In the modern world, technological progress does not stand still, but many homes still use simple stoves for heating. Despite the fact that this type of heating is one of the most popular and familiar options, it has some significant disadvantages. For example, the most significant of them can be considered the need to prepare coal or firewood, as well as a noticeable difference in air temperature during the heating of the stove and after it cools down.

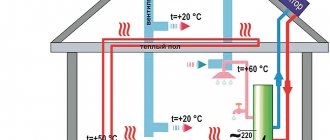

In such cases, a real salvation will be a well-chosen scheme for heating a private house with a centralized heating system using electric or gas boilers.

Here you can see an independent comparison of different heating systems for a country house

Color combinations

Stylists advise taking into account the following nuances:

- direction in the interior;

- combination of shades;

- illumination

It is much easier to choose a palette if the style for the kitchen and living room has already been selected. For example, neoclassicism and Provence have their own combinations. In a classic interior, designers combine pastel colors, pale colors, which are slightly diluted with dark shades. In French country houses you can often see soft blue, pink, and pistachio colors. Art Deco designers make up objects and finishing materials in black and white, sometimes beige and brown or silver and black. The main thing is to choose a shade for the walls. White will become universal, it will expand the space, and later you can paint them with any paint. However, in the cooking area, white ceases to look fresh. Beige or gray shades would be more practical. This background will highlight the other colors. In a monochrome interior, designers recommend gluing wallpaper in an unusual color or with a photo print.

Methods for laying heating pipelines

In the heating system of a cottage, pipes can be laid in two ways:

Open laying method

In this case, they are laid along the walls, parallel to the baseboards. Throughout their entire length they are within visibility range.

Advantages of this method:

- Access to pipes without dismantling structures

- Low heat loss

- Easy heating installation

Main disadvantages:

- The pipeline often spoils the appearance of the premises and does not fit into the design

- To avoid sagging and deformation, not all types of pipes can be used

Hidden laying method

The pipe is walled up in the wall, in the floor or decorated with external material.

The main advantages of hidden pipeline installation:

- Possibility to hide highways so they don’t spoil the interior

- Possibility to use pipes made from modern materials

The disadvantages include:

- Access to pipes is difficult in case of need for possible repairs, replacement of individual sections, or elimination of emergency situations

- Due to large heat losses, the lines must be thermally insulated

When performing hidden routing, you must use only reliable and proven pipes. The best option is pipes made of cross-linked polyethylene.

Filling the coolant with this method must be performed only after a hydraulic test of the heating system.

Heating schemes

In order for the house to really be warm, the equipment not to break down, and the financial costs of heating not to be exorbitant, it is necessary to carefully plan the choice of appliances. First of all, you should decide on the scheme by which the house will be heated. It can be single-pipe or double-pipe.

With one pipe

According to it, all radiators in the house are connected in series and form a single chain. The coolant enters the main pipe, which can be installed in two ways. If the pipe is laid in the upper part of the room, then the radiators are also mounted at the top, which is inconvenient and unsightly. Installing a pipe under heating devices looks more aesthetically pleasing, but requires that each radiator be equipped with a special tap necessary to remove excess air from the battery.

See also: how to properly bleed air from a heating battery.

According to a single-pipe heating system, all radiators in the house are connected in series and form a single circuit

Designing and implementing a single-pipe circuit is not difficult. Since the system involves a small number of pipes, they will not clutter up the space in the house, and their installation does not require a lot of material. However, the heat will be distributed unevenly according to this scheme.

You can see a heating diagram with underfloor heating in this video:

Two-pipe system

It involves installing not only the supply pipe, but also the return pipe. The water entering the battery through the supply pipe flows back into the main line through the return pipe. Heating devices connected according to this scheme heat up equally, independently of each other. Each radiator can be equipped with a thermostat that allows you to monitor the water temperature and control heat transfer.

Read more: one-pipe and two-pipe heating systems in a private house.

Heaters connected by a two-pipe system heat up independently of each other

The main disadvantage of the two-pipe scheme is its cost. To install a double circuit of pipes, a larger amount of material will be required, which will significantly affect the cost of installation.

Video description

In our video we’ll talk about heating in a private country house.

Our guest is the author and presenter of the Teplo-Voda channel Vladimir Sukhorukov: Modern boilers included in a home heating project are equipped with an electronic system that is responsible for the operation and functionality of the device. In addition to the boiler, the project includes wiring from pipes, radiators, pumps and other elements.

They can be easily bought in specialized stores, their assortment is large, the materials from which they are made can be very different, and so can the “sophistication” of control systems. They differ from each other in power, properties, brand ratings, quality and cost.

Components for heating systems are made from various materials Source nts-sk.ru

What is included in the project?

Professionally drawn up project documentation should include the following items:

- company letterhead with seal;

- organization license;

- explanatory information about the project points;

- a detailed plan for routing highways (including high-rise ones);

- estimate;

- instructions for performing work;

- specification of materials and equipment;

- project sketch;

- drawing detailing all components of the heating main;

- plan for wiring communications and connecting nodes.

Heating scheme

There are two main types of heating systems - single-pipe and double-pipe.

- In a single-pipe system, the coolant moves along a ring consisting of one pipe, to which radiators are connected in series.

