If we try to characterize the bypass in the heating system from the point of view of the average person, then it will be a kind of jumper in the form of a piece of pipe that is installed between the direct and return wiring of the heating radiator.

Bypass in the heating system

The heating system of a residential building contains a list of components, and disruption of at least one of them can cause not only interruptions in operation, but also destruction. In addition, it is imperative to ensure comfortable repair and replacement of various system components. This is precisely the purpose of a bypass in a heating system. This is a section of parallel pipeline. For example, when installing a section of pipeline in parallel with the radiator, you can maintain the functionality of the entire heating system when cleaning, repairing or replacing the unit.

Installing a circulation pump without bypass

Heat is one of the defining means of human existence.

Modern technologies make it possible to create the most comfortable living conditions. To be able to independently control the temperature in the house, they came up with a bypass - essentially a regulator of the heat supply in a water heating system. But installing a circulation pump without a bypass is becoming more common. Let's think about why? The point of installing a bypass, simply put, is the ability to manually return excess coolant to the riser. In addition, it is needed when repairing batteries; this simple device greatly facilitates the process of filling or draining the system, and during a power outage it does not allow heating systems to stop.

New generation boilers, which have a circulation pump without a bypass, are easier to design and install. All operation of the equipment is carried out due to the actions of the pump itself. In addition, they are more economical, since there is no need to strongly heat the water in the supply pipe (according to the laws of physics, cold water simply cannot rise up the riser). Installing a circulation pump without a bypass allows you to evenly distribute heat over large areas with a significant number of batteries or several floors. However, such designs also have a significant drawback. The fact is that, as mentioned above, the bypass during a power outage prevents heating systems from stopping their operation. You can, of course, purchase an electricity generator, for example, a gasoline one, but if there are regular power outages, it is better to look for another way out of the situation.

And now to the question: is it necessary to install a circulation pump without a bypass? Everyone, of course, decides for themselves. But keep in mind that if this small device is abandoned, the heating system should not depend on the availability of electricity and function without failure. But this necessary element of water heating significantly facilitates the operation of the entire system, while it does not take much time to install and does not require large material costs. Installing a bypass will significantly reduce energy costs and create a cozy and comfortable environment in your home to the delight of your family and friends. Just remember that the bypass should not be installed in systems where there is no natural circulation of the coolant or where there are reverse slopes.

The radiator and battery replacement company provides services for the transfer of hot water and cold water in the city of Zelenograd. We guarantee the assistance of highly qualified specialists who will carry out the work quickly and efficiently.

Using a double-circuit gas boiler makes it possible to kill two birds with one stone - to provide hot water supply and organize a heating system for the house with a coolant. That is, with the help of one boiler, two rather serious problems are solved at once.

The cold can ruin anyone's mood. In apartments and houses in winter, many radiators do not heat the rooms well. In such a situation, replacing heating batteries at the Naro-Fominsk welding site will help. Today these services in the city are provided by the computer.

Source of the article: https://sgsr.ru/ovchd/ustanovka-tsirkulyatsionnogo-nasosa-bez-baypasa.html

Where is bypass used?

The bypass must keep the entire system in working order even if one of its elements breaks down or the electricity is cut off. All units that are connected using the device can be easily disconnected from the base; to do this, you only need to close two taps, after which the coolant will flow along the bypass path.

On radiator trim

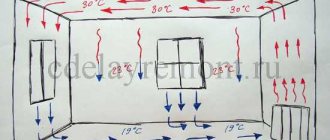

The jumper is used only for radiator devices operating in single-pipe heating structures; it is not needed for two-pipe circuits, since in this case all units will be connected in parallel to each. Since single-pipe wiring requires a serial connection, the coolant will cool as it approaches each device, the furthest of which will receive a minimum of heat. This problem is solved by a bypass, which helps make the flow movement independent and helps the coolant pass directly into the radiator.

On the circulation pump

A bypass enhances the efficiency of the circulation pump.

