Installing a warm water floor makes life in an apartment much more comfortable in winter. If the rooms have an area exceeding 50 sq. m, then a pump will be needed to ensure the movement of the coolant. When choosing, you need to consider the design features, only then can you count on reliable and trouble-free operation of the pump.

Installation of a pump for heated floors Source bouw.ru

Heated floor pump - selection and installation

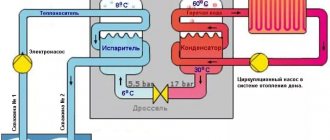

To ensure the operation of the mixing unit, which lowers the temperature of the coolant for the heated floor, an additional circulation pump is needed. Which mainly ensures the movement of the coolant along the contours (loops) of the heating pipeline.

In this case, when the temperature of the coolant is formed not by the mixing unit, but in some other way (RTL adjustment, boiler, solar collector, external mixer), then the pump in the heated floor circuit will most likely not be useful, the general one in the heating system will be enough .

But in most cases, heated floors are created with their own pumping and mixing unit.

The pump for water heated floors can be selected based on technical aspects and other characteristics (including the manufacturer’s brand). The calculation depends on the area of the house, water temperature, degree of insulation of the room and weather conditions of the area. You can install such a device without the help of others, but only if you have the appropriate abilities. Errors in pump installation will inevitably lead to air congestion and a drop in performance.

Wet pump

A design feature is that the rotor (moving part) has specific contact with the coolant. Crude pumps are a balanced option for heating a personal home.

The equipment's performance is only sufficient for small circuits. The device is not suitable for high-rise buildings with a large heated area.

Practical recommendations for the maintenance and operation of circulation pumps

Circulation pump

In order to extend the operating time of the circulation pump, you need to follow several rules.

1. The body of modern pumps is made of fragile stainless alloys, and not of cast iron, as was previously done. Do not tighten the connecting elements with great force, do not use tow for sealing. To avoid leaks, it is strongly recommended to use only modern tapes. They hold water pressure perfectly, and to completely seal the connections there is no need to tighten the nuts too much.

2. The pump must be located in such a place that, if necessary, repair work or routine maintenance can be carried out without problems. Foreign manufacturers produce very high-quality pumps, but taking into account domestic operating conditions and the chemical composition of water, it is recommended to check their technical condition before each heating season

Particular attention should be paid to the integrity of the oil seal to waterproof the pump shaft from the rotor. If the water contains a lot of dissolved calcium, then over time hard deposits form on metal surfaces, damaging the seal.

They must be carefully removed.

3

Before starting the underfloor heating system for the first time, it is important to completely remove all air pockets. To do this, you will have to change the water in the system several times and, if necessary, install a special valve

The presence of air pockets creates obstacles to the movement of coolants, the floor heating temperature is lower than the set one. The automation constantly turns on the pump, as a result its operating time increases significantly, and the warranty service life is exhausted prematurely.

If all installation work is carried out in accordance with the recommendations, the power and performance indicators of the pump are selected correctly, technical routine work is carried out in a timely manner and in full, that is, a guarantee of the effective functioning of the floor heating system.

Is it possible to lay laminate flooring on a heated floor?

You will find out whether it is possible to lay laminate flooring on a heated floor, on linoleum, parquet boards, whether a heated floor is needed in the house, in the hallway, in the corridor, whether a heated floor is harmful.

Heated floors have become very popular due to the comfort and warmth they provide to the home. choose laminate as a decorative layer for a warm Not only does it have an affordable price, but also good wear resistance, but is it possible to lay laminate flooring on a heated floor?

In this matter, it is worth keeping in mind that warm floors can be different, and therefore the laminate needs to be selected correctly. Floors of this type can heat up at different intensities, and this directly affects the quality of the coating.

READ Installing a maunfeld hob into a worktop

In principle, laminate can be laid on electronic, water and film heated floors, just like linoleum and parquet boards, if during installation all requirements for the use of the building material were met.