- In a two-pipe system, the hot coolant is supplied to the radiators through one pipe, and the cooled coolant is discharged to the boiler through the other.

The single-pipe system has two major disadvantages, so it is rarely used in private construction, despite the insignificant savings in pipes.

The disadvantages are as follows. The coolant cools down, so the last radiator is much colder than the first. Therefore, the system cannot be extended, it is applicable in small houses, and the last radiators must be of greater power to equalize the heat output.

Changing the operating parameters of one radiator affects others. It is difficult to configure the selection of the required thermal power for each radiator.

Two-pipe systems

There are several types of two-pipe radiator circuits.

- Sequential (passing circuit) - all radiators on the same floor are connected to one supply pipeline and one return line. The scheme is the most stable, does not require adjustments, and is applicable in the largest houses.

- Dead-end (wing circuit) - all heating is divided into several arms consisting of two pipelines - supply and return, between which radiators are connected in parallel. The scheme works great in small houses, provided the shoulders are equal.

- Beam (collector circuit) - pairs of pipelines depart from the collector to each radiator. There is a disadvantage in the complexity of laying pipes, and the complexity of setting up distribution in the manifold. But the system can be quickly controlled from one place, and all pipes are of small diameter. It is used provided that the collector is installed in the center and all connections are equal.

Usually, for a private house, they choose a ride if the house is large. Or a dead-end with heating divided into 2 or several identical arms for a small house, which allows reducing the diameters of the main pipelines.

As you can see, understanding the choice of the main parameters of the heating system is not so difficult. The decisions made also determine the choice of all technical means of the heating system.

Selecting a heating device

When drawing up a heating scheme for a two-story, three-story or one-story house, specialists will definitely discuss with the customer which heating devices are preferable to use. It can be:

- convectors;

- radiators.

Radiators are ideal for central heating systems. They operate on a combined principle. This makes them perfect for installation in 2-story houses.

Radiators are made from different metals: cast iron, steel or aluminum, they can be forged and ceramic.

What is included in a professionally designed heating system project?

When ordering a project from the company’s specialized specialists, the customer should receive:

- Title page with the original seal of the organization.

- Explanatory note (mandatory) to the created project.

- Communications layout plan (general).

- Elevation plan of the same wiring.

- Estimate: for the project, materials, types of work and their cost.

- Specification of materials and special equipment.

- The project is in the form of a detailed sketch.

- A drawing with precise detail and dimensions of all main and additional components.

- Utility wiring plan, connection points and tie-ins.

Before creating a project, an engineer must arrive on site to take the necessary measurements and draw up a preliminary drawing. After which a contract is drawn up with the customer, all possible options are considered, taking into account the client’s preferences and wishes. Each customer has the right to demand from the design company a copy of the project in electronic form or request a copy of it in paper form.

Price list

Important: the prices indicated are for the design of household systems with a power of up to 100 kW. The cost of designing systems with a power of over 100 kW is discussed individually.

Minimum prices for design sections:

- Heating: 16'500 rub.

- Ventilation: RUB 11,000

- Air conditioning: 11'000 rub.

- Water supply: 5'500 rub.

- Sewerage: 5'500 rub.

The minimum cost of the project is 16,500 rubles.

| Type of work | Price |

| Drawing up a dimensional plan for premises up to 500 m² | 60 RUR/m² |

| Drawing up a dimensional plan for premises of 500 m² or more | 46 RUR/m² |

| Thermal engineering calculations up to 500 m² (floor height up to 4 m) | 60 RUR/m² |

| Thermal engineering calculations for 500 m² or more (floor height up to 4 m) | 46 RUR/m² |

| 3D heating design up to 500 m² | 121 RUR/m² |

| 3D heating design for 500 m² or more | 91 RUR/m² |

| Calculation of systems based on heat pumps | 632 RUR/kW |

| Calculation of systems based on solar collectors | 632 RUR/kW |

| Calculation of systems based on combined energy sources | 316 RUR/kW |

| Calculation of systems of increased complexity (non-standard solutions) | 316 RUR/kW |

| Selecting heating in 4 steps! | |

| Calculation of automation and dispatch systems for boiler houses | 316 RUR/kW |

| Calculation of systems based on cascade installations | 316 RUR/kW |

| Boiler house design up to 30 kW | RUR 25,300/pcs. |

| Boiler house design up to 60 kW | RUB 31,625/pcs. |

| Boiler house design up to 100 kW | RUB 37,950/pcs. |

| Design of a boiler house 100 kW or more | negotiable |

| Snow melting system design | 379 RUR/m² |

| HVAC engineer consultation (30 minutes) | 2200 rub./pcs. |

| Subscription service "Standard" | 1650 rub./pcs. |

| Premium subscription service | 3850 RUR/pcs. |

| Heating cost? | |

| Subscriber service "VIP" | 7150 RUR/pcs. |

| Heating installation Price list Water supply installation Price list Sewage installation Price list | |

Electric

To heat your home, you can use electrical appliances: convectors, long-wave infrared heaters or “warm floor” systems. Also, to achieve maximum effect, it is recommended to combine several electrical appliances.