A circulation pump is connected using a device only in designs with natural circulation; in this case, a bypass is needed only to enhance the efficiency of operation. This is a good option for systems in which an accelerating type collector is installed, as well as pipes with the required slope and diameter. Systems with forced circulation do not require the installation of a bypass.

For heated floors

In heated floors of any type, a mixing unit with a bypass bypass pipeline is constantly installed. The jumper itself is needed for the heated floor to operate without interruption; this is an important element, without which the system will not be able to function. In heated coatings, a certain temperature must be maintained at all times; the bypass is responsible for adjusting it and bringing it to the required value.

Where should the pump be installed, on the coolant supply or return?

In the last article I touched on this issue, here I will repeat and add. Practitioners believe that there is no fundamental difference where to install the circulation pump into the coolant supply or return. Modern circulation pumps are not afraid of pressure and work great in both places.

However, in practice, it is more often necessary to repair pumps installed for direct coolant supply in systems with solid fuel heating boilers. It is in them that the system boils for a long time and the circulation pump fails.

Let's return to the topic of the article and look at two options for inserting a circulation pump.

For systems with a solid fuel boiler

When used in combination with solid fuel heating equipment, a circular pump allows you to create a small circulation circuit.

To do this, the bypass pipe is placed in the supply, where there is a coolant heated to the limit, and is connected to a three-way valve located on the other side of the structure. Thanks to the valve, hot water from the circulation pump and cold water coming from the return circuit are mixed. As a result, a coolant whose temperature exceeds 50 degrees is returned to the boiler for the future heating cycle.

The need to return warm liquid to the boiler is due to the fact that otherwise condensation will form on the iron walls of the combustion chamber, which will encourage corrosion and cause damage to the unit. If you supplement the system with a circular pump, then such problems can be very easily avoided.

Option 1. Non-volatile connection of the circulation pump

The non-volatile connection of the circulation pump allows you to automatically, without human intervention, switch the system to natural and forced circulation. This is achieved by installing a ball valve rather than a ball valve on the shut-off bypass.

This scheme works like this. When the pump is operating, the ball valve ball is pressed by the pressure of the pump and blocks the natural circulation line. If the power supply to the pump is interrupted or the pump fails, the valve ball floats up and the natural circulation of the coolant is resumed.

Principle of operation

The coolant, water, and gaseous medium, moving through the pipeline, exert pressure on the valve, which is held in place by a spring. As soon as the pressure force reaches a predetermined level, the valve opens and the excess volume of the working medium is discharged through a special branch into another circuit of the system.

After the level drops to normal, the spiral returns the valve to its original position and the contents of the pipeline continue to circulate.

In a car, the turbine bypass assembly has a damper, the full opening or closing of which depends on the activator lever. The length of its pull can change over time under the influence of various factors. Therefore, this is monitored and the traction is adjusted.

How to choose a ball valve

If we imagine the mechanics and physics of closing a pipe with a ball valve ball, then a logical question arises: how will a ball valve work if it is installed not vertically, but horizontally or at an angle.

Practitioners recommend using a cast iron valve “Tech-Pol” (Poland). It works in both horizontal and vertical positions.

How to install the system

It is advisable to install bypasses simultaneously with the installation of the heating system. Sometimes such a device needs to be installed in an existing heating system. The most preferable installation season in the latter case is the warm seasons, since during such periods the heating system is not operated. It should be remembered that when carrying out installation work, the liquid must be drained from the pipeline.

https://youtube.com/watch?v=WBFqxw11N04

It should be noted that the work itself and the complexity of its implementation are directly dependent on the materials from which the pipeline is made, as well as the heating circuit itself. The simplest work will be with metal-plastic. And polypropylene or metal requires the use of welding devices. That is, you won’t be able to install it yourself; you will need the help of specialists.

When installing yourself, you need to remember that first of all attention is paid to the section of the bypass route, which is installed parallel to the return

It is important not to forget to install the shut-off valves as well. You also need to be careful about the sides of the pipe - it’s better not to confuse them.

