A bypass is a piece of pipe identical to a section of the main, installed in its key places. It is installed only in single-pipe circuits that ensure the flow of coolant through only one pipeline, which originates from the boiler and ends near it. At the same time, the water first leaves the heat generator in the direction of all the radiators of the house, and then, having given up its heat to them, returns to it.

The main difference between two-pipe systems and their single-circuit counterparts is the ability to separate the coolant supplied and returned to the boiler into separate flows. Therefore, for a two-pipe system there is no need to install a bypass. And in the case of one circuit, when both the supply and return are inseparable and flow in one stream, it is simply necessary.

This bypass structure is mounted on contours from one pipe, which can run in 2 planes: vertical and horizontal. This means that the bypass can be installed in different ways. Vertical contours are found in buildings with a height of 2 or more floors, horizontal contours are found in private one-story buildings and apartments.

Depending on the functions assigned to such a bypass structure, the location of its installation is selected: on a pump that drives the coolant through a pipe or on separate radiators.

Regardless of the installation location, the bypass element ensures continuity of fluid flow in the pipeline regardless of the serviceability of the main units. In a heating circuit, the bypass is a spare channel through which the liquid continues to circulate in the circuit, which means that pressure drops and surges will not occur in it.

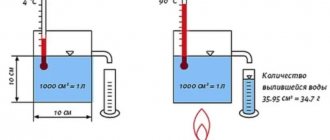

Principle of operation

Photo of the device:

It is not difficult to understand that even initially insignificant defects in the operation of engineering systems and communications can turn into serious problems.

The discomfort and even danger to health caused by heating malfunctions can hardly be overestimated.

That’s why attentive, thoughtful homeowners should be busy preventing such problems. The bypass, which is widely used in heating circuits and plumbing systems, plays a significant role in it.

Its design is not particularly complicated - it is just a jumper in the form of a pipe, supplemented with control devices.

The bypass valve ensures the passage of liquid (drinking water or coolant in the heating system) away from one or another technical unit.

Quite simply, this is a workaround for water in case of unforeseen situations. If everything works normally, the flow moves calmly and measuredly along the jumper.

But under certain conditions, the locking element closes and the liquid rushes away from the previous trajectory. This effect is achieved because the diameter of the bypass is invariably smaller than that of the pipe that supplies water to it.

The use of such a device allows:

- make service work on pipelines much easier;

- increase the efficiency of equipment;

- reduce unproductive energy costs;

- radically solve the problem of filling pipes and other water infrastructure with air;

- guarantee relatively stable performance even in unusual situations.

Sometimes you may come across arguments that installing a bypass is unprofitable. In fact, this is not so - when installing such a device, you can significantly save energy.

The reduction in water supply to the batteries is up to 35%, and therefore it is possible to reduce thermal energy consumption by approximately 15%.

Since many real systems consume a lot of heat, there will be no negative consequences. A more detailed picture can be understood in consultation with specialists.

Connecting the pump via bypass

It is advisable to connect the circulation pump via bypass only in those systems that were originally designed for natural circulation, i.e. they must have an accelerating manifold, pipe slopes must be observed and their diameters must be correctly selected. The pump in such systems is not intended to ensure their operation, but to increase efficiency.

For systems that were designed for forced circulation at the design stage, a bypass is simply irrelevant. Such systems operate only due to the pump, so when it is turned off, the circulation of the coolant simply stops. Bypass in this case will not solve the problem.

When connecting the pump via a bypass line, it becomes possible for counterflow in the bypass. In addition, a closed circulation loop is formed between the pump and the bypass itself. In order for such a circuit to function normally, the bypass device must be equipped with a ball valve or check valve.

When the pump is running, the device blocks the flow of liquid through the bypass pipe. The valve does this work automatically, but the tap has to be adjusted manually. When the pump stops, the bypass opens, which allows coolants from different circuits to mix. A similar scheme is not applicable in the case of injection bypasses - they completely eliminate the possibility of reverse coolant flow.

Types of bypass in the heating system.

In addition to the fact that shut-off valves are installed on the inlet and outlet pipes, they are also installed on the bypass. There are the following types of bypasses, in contrast to the type of fittings:

Fixed bypass pipe

Standard pipe without additional elements. The coolant flows through such a pipe in a free mode. Bypasses of this type are usually used when installing batteries. When installing this type of bypass pipe, it is worth remembering that the liquid from two pipes will choose the one with a larger diameter (lower hydraulic resistance). Accordingly, the diameter of the vertical bypass pipe cannot exceed the diameter of the main pipe.

When installing a horizontal bypass, its diameter is usually equal to the diameter of the main pipe. The pipe going to the heating device should be narrower. The law that applies here is that a medium with a high temperature tends to rise due to its lower specific gravity.

Manual bypass

This is a pipe with a ball valve built into it. The choice of this particular type of tap is due to the fact that in the open position it does not interfere with the flow of liquid at all, and therefore does not provide additional resistance. This type of bypass pipe is convenient in terms of adjusting the amount of liquid flowing through it. It is worth noting that the component internal parts of the ball valve can stick to each other. As a result of this, sometimes you just need to turn it, for prevention. This type of bypass found its main use when installing batteries of a 1-pipe main and when piping hydraulic pumps.

Automatic bypass

Found application in piping the pump of a gravity heating system. Liquid in such a system almost always circulates without the participation of a pumping device. In this case, an electric supercharger is installed in the system to increase the speed of coolant flow. This reduces heat loss and increases the overall efficiency of the system. The liquid in this type of bypass is redirected automatically. When the coolant passes through the device, the bypass pipe closes automatically. When the pump stops due to various reasons (breakdown, power outage, etc.), the liquid is redirected to the bypass. There are several types of automatic bypasses:

Valve automatic bypass

Includes a ball valve, which creates almost no resistance to the free flow of liquid through the pipe in free mode. When the pump is turned on, the flow speed increases. The liquid from the outlet of the pipe is directed into the main line and begins to flow in 2 directions. When moving along a straight path, no obstacles arise, but when moving backwards, the coolant runs into the check valve. One of the disadvantages of this type of bypass is its increased sensitivity to contaminated water. If even small debris gets in, such a system can break down.