With any of these methods, large payments for energy consumption cannot be avoided, so it is recommended to install them in cases where there are no alternative heat sources.

Heating pipe materials

When developing a system, depending on the method of laying pipes, their material is selected. This is due to its thermal expansion and flexibility.

For example, steel pipes can be laid both inside and outside. It is recommended to lay cross-linked polyethylene and metal plastic in a hidden way. The open method of laying them is undesirable, since due to significant sagging the aesthetics of the interior are disrupted. It is advisable to lay polypropylene lines openly. Otherwise, possible leaks at the joints may not be detected in time.

Next, we will take a closer look at the main types of heating pipelines and list their main advantages and disadvantages.

Cross-linked polyethylene

Modern technologies for manufacturing pipes from this material make it possible to achieve high consumer properties. Pipes made using cross-linking methods are labeled PEX.

Leading manufacturers of cross-linked polyethylene pipes produce press fittings for them. They are crimped using a special tool. The resulting compounds are highly durable.

Advantages:

- Flexibility, tensile strength, ability to return to its original state even with severe deformation

- Ability to withstand high pressure - up to 10-12 atmospheres

- Simple heating installation when using these pipes

- Resistance to high temperatures and aggressive environments

Flaws:

- UV Vulnerability

- Softness of the coating (this can lead to the pipe walls being eaten by mice and rats). This is also why such pipes are used mainly in internal communications. It is recommended to lay them in the ground in metal shells

- XLPE pipes and fittings for them are relatively expensive

- High cost of tools for joining a pipe with a fitting

Polypropylene

This is a lightweight material obtained from petroleum products. Both the pipes themselves and fittings are made from it. The pipes are connected to each other using fittings using the soldering method.

Advantages:

- Low price

- Resistance to aggressive chemicals

- Easy to assemble

- Low price tools for soldering joints

Flaws:

- Deterioration of properties under the influence of sunlight

- Flammability

- Criticality to high (above 70 degrees C) coolant temperature

- Low durability

Installation of heating in a private house using polypropylene pipes is used when the internal heating system is laid open.

Modern polypropylene pipes, in order to improve their consumer qualities and reliability, are reinforced. Reinforcement materials are fiberglass or aluminum. The best option for heating is glass fiber reinforced polypropylene.

Metal-plastic

The name of the material reflects its structure. It consists of layers of polyethylene, aluminum and an adhesive layer. Pipes made from this material are used with brass fittings.

Advantages:

- High strength

- Durability

- Resistance to high temperatures, sunlight and aggressive environments

- Flexibility

- Ease of installation of metal-plastic pipes

Flaws:

- Weak resistance to system pressure

- Relatively high cost

- Tendency to thermal deformation

- Delamination when the maximum permissible pressure is exceeded

- High cost and lack of versatility of the tool for working with the material

Heating in a private house with metal-plastic pipes is used mainly for internal installation.

Steel

This material is traditionally used for the manufacture of heating pipelines. Until recently, almost all pipes for heating premises were made only from this material. Connections between lines are carried out by welding or using threaded fittings.

Advantages:

- High strength, resistance to mechanical loads

- Ability to withstand any temperature and coolant pressure

- Low price

- Low coefficient of thermal expansion

Flaws:

- Labor-intensive and complex installation of heating in a private house using these pipes

- Lack of flexibility

- Susceptibility to corrosion

- Internal overgrowth

- The service life (compared to modern materials) is relatively short - up to 15-20 years, depending on operating conditions.

Copper

Heating systems built on copper pipes are rare. The reason is the high price of such pipelines.

Advantages:

- High strength, resistance to mechanical stress, high temperature and pressure

- Long service life

- No corrosion

- Aesthetics (with open gasket)

Flaws:

- High price of material

- Criticality to the presence of impurities in the coolant and its composition

- Labor-intensive installation of heating in the house

- Negative galvanic processes when joining with certain materials

It should be remembered that installing copper pipes in front of steel pipes and radiators is unacceptable. This leads to negative galvanic processes. To avoid this, it is necessary to lay copper pipes after the steel sections along the flow of the coolant or make a galvanic gasket from a neutral material (for example, bronze, brass).

Stainless steel

Heating a house from stainless steel pipes is significantly more expensive, but they do not have one of the main disadvantages - susceptibility to corrosion. As a result, stainless steel pipelines last much longer and can be used in almost any heating systems. But their cost is very high and they are used in very rare cases.

Bellows pipes

They are corrugated flexible stainless steel hoses. They are not often used in heating systems. Sometimes they act as inlets to radiators or convectors, if the use of ordinary pipes for this purpose is difficult for some reason.

Wiring options

We will present all possible schematic diagrams for water heating of a one-story house; however, the author strongly recommends abandoning two of them in favor of the third. Rationale? Let's start with getting acquainted.

Two-pipe

The diagram of a two-pipe heating system for a one-story house looks like this:

- There are two pipelines running along the perimeter of the house (under the floor or in the living room) - supply and return.

- Radiators, registers, fan coils or convectors are embedded in them as jumpers, creating a kind of short circuit.

It is clear that water will tend to circulate through the heating devices closest to the circulation pump. To ensure that those further away also get heat, the heating system is balanced: the passage of water through some of the radiators is limited by throttles.

