically clean radiators, you need to prepare containers for draining dirty liquid, unnecessary old rags that absorb moisture well, as well as polyethylene so as not to harm the floor covering at the cleaning site or while moving the radiator for washing. In addition, you will need keys, a gas burner or kerosene lamp, a hose to match the size of the heating pipe, a cleaning cable and an iron brush. When using the chemical method, you will need a reagent that does not destroy batteries, a compressor, or an apparatus for introducing liquid into the heating system. Choose a reliable machine; cost savings in this case may affect the quality of washing. This takes into account the type of cleaning material used.

Voting for the best means for flushing heating systems

Which heating system flushing product would you choose or recommend?

HeatGUARDEX Cleaner 808R

25.00 % ( 8 )

GEB G30 Desembuant

25.00 % ( 8 )

SteelTEX ZINC

6.25 % ( 2 )

G63

0.00 % ( 0 )

SYNTILOR Watesup All

9.38 % ( 3 )

YNTILOR Watesup

3.13 % ( 1 )

TELAKKA HEAT

9.38 % ( 3 )

Heat Guardex Cleaner 824R

9.38 % ( 3 )

ARGUS SUPER POWER

0.00 % ( 0 )

How to clean the heating system in a private house yourself: a review of excellent methods

Comfortable warmth in your home in most cases depends on the constant operation of the heating system. In this regard, heat supply maintenance is considered the key point.

One of the most important options for caring for a heating system is washing the pipes and elements of the heating system.

You may immediately have several reasonable questions:

— Why wash the system?

— Is it possible to make this working volume independently?

— What are the methods for flushing heat supply?

The purpose of this article will be detailed and comprehensive answers to the questions that have arisen.