Injection automatic bypass

The injection automatic bypass is based on the principle of a hydraulic elevator. On the main line, a pump unit is installed located on a narrower bypass pipe. The ends of the bypass pipe partially extend into the main line. The flow of liquid into the inlet pipe is created due to the appearance of a vacuum area around it. This area arises due to the pumping unit. The coolant comes out of the outlet pipe under pressure with acceleration. Due to this, the reverse flow of liquid is eliminated. In the event that the pump unit does not work, water flows by gravity through the bypass.

What is the difference between a mechanical mod and a boxing mod?

A mechanical mod is the simplest example of an electronic cigarette. The structure contains a battery (power source), a connector, an atomizer, a liquid tank and a drip tip. The classic version without any boards or other electronic add-ons.

It is beneficial to choose a fur mod for the following reasons:

- Compact size and reasonable price. Premium mech mods are more expensive than mech mods, but they are mostly not bought for vaping. Standard vapes will cost several times less than electronics. In addition, these are miniature and convenient devices that are lightweight.

- A mechanical vape allows you to vape on any type of coil. This is a key advantage. On the boxes, the choice is limited due to the functional characteristics of the electronic board.

- With mech mods you can vape on low-resistance coils and even survive the inept attempts of a beginner. At first, it is difficult to wind a good spiral - it will take practice.

- The devices are reliable due to their simple configuration. The board inside will not burn out, any parts can be easily changed with your own hands, which reduces costs, time, and most importantly, helps you vape without forced breaks.

The advantages of mechanical mods have disadvantages. This is easy to check. It is enough to make self-winding, which the battery does not support, and the battery will overheat, and in the worst case, explode.

Another drawback is uneven vaping. The lower the battery charge level, the less steam and, accordingly, the pleasure of use.

Installation rules when installing the pump

Circulation pumps most often crash into the heating system precisely on bypasses. This makes it possible to quickly repair and replace them in the future. In single-pipe systems, the use of a bypass when installing a pump makes it possible to have an unimpeded natural flow of coolant in the event of a power outage.

Install a bypass when installing the pump in compliance with the following rules:

- place the bypass unit about a meter from the boiler;

- the insertion is made into the outlet main;

- during installation, the bypass is aligned and centered along the pipe;

The pump is included in such a circuit, taking into account the position of the arrow marked on the body, indicating the direction of the coolant flow.

Bypasses with manual adjustment

Bypasses that are adjusted manually (manual bypasses) are equipped with ball valves. The use of ball valves is determined by the fact that they do not change the pipeline capacity at all when switching, since the hydraulic resistance in the system does not change. This quality makes the ball valve an optimal option for bypass.

Shut-off valves of this type allow you to regulate the volume of liquid that passes through the bypass section. When the tap is closed, the coolant moves in full along the main line. The operation of ball valves has one important nuance - they need to be turned regularly, even if there is no need to adjust the system. This is due to the fact that if left stagnant for a long time, the taps may become tightly stuck and will have to be replaced. Sometimes a heating system feed valve is also installed, which plays a significant role.

Manual bypasses in heating systems can be used in several ways. Most often they are used to connect batteries to a single-pipe main, as well as for piping circulation pumps.

Heating system of a multi-storey building

The heating system of a multi-storey building is quite complex and its implementation is a very responsible undertaking, the result of which will affect all people in the building.

There are several heating schemes for multi-storey buildings, each of which has its own advantages and disadvantages:

- The single-pipe vertical heating system for a multi-storey building is a reliable system, which is why it is popular. In addition, its implementation requires less material costs, ease of installation, and parts can be unified. One of the disadvantages can be noted: during the heating season there are periods when the air temperature outside rises, which means that less coolant gets into the radiators (due to their blocking) and it leaves the system not cooled down.

- A two-pipe vertical heating system for a multi-storey building - this system allows you to directly save heat. If necessary, the thermostat closes, and the coolant will continue to flow into unregulated risers, which are located on the staircases of the building. Due to the fact that with such a scheme gravitational pressure arises in the riser, heating is often organized using the lower gasket of the distribution line.

- The two-pipe horizontal system is the most optimal in terms of both hydrodynamic and thermal performance indicators. This system can be used in houses of various storeys. Such a system allows you to effectively save heat and is also low-vulnerable even in cases that were not taken into account by the design. The only drawback is the high cost.

Before starting installation work, it is necessary to design the heating. As a rule, the design of the heating system of a multi-storey building is carried out at the design stage of the house itself. In the process of designing a heating system, calculations are made and a multi-story heating scheme is developed down to the location of pipes and heating devices. At the end of the work on the project, it goes through the stage of coordination and approval by government authorities.

As soon as the project has been agreed upon and all necessary decisions have been received, the stage of selecting equipment and materials, their purchase, and their delivery to the site begins. At the site, a team of installers is already starting installation work.

Our installers carry out all work in compliance with all standards, as well as in strict accordance with the design documentation. At the final stage, the heating system of a multi-storey building is pressurized and commissioning work is carried out.

The heating system of a multi-story building is of particular interest; it can be considered using the example of a standard five-story building. It is necessary to find out how heating and hot water supply function in such a house.

Heating diagram for a two-story house.

A five-story building requires central heating. the house has a heating main inlet, there are water valves, and there may be several heating units.

In most houses, the heating unit is locked, which is done to achieve safety. Despite the fact that all this may seem very complicated, the heating system can be described in simple words. The easiest way is to take a five-story building as an example.

The heating scheme for the house is as follows. After the water valves there are mud traps (there can be only one mud trap). If the heating system is open, then after the mud traps through the inserts there are valves that are located from processing and supply. The heating system is designed in such a way that water, depending on the circumstances, cannot be taken from the back of the house or from the supply. The thing is that the central heating system of an apartment building operates on water that is superheated, the water is supplied from a boiler room or from a thermal power plant, its pressure ranges from 6 to 10 kgf, and the water temperature reaches 1500°C. Water is in a liquid state even in very cold weather due to increased pressure, so it does not boil in the pipeline to form steam.