You also need to be careful about the sides of the pipe - it’s better not to confuse them.

So, a bypass is an important and useful device that can be helpful in many situations, so it is better not to neglect its installation.

conclusions

A high-quality installation of a circulation pump in a heating system includes (required):

- Checking the pump markings;

- Installation of a pump with a bypass line;

- According to the movement of the coolant, we place a coarse filter (preferably magnetic) in front of the pump. Without a filter, the pump blades will quickly fail;

- We surround the pump with ball shut-off valves. This will allow you to repair the pump at any time, without disturbing the operation of the heating system;

- We install either a ball valve or a cast iron ball valve in the main coolant line. They will allow the coolant to bypass the pump in case of failure and not disrupt the heating system.

Shut-off valves on the bypass

In the area of the heating system where the diameter narrows, reducing the flow rate, only ball valves can be used.

Ball valve

Such valves have a metal ball built into the body with a hole of the required diameter. Thanks to this design, there will be no reduction in clearance in a fully open valve. But we note that such valves cannot be repaired; therefore, if they malfunction, they are replaced.

During the operation of ball valves, you should be aware that if they are not used for a long time, they can stick. That is why they need to be turned periodically, even if there is no need.

How not to install a pump in heating

A circulation pump will help increase the efficiency of the heating system, which will allow the coolant to move faster in the pipes. At the same time, the high performance of the pump depends on the correct installation. If the heating pump is installed incorrectly, it may cause noise, reduced power, airing and uneven heat distribution.

This article from a construction magazine will tell you how to properly install a heating pump, and what benefits will come from installing it.

Power connection

The circulation pumps operate from a 220 V network. The connection is standard; a separate power supply line with a circuit breaker is desirable. The connection requires three wires - phase, neutral and ground.

Circulation pump electrical connection diagram

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power wire. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing several bolts and find three connectors. They are usually labeled (the pictograms are N - neutral wire, L - phase, and “ground” has an international designation), so it’s hard to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - install a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pulls” electricity to a maximum of 250-300 W. But when organizing, you need to calculate everything and select the battery capacity. The disadvantage of such a system is the need to ensure that the batteries do not discharge.

How to connect a circulator to electricity through a stabilizer

What does installing a circulation pump in a heating system provide?

Half a century ago, the so-called “steam heating” became most widespread. The operating principle of such heating is based on temperature differences, and the coolant circulates through the pipes by gravity. At that time, circulation pumps were used only in centralized heating networks. They had more power and the same dimensions.

In many ways, the situation has changed with the advent of small and compact pumps, the dimensions of which allowed them to be used in domestic heating systems. Installing a circulation pump provides a significant increase in power and increases the efficiency of the heating system.

Circulation pumps are installed for heating in order to:

- Increase the speed of coolant movement. In this case, the premises will be heated much faster;

- Increase the capacity of the pipes, and thereby heat the distant radiators in the house;

- For forced pumping of coolant in closed heating systems;

- When installing underfloor heating systems;

- To generally improve the heating efficiency of your home.

At the same time, the only drawback of the circulation pump is its dependence on electricity.

If it is not there, then the pump will not work. The problem is partially solved by installing uninterruptible power supplies and installing a bypass, which makes it possible to use the heating system when the circulation pump, for some reason, does not work.

Fixed Circular Pump

The device of unregulated circular pumps is an ordinary pipe that does not have any equipment. The pipe will regularly be in the open state, and the liquid moves through it arbitrarily; in other words, there is no opportunity to influence the intensity of the water flow. Unregulated bypass pipes are very often used to connect devices for heating a room.

When designing a heating system, it is imperative to keep in mind the fact that water always moves primarily through those areas where the amount of resistance in terms of hydraulics is minimal. In the case of a circular pump, this means that the diameter inside its vertical section must be less than the internal cross-section of the main pipeline. If this requirement is not met, then the coolant will simply gravitate towards the circular pump.