Film floors are ideal for laminate flooring. They moderately heat the surface and are correctly adjusted using a special device.

In a water field, the thickness of the screed cannot be less than 30 mm. In this case, it will be difficult to regulate the temperature, since it is pumped up more slowly. If you plan to connect such a floor to central heating, then laminate cannot be installed.

With an electronic warm field, the screed cannot be thicker than 30 mm, otherwise there will be excessive energy consumption. To establish the desired level of control, you need a reliable system.

Data for calculations

Calculations and design are based on several characteristics of the room, as well as the choice of heating option - main or additional. Important indicators are the type, configuration and area of the room in which the installation of this type of heating system is planned. The optimal option is to use a floor plan indicating all the parameters and dimensions necessary for calculations. You are allowed to take the most accurate measurements yourself.

Heated floor calculation schedule

To determine the amount of heat loss, you will need the following data:

- the type of materials used in the construction process;

- glazing option, including type of profile and glass unit;

- temperature indicators in the region of residence;

- use of additional heating sources;

- exact dimensions of the room area;

- expected temperature in the room;

- floor height.

In addition, the thickness and insulation of the floor, as well as the type of floor covering to be used, are taken into account, which has a direct impact on the efficiency of the entire heating system.

When performing calculations, you should take into account the desired temperature for the room being equipped. Consumption of underfloor heating pipe depending on the loop pitch

Consumption of underfloor heating pipe depending on the loop pitch

| Pitch, mm | Pipe consumption per 1 m2, m p. |

| 100 | 10 |

| 150 | 6,7 |

| 200 | 5 |

| 250 | 4 |

| 300 | 3,4 |

Do you need a pump for underfloor heating? Detailed answers.

Before wondering whether a pump is needed for a heated floor, it is worth knowing how much heat will be needed to heat the room.

To choose a pump, you need to control two parameters: productivity, which is determined in cubic meters per hour, and pressure. When choosing a pump, performance should be in reserve. Approximately 20% of the total amount of water distilled during the specified period of time. This is the only way the equipment will last longer.

The pressure exerted by the pump must be such that it can successfully overcome all the twists and turns in the heating system.

Additional criteria for using a pump are the type of coolant and temperature. Remember that during operation, such equipment produces additional noise in the house, which can be minimized if the running parts are regularly lubricated.

Due to the fact that there is a sharp change in pressure in the heating system, when choosing a pump you need to take into account the power of the unit. It must exceed that which characterizes the heating system.

Typically, the flow rate in the system is variable, so it is best to take adjustable equipment. It is important to keep in mind that all loops in the system must be balanced against possible fluctuations.

Criteria for proper selection of equipment

All installation efforts will be reduced to zero if the equipment is selected incorrectly. In order not to make a mistake, it is necessary to first analyze all aspects of a particular heating system and make the necessary calculations.

Main types of pumps

According to their design features, all devices are divided into 2 categories: with a wet and dry rotor.

Wet type pumps. This option is suitable for private homes. The unit is compact, almost silent and has a modular structure that is convenient for maintenance and repair.

But, unfortunately, it does not have high productivity - the maximum efficiency of modern models reaches 52-54%.

Circulation devices for heating networks should not be confused with similar devices for hot water supply. The heating pump does not require an anti-corrosion bronze or stainless steel housing and additional protection against scale - accordingly, it is cheaper

Pumps with a dry rotor are productive, unpretentious to the quality of the coolant, capable of operating under high pressure and do not require a strictly horizontal position on the pipe. However, they are noisier, and their operation is accompanied by vibration. Many models are installed on a foundation or metal support frame.

For installation of console, monoblock or “In-line” models, a separate room is required - a boiler room. It is advisable to use them when a flow rate of more than 100 m³/h is required, that is, for servicing groups of cottages or apartment buildings.

Brief overview of technical characteristics

When choosing a pump, you should definitely study the technical characteristics and compare them with the requirements of the heating system.