When the temperature is so high, the hot water supply is turned on from the back of the building, where the water temperature does not exceed 700°C. If the temperature of the coolant is low (this happens in spring and autumn), then for the normal functioning of the hot water supply this temperature cannot be sufficient, then the water for the hot water supply comes from the supply to the building.

Now you can disassemble the open heating system of such a house (this is called an open water intake), this scheme is one of the most common.

Shut-off and control valves for radiators

A heating system cannot operate as efficiently as possible if it does not provide for the installation of various valves, faucets, faucets, sensors, etc. With the help of shut-off and control valves in the heating network, the movement of the coolant is controlled, as well as its correct distribution. For example, when the temperature of the external air (outside) decreases, the supply of coolant to the heating devices is reduced and vice versa.

There are two types of coolant adjustment:

- high quality. It is designed to change the temperature of the coolant in pipelines and heating devices. Can operate on the basis of an automatic control system.

- quantitative. With its help, you can change (increase or decrease) the flow of coolant in the heating system if necessary.

Shut-off and control valves for radiators refer to local control of a certain section of the heating line. This means that residents of apartments, country houses, and dachas can independently change the supply and temperature of the coolant in heating devices. To do this, automatic or manual valves, air vents, taps, etc. are installed in front of the radiators. Each device has its own purpose.

Most often, three-way valves or double adjustment valves are installed to locally regulate water flow. The fittings are mounted on every heating device in an apartment or house. Specialists are constantly working on the production of walk-through valves. They make changes to the valve design to make it work more efficiently. The straight-through valves are equipped with a throttling element. This allows you to regulate the coolant supply more accurately.

Thermostatic fittings facilitate the operation of the heating system. Valves with sensors are also installed directly in front of heating devices. They have a temperature scale. With its help, the user sets the operating mode of the heating network.

Thermostatic head is sensitive to changes in the microclimate in the room. With the help of its work, the desired temperature regime is set in the apartment, depending on the weather conditions outside.

The need to create a bypass node

Bypass (English - bypass) is a part of the pipeline that has shut-off and adjustable valves and is designed to bypass any section of the heating main on which the equipment is mounted. This element is mainly used in single-pipe circuits, where the liquid heated by the boiler is transferred from one battery to another and then returned to the collector. The coolant flows freely through the bypass, and if it is necessary to disconnect the connected devices, the valve built into the unit is closed and, heated to the desired temperature, the water flows freely further through the pipes.

Bypass in a heating system - what is it in a single-pipe scheme?

Although single-pipe schemes are already technologically and morally outdated, they are still found in buildings built during the times of the USSR and the CIS. For this reason, when creating bypass sections in such schemes, you should adhere to certain insertion conditions.

Bypass in a single-pipe heating circuit

To create a bypass section you will need:

- a piece of pipe of the required length;

- tees and couplings;

- welding machine.

The bypass pipe must be placed away from the main riser of the heating main. In the section between the radiator battery and the bypass, it is necessary to embed a ball valve, which is necessary to regulate the coolant supply.

It is also possible to create a bypass section in a two-pipe schemeThe bypass has several areas of application, but we are talking about heating, so we will consider the possibilities of its use in this light. So, when understanding what it is - a bypass in a heating system, we take into account that it is mainly installed:

- in heating circuits with a boiler and pump, for subsequently carrying out planned repairs, inspection or replacement of devices without stopping the heating main;

- for debugging the temperature regime, which is carried out due to the installed shut-off and control valves;

- as a device that allows you to reduce fuel consumption for heating and at the same time maintain a stable temperature. In addition, the consumption of circulating fluid is reduced by up to 35%, which also reduces financial costs.

Bypass section on the circulation pump

Heating bypasses are available with both automatic and manual control. Automatic models operate autonomously and are activated when the pump is connected to the heating circuit. When the coolant blower starts, the valve opens under liquid pressure, and when turned off, it closes automatically. Bypasses can be divided into bypass units installed on radiators and pumps. The former are mounted directly next to the battery (to remove the heating element without disconnecting the line), and the latter are used to disconnect equipment or change the operating mode of the pump and are installed directly with it.

Installation on a radiator

Bypass on the heating radiator

In the area where the battery is located, a bypass is installed in a single-pipe heating system so that if circulation in the radiator stops, water can flow freely further along the circuit. In a vertical scheme, the radiator is connected to the riser by two pipes. The bypass on the heating radiator connects these pipes to each other and is installed in front of the battery. There should be no shut-off valves between the central line and the bypass in order to eliminate the human factor or the possibility of blocking the circulation in the event of a valve breakdown.

Functions of the bypass installed in front of the radiator:

- ensuring continuous circulation along the main circuit ring;

- coolant temperature regulation.

In single-pipe circuits, the coolant passes through the radiators, giving off some of the heat, and is drawn into the further flow. Accordingly, the coolant reaches each subsequent radiator a little colder.

Installing a bypass for heating makes it possible to mix the coolant from the central line with that which has passed through the battery, thereby increasing its temperature.

It turns out that if our water was 80 degrees before the first battery, then after it it will cool down to about 70 degrees. The coolant that passes through the bypass does not suffer such heat loss, therefore, when mixing liquids, the temperature of the total flow rises to approximately 75 degrees.

The horizontal single-pipe heating circuit works on the same principle, only the circuit in it is in a horizontal position in the area under the battery. At the same time, for proper circulation it is necessary to select the required bypass diameter in the heating system.