When designing a horizontal heating distribution structure, other rules apply that must be taken into account before adding a circular pump to the heating system. The heated coolant has a very low specific gravity and always tries to move upward

In order for the system to work well, taking into account the rules, the diameter of the part located at the bottom of the circulation pump must be the same as the diameter of the pipeline, and the cross-section of the pipe section leading to the heat exchanger must be smaller.

How not to install a circulation pump in heating

It was said above that the efficiency of the equipment depends on the correct installation of the circulation pump in the heating system. Let's look at the main mistakes when installing a circulation pump, which will help to avoid them in the future.

For return or delivery?

Considering the fairly large temperature difference between the return and supply heating lines, it is better to install the pump on the return line. In this case, the pump will overheat less and will not boil when critical temperatures occur.

Dirt filter.

A prerequisite for the normal functioning of the circulation pump is the presence of a coarse filter (with a metal mesh inside). Otherwise, the pump may quickly become clogged and fail. Also, in order to be able to repair or replace the existing circulation pump, two taps must be installed for quick replacement.

In what area should I put it?

The heating pump can be installed on almost any section of the pipeline: vertical, horizontal and even inclined. The only point that will need to be taken into account is that the rotor of the circulation pump is only in the horizontal plane. In simple words, the pump cannot be installed with the rotor up and down.

How to set it correctly?

When installing, the box on the pump with terminals should be at the top or, in extreme cases, on the side. It is not allowed to install the circulation pump in such a way that the plastic box is located at the bottom. Otherwise, a short circuit may occur, which will result in pump failure.

Where should the arrow on the pump point?

And, of course, when installing the pump, you need to take into account the direction of coolant flow in the heating system. If the pump is installed on the return line, then its arrow should point towards the heating boiler. If on the contrary, then, accordingly, the arrow should be directed in the other direction.

Proper installation of a circulation pump in a heating system will help avoid a number of problems associated with the operation of expensive equipment.

Source of the article: https://zen.yandex.ru/media/samastroyka/kak-nelzia-ustanavlivat-nasos-v-otoplenie-5e6761a70bdae7000472cd56

Automated Circular Pumps

Circular pumps with automatic adjustment in most cases are installed in the piping of a pump installed in a system with gravitational circulation of the coolant. The same heating systems will usually work on their own, however, thanks to the pump, the speed of fluid movement along the circuit increases, which makes it possible to reduce heat loss and increase the efficiency of heat supply.

The presence of an automated circulation pump in the pump piping allows the system to independently configure its own operation, i.e. no human intervention is required. When the pump does not stop operating, the coolant passes through it, and the bypass is currently blocked. When the pump stops, the circular pump opens and the liquid moves in it, while the stationary impeller of the pump closes the flow of the coolant.

Automated circular pumps are divided into two types:

The design of the first type of device has a check ball valve. The hydraulic resistance of the valve is minimal, thanks to this the liquid easily moves on its own. When the pump is turned on, the coolant begins to move faster, is transported into the main line and diverges in two directions.

The subsequent movement of the liquid occurs without any interference, and the reverse flow is blocked by the valve. The operating principle of the valve itself is very simple - the hydraulic pressure on the outlet side exceeds the pressure on the inlet side, thanks to which the ball is closely pressed against the seat of the structure and does not allow the fluid to move.

Valve circular pumps are very convenient and simple, but they are quite capricious regarding the quality of the water that fills the heating system. If the water mass contains various impurities, such as rust or scale, the valve absorbs dirt too quickly and becomes unusable, so it must be replaced.

Injection circular pumps are devices that are functionally similar to a hydraulic elevator. A pumping unit is installed in the central main line, which is connected to the key circuit using pipes with a smaller diameter. With such a scheme, both pipe sections are inserted into the middle of the main pipeline.

When the pump starts, some of the liquid enters a section of pipe and is forced through the apparatus, repeatedly accelerating in the process. The output section of the pipe, which is slightly narrowed and visually resembles a nozzle, does not stop working as the speed increases; thanks to it, productive pumping of liquid is ensured.

