To be able to grow plants or seedlings all year round, you need to organize a suitable room for this. In this case, the best option is to arrange a greenhouse. Such structures are an ideal addition to a country house, as they open up many possibilities. Heating the greenhouse with a long-burning boiler will ensure year-round operation of the greenhouse. It is important to correctly calculate the power of the heating elements.

Heating in the greenhouse makes it possible to use it all year round

Specifics of maintaining temperature

Heat leaves the greenhouse through the ceiling and walls, as well as as a result of fresh air entering through the ventilation holes. To compensate for such heat loss, it is necessary to organize an efficient heating system. Before starting any installation work, experts recommend insulating the structure. It is important to minimize the entry of outside air.

Important attention should be paid not only to the material with which the frame of the structure is sheathed, but also to the features of its installation. The greenhouse should fit as closely as possible to the ground. The best option would be to build a foundation that is laid at a shallow depth. It is additionally insulated. At the same time, the strength of the base is important, which ensures reliable installation of the structure.

The depth of the foundation should be 30 cm. Such conditions are imposed even on structures that are erected in regions with harsh climatic conditions. Through the soil, which is located inside the greenhouse, heat escapes in very small quantities. As for heat loss around the perimeter, it can be reduced with the help of ordinary snow, which is a natural seasonal insulation.

Solid fuel boilers are ideal for greenhouses

To ensure normal plant growth, it is necessary to establish optimal temperature conditions, as well as ventilation of the structure. If all systems are properly organized, the ground temperature will be the same as in the summer.

The depth of soil freezing depends on the geographical features of the region. To overcome any natural limitations, it is necessary to create optimal conditions for plant growth. Thermal energy can be directed both into the surrounding air and into the soil itself. In the latter case, the optimal condition is to install an underground pipeline.

Heating a greenhouse entails considerable material costs, which depend on the following factors:

- The area of the walls, as well as the roof of the structure. The smaller the surfaces, the lower the heat loss. In this regard, experts recommend using semicircular or rectangular frames to build a greenhouse.

- Thermal conductivity of the material. If the coefficient is low, the material will retain heat well.

- Difference between outside and inside temperatures. With a significant difference in temperature conditions, heat loss is significantly high.

- The presence of cracks and places where the finishing material does not adhere tightly to the greenhouse frame. Through them, cold air will flow into the structure, which will lead to a decrease in temperature.

There is a large selection of greenhouses on the modern market. Therefore, there is no unified system for organizing the heating of a building. In each case, it is necessary to develop an individual project.

The unit can be built by hand or purchased ready-made

About the efficiency of various electric heating systems

As for heating with electricity, direct heating systems are more economical: fan heaters, convectors, heating cables and heated film floors. The lower efficiency of a water system with an electric boiler is explained by losses in the delivery of coolant: overcoming the hydraulic resistance of the liquid, the operation of the circulation pump. Warm floors have the best performance due to optimal temperature distribution. How to ensure their safe operation in a greenhouse is a separate issue. But the difference between different types of electric heating is small, we are talking about only a few percent.

https://vasha-teplitsa.ru/wp-content/uploads/2014/05/banya18430.jpg — It’s quite possible to create a warm floor using a heating cable in a greenhouse. It can be protected from possible damage by a strong mesh laid on top.

Comparison of furnaces and traditional heat generators

Most heating devices operate on the principle of rapid combustion of fuel. It is set on fire from below, and the fire goes upward. In this case, oxygen access to the combustion zone is open. The disadvantage of such a system is that the temperature constantly fluctuates. The fuel resource is not completely consumed, and as a result of combustion, soot and soot are formed. Throughout the operation of the unit, it is necessary to constantly adjust the draft and frequently add fuel.

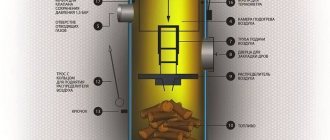

As for long-burning units, their operating principle is somewhat different from heat generators. In this case, the fire moves in the opposite direction: from top to bottom. This makes it possible to fully load the firebox as much as possible. The fuel burns gradually. Oxygen is supplied directly to the fire itself. Burning is slow. This generates less heat. Thanks to this, it is possible to create a comfortable temperature that is optimal for greenhouses.

Among the most efficient units, it is worth highlighting gas generator or pyrolysis furnaces. Their peculiarity lies in the fact that with the slow combustion of fuel, flammable vapors are formed, which subsequently also enter into the combustion process. Thus, the efficiency of the unit increases and fuel costs are reduced. The disadvantage is that when gases are removed, condensation forms in the chimney. Therefore, the pipe must be insulated.

A gas boiler has the following advantages:

- Economical and high efficiency. Fuel is relatively inexpensive. In this case, it is possible to use wood and other things. Such units are relatively inexpensive. The efficiency of the unit is close to 85%.

- Easy to maintain. It is enough to do only a few downloads throughout the day. When the desired temperature is reached, the operation of the unit is controlled using the combustion chamber draft.

- High functionality. The stoves are ideal for the construction of heating systems of various types, as well as hot water supply.

Modern units can be built independently or purchased ready-made. To make the right choice, it is worth considering the main characteristics of existing models.

Boilers operate on different fuels

Types of heating boilers

There are several types of boilers that can be used to heat a greenhouse.

Gas. How to connect registers correctly?

A gas boiler consists of various components, in particular a steel or cast iron heat exchanger, an atmospheric burner (sometimes), a control system, a water circulation pump, an expansion tank and a safety valve.