The following indicators are important:

- pressure that covers hydraulic losses in the circuit;

- productivity - volume of water or supply over a certain time interval;

- operating coolant temperature, max and min – for modern models on average +2 ºС… +110 ºС;

- power – taking into account hydraulic losses, mechanical power prevails over useful power.

Structural details are also important, for example, the inlet/outlet diameter of the pipes. For heating systems, the average parameters are 25 mm and 32 mm.

The number of electric pumps is selected based on the length of the heating main. If the total length of the circuits is up to 80 m, one device is sufficient; if more, additional devices will be required

An example of a unit for equipping a residential heating network with an area of 100 m² is a Grundfos UPS pump with a 32 mm pipe connection, a capacity of 62 l/s and a weight of 3.65 kg. The compact and low-noise cast iron device is inaudible even behind a thin partition, and its power is sufficient to transport liquid to the 2nd floor.

Pumps with built-in electronics allow you to quickly switch equipment to a more convenient mode depending on changes in temperature or pressure in the network. Automatic devices are equipped with digital displays that provide maximum information on the operation of the pump: temperature, resistance, pressure, etc.

Additional information on the calculation and selection of a circulation pump for heating is presented in the articles:

- How to calculate a heating pump: examples of calculations and rules for selecting equipment

- Selection of a circulation pump: device, types and rules for choosing a heating pump

- Circulation pump for heating: ten best models and tips for buyers

Do you need a pump for a warm water floor?

Oasis

The pump is suitable for installation in underfloor heating systems of apartments and houses. Made by the Chinese brand Forte. It is characterized by a long service life, thanks to a body made of cast iron or duralumin, and small dimensions.

The models have 3 high-speed modes, but it is recommended to use them with clean, not very dirty water (for comparison: some Wilo devices can work even in harsh environments).

At the same time, many buyers call Oasis pumps the best option for economical floor heating systems, because they are cheaper than their European counterparts.

How to calculate a pump

Attention should be paid to flow and pressure - productivity. The hydraulic resistance overcome by the pump is equal to the maximum pressure in the pipes, and the flow rate is 0.

The selection of the model is based on the volume of the coolant. Based on this, the hydraulic resistance is calculated. Heat loss is affected by:

- thermal conductivity of materials;

- fencing;

- location of the house relative to the cardinal directions;

- temperature in the environment.

After calculating the coolant flow, it is necessary to determine the resistance parameter in the heated circuit. For this, standard tables are used. Once finished, you can begin choosing a model.

As an example, we can take a pump for a house with an area of 200 m2. Inside the equipment there is a two-pipe system of pipes with a diameter of 32 mm, length - 50 m, material - polypropylene, temperature chart - 70-90 degrees. The losses are equal to 24 kW at a mass flow of 1.03 m3/h. Further, the table determines the hydraulic resistance, in this case - 1.8 mbar/linear. m. For a length of 50 meters, the result is 90 mbar. It is necessary to sum it up with the resistance of the system parts, for example, it will be 1 m. As a result, the owner will need a productivity of 1.1 m3/h with a pressure of 2 m. Based on the obtained parameters, you can purchase a device with sufficient characteristics.

Is it necessary, and in what cases?

Many owners of suburban real estate, and especially two-story houses, are interested in the question of installing an additional circulation pump in the heating system. They come to this conclusion after uneven heating of the radiators in the rooms, provided that the boiler has sufficient power. If the temperature difference between the boiler and the coolant in the pipelines exceeds 20 degrees, then you will need to remove air pockets or set the existing pump to an increased speed.

Installation of additional pumping equipment is necessary in the following cases:

- When adding an additional circuit to the heating system, and especially when the pipe length exceeds 80 meters;

- For uniform movement of coolant in pipelines.

An additional pump in the heating system may not be useful if it is balanced using balancing and control valves, so before purchasing additional equipment, bleed the air from the batteries and add water to the system. If everything works fine, then there is no point in installing an additional pump.