A vacuum is formed behind the outlet section of the pipe, due to which the coolant begins to be sucked out of the circulation pump. The flow, moving under pressure, pulls all the liquid with it, and it continues to move along the key highway with noticeable acceleration. This effect makes it possible to completely prevent the possibility of reverse flow of liquid.

The above procedure does not stop working only when the pump is on. If the pump equipment is turned off, then the coolant flows in full through the circular pump under the influence of gravitational forces.

Bypass installation options

Once we have determined what a bypass line is, we will consider the question of why it is needed and where it is installed. Depending on the problem being solved, the element takes the form of a bypass pipeline or a straight section connecting the supply line to the return line.

Reference. The English word bypass literally means “bypass”, “bypass”.

There are several options for installing bypasses in heating systems:

- On radiators of closed and open single-pipe systems.

- Parallel to the circulation pump operating in a gravity (otherwise known as gravitational) heating network.

- A jumper between the supply and return, forming a small circulation circuit for heating a solid fuel boiler.

- In various mixing units.

In apartment buildings where heated towel rails are connected to a common hot water supply riser, a bypass line is also used, which operates in a similar way to a radiator line (item 1 of the list). We will explain further why it is needed there.

The pipes of heated towel rails have a large diameter and capacity; a jumper is only needed for convenient removal of the coil

The first two options are well known to owners of private houses and apartments. Unfortunately, some owners, who consider themselves major specialists, “improve” bypasses or install jumpers where they interfere with the normal operation of the heating system. We will also consider random and intentional errors.

Tips and tricks

Before proceeding with the installation of a bypass in the heating system of an apartment building, first of all, you should notify representatives of the local housing and communal services in writing about your decision in order to agree on the issue of temporarily shutting off the coolant supply from the boiler room. After that, follow these recommendations:

In order for water to flow normally into the heating device, it is necessary that the diameter of the pipe in the bypass section be one size smaller than in the general circuit. When purchasing a ready-made bypass unit, it is necessary to require a quality certificate, which will serve as a guarantee of durable and normal operation of the device. When purchasing elements of the bypass section, you should check the threaded connections - they should be easy to unscrew and not twist when tightened. When deciding to install a bypass, use only ball valves, since they not only have low hydraulic resistance, but are also easy to open and close. It doesn’t matter whether the bypass is working or not, it is necessary to open and close all the valves from time to time to avoid sticking of the ball and will significantly increase the service life of all elements of the assembly. Before putting the heating into operation after a long period of inactivity, it is imperative to ventilate the area with the circulation pump. Throughout the heating season, preventive cleaning of filters installed in the bypass system should be carried out. To avoid mistakes and to ensure that the heating works efficiently, it is advisable to entrust all work to an experienced specialist.

Bypass installation examples

Installation errors

Some home, or rather, apartment craftsmen, when replacing old cast-iron radiators with new aluminum ones, deliberately make two stupid mistakes:

- install a ball valve on a straight bypass pipe in order to direct all the coolant into its own battery;

- Having listened to the advice of “smart” people, they assemble a mixing unit with a three-way valve in order to regulate the heat transfer of the heating device.

Let’s immediately make a reservation that such installation in a private house is not considered a mistake: you live there alone and control the heating yourself. In a high-rise building, such actions harm your neighbors, since you unbalance the system and take away more heat. This means that adjacent apartments receive less. How this happens, watch the video:

Instead of further listing the errors, we suggest that you familiarize yourself with the recommendations on how to properly install the bypass yourself:

- The jumper on the battery of an apartment building is a pipe without any shut-off fittings or valves. The maximum that is allowed is to reduce the diameter by 1 standard size (riser DN 20 - connector DN 15);

- If you want to regulate the heat transfer of radiators, please install manual or automatic thermostats. There are special full-bore models for centralized networks.

In multi-storey buildings with common risers, it is unacceptable to install fittings on the bypass pipeline

- If energy-independent gravitational heating is installed in a country house, install the pump only on the bypass. Gravity flow is not provided - no jumper is needed.