Photo 2. Gas boiler for heating a greenhouse. The device is quite large and is often located outside the greenhouse.

The device operates on the basis of natural or liquefied gas, is unpretentious to water quality and can be installed anywhere in the greenhouse.

Technical characteristics of the greenhouse boiler:

- Efficiency minimum 93%;

- power - from 40 kW;

- the volume of water in the boiler is at least 6 liters;

- device height is about a meter;

- width - 54-60 cm;

- length - 90 cm;

- gas consumption - minimum 5.0 kb. m/hour.

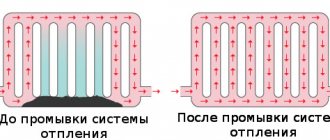

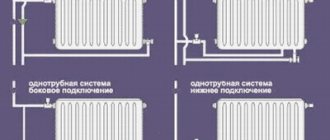

After turning on the boiler, the water flowing through it is heated in the heat exchanger to the required temperature and supplied to the system circuit by a pump. This is a single-circuit option that is used only for heating. To heat the greenhouse and supply hot water, double-circuit devices with a built-in hot water heating circuit are used. Mostly single-circuit models are used for greenhouses. Smoke is removed through a specially equipped chimney or through a steel pipe.

In order to connect the register to the water circuit, you need to find out where the hot water will be supplied and where the cold water will go. Next, holes are made at the ends of the register for threaded couplings, to which fittings are then attached that connect the heat exchanger to the water circuit. An air vent is welded on the opposite side of the supply. It can be located at the end, but it is better for the valve to be at the top.

Since the register is heavy, it is necessary to provide reliable fastenings. There are two ways to place the heat exchanger: wall-mounted and floor-mounted.

In order to install the register on the floor, you need to make legs, and also additionally fix the device against the wall.

Also, do not forget that the distance from the surface of the register to the walls and floor should be about 25 centimeters.

Advantages: the gas boiler is unpretentious in maintenance and does not require constant human intervention. It heats up instantly and ensures even heat distribution inside the greenhouse.

Disadvantages: high price for models for heating a large area, costs for gas supply, need to coordinate the connection of the boiler.

Buleryan

This is a convection oven that maintains a long combustion cycle. Such a device is used extremely rarely for heating a greenhouse. Buleryan combines several functions. It acts as a gas generator, furnace, and heater. The unit has a fairly simple design, which makes it possible to build it yourself.

The oven is presented in the form of a metal container, which has a barrel shape. The firebox has two tiers. Convection pipes are directed towards its center. The principle of operation is that in the first chamber the firewood smolders, resulting in the release of gas. In the second part of the furnace, gases are burned. The design is equipped with a chimney damper, a draft regulator and a door through which fuel is loaded.

Option #4 - electric soil heating

Electric heating of the soil allows you to put the greenhouse into operation somewhat faster than when installing other heating systems. It also has the following advantages:

- uniform heating of the entire area of the building;

- minimal installation costs;

- low labor costs for system maintenance;

- relative efficiency;

- elementary control.

In fact, this is a kind of analogue of “warm floors”, often installed in residential premises. To equip it, create a layer of waterproof thermal insulation, pour sand on top in a layer of 5 cm, lay the cable in increments of at least 12 cm, and form another similar sand layer; A protective mesh is placed on top of the sand.

The power of the resistive cable for electrical heating of the soil should be no more than 15 W/m - otherwise the root system of the plants may dry out

Butakova

Today, the market offers a wide range of stoves from various manufacturers. The rectangular unit is equipped with an ash pan. It has convection pipes. The operation is similar to the previous heating equipment. Thanks to its special design, Butakova is highly efficient. Despite all its advantages, it is rarely used for heating greenhouses.

When installing and constructing equipment, it is worth taking into account the design features and operating principle

About agricultural economics

Heating a greenhouse with electricity is by no means a cheap thing. Such solutions are not used in the agro-industrial sector; they are unprofitable. You are not the first to come up with such an idea, but if you are interested in the economic side of the issue, calculate the costs and compare with the possible benefits. All your predecessors abandoned the idea of heating greenhouses with electricity; it is much cheaper to buy vegetables and fruits.

For comparison - a comparison of the cost of installing heating equipment using different energy sources, using different energy sources

And operating costs. The data is given for the Moscow region; in a particular area, the cost of solid fuel can be much lower. Electric heating with low initial costs is extremely expensive to use

Bubafonya

Making previous models with your own hands is quite difficult and almost impossible. As for the Bubafoni stove, the situation here is completely different. Having knowledge and skills in plumbing and welding, you can easily make a unit at home. It is home-made installations that are most often used for heating greenhouses and other auxiliary buildings that are located on a personal plot.

To make a boiler for a greenhouse with your own hands, you use various materials that can be found on the site or purchased in a store. An old gas cylinder or steel barrel is ideal for creating an equipment housing. It contains an ash pan and a fuel chamber with a door through which fuel is loaded. The design includes a metal pancake that ensures smoldering of firewood.

Important! The advantage of Bubafoni is that, thanks to its design and operating principle, it is able to function on one bookmark for a long time.

Installing equipment in a greenhouse is easy

About induction

An induction boiler has absolutely no advantages over conventional ones equipped with heating elements. All the talk about this is the fantasy of marketers and sellers with the goal of selling their product to gullible customers. The percentage of electricity converted into thermal form is almost the same for all types of heating devices. Do not equate boilers with kitchen stoves - indeed, an induction surface is more economical than steel “pancakes”, there are no losses