There seem to be two disadvantages to this scheme:

- Unreasonably high pipe consumption.

- Risk of defrosting without balancing.

It is enough for a curious child to open the nearby throttles all the way - and after a short time the circulation in the distant batteries will decrease to zero. The author had the opportunity to restore two-pipe heating systems after such events: both pipes and radiators were torn apart by ice.

Two-pipe heating. This is possible, but there is a simpler and more reliable option.

Radial

This diagram of the heating system of a one-story house looks like this:

- Collectors are mounted on the forward and return pipelines - combs with chokes on each branch.

- From each pair of bends (one from the supply and one from the return) a pair of pipes goes to the battery.

In terms of adjustment, its capabilities and convenience, such a scheme is beyond praise. But with installation everything is worse: you will be faced with the need to hide at least half a dozen pipes in the floor screed or behind false walls. More often - much more. Of course, their total cost will not please you either.

You definitely can’t call beam wiring simple and cheap.

Single-pipe

The simplest diagram of a single-pipe heating system for a one-story house, the so-called Leningradka, is mounted as follows:

A large diameter pipe is installed around the perimeter of the house (no smaller than DN32. Bigger is better).

The pipe is mounted inside the living space: then all the heat that is given off by its surface will serve to heat the room. And where it is most needed - near the external walls. On the supply side, the wiring should be slightly higher than where the return flow returns to the boiler.

1-boiler 2-expansion tank. 3-heating registers. 4-chokes. 5-circle of the entrance door. 6-reset. The arrows show the slope of the pipes. This scheme ensures natural circulation.

Radiators or convectors are cut into the loop with a pipe of smaller diameter (usually DN20). It is advisable to install chokes and heater shut-off valves on the supply lines; An air vent in the top plug wouldn't hurt either. However, this heating scheme for a one-story house allows you to start the heat without additional fittings.

Chokes are useful to equalize the temperature of radiators along the ring; The air vents will release air, which without them will be displaced by water into the upper part of the heating device and will somewhat reduce the efficiency of heat transfer.

What do we get?

- The described heating of a one-story private house can be installed with your own hands very quickly and at minimal cost.

- No heat is lost: all communications are located inside the living rooms.

- When the circulation pump stops, the movement of the coolant will slow down, but will not stop. The thermal expansion of water is sufficient to continue circulation.

The key point here is the diameter of the ring around the perimeter of the house. The smaller it is, the slower the natural circulation of water.

Selection of coolant

It is not enough to draw up a diagram of heating boilers and decide on a heat source; it is important to make the right choice of coolant.

For houses that have an electric, fireplace or stove heating system, a coolant in the form of heated air is well suited. But it has its drawbacks:

- low heat transfer; insufficient density;

- insufficient heat capacity.

Liquid substances do not have these disadvantages. They absorb the body well and also release it well, retaining heat for some time. Therefore, most experts believe that water is the best coolant of all existing ones. The main thing is to ensure continuity of the process through circulation.

It is important to know! Experts warn that in order to prevent the pipes from becoming coated from the inside, and the heating system to remain operational longer, you should “run” it through a filter for purification before using water as a coolant.

If the house is intended for seasonal use, antifreeze should be used as coolants. It does not freeze in the cold season, so the heating system is always in working order.

Other tips

The living room with the kitchen can be combined and decorated with various shortcomings

It is important to calculate and anticipate everything in advance. Decorators and craftsmen share tips that will help avoid problems during repairs and furnishings:

The result depends on how detailed the project is drawn up. Oddly enough, it is worth taking into account the growth of loved ones and relatives. It is also recommended to calculate the approximate number of possible guests. You can get rid of food smells by installing a strong hood or ventilation system.

Small models are more suitable for housewives who do little cooking. If you plan to have a sleeping place in the living room, then it is important that the ringing of appliances and other kitchen utensils is not heard. Silent dishwashers and other appliances will come in handy.

In addition, you can install a sliding door and install a soundproof partition. If there is sensitivity to ultraviolet radiation, the owners hang thick curtains made of light-proof fabric. If household appliances do not match the direction of the interior, they are hidden behind furniture or put away in kitchen cabinets. When installing luminaires and lamps, they are guided by several criteria

It is important that the light falls evenly throughout the entire space. Especially bright lighting is preferable in the kitchen area and where the dining table is installed

In the living room, designers create a subdued atmosphere using wall sconces and table lamps. Multi-level stretch ceilings with LED strip also look good in this room. Moisture-resistant finishing materials are more durable and easy to clean. Thus, they retain their appearance for a long time. The kitchen combined with the living room combines:

- personal tastes of the owners;

- reliable finishing materials;

- current design ideas;

- convenience;

- trends. The best photos of kitchen living room design

Basic rules for installing heating pipelines

It must be remembered that pipeline routing is performed after all heating devices are installed in the selected locations. The optimal sequence of installation operations is as follows:

Marking the passage of heating pipes

It is better to do this in advance, before installation. During the marking process, as a rule, installation difficulties are revealed that are caused by the architectural and construction features of the cottage. Knowing them, you can prepare in advance to solve them or change routes.

Most often, highway marks are applied to the walls. In some cases, they can be performed on the floor, but in this case they can be rubbed down by people passing through the premises.