- When assembling mixing units yourself, make sure that the circulation pump is on the side of the open outlet of the valve. Other options don't work.

- A three-way valve equipped with a thermal head operates from a remote temperature sensor. Place the latter on the pipe behind the valve, where the mixed coolant exits. Then the element can be guided by its temperature.

Point #3 requires clarification. With 3-way valves, one pipe is always open - the one from which the resulting mixture comes out. A pump is installed on the same side. If the unit is placed on any inlet pipe, then further events will follow one of two scenarios: the circulation will stop or the coolant will flow through the bypass, close in the boiler circuit and not get into the radiators.

Operating principle of the bypass valve

If an unusual situation occurs, a power outage or a pump breakdown, the pressure stops and the valve automatically closes the jumper, allowing water to flow naturally. This allows the heating system to be fully automated. The disadvantage of automatic bypass is sensitivity to water contamination and small contaminants. Before installation, it is recommended to clean the water supply system of the AED to remove deposits and rust in pipes and radiators.

Before starting work, you need to decide on the material of the water supply system. For polypropylene pipes, dismountable connections are used, and first the pump block is assembled along with the bypass. The branch is connected using tees mounted in the main pipe. For the steel version, first the pipes are soldered in, then the valve on the bypass. The bypass system is installed towards the coolant and must be assembled in a certain sequence.

Assembly diagram:

- Filter;

- Check valve;

- Forced action pump.

The diameter of the bypass line passage must be equal to the return diameter. Experts recommend that all taps be equipped with dismountable fittings during installation. In this case, various situations will be eliminated during the repair.

Operating principle of the bypass valve

Before starting installation work on installing the pump, it is necessary to drain the coolant from the system. The entire structure is oriented so that the outlet pipelines are vertical or horizontal, depending on the stroke of the pipe.

How the bypass line works:

- They assemble a section of the bypass that will be located parallel to the highway;

- A section equal to the length of the bypass is cut off from the return;

- Tees are installed at the ends of the line;

- A section with shut-off valves or valve is mounted between them;

- The assembled section of the bypass is connected to the main line with pipes of equal length.

During installation, it is necessary to leave space for subsequent dismantling of the pump and other elements. It is necessary to carry out the installation correctly, making sure that the arrow on the housing coincides with the coolant current.

Recommendations for bypass installation

When installing a bypass, certain rules must be observed:

- The bypass diameter should be one caliber smaller than the main pipe. Otherwise, according to the laws of hydraulics, all the coolant will flow along the path of least resistance past the heating radiator. For example, if the liner has a ∅ ¾ inch diameter, then for the bypass you need to use a ∅ ½ inch diameter.

- The bypass must be installed as close as possible to the heating radiator and, accordingly, further from the riser.

- At the design stage, decide how automated the heating radiator control process should be. Accordingly, use shut-off valves or thermostats in the future.

- It should be taken into account that after installing a bypass, the radiator will receive 30-35% less coolant, and heat transfer will decrease by 10-15%. Taking this into account, you need to select the size of the new radiator.

- It is not recommended to install a shut-off valve on the bypass itself. This is especially true in apartment buildings, when, through carelessness, by turning off this tap and the taps on the radiator, you stop the flow of coolant in the entire system.

Battery tying

If the installation of the system is carried out independently, then you need to know all the requirements that apply to this or that element. This also applies to the bypass. It is often installed in places where radiators are mounted. But why do you need a bypass in a heating system? This issue needs to be looked at more carefully.

Radiators are tied according to a simple pattern

Why is it needed?

Previously, single-pipe heating was used in the construction and improvement of houses. This greatly simplified the work and also reduced costs. In this case, two collectors were installed in the elevator unit, which were responsible for supplying and processing the coolant. Further heating was developed according to different schemes:

- Top feed. There was a pipe running from the collector to the top floor. The coolant was supplied upward through this riser. After that, it went down, passing through all the radiators.