Why install a bypass

More hot water passes through an additional tube connecting the incoming and outgoing flows, and correspondingly less of it enters the radiator. This is normal and fully complies with housing and operational standards, if good circulation of hot water is ensured and the standards for heating the room are observed. In practice, in apartment buildings on the upper and lower floors (depending on the type of coolant supply), there is a significant decrease in temperature in the radiators due to the natural cooling of the coolant. In this case, additional losses through the bypass affect the rate of heating of the room. The hot water supplied to the apartment from the common system, as a rule, circulates poorly due to accumulated rust and scale. In some cases, pipes are installed incorrectly, with a narrowed inlet flow diameter.

Radiator connection options

In modern construction, several schemes for connecting heating devices are practiced. Radiator connection options: diagonal, bottom, side. The installation of each heating device circuit has its own characteristics.

Diagonal connection

Radiators in operation are the most efficient. The coolant supply pipeline is connected to the heating device from above. The return line is connected to the radiator from below, on the opposite side. The diagonal connection allows you to warm up the heating device, which has a large thermal output (many sections). Typically, this scheme is used in large rooms. Installing radiators in a diagonal manner is complex and time-consuming. It requires the involvement of experienced, qualified craftsmen.

The main advantages of this scheme:

- quick and easy installation;

- saving on expensive materials and energy resources;

- It is possible to install a bypass.

Lateral connection of radiators is used not only in apartments of multi-storey buildings, but also in cottages, townhouses, dachas, office and industrial premises.

Let's understand what a bypass is in a heating system

Today, many are able to move out of town and live in a large, beautiful house. But in order to feel comfortable in it, you need to carefully consider all engineering communications. The first priority is to install an efficient heating system. It should create a favorable microclimate in winter so that it is warm enough, but not too hot and stuffy. For these purposes, engineers have developed a special device - a bypass. Information about what a bypass is and how it is used in a heating system is of interest to many. Therefore, we offer a detailed analysis of this issue.

Any specialist with a technical education knows what a bypass is and how it works in a heating system. But the average person does not understand why the described installation is needed, what it is, and what the principle of its operation is.

In fact, a bypass is an ordinary jumper, a small section of pipe. It is installed between two pipes - supply and return. The diameter of this pipe is an order of magnitude smaller than the diameter of the main heating distribution.

This is needed for several purposes:

- To regulate the amount of hot water in the radiators.

- Ensuring the functioning of volatile systems.

- Increasing the efficiency of the simplest single-pipe heating system.

How does the bypass work in a particular embodiment?

Adjusting hot water in radiators

Using a jumper, you can quickly return excess hot water from the battery to the vertical riser. This process is carried out both manually and automatically.

In the event of an emergency, for example, a battery leak, the described installation acts as a shut-off valve. If a bypass is installed, it is very easy to repair the radiator without emergency shutdown of the closed heating system

And this is very important, especially in winter

Ensuring the functioning of heating in the event of power outages

To increase the heat transfer of batteries in autonomous heating systems, the installation of a circulation pump is encouraged. But its use makes the system volatile. Therefore, many ordinary people, when choosing heating equipment and turning to specialists, ask the question: “What to do in case of frequent power outages in the house?”

It is the bypass that can save the situation. At such moments, it will allow you to simply turn off the taps supplying hot water to the pump and open the shutter mechanism on the central main pipe. Then the heating will work on the principle of natural circulation.

Note! If a bypass with a valve is installed in the heating network, the system will switch without human intervention, that is, in automatic mode. If it is necessary to install additional devices on the jumper, for example, a cleaning filter or check valve, they are mounted towards the coolant

Correct installation of the bypass next to the riser into which the circulation pump is embedded requires the use of reliable shut-off valves. It is better to place the jumper itself horizontally - this way it will protect the heating line from the formation of air pockets.

Restoration of single-pipe heating

Module with tap

Today, rarely does anyone use a single-pipe heating system to heat a private home. But it can still be seen in Soviet buildings. It also happens that such an installation demonstrates good efficiency, and the houses get quite hot in winter. A correctly installed jumper will help maintain the necessary balance here too.

It is also possible to install it on a single-pipe distribution, but to do this you must follow the following rules:

- In the described case, you will have to install the bypass as far as possible from the vertical riser and as close as possible to the battery itself.

- The bypass pipe is installed directly at the installation site. To do this, you need a tee and a pipe, the diameter of which is an order of magnitude lower than the diameter of a single-pipe pipeline. A couple of welded joints will help connect all this to the system. Specialized stores sell ready-made bypass structures that are mounted using conventional threaded connections.

- A control valve must be installed between the radiator inlet and the bypass.

Note! Installing the device in a single-pipe network allows you to get a banal thermostat. But it will help you independently control and create a favorable microclimate

What to choose

Today in stores you can find ready-made bypasses designed for a certain capacity and pipe diameter. This is not the best solution.

Construction and design of heating systems is a complex engineering task that must be performed by a specialist with the appropriate profile. In this case, each element will be in its place and be useful. An incorrectly designed heating network will operate with large heat losses, while consuming a large amount of energy. Therefore, if you decide to calculate the heating network in your home yourself, do not forget to prepare properly and make a preliminary plan for the heating network for your home - think about what kind of boiler you will need, what the capacity of the expansion tank should be, where and how many valves and taps needs to be delivered, and so on.

If you do not feel strong enough to do such work, contact specialists who will promptly complete all the work and provide after-sales service for the heating system in your home.

It is also not worth saving on individual components of heating systems. All parts of the network must be of high quality and have a manufacturer's warranty. This approach will allow you to be completely confident that the house will always be warm and cozy.

Step-by-step technology for installing a bypass yourself

Recommendations from experts will help you install a water bypass valve, taking into account all the nuances:

- There should be a much greater distance from the vertical riser to the bypass than from the valve to the radiator.

- If you don’t have a factory product at hand, a homemade one from a piece of pipe with two tees will do. Docking by welding or threading. Threaded connections are available on ready-made tees, and the ends of the pipe can be equipped with threads yourself.

- Regulating or thermal control equipment must be installed in the area between the bypass valve and the battery. Additional equipment will be useful for adjusting the heating temperature and will help make the system more efficient.