Making the necessary technological holes and grooves

It is also better to complete this stage in advance throughout the entire work area. The locations of the required holes and the passage of the grooves are determined during the marking.

The grooves can be cut with a wall chaser. If this tool is not available, then they are first marked with a grinder and then hollowed out with a hammer drill.

Pipe insulation

This must be done if hidden wiring is performed. The main purpose of insulation is to prevent heat loss and increase the efficiency of the system as a whole.

Insulation is carried out with a special heat insulator, which is made according to the diameter of the pipes. It is put on the pipes manually at the installation site. Rubber-based heat insulator is considered the most effective and durable. But its price is also higher compared to analogues.

Laying and securing pipes on building structures

Pipes must be secured not only with open, but also with hidden wiring of the heating system of a private cottage.

With open wiring, the pipes are attached to the walls with special clips. Self-tapping screws or nails are used as fasteners (depending on the wall material).

If hidden wiring is performed, then the pipes are secured to the wall in grooves or to the floor with special clamps or punched tape. If the main consists of several pipes, for example, coming from the collector, then they must be fastened into loops. The fasteners that are used are the same.

Connection to heating devices

Depending on the design of the radiator, pipes can be connected to it either directly or via multiflex. In any case, connection fittings are used for connection, which are supplied in the kit.

When manifold wiring the heating system of a private house, the connection is made not only to heating devices, but also to floor collectors. As in the previous case, connection is made using complete connecting fittings.

Hydraulic and pneumatic tests

This is a necessary component of installation work. During the process, the system is filled with water or air. Then, using a special pump or compressor, excess pressure is created in it (~1.5 workers when testing with water). After an hour, the results are taken - there should be no drop in pressure.

If during testing there is a drop in pressure in the system, then leak points are identified. Then work is carried out to eliminate the causes of the leak. After this, hydraulic tests of the system are carried out again.

Sealing holes

Filling the floor screed and sealing the grooves when laying hidden pipes must be done only after successful hydraulic tests. This is general construction work. The sealing of grooves is usually done manually, most often with plaster.

District heating design

Heating scheme for an apartment building

It is much more difficult to design a heating system for an apartment building. Difficulties are associated with adapting the system to the central pipeline, as well as uniform distribution of the coolant among all consumers.

Until recently, the organization of heat supply to multi-storey buildings was carried out in only one way - by connecting to the central heating main. This entailed the impossibility of changing the temperature regime of the system by apartment residents, as well as a direct dependence on the quality of services of the management company.

Special engineering bureaus are engaged in the design of heating systems for apartment buildings. The following factors are taken into account:

- Number of storeys of the house, its area. Parameters for residential and non-residential premises are calculated separately;

- The degree of thermal insulation of walls and window structures. In this case, the calculated temperature of the outside air for heating design must be compensated by the heated air inside, taking into account the heat losses of the building;

- Thermal operating mode. To reduce losses when hot water passes through external pipes, its temperature can range from +90°C to +110°C. To reduce this indicator, an elevator unit is installed in each house, which is also taken into account when drawing up technical specifications for heat supply design.

Taking into account all these features, most residents of apartment buildings refuse central heating services at the first opportunity. As an alternative, autonomous heating systems for an apartment building are designed, which are almost completely similar to those described above.

Over time, the performance of a home may deteriorate. Accordingly, it is necessary to either improve the thermal insulation of external walls or increase the level of air heating in apartments.

Heating a cottage without gas - possible options

Scheme of electric heating for a cottage

But what to do if it is not possible to organize gas heating for the cottage? Installing solid fuel boilers is not always advisable. Therefore, country property owners are considering alternative options for heating a cottage without gas.

The easiest way to maintain a comfortable temperature in the rooms of a cottage is to install an electric heating boiler. It can be either the main source of thermal energy or an auxiliary one. However, it will be characterized by high energy consumption costs. This will significantly affect the family budget of those living in a large cottage.

Therefore, we suggest considering other alternative methods of heating a cottage without gas. Each of them has specifics of service and configuration and is not always suitable for organizing the heat supply of a particular residential building.

Along with the installation of an electric boiler for heating the cottage, it is recommended to install a heat accumulator. With its help, you can switch to the night mode of operation of the equipment - at this time there is a preferential tariff for heating payments.

Stove heating for the cottage

Stove heating together with an electric boiler

During the initial analysis, we can conclude that stove heating of cottages is ineffective. However, it is necessary to take into account the operating features and characteristics of a country house - its total volume, degree of thermal insulation and frequency of residence.

For small buildings and in the absence of a gas main, combined heat supply can be installed. Considering that many old cottages have stove heating installed, a small modernization is being done to improve its characteristics:

- Installation of an electric boiler . It must have a coolant temperature sensor and a function to turn off the heating element when optimal water heating is achieved. A heat exchanger is installed in the furnace and connected to a common water heating system. As a result, the coolant is heated from it, and the electric boiler only maintains the desired temperature level;

- Air heating . A solid air pocket is installed around the furnace firebox, which is isolated from the combustion chamber. Air lines are connected to this structure, which deliver hot air to the premises of the cottage. To increase the air exchange rate, it is possible to install fans.