- Bottom feed. In this case, the coolant begins to flow into the radiator when it is raised up. This series connection of devices has some disadvantages.

In both the first and second cases, the connection is made in series. This means that if a problem occurs on some equipment, you will have to turn off the entire system. To circumvent this problem, special jumper pipes were included in the system. So, if necessary, the radiator is disconnected from the system using taps without disturbing its operation. This makes it possible to easily repair the battery.

The jumper is installed closer to the battery

This is not the only reason for using a jumper in heating. The room is heated using radiators. If there is a bypass with valves, apartment owners have the opportunity to independently adjust the coolant supply. Thus, controlling the temperature in the house is not difficult.

The dressing tube has different shapes

Bypass installation

To carry out heating installation, you must have certain knowledge and skills. This takes into account the method of pipeline assembly. For this purpose, threaded and fitting connections are used, as well as pipe soldering. Having these skills will make the job easier. It is worth considering some rules and recommendations from experts:

- There should be no valves between the rack and the bypass. Otherwise, the coolant circulation may be disrupted.

- On the vertical riser pipe, the jumper is mounted in close proximity to the battery. In this case, space must be provided for installing shut-off valves. It is mounted on both sides of the radiator.

- Do not install valves on the bypass unless necessary. If you install taps on the jumper, the circuit will become unbalanced. In an autonomous system of a private house, this in turn allows you to redirect the flow. In a multi-story building, this option is ineffective and is a violation of standards.

- The size of the pipes is important. The diameter of the insert is two sizes smaller than the section of the stand. The pipes that go to the radiators are made one size smaller. In the horizontal scheme, the size ratio is somewhat different.

Compliance with the dimensions of pipes and pipes will ensure normal operation of the system, in accordance with all the laws of hydraulics. As for installation, its features directly depend on the type of material used. If we are talking about a metal pipeline, then it is enough to simply weld the jumper and install the taps.

Installation is carried out in different ways

The use of polypropylene, as well as metal-plastic, requires the use of special fittings. You can build a bypass yourself from a pipe of the required size or purchase a ready-made part.

The pump is often installed on a jumper

Installation in a small circuit of a solid fuel boiler

In the classic version of a single-pipe system, the bypass is mounted next to the radiators. When using solid fuel boilers for heating, the bypass jumper is often used for the entire heating system of the house.

Installation is carried out in the direction of the coolant:

- installation of a check valve, pumping equipment and filter system is carried out;

- installation of the unit in the main pipeline is carried out using couplings;

- An additional tap is placed on the jumper, allowing, if necessary, to shut off the circulation of liquid.

Installation on the return line of the heating system

Installing a bypass is not considered labor-intensive if you carefully study the operation and installation nuances. With the correct selection of components, the heating system will be more energy efficient and reliable.

Bypasses with manual adjustment

Bypasses that are adjusted manually (manual bypasses) are equipped with ball valves. The use of ball valves is determined by the fact that they do not change the pipeline capacity at all when switching, since the hydraulic resistance in the system does not change. This quality makes the ball valve an optimal option for bypass.

Shut-off valves of this type allow you to regulate the volume of liquid that passes through the bypass section. When the tap is closed, the coolant moves in full along the main line. The operation of ball valves has one important nuance - they need to be turned regularly, even if there is no need to adjust the system. This is due to the fact that if left stagnant for a long time, the taps may become tightly stuck and will have to be replaced. Sometimes a heating system feed valve is also installed, which plays a significant role.

Manual bypasses in heating systems can be used in several ways. Most often they are used to connect batteries to a single-pipe main, as well as for piping circulation pumps.

The battery does not heat in a private house

The reason why batteries in a private home do not heat up may be a number of factors. We can only consider the question in general. There are different reasons and they are not always obvious. Sometimes such a small thing as a faulty faucet or a clogged chimney can become a stumbling block. Despite this, there are no hopeless situations, the main thing is to determine the reason why the battery in a private house does not heat, the rest is a matter of technology.