- To make it more convenient to remove the pump, the bypass pipeline should be supplemented with shut-off valves. To turn off the water supply, turn off the taps, remove the pump, repair it, install it, then you can start circulating water through the pipes again.

- To start an old heating system that has not worked for a long time, a bypass device with a circulation pump, a check valve and ball valves is installed. The pumping equipment will run water through the pipes, the check valve will not allow the coolant to flow back, and it is convenient to regulate the intensity of water supply to the system using ball valves.

- To circulate the coolant at a given speed and enter the batteries without delay, the bypass is constructed from a pipe with a cross-section one size smaller than the cross-section of the central pipeline.

- When connecting the pump to the bypass device, you need to equip the system with a ball valve or check valve.

- When laying out the contours of a heated floor, a bypass must be equipped. The bypass pipeline will ensure the supply of coolant from the mixer after mixing the hot and chilled water (return). Three-way valves allow a small portion of hot water to pass through; most of the coolant for the desired heating mode circulates through the bypass pipe, is transported along the circuit and is directed to the heating device (boiler).

- In the process of arranging a small circuit of a solid fuel boiler, the bypass device must be installed so that one pipe is connected to the supply pipeline with the maximum heated coolant, the second pipe must be connected to a three-way valve installed on the water return pipe.

Step-by-step installation of the device:

- increase the distance of the threaded ends in the area where the pump was previously screwed on;

- assemble the pumping equipment, the assembly around the pump, tighten the ball valves;

- all pump connections are detachable, you do not have to use welding, you need to ensure the twisting strength and tightness of the joints;

- behind the ball valves, install a tee with a cross-sectional size that is equal to the diameter of the pipeline;

- remove the pump, cut the main pipe, install a unit connecting both parts of the pipeline to the main main;

- once this section of the bypass is assembled, install the pump in place;

- raise the pipeline in relation to the tees so that it does not interfere with the operation of the pump;

- bring the two pipes together by rotating, screw on the jumper, ball valves - all parts are equipped with threads and detachable connections, there will be no difficulties with tightening.

The bypass valve pipe can be positioned vertically or horizontally; the position does not affect the functionality of the bypass.

There are nuances in the case of inserting the device when installing a bypass pipe:

- The cross-section of the bypass pipe must be selected 1 size smaller than the cross-section of the internal tunnel of the main pipeline.

- Install the jumper as close to the radiator as possible.

- In an apartment in a multi-storey building, a bypass tap is not installed.

Types of jumpers

There are three types of bypass, they can be distinguished by the mechanisms responsible for the shut-off function, the list looks like this:

- Mechanical action is used for control.

- Non-adjustable, static models.

- Elements equipped with automation.

Each of the presented types has its own design features, and the methods of application are also somewhat different. To understand in detail all the small points and understand what kind of bypass is needed, it is worth considering each design option separately.

With manual regulation

To adjust in this situation, a ball valve is used; this type of bypass has gained wide popularity because at the moment of opening, the permeability of the pipe fully complies with generally accepted requirements, and if necessary, the path can be cut off without problems.

The absence of hydraulic resistance has a beneficial effect on the functionality of the line, and with the help of an additional element it will be possible to regulate the fluid pressure.

Experts advise paying attention to one nuance: the valve on the bypass may become stuck over time; to avoid such negative consequences, it is necessary to turn it periodically, preventing the structure from being down. Often the type of connection, which will subsequently regulate the manual bypass, is used to connect batteries in a single-pipe circuit or when piping a circular pump

Often, the type of connection that will later regulate the manual bypass is used to connect batteries in a single-pipe circuit or when piping a circular pump.

Auto

Known types include:

- Valve.

- Injection.

Such units can be seen in a gravity-type pipeline, since for good heating operation it is not necessary to install equipment responsible for the forced movement of the coolant. The valve type of device serves to prevent the unimpeded movement of liquid in the opposite direction.

Injection bypass

Among the disadvantages, it is worth highlighting the increased sensitivity of the main element to the purity of water; such unpleasant contaminants as the following can cause problems in the process of a circulation pump with a bypass:

- Scale.

- Rust.

- Metal shavings.

- Scale.

The injection model operates on the principle of a hydraulic elevator; at the moment the pumping equipment starts, some part of the diffuser of the inlet pipe is filled with liquid, where it is accelerated. At the moment of discharge, due to the narrowing of the pipe, the coolant from the bypass is drawn in and directed at a different speed due to the transfer of kinetic energy.

When the pump is turned off, the line can work fruitfully in a natural mode, water calmly passes through the bypass, such structures are much less likely to become clogged, this is due to the lack of precisely fitted parts.

Unregulated

There is no additional equipment on this component of the heating system; it looks like a regular bypass pipe. The mode becomes uncontrollable, liquid passes through the gap in the line constantly; similar elements were provided for connecting radiators.

In a scheme with vertical installation of a bypass in a heating system, it is necessary to take into account some nuances; the diameter of the bypass cross-section should be slightly smaller than the circuit pipe. The horizontal type of insertion will require compliance with other requirements, because hot water will tend to rise, the jumper must be created with the same diameter as the main, and the pipe suitable for the battery must have a smaller cross-section.

Application

If there is a pump in the heating circuit, it is installed directly on the bypass part. This is a common practice when an electric pump is installed in a gravity circuit - a single pipeline in which the coolant circulates by gravity.

It accelerates the speed of water flow through the pipes and thereby increases the efficiency of the entire heating system. This is due to the fact that due to the high flow rate of the coolant, it manages to pass through the entire circuit without losing most of the thermal energy.

In practice, this is expressed in the fact that the last radiator of the circuit receives not cold or barely warm water, but rather hot water, which still has a sufficient amount of thermal energy to ensure heating of the room in which it is installed.

Blitz tips

- Installing a bypass is desirable in conditions of insufficient natural circulation of fluid in the heating circuit.

- When constructing a bypass yourself , it is not necessary to select each of its elements separately; it is better to purchase a ready-made assembly from a specialized store, which will save time and guarantee against inconsistencies between elements during the assembly process.