Malfunctions and how to fix them

Problems may arise during operation of the circulation pump. One of them is salt deposits on the impeller when water is used as a coolant. The process is especially activated when water is heated above 55 degrees. Therefore, most models have a thermostat; it turns off the device so that the water cools down to the required degree.

But even so, salt will still accumulate a little. When the system is operating, this fact does not significantly affect the pump. But when you turn on the warm water floor after a long period of inactivity, the pump may fail because the salt clogs the rotor. The problem is easily solved; you need to manually rotate the impeller.

Another point that may arise is airing. The reason for the formation of air plugs in a pipeline or unit lies in improper installation or operation of the equipment. There are several ways to avoid this:

- By removing air plugs in the main pipes, this is done before the heating is turned on;

- By installing separators or air valves;

- Carrying out periodic maintenance of equipment - this is especially important to do when unheated zones appear.

To avoid air locks, sudden changes in the temperature level and pressure in the system should not be carried out.

Where to put

In the autonomous heating system of a private home, it is recommended to install circulation pumps with a wet rotor, which rotate without the use of special lubricants. The coolant and lubricating element here are the coolant. When installing such a device, you need to take into account the following rules:

- The pump shaft must be in a horizontal position relative to the floor surface;

- The movement of water flow in the system must coincide with the direction of the arrow on the device;

- To prevent water from entering the pump terminals, the box should be installed on the top or side of the equipment.

Correct installation of an additional pump in the home heating system

According to some users, it is better to install the pump on the return pipeline. Here the coolant temperature is low, which will increase the service life of the device, but not all experts agree with this statement. The fact is that the pump is designed for operation in a coolant environment whose temperature can reach 110 degrees.

How to make a heated floor without a pump, mixing unit and manifold. MULTIBOX

Methods for connecting an additional device: how to install it?

Often additional pumps are installed in the heating or water supply system. There are several reasons for such modernization.

For example, if there is not enough pressure for normal operation of the washing machine, or when installing a heated towel rail, heated floor, or connecting an additional circuit.

The rules and methods for installing an additional device are the same as for the main one. The additional highway is simply regarded as a separate system.

Sometimes such modernization is carried out to strengthen the system in the dead of winter, during severe cold weather. In this case, the drive is connected to a thermal relay-thermostat. Accordingly, when the coolant temperature drops in a given area, additional circulation is turned on, increasing the coolant current.

Reference! Pumps are installed in the water supply system for approximately the same purposes. But only in this case is a system with a timer preferable, since amplification will be required only during peak analysis hours: in the morning and in the evening. The rest of the time, the standard system is sufficient.

The electrical part is easy to connect. According to the marking of the contact group: zero, phase, ground.

Warm water floor pump

A pump for a warm water floor is not the most expensive, but an indispensable element of the heating system, on which the efficiency of its operation (heat loss and efficiency) depends on almost everything.

READ What should be the temperature of a water heated floor?

These are devices whose operating mechanism is based on the development of centrifugal force.

In fact, the main elements of the unit are:

- housing (depending on the size and power of the unit, it can be made of polymer materials, stainless steel and cast iron);

- a shaft with an impeller that draws in and pushes water;

- an electric motor that causes the rotor (shaft) to spin.

Main types of collectors

A stainless steel manifold lasts longer than brass or metal ones.

The operation of the device is as follows: water from the boiler flows into a storage tank. Such a tank is located at a height above the “comb”. The coolant enters the distributor with shut-off and control valves. From the distributor, the flows diverge into separate branches. The output pipes are collected at the bottom of the “comb” to be sent to the boiler for heating.

Usually the unit is a piece of pipe with a certain number of bends. As the technical specifications become more complex, the complexity increases tenfold, the complexity of setting up the automation and installation become many times more complicated.

Made of stainless steel

Stainless steel manifolds are stronger than brass. They have a large flow area that equalizes the pressure of the flows of different coolant consumers. The Valtek heating collector is designed for an average of 50 years of operation at a pressure of 10 atm. and temperatures up to 130 degrees.