Insufficient boiler power

If the radiators in a private house do not heat well, then one of the reasons may lie in the heating boiler. In your home, you can say with almost 100% probability that the heating circuit is autonomous. So the boiler is standing. It could be:

Why do batteries heat poorly in a private home? The reason may be an incorrectly selected boiler power. That is, it does not have enough resources to heat the required amount of liquid. The first sign that the power has been selected incorrectly is the constant operation of the heating device, without shutdowns.

Although in this case the heat exchangers will heat up at least a little. And if the water in them is completely cold, it means that the boiler is broken or cannot turn on. Modern units have a minimum pressure requirement in the system. If this requirement is not met, it will not turn on. In addition, there is an automation and security system.

Let's take, for example, a gas boiler. It contains a sensor that monitors that all gases go into the chimney. It is possible that the chimney or some smoke outlet pipe is clogged. In any case, the sensor will send a command to the control unit and it will not allow the boiler to turn on.

Problems with the batteries themselves

The batteries in a private house do not heat up, what should I do? If no problems are found with the boiler and it is working correctly, then the reason why the batteries are cold should be looked for in the circuit itself. Possible options:

- airing;

- pollution;

- insufficient pressure;

- incorrect pipe routing;

- Incorrect connection of heat exchangers.

If the batteries are cold, then you need to check all the above factors. We have already written in more detail about what to do if the batteries do not heat up. The specificity of a private house is that all characteristics can be controlled independently.

Then make sure there is no dirt in the pipes and heat exchangers. How to do it? You will have to drain water from cold radiators in a private house. What to do is known, you need to unscrew one end (bottom) of the battery and substitute a larger vessel. If black water flows, then there is nothing to think about - this is pollution. It is necessary to rinse the circuit to clean water. Sometimes thick liquid flows out of radiators along with water. This is dirt collected in copious amounts.

What other reasons could there be for cold radiators in a private home? If the problem is not air or pollution, then circulation is broken. This may be due to low blood pressure. In general, in an autonomous circuit the coolant pressure does not exceed two atmospheres. If you have new batteries, then look at their data sheet. In modern heat exchangers, the operating pressure requirements are higher than in Soviet models

Pay attention to this

Disruption of coolant circulation

We will separately consider the disruption of coolant circulation due to improper pipe routing and piping of heat exchangers, as a result of which the batteries are cold. In your home, you are free to choose the method of pipe routing. It could be:

- two-pipe heating system;

- single-pipe heating system.

It so happened that many people previously preferred a single-pipe heating system, also known as “Leningradka”. It was believed that it was simpler and cheaper, but in reality this is not the case. In addition, in this scheme it is very difficult to regulate the temperature of the heat exchangers as they move away from the boiler room. The farther from the boiler, the more sections there should be. Therefore, it is not uncommon that the last battery in a private house does not heat. The coolant flows through one pipe. In such a scheme there is no return.

It turns out that water enters the heat exchanger, cools there and is again drawn into the general flow. Accordingly, after each radiator the overall flow becomes colder. The difference increases with distance from the heating element. As a result, the water may reach the extreme heat exchanger almost cold.

In a two-pipe system, errors may be made in the piping:

- incorrectly installed shut-off valves;

- incorrect connection of the heat exchanger (there are three types: side, bottom, diagonal);

- The diameter of the bends is incorrectly selected.

Installation in a small circuit of a solid fuel boiler

In the classic version of a single-pipe system, the bypass is mounted next to the radiators. When using solid fuel boilers for heating, the bypass jumper is often used for the entire heating system of the house.

Installation is carried out in the direction of the coolant:

- installation of a check valve, pumping equipment and filter system is carried out;

- installation of the unit in the main pipeline is carried out using couplings;

- An additional tap is placed on the jumper, allowing, if necessary, to shut off the circulation of liquid.

Installation on the return line of the heating system

Installing a bypass is not considered labor-intensive if you carefully study the work and installation nuances. With the correct selection of components, the heating system will be more energy efficient and reliable.