- To automatically regulate the temperature in your home, you can use a thermostat with a built-in ball valve.

- Horizontal installation of the device is preferable due to the lower likelihood of air accumulation in it.

- When installing the device, additional support points and clamps should be provided in advance to prevent it from moving under the influence of gravity or other factors.

- In case of poor water quality with a large number of impurities and suspended matter, to increase service life, you should choose special pumps with filters, which are recommended to be periodically removed and cleaned.

Examples of using bypass

Example #1 - adjusting the coolant

The functional purpose of the bypass is to return excess coolant from the heating battery to the riser when its quantity changes using a manual or automatic thermostat. In other words, the coolant is transported through the bypass parallel to the shut-off and control valves. Without this element, it is impossible to repair the battery when the heating system is in working order. The bypass also speeds up the process of filling or emptying the system.

This is how a bypass can be introduced into a heating system

Example #2 - system operation without electricity

Installing a bypass in a heating system is especially important when installing modern heating systems that involve the use of circulation pumps. People who are faced with heating installation for the first time often ask the craftsmen or consultants in stores: “How will the system work if the electricity goes out?” After all, everyone is accustomed to the fact that the standard floor-standing boiler used in the past was not connected to electricity. And equipping the heating system with a circulation pump makes it energy-dependent.

That's exactly where the bypass comes to the rescue in such situations. Its role in this case is very simple - at the moment of a power outage in the network, the consumer must turn off the coolant supply taps to the pump and open the tap on the central pipe. By the way, this can happen automatically if a bypass with a valve is used. These simple manipulations switch the heating system to natural circulation mode.

Installation of devices on the bypass should be carried out towards the coolant in the following sequence:

- filter;

- check valve;

- circulation pump.

It is important to note that the introduction of a bypass into the riser near the circulation pump must be carried out using shut-off valves. It’s better to install the element itself horizontally

In this case, the system will be protected from air accumulation.

Schematic representation of a bypass pipe built into the heating system

Example #3 - resuscitation of single-pipe heating

Yes, the single-pipe heating system is obsolete today, but it can still be found quite often in Soviet-built buildings. Moreover, there are such miracles when such heating functions very efficiently even in apartments in winter, it’s simply hot. Installing a bypass will also help correct the situation. In principle, there is nothing complicated in this work, but it is still worth meeting some conditions:

- The bypass should be located at the maximum distance from the vertical section of the pipe, that is, as close to the battery as possible.

- The bypass pipe can be made directly at the installation site - a pipe, a tee and welding work will be required. Or you can purchase such an element ready-made and install it on threaded connections.

- The radiator inlet and bypass must be separated by a control valve or radiator thermostat.

By installing such a device, you will get a banal “temperature regulator in the house.”

The essence of bypass and its purpose

A bypass built into a water heating system is a bypass pipeline designed to transport coolant parallel to the existing shut-off valves.

This element of the heating system is almost indispensable when carrying out repairs, without shutting off the water supply. In addition, the bypass makes it possible to speed up the process of filling or draining the heating system. In addition, it is used to regulate the flow power of the supplied coolant. Bypass for heating - used during repairs

The word “bypass” is of English origin and is translated as “bypass” or “bypass”. Simply put, this is a piece of pipe that runs parallel to the main device or branch and is designed to temporarily divert water through it, bypassing the main mechanism. Sometimes this backup path may be equipped with a crane. It comes with a check valve or without additional devices at all.

Typical bypass device

Today we can talk about two main types of bypass: automatic, that is, equipped with a check valve, and manual, which does not have any additional devices. Sometimes an electric circulation pump is included in a circuit with a check valve. It is used as necessary to regulate the coolant flow. It works as follows: the pump turns on and increases the pressure in this part of the system, as a result of which the valve opens and directs the fluid flow in the required direction. When the pump is turned off, the pressure drops, which closes the valve, blocking the pipe. However, such a system is capable of operating with natural circulation without connecting electricity. The complexity of the design greatly affects the reliability of this system, which over time can lead to interruptions in its operation due to incomplete blockage of the pipe due to blockages. This problem leads to an imbalance in the room temperature. Automatic bypasses have found their application in water heated floor systems. They allow the circuit to maintain the set parameters without spending a lot of time and energy.

Automatic bypass equipped with check valve

A valveless bypass allows the coolant to freely flow around the radiator without draining the entire system and shutting off the water. If you need to replace the heating battery in an apartment in an apartment building, then you will not disturb your neighbors in any way, they will not even know about it. The main feature of bypasses is that the pipe is one stage narrower than in the main system. For example, for a ¾ thread system, a ½ device is suitable. This is due to physical law, because water flows along the path of least resistance. That is, until you turn off the taps to the radiator, the coolant will flow freely through it, and at the moment the tap is closed, the coolant will rush into the bypass, bypassing the heating device.

Sometimes installing a bypass is also advisable on water supply or water treatment systems. Here it is installed to ensure water bypass around complex filter systems. This is necessary for the convenience of carrying out repair or routine maintenance of this equipment without interrupting the water supply.

Manual valveless bypass

There are also so-called mixing bypasses. They can be found in heating systems and water pipes. In heating systems, they allow fine tuning of the coolant flow, thereby regulating the temperature in the room. This is especially true in water heated floor systems. In the case of water purification systems, mixing bypasses regulate the content of salts, oxides and other substances in the water.

Battery tying

If the installation of the system is carried out independently, then you need to know all the requirements that apply to this or that element. This also applies to the bypass. It is often installed in places where radiators are mounted. But why do you need a bypass in a heating system? This issue needs to be looked at more carefully.

Radiators are tied according to a simple pattern

Why is it needed?

Previously, single-pipe heating was used in the construction and improvement of houses. This greatly simplified the work and also reduced costs. In this case, two collectors were installed in the elevator unit, which were responsible for supplying and processing the coolant. Further heating was developed according to different schemes:

- Top feed. There was a pipe running from the collector to the top floor. The coolant was supplied upward through this riser. After that, it went down, passing through all the radiators.