Branded models are reliable - even the appearance of a weld does not lead to corrosion. When buying models from cheap manufacturers, you can end up with low-quality metal and surface corrosion.

Made from polypropylene

You can assemble a polypropylene manifold with your own hands from pipes and fittings.

The polymer comb is made from polypropylene pipes. This lightweight material is not as durable as steel, but it will successfully last for many years. Plastic manifolds are extremely cheap. The use is justified when circulating coolant in several heating devices. If your main goal is to save money, this option is suitable.

The stores offer models with fittings and manifolds with shut-off valves.

To switch to a metal product with threads, combination fittings are used.

Plastic combs are common in Ukraine. To strengthen the structure, up to 30% glass fiber is added to the PA66 polyamide in factory technopolymers to increase strength.

The disadvantage of polymer products is their thick walls. They narrow the cross-section of the passage with the same dimensions of the part. Steel components are stronger, the walls can be made thinner - the internal cross-section increases and passes several percent more liquid per unit of time under the same conditions.

Another disadvantage of polymers is oxygen permeability. Fiberglass reinforcement reduces this to a minimum. But oxygen diffusion is present.

The advantages of polymer products are resistance to aggressive environments, electrochemical corrosion, and low thermal conductivity. For the same tube length, polymer loses less heat than steel or brass.

Made of brass

It is recommended to buy brass manifolds with a nickel coating.

This material is a leader in the manufacture of combs. For production in Europe, a hollow brass rod is made. For dozens of years, products were made from it - cut to the required length, holes drilled for flow meters, valves, and threads cut. There are also stamped models on the market.

Due to rising prices for brass, manufacturers switched to cheap materials - steel and plastic. However, brass models are still preferable. They have one drawback - leaching of zinc. But it is leveled out by chrome or nickel plating of the surface.

In low-temperature conditions, the advantages of low expansion of brass are leveled out and are relative.

Warm water floor pump

A pump for a warm water floor is not the most expensive, but an indispensable element of the heating system, on which the efficiency of its operation (heat loss and efficiency) depends on almost everything.

These are devices whose operating mechanism is based on the development of centrifugal force.

In fact, the main elements of the unit are:

- housing (depending on the size and power of the unit, it can be made of polymer materials, stainless steel and cast iron);

- a shaft with an impeller that draws in and pushes water;

- an electric motor that causes the rotor (shaft) to spin.

Design and principle of operation

Operating principle of a warm water floor collector

The device includes the following elements:

- frame;

- a motor equipped with an impeller and connected to the housing;

- parts for connecting parts.

Sometimes the pump is equipped with an air vent, but this is rare. More often they use a special nut - if you unscrew it, the air comes out of the system on its own.

The principle of operation of the mechanism is simple: the liquid is directed into the housing, where, thanks to the rotation of the impeller, it is picked up and released further by pressure. Due to this process, forced circulation of water occurs.

Some pumps have 2 motors installed - this way the equipment will continue circulation even at maximum loads. The second engine is connected if necessary and takes on part of the work. The device is also considered more reliable due to the reserve. However, equipment with 2 motors is more expensive and the owner will have to decide for himself whether such a purchase is reasonable.

The pump is installed at any point in the system - usually at the edge of the supply or return circuit. It is recommended to select the location for installation of overclocking equipment individually. There are no special requirements - the operating temperature is not important, but it would be wiser to install the device where it is lower.

Why do you need a pump?

A special feature of a water floor is that the length of the pipe can exceed 1 m with a maximum diameter of 2 Washing machine. There are several such circuits in the system. The circulation of water is also hampered by turns, of which there are quite a lot in the system. Good circulation can only be ensured by equipping the water heated floor system with a pump. Let's take a closer look at how to choose the right pump , and what points you should pay special attention to.

Manufacturers offer a wide variety of models. They differ in functionality and, naturally, pricing policy. Don't settle for economical options. They have no additional abilities and are usually not durable.