You can also opt for traditional stove heating at home. Then you should make a system of air ducts and chimneys. With their help, the wall next to which the stove is installed will be heated. Stove heating requires annual cleaning of chimneys. A large amount of soot inside the pipes will worsen traction performance.

Criteria for choosing types of heating radiators for an apartment

- Operating pressure.

This indicator can be found in the product passport, which you should definitely pay attention to. It should not exceed the pressure in the heating system (in any case, no more than 1.5 times)

If we take into account the operating features of Russian utility organizations, pressure drops (test and working) become one of the most important causes of failure of modern heating devices.

For example, the average pressure level in five-story old residential buildings is usually up to 8 atmospheres. While in modern multi-storey buildings, a coolant with an operating pressure of up to 15 atmospheres is most often used.

- Resistant to water hammer.

This determines the service life of the product and the operating efficiency of all types of heating radiators. It is impossible to protect yourself from water hammer in an apartment with centralized heating. Therefore, it is necessary to choose heating devices with high resistance to water hammer.

- Number of sections.

Some heating devices can be expanded during use. And if you do not have the opportunity to immediately determine the required size of the radiator, or you are not sure of the efficiency of a particular model, you should give preference to these types of heating radiators.

- Radiator power.

This factor is certainly key. Not all types of heating devices are capable of maintaining an optimal microclimate in homes if the temperature drops to -40 °C in winter

Then you should pay attention to the maximum coolant temperature. Some models from foreign manufacturers are rated up to +90 °C

But in those regions where severe winters are expected, it is necessary to select products with a maximum temperature of up to +130 ° C.

- Coolant composition.

Almost no Russian utility organization is distinguished by the high quality of the coolant, which wears out the walls of the radiator. When choosing a heating device, you should take this factor into account and choose a radiator with thick walls.

- Design and design of products.

If you are choosing a battery for an apartment with modern decoration, then you probably do not want to install an old-style volumetric structure.

- Product service life.

This criterion is determined by the working conditions and technical features of the utility service. Replacing batteries in an apartment is not the cheapest thing, so when choosing a device, give preference to types of heating radiators that will last you at least 20–25 years.

- Easy to install.

This is important if you plan to install radiators yourself. A heavy cast iron structure is not suitable for these purposes, while lightweight panel batteries can be installed by anyone.

- Manufacturer.

As a rule, the fame and impeccable reputation of the manufacturing company is important. The modern market offers products from numerous European and domestic manufacturers. Consumers often give preference to German and Italian companies, as well as Spanish, Austrian and Polish brands.

Radiators from AQUALINK are quite popular. These heating devices are suitable for installation in both autonomous and centralized heating systems. Heating devices made of aluminum and bimetallic types of radiators are designed specifically for use in heating systems in the Russian Federation. Due to the high heat transfer of the sections, the AQUALINK device is suitable for use in low-temperature heating systems, and due to the low inertia, fast and effective thermoregulation in rooms is carried out.

Our

supplies aluminum and bimetallic radiators to Russia. The main areas of our activity are presented:

- large wholesale trade in engineering plumbing equipment;

- organizing the delivery of our goods throughout the Russian Federation and the CIS;

- production of sanitary products.

Aluminum and bimetallic types of AQUALINK heating radiators are presented in a rich assortment with a different number of sections - 4, 6, 8, 10, 12. All radiator models are painted with snow-white epoxy enamel. You can also choose components for heating devices, which are represented by kits for connecting batteries, mounting brackets, adapters, plugs, manual air vents, control and shut-off valves. All products are insured and have passed the voluntary certification procedure in the GOST R system.

Rules for installing a gas boiler

Schematic instructions for installing the unit, which must only be carried out by a licensed gas technician, are available in the technical documentation supplied with the product.

Installation is carried out in compliance with the following rules:

- Installation work on gas equipment is allowed to be carried out at air temperatures from 5 to 35 degrees Celsius.

- Marking the location of the boiler mounting brackets on the wall is done using a building level.

- The location of the boiler must provide easy access to it.

- When installing a double-circuit gas unit, a strainer with a ball valve is installed on the coolant return pipe (to protect the heat exchanger from clogging).

- A fuel consumption meter and a gas shut-off valve are installed on the pipe connecting the boiler to the central gas main.

- A gas leak sensor and an automatic shut-off valve are installed in the boiler room.

- The gas unit must be grounded if its design contains components that consume electricity.

- The circuit is filled with water after connecting the unit’s pipes to the water and gas supply systems, but in a position disconnected from the power supply.

- Filling with coolant is carried out slowly, allowing air to escape from the system through air vents.

- Before starting the boiler, a control check of the gas pipeline connections is carried out for leaks by applying soap foam to the areas being checked.

Heating is started only when the entire system is ready, connecting the equipment to the electrical network, when the defects have been eliminated in full.

Chimney device for a gas boiler

Not only the efficiency of a gas heating system, but also the safety of operation of this equipment depends on the correct installation of the smoke exhaust system.

Gas combustion products, almost invisible visually, are toxic to humans and aggressive to many materials. Therefore, when installing a chimney for a gas unit, it is necessary to take into account many requirements, starting with the design and ending with the material of execution. The chimney, designed to operate a gas boiler, is also suitable for connecting solid and liquid fuel units.