- Bottom feed. In this case, the coolant begins to flow into the radiator when it is raised up. This series connection of devices has some disadvantages.

In both the first and second cases, the connection is made in series. This means that if a problem occurs on some equipment, you will have to turn off the entire system. To circumvent this problem, special jumper pipes were included in the system. So, if necessary, the radiator is disconnected from the system using taps without disturbing its operation. This makes it possible to easily repair the battery.

The jumper is installed closer to the battery

This is not the only reason for using a jumper in heating. The room is heated using radiators. If there is a bypass with valves, apartment owners have the opportunity to independently adjust the coolant supply. Thus, controlling the temperature in the house is not difficult.

The dressing tube has different shapes

Bypass installation

To carry out heating installation, you must have certain knowledge and skills. This takes into account the method of pipeline assembly. For this purpose, threaded and fitting connections are used, as well as pipe soldering. Having these skills will make the job easier. It is worth considering some rules and recommendations from experts:

- There should be no valves between the rack and the bypass. Otherwise, the coolant circulation may be disrupted.

- On the vertical riser pipe, the jumper is mounted in close proximity to the battery. In this case, space must be provided for installing shut-off valves. It is mounted on both sides of the radiator.

- Do not install valves on the bypass unless necessary. If you install taps on the jumper, the circuit will become unbalanced. In an autonomous system of a private house, this in turn allows you to redirect the flow. In a multi-story building, this option is ineffective and is a violation of standards.

- The size of the pipes is important. The diameter of the insert is two sizes smaller than the section of the stand. The pipes that go to the radiators are made one size smaller. In the horizontal scheme, the size ratio is somewhat different.

Compliance with the dimensions of pipes and pipes will ensure normal operation of the system, in accordance with all the laws of hydraulics. As for installation, its features directly depend on the type of material used. If we are talking about a metal pipeline, then it is enough to simply weld the jumper and install the taps.

Installation is carried out in different ways

The use of polypropylene, as well as metal-plastic, requires the use of special fittings. You can build a bypass yourself from a pipe of the required size or purchase a ready-made part.

The pump is often installed on a jumper

Additional circulation pumps

The circulation pump (hereinafter referred to as CN), as a rule, is installed on the coolant return pipe (return). The classic place for inserting a bypass with an installed pump is in close proximity to a gas, electric, diesel, solid fuel boiler, but this cannot be the rule. For example, for a two-story house, the power of an integrated or near-boiler central heating system may not be enough, and then it is installed on the second floor to ensure proper water rise. In addition, the central pump can be embedded in a remote wing of the building to ensure uniform circulation of fluid throughout the pipeline.

1 – the heating circuit serves as a bypass; 2 – the bypass pipe serves as a bypassSource cementequipment.org

As mentioned above, either the main or bypass branch of the circuit can be used as a bypass (see photo above). Most often, the section under the central passage and the main passage have different diameters, but this is not necessary. Taking into account the forced suction of liquid, the diameter on the bypass with a pump is usually smaller, for example, bypass Ø 32 mm, and on the central pump - 25 mm. But here it should be noted that not only calculations, but also many years of experience of plumbers indicate that the diameter of the pipes at this unit should be different.

Assembly and installation

Having purchased a bypass for the central heating unit, you will have to assemble it yourself Source scparts.co.uk

If you are interested in an automatic bypass, then this is from the realm of fantasy: a hollow profile or bypass cannot be automated, since it is just a piece of metal (steel, copper, brass) or polypropylene. If we talk about installing a central pump, then this unit can be purchased in a store and it is pre-provided with pipes for mounting the pump. If you have a metal heating circuit, then this is very convenient, but when the piping is made of PPR, then this unit will have to be welded yourself, however, it is not so difficult.

Before assembly, you will have to decide how you will pack the docking units: with fum tape or cable ties. Old plumbers from the times of the USSR always advocate the second option, but many years of practice suggest that both materials are perfect for this purpose, and fumka is much more practical in work. But, no matter what material you prefer, Unipak plumbing paste will never be superfluous - it is smeared over tape or tow to ensure a reliable connection (without leaks).

The arrow on the pump must correspond to the direction of the coolant. Source homedepot.com

After complete assembly of this unit (bypass and central control), pay attention to which direction the arrow on the pump body points (it can be clearly seen in the top photo). It should indicate the direction of coolant flow and, since the installation is done on the return line, it will be “to the boiler”

Remember this important detail and then the turbine blades will rotate in suction mode, and this is the correct option.

The insertion is carried out in different ways: someone cuts a thread and mounts it on one side on a spigot, on the other on an American one (the best option), someone connects the pipes by welding (gas or electric), and someone attaches the assembly to a rubber the coupling, squeezing it with clamps, having previously lubricated it with sealant. Any option is appropriate here: the pressure in autonomous heating systems is low (only 1.5-2 atm), and the water is no longer hot.

Stepping back from the boiler at least half a meter, you need to mark the coolant return pipe for tapping. This is not difficult to do: just attach the previously assembled assembly and make marks with a scriber or marker. Then, strictly according to the markings, a section of the pipe is amputated using a grinder with a cutting disc. If everything was done without errors, then the assembly will fit flush into the seat or you will even have to hammer it in. The exception is the situation when installation is done using an American and a drive - there are quite acceptable gaps, but not more than 0.5-3.0 mm.

All that remains is to launch the central station and test the system. Source tacomaworld.com

The photo above shows the assembled unit - all that remains is to pump the coolant into the system, plug the pump into the outlet and test the operation of the circuit. Here the bypass plays a different role than the jumper on the battery. In our case, water is not discharged: it can circulate through the main circuit in normal mode or be accelerated by the engine turbine (works for suction, occasionally for supply). It turns out that when the central heating system is turned off, the heating of the system will be less intense due to the low speed of the coolant.

Mechanism designs

In general, the bypass design may include the following elements:

- Pipe.

- Circulation pump.