It is better if the floor heating pump has a speed switching function. A balanced option is a three-speed pump. This will allow you to maintain a suitable temperature in the system. Water is supplied to the system at a certain speed. Naturally, movement through the system occurs at the same speed.

When the temperature in the room decreases, the coolant will give off more heat and, consequently, cool faster. And the temperature of the water in the pipes will drop. To prevent this from happening, it is necessary to increase the rate of coolant supply to the system. This type of device can be controlled manually.

If you want to do everything so that the system works without the help of others, then you can automate the mechanism. Now we have everything we need for this.

As for the type of equipment, it is better to purchase a circulation pump for a water floor. Such a device supplies fluid to the system at a given speed. At the same time, unnecessary pressure is not created.

There are wet and dry rotor pumps. The first ones are not very powerful. Therefore, they are not suitable for a huge room. The largest square area they can handle is 400 sq.m. The advantages of this type of equipment include low power consumption and reliability. It is also necessary to emphasize that wet rotor pumps operate very quietly.

If the area of the room exceeds 400 sq. m., then the system must be equipped with a pump with a dry rotor. During operation of such a unit, it is necessary to systematically carry out technical maintenance. Specifically, clean and lubricate.

The next point that you should pay attention to when choosing a device is the presence of an outlet valve. If the underfloor heating system is equipped with air bleed valves, then the presence of a valve is not inevitable. If not, then the air trapped in the pipes will interfere with the circulation of water.

The pumps differ not only in their features, type and multifunctional features, but also in their appearance. Manufacturers offer pumps whose bodies are made of cast iron, stainless steel or polymer material. If the system is 100% sealed, then essentially you can choose any option. If there are doubts about the density, then the metal option will not work. When exposed to air, the metal will begin to oxidize, which will lead to unit malfunction.

Increased attention should be paid to the marking of the device and its dimensions. The marking of pumps implies the presence of two numbers, written with a fraction. The first one shows the diameter of the inlet or outlet holes. Values are indicated in millimeters. The 2nd number indicates the lift height. The marking contains another number, written with a hyphen from the first two. It indicates the installation length.

READ Which pump is needed for heated floors

And, of course, it’s worth talking about the manufacturers. European firms have proven themselves to be the best. There is no point in saving on equipment. The pump itself can be called the “heart” of the system. Therefore, it makes sense to purchase equipment from German manufacturers.

Why is a pump needed in a heating system?

Most residents of the upper floors of apartment buildings are well aware of the phenomenon of cold radiators. This is the result of a lack of pressure in the system necessary for its normal operation. The coolant moves through the pipes slowly and cools down on the lower floors. Owners of a private home may face the same situation: at the farthest point of the heating system, the pipes and radiators are too cold. A circulation pump will help solve the problem effectively.

Please note that heating systems with natural circulation of coolant can be quite effective in small private homes, but even in this case it makes sense to consider forced circulation, since if the system is properly configured this will reduce overall heating costs

In simple terms, such a pump is a motor with a rotor that is immersed in a coolant. The rotor rotates, causing water or other heated liquid to move through the system at a given speed, creating the required pressure. The pump can operate in various modes. For example, by setting the device to maximum, you can quickly warm up a house that has cooled down in the absence of the owners. Then they restore the settings that allow you to get the greatest amount of heat at the minimum costs. There are models of circulation pumps with a “dry” and “wet” rotor. In the first case, the pump rotor is only partially immersed in the liquid, and in the second case, completely. Pumps with a “wet” rotor make less noise during operation.

Warm water floor pump

A pump for a warm water floor is not the most expensive, but an indispensable element of the heating system, on which the efficiency of its operation (heat loss and efficiency) depends on almost everything.

These are devices whose operating mechanism is based on the development of centrifugal force.

In fact, the main elements of the unit are:

- housing (depending on the size and power of the unit, it can be made of polymer materials, stainless steel and cast iron);

- a shaft with an impeller that draws in and pushes water;

- an electric motor that causes the rotor (shaft) to spin.