First of all, the design of the chimney depends on the design of the combustion chamber of the gas boiler.

If the unit has an open chamber, that is, to burn gas it consumes oxygen from the air in the room, then a chimney is installed in one direction - removing smoke from the room outside.

When designing a gas boiler that includes a closed chamber, a so-called coaxial chimney is installed, a pipe in a pipe, through which two flows move towards each other - fuel combustion products and air into the combustion chamber.

The chimney can be internal or external. The efficiency of a heating system with an internal chimney is higher, since the surface of the pipe is an additional area for heat transfer of the temperature of hot gases into the room, but with this design it is necessary to specially arrange the passages of the smoke exhaust system through the interfloor ceilings and roof.

The combustion products of gas fuel contain nitrogen and sulfur-containing compounds, which, condensing on the inner surface of the pipe, destroy the chimney if it is made of brick or ordinary steel. Therefore, chimney pipes are equipped with external thermal insulation, and stainless steel and ceramics are considered the best materials for their manufacture.

The chimney can also be installed from pre-insulated pipes - pipe material on which the insulation is already made between two steel shells. Installation of this design is much faster, but the cost of this material is much higher than the price of conventional chimney pipes. Accordingly, new heating systems for cottages built according to individual projects are equipped with chimneys made from pre-insulated pipes.

Self-installation of gas equipment is prohibited for good reason - working with gas-powered units requires professional knowledge, and errors during installation can lead to accidents, the scale of which is unpredictable. Therefore, without special training, the information received on the installation of gas boilers should be used exclusively to monitor the performance of work by the contractor, where the presence of the human factor has not been canceled.

The requirements and standards for installing gas equipment are set out in more detail in the following regulatory documents:

- SNiP II-35-76* “Boiler installations”;

- SNiP 4.02-08-2003 “Boiler installations”;

- SNiP 42-01-2002 “Gas distribution systems”;

- SP-41-104-2000 - Set of rules for the design of autonomous heat supply systems;

- SNiP 2.04.05-91 “Smoke protection in case of fire.”

Instructions for designing heating systems

If you approach it correctly and wisely, you can design heating and water supply systems yourself. First, choose the system that suits your home. Many houses in rural areas are heated by stoves. It is reliable, proven over centuries. But there are small disadvantages: you need to regularly prepare firewood and temperature changes often occur in the house.

A stove is one of the easiest ways to heat a private home.

Explore examples of heating system projects. See how heating systems using electricity and gas boilers suit you. If you are confident in the uninterrupted supply of electricity, then you can use them. Boilers do not have the disadvantages that a furnace has, but they depend on electricity. Therefore, combined heating may be a good solution. It includes a wood stove and a boiler, such as a gas one. Then you will be less dependent on various surprises.

First, you need to know the volume and area of the room that will be heated, take all measurements and make a table in which you will summarize the volumes of residential and utility rooms. Make it convenient for you so that it is clear and easy to view the necessary information. Then, on the house diagram, highlight the places where you want to install heating devices (such as risers, stoves, boilers, radiators, and so on). Make a diagram of the heating pipes, of course, if you have one.

Heating system drawing

When designing and calculating heating systems, it is necessary to take into account the relative location of residential premises. If the house has more than one floor, you will need to draw up a floor plan and indicate the places where chimneys, risers and other communications will be installed

It is imperative to provide a fire protection system for the home. This is especially necessary if you decide to use stove heating, especially where the heating pipes will be vented outside.

The development of a heating project also takes into account the location of the house in relation to the wind rose and even the sides of the horizon. It would be nice to have data on the wind load on average per year; they will make heating more efficient and economical. And correctly calculate the required power and number of heating devices.

Wind load map of Russia

Taking into account the type of heating you choose, prepare the materials, tools and equipment you will need. To make your work easier, you can make a detailed list of everything you need

Calculate financial costs. It is not at all necessary to purchase materials in large quantities, in reserve.

If you find it difficult to design heating and ventilation systems yourself, it is better to use the services of professionals. They will conduct a consultation, during which all technical and organizational issues regarding the design of heating and other engineering systems will be considered. Based on the data on your home, the designers will run a heating design program and you will find out how much the heating project costs.

https://youtube.com/watch?v=JvkIH_HzwXA

The program for designing a heating system is carried out taking into account the technical specifications given by the customer, data about the house, and the contract for system design. Then, at a meeting between the designer and the customer, various nuances, technical specifications are discussed, and the cost of heating design is determined. If the parties have no questions or complaints against each other, they enter into an agreement

It is very important at this stage to find out and clarify the nuances. This is done in order to eliminate various misunderstandings and discontent in the future.

It happens that a specialist goes to the site. This is usually necessary when designing is carried out for an already constructed building, which complicates the designer’s work.

How to heat a country house

A competent project does not stop at the type of equipment that the company is interested in selling to you, but offers different options for heating your home. For example, you have a gas main connected to your house. Gas is a fairly inexpensive type of fuel with a high calorific value. A single or double circuit boiler is installed. Gas boilers are relatively inexpensive, very efficient and operate without replacement for several decades.