- Valves. There should be two valves. There are several types of bypass pipe valves, which will be discussed below:

- Cranes with a movable stem. When using such taps, the internal lumen of the pipe is blocked with a rubber washer. A special feature of this type of cranes is that they can be repaired without much difficulty. The disadvantage of representatives of this type is that the internal clearance of such faucets is half the nominal value, which contributes to the loss of coolant.

- Ball valves. This type of faucet closes the gap using a metal ball that has a specific clearance. When the tap is fully opened, the internal clearance is no less than the nominal one, so there is no loss of coolant. However, this type also has a drawback - if not used for a long time, the ball sticks to the seal, as a result of which the faucet handle simply does not yield to force.

- Shut-off valves. The shut-off valve is a valve on a straight line. If it is absent, then the water, driven by the pump on the bypass, enters the direct line and then back into the jumper. So it will circle around one small contour. Therefore, a valve is needed that will prevent the flow of coolant to the pump. When choosing this valve, you can also note the following two options:

- Ball valve. The characteristics of such cranes are discussed above.

- Check valve. Its device includes a metal ball that is capable of closing the inlet under water pressure, so no human intervention is required. When the pump is turned on, under water pressure, the valve will close on its own, thereby ensuring proper operation of the system.

Choosing a location for installing heating devices

Radiators are installed under windows. This is a long established rule. The largest heat losses occur from windows in a room. The length of the radiator should be 0.7-0.9 times the length of the window sill. If it is necessary to install several heating devices in a room, but there is only one window, it is advisable to mount them on load-bearing walls.

The distance between the floor and the radiator must be no less than 100 mm. Ignoring this rule leads to a decrease in the efficiency of the heating device. It will also be difficult to clean, repair, or replace individual parts of the radiator. The distance between the heating device and the wall must be at least 50 mm. So the radiators will not heat the wall, but will give off their heat to increase the temperature of the internal air. It is prohibited to change the connection diagram of heating devices on your own in apartments and country houses. Repair of heating systems must be carried out in advance with the locality management services.

Where else is bypass used?

In addition, the bypass is installed in a heated floor, in the circuit of a solid fuel boiler and other places in the heating system. In each case, the operating principle of the jumper has characteristic features.

Bypass in a water heated floor system

Often, heated floors are constructed using a collector circuit. This makes it possible to ensure normal operation of the circuit. As a result, normal pressure and temperature indicators are created in different circuits.

Collecting and mixing units used when laying pipes allow the system contours to be balanced as accurately as possible. They are often equipped with circulation pumps and thermostatic devices. With their help, the coolant of the supply circuit and the return flow are mixed. Thus, the required temperature is created and the pressure in the branches of the system is equalized.

During the installation of a heated floor, the piping is installed

Despite modern technology, the pump is not able to smoothly change the pressure. New models have several stages of adjustment. As a result, performance and pressure are regulated using individual balancing valves. Some mixing units are equipped with bypasses that have a balancing valve.

In practice, many experts consider such elements unnecessary. Many collector units are designed without a bypass. Despite this, the node performs certain functions. First of all, it is worth noting that the jumper protects the pump from overload and prevents pressure surges. If necessary, excess coolant is redirected to the return line.

The jumper can be purchased ready-made

Bypass in the solid fuel boiler system

It is difficult to regulate the operation of equipment. During the combustion of solid fuel, a high temperature is created. And that is not all. As a result of the combustion of coal or wood, a lot of smoke is produced, which contains solid suspensions that settle in the form of soot.

When the boiler starts, cold coolant is supplied to it. This creates an increased temperature difference, which manifests itself in the form of condensation on the walls of the heat exchanger. The danger of this phenomenon is clogging of the channels and chimney. Condensation also negatively affects the condition of cast iron and steel heat exchangers.

Using the piping, a small heating circuit is created

To eliminate this problem, it is necessary to reduce the time between the arrival and heating of the coolant during startup. A small circulation circle, which includes a bypass, will help to cope with this. Thanks to it, heating is carried out faster, condensation does not form. A special tap or thermostatic valve is installed on the return line, designed for the standard operating temperature.

There may be several jumpers in the system

Finished pump with jumperInstallation of steel jumper pipe

When the coolant heats up to a certain value, the valve begins to open slightly. Cold water is supplied to the circuit, and hot water is supplied to the pipes. Such a smooth start protects the boiler from negative factors. This significantly extends the service life of the unit and the heating system as a whole.

Bypass is an important heating element. Therefore, if necessary, plumbing experts recommend installing a unit in the system. Such a device will improve heating efficiency and create optimal conditions for repairing communication elements.

average rating

more than 0 ratings

Share link

Price and recommendations

If we analyze the prices for bypass and components, we can summarize that they are not that high and completely depend on the region of your residence. So, in Moscow you can buy it for 5,000 rubles, and in Yekaterinburg for only 3,000 rubles. These amounts are simply meager compared to those that you will save on heating when using this pipe and taps.

How to choose a suitable bypass?

Just follow our advice and you definitely won’t go wrong:

- Buy only certified products.

- Demand to show the seller a hygiene certificate.

- Upon visual inspection, the bypass you choose should be smooth, without any dents, chips or signs of corrosion.

- If the product has threaded connections, check that they are easy to screw on and off.

- Welding seams must be solid, without pores.

- After purchasing a product, always keep the receipt and warranty card until the period indicated on it expires.

How to make a bypass without overcooking the riser (video)

Popular queries

automation pools and fountains household appliances bathroom fans air ducts country toilet shower cabin chimneys shut-off valves tools sewerage well convectors air conditioning boiler equipment taps and mixers external water supply pumping equipment heaters lighting water treatment air purification furnaces design work with pipes radiators do-it-yourself welding work septic tanks well solar panels heating circuits coolant underfloor heating air humidification insulation filters electrical wiring

Editor's Choice

How to correctly transmit meter readings for electricity

Water pressure regulator in the water supply system

Solar panels for home: is the cost of the kit justified?

Pipe area and paint consumption calculator

Review of the best energy-saving heaters for the home