How many pumps should there be in the heating system?

How to properly install a heated floor pump

The pump is installed between the three-way valve and the underfloor heating manifold. Only in this case will the entire heated floor system work. Mixing unit for heated floors - design

If you install a pump between the connection to the radiator network and the three-way valve, the mixing unit will not be multifunctional, and the heated floor will not work.

The pump is attached to the flanges using union nuts, which are usually included in the kit. Installing a pump usually does not cause any problems if the connections are made correctly, maintaining suitable distances.

Choices, modern pumps

When using modern ALPHA models, it is important to take into account that the “proportional pressure” and “AUTOADAPT” modes are simply not suitable for heated floors - set the appropriate mode.

If the heat loss is greater or the house ( warm floor) is poorly insulated, accordingly, the value of the area of the warm floor at which it is necessary to move from one pump to another shifts to the smallest side... The main role in this is played by the degree of insulation of the warm floor itself. How to insulate a warm floor correct, but clearer values can only be obtained by thermal engineering calculations and calculations of heated floors…. which many consider simply unnecessary...

Connection to an individual heating boiler

The presence of an individual heating boiler in an apartment or private house eliminates all organizational problems in permitting the installation of water heated floors. In this case, connecting a warm water floor does not require any permits. Depending on the location and operation conditions of the facility, boilers can be of various types:

- on gas fuel;

- on liquid fuel (diesel, fuel oil);

- solid fuel: firewood, pellets, coal;

- electrical;

- combined.

In apartments in multi-storey buildings, gas or electric heating boilers are most often used; connecting a heated floor circuit to the central heating system is not required. In this case, the diagram differs slightly, but the functional purpose of the main elements remains the same.

Diagram of a water heated floor system in a private house with an autonomous boiler

Essential elements:

- boiler;

- expansion tank;

- pressure gauge;

- circulation pump;

- manifold for underfloor heating;

Unlike the case with central heating, connecting a heated floor to a boiler does not require installing a three-way valve to regulate the temperature of the coolant. Its installation is not necessary; the temperature can be changed from the boiler control panel. Temperature control sensors are also located on the external control panel.

The expansion tank serves to maintain stable pressure in the system; when heated, the volume of liquid increases. To prevent the underfloor heating collector, pump and other expensive elements in the pipeline system from collapsing, the tank compensates for the expansion of the coolant volume. The pressure gauge shows the pressure in the pipes. The main thing is that before pouring the solution into a warm floor, you need to check the functionality of all components.

Control panel on the boiler body

Regardless of the modification of the device and its manufacturer, all panels have basic options, and some additional programming functions:

- buttons or regulators for increasing and decreasing the supply coolant temperature;

- button for automatically setting a comfortable, economical temperature mode, room temperature – 20-22 ̊C;

- It is possible to program control, set the modes “winter”, “summer”, “vacation”, “function of protecting the system from freezing of liquid”.

How to make specific settings for boilers with different control panels is described in the operating instructions. Filling a water heated floor with a solution for a separate boiler is done in the same way as for central heating.

Remote control panel

Pump parameters

In addition to the availability of additional functions and type, the pumps differ in initial parameters. Specifically, productivity and pressure. Since water will need to be supplied to the system, the performance will be equal to dividing the power of the heating circuit, multiplied by 0.86 and the difference in the supply temperature and the return coolant temperature. This difference is, as practice shows, 500.

If there are several circuits in the system, you need to find the performance of each of them and summarize the obtained results among themselves.

The created pressure depends on the hydraulic resistance of the pipe, its length and the power reserve factor. To calculate the pressure, you need to add the product of the hydraulic resistance of 1 meter of pipe by its length with the power reserve coefficient and divide everything by 1000. The pressure is needed for normal coolant circulation in the system.

Such a parameter as power depends on the quadrature. There are tables corresponding to the heated area and the required pump power. When calculating them, it is assumed that the house is normally insulated and is not located further north or south of the middle zone. Experts advise adding another 20% to this parameter in case of severe frosts.

Purpose

To decide whether installation of a pump is required for a fully functioning system, let’s consider the positive and negative aspects of this solution.

The positive arguments are:

- After connecting the circulation pump to the heating system, its inertia will significantly decrease. Thanks to this, the rate of heating of the system from the moment the boiler is ignited until optimal performance is achieved will significantly increase. The forced-injected coolant will begin to warm up the house within a few minutes.

- The temperature readings of devices located at different points in the system will be equalized. Increasing the speed of movement of the coolant will not allow it to quickly cool down in the interval between supply and return, so that pipes in distant points of the house will also be warm.

- If there are sections of pipes with a slope in the direction opposite to the coolant flow, air pockets may form in the system. Connecting the pump to the heating boiler will increase the pressure drop in the circuit so that the coolant can circulate freely, regardless of the presence of air pockets.

Among the disadvantages of installing a circulation pump are the following factors:

- Fixed electricity costs - for successful use it is necessary to connect the circulation pump to the mains. Although its power at maximum values does not exceed 100 watts, the losses will still be constant.

- The forced circulation of the coolant provided for by the project, if it is the only option, makes the system vulnerable in the event of a power outage. If the movement of liquid along the circuit stops, the boiler may overheat the coolant and damage the pipes, and when the heating is turned off, they may freeze.

Thus, in order to ensure that the heating system can operate under any conditions, at the time of its design it is necessary to provide for both natural circulation and the use of a circulation pump.

Important Installation Features

The main secret of correct pump installation is the horizontal orientation of its rotor. If you install the rotor vertically, the pump will lose up to 30% of its power.

The installation location in water heated floor systems is often the supply branch of the pipeline after the mixing unit.

We calculate the heating circulation pump correctly.

Possible malfunctions and their elimination:

- A frequent problem that besets homeowners at the very beginning of a new heating season is the accumulation of salts on the rotor impeller, especially when using ordinary hard tap water as a coolant.

- If you look at the information “warm floors, water pump and water heater,” you can note that such a heating system is not designed for temperatures above 50⁰C, because at higher temperatures the rotor becomes coked with salt deposits. Not every pump model is equipped with a sensor that monitors the water temperature and turns off the pump until the water temperature returns to normal.

- A device that refuses to pump water can be “stirred up” by turning the impeller a couple of times with a screwdriver. After a few free turns, the device can be installed in place and plugged into the network.

Sources:

https://www.all-answers.ru/index/dom-i-dacha/osobennosti-teplogo-pola https://stroykoblog.ru/stati/nuzhen-li-nasos-na-teplyj-vodyanoj-pol.html https://pilonstroy.ru/raznoe/nuzhen-li-nasos-na-teplyj-vodyanoj-pol.html

Trouble-shooting

The quality of tap water, namely the water used in the underfloor heating system, leaves much to be desired. Some time after using the pump, salts are deposited on its elements in contact with water. If the pump runs continuously, there will be no problems. In the summer months, the heated floor is usually turned off.

And so, after trying to turn it on, problems begin. The pump simply refuses to “pump water”. At the same time, it hums, which indicates the operating condition of the unit. The coolant does not enter the system because the rotor cannot turn. It is necessary, using available means, to rotate the impeller two or three times. If the unit does not start working, then you need to contact a specialist.

When choosing a pump for a heated floor, you need to pay attention to many factors: type of equipment, country of origin, parameters, functionality, etc. If you approach the choice with a certain degree of negligence, the system may not work as desired.

Electric pump installation options

Circulation units are allowed to be installed both at the inlet and outlet of liquid from the pipeline. The installation location is usually selected based on the characteristics of the circuit.

At the water outlet, its temperature is much lower than at the inlet, which is preferable for pumps. But installation at the end of the circuit is not mandatory, since all units are manufactured with a certain margin of safety relative to the maximum operating temperature conditions.