Sample diagram of a gas heating project for a house

If we are considering mains gas, it is possible to deliver gas in cylinders.

Disadvantages of autonomous home heating with gas

Gas in cylinders:

- It will require installing an expensive reducer in the boiler to reduce pressure.

- It will fly away like smoke down a chimney, literally. For example, a house of about 150-200 m2 with a double-circuit boiler powered by bottled gas may require 10-14 bottles per week.

These are real life examples. There are houses with not the worst thermal insulation, the temperature outside the window is down to minus 25, the area does not differ critically, but they are unlucky - there is no gas pipeline nearby. Which exit? Use other heat sources or calculate an unconventional heating system.

Which system should you choose?

The design of the heating of a private house is carried out taking into account the energy carrier that will be used to heat the room. There are several most common systems through which heat is supplied to all interior spaces of a building:

An “open fire” means a fireplace hearth or stove. Both of these heat sources are ineffective in providing full-fledged home heating, as they distribute hot air unevenly. They are most often included in a heating project as decorative elements. Let's look at other systems in more detail.

A heating project based on the most common water system is the planning of a closed circuit through which hot water is continuously circulated. In this case, the function of a heater is performed by a boiler, from which pipes are distributed throughout the rooms and adjacent to radiators that give off the main amount of heat.

Having carried out heat transfer, the water flows back into the boiler, where it is heated again and repeats the technological cycle. Boilers operating on any fuel serve as heaters for water heating. The water heating system is divided into two types: natural and forced.

Natural circulation

In the first case, the coolant circulates through pipes and radiators without the influence of additional force. This effect is achieved by a certain method of installing heating main elements.

The design of heating with natural circulation of water provides for the necessary angle of inclination of the pipes, allowing the process to proceed under the influence of gravity.

Hot water is lighter than cold water, so it flows to the highest point of the riser. Having given up its heat to the radiators along the way, the cooled coolant is displaced by the hot one and drops to the lowest point of the system (into the boiler), where it heats up again.

Forced circulation

The forced movement of water through the system is achieved by the operation of a circulation pump integrated into the heating boiler. Unlike natural circulation, forced circulation requires a source of electricity from which the pump is powered.

Natural and forced water circulation systems can be used for single-pipe, two-pipe and collector installations. In the first case, the design of heating systems involves the installation of one pipe, which performs the function of supplying and draining water simultaneously.

With this scheme, the temperature of the radiator farthest from the boiler will be lower than that of the one closest. In addition, if one battery fails, the others will also cease to function, since they cannot be turned off individually.

Two-pipe wiring allows for uniform heating of the batteries due to the fact that the supply pipe is connected in parallel to each of them. The second pipe carries the cooled coolant back to the boiler. If a tap is installed on each radiator, they can be turned off individually.

Manifold wiring is the most convenient, since after its installation you can regulate the temperature of the coolant in each individual room. This method of heating the room will require the installation of a collector cabinet.

Such a system can be installed exclusively at the construction stage. It is not suitable for a finished private house. This is explained by the need to install metal, plastic or textile air ducts through which hot air heated by the heat generator is blown out.

A warm flow enters the room from under the ceiling and displaces cold air, which, in turn, returns through the air ducts to the heat generator.

Designing heating using the air heating method allows you to install a system for external intake of clean air, which is mixed with the flow. Circulation can be achieved by gravity or by force.

Natural air exchange occurs due to temperature differences, and forced air exchange is carried out using special ventilation equipment. The heat generator can burn diesel fuel, natural gas (mainline or bottled) and kerosene. Combustion products are discharged through the chimney.

Selecting a Heat Source

The source of heat in the house is a heat generator, which heats the medium to the required temperature and thereby creates comfortable living conditions for people. Ideally, the heat generator can maintain the set parameters for 24 hours.

Good to know! Having drawn up a single heating project for a two-story house, experts claim that it is ideal to purchase a gas boiler with a power of 28 kW, equipped with a closed combustion chamber, comfortable for people with electronic ignition.

Experts often advise using combined heating in houses with 2 floors. For example, you can choose from:

- heating boilers;

- ovens;

- infrared emitter;

- fireplace;

- solar collector;

- thermal pump installations;

- and so on.

Interesting fact! It has been proven that the use of a minimum set of solar collectors pays off in three years.

In all houses, regardless of number of floors, the following heat sources are used:

- electrical;

- gas;

- solid fuel;

- liquid fuel.

Important! Electric and gas sources are considered economically profitable.

How does an electric boiler work?

The operating diagram of an electric boiler looks like this:

- the boiler heats up to the set temperature;

- heat passes through the pipes to the radiators;

- partial cooling occurs;

- under the influence of the pump, the heat goes back into the boiler.

Registers

Another type of heating devices are registers. They are welded or assembled structures made of metal (usually steel) pipes. The pipes are connected to each other by jumpers through which the coolant circulates. Cottages are extremely rarely heated by registers, due to their unattractive appearance. Registers are most often used at industrial facilities.

Heating a house with water heated floors

In recent years, water-based heated floors have been gaining popularity. If the room is large, radiators do not always effectively heat the entire space, especially in the center of the room. In this case, in addition to radiators, it is advisable to install heated floors. The heated air rising from them evenly fills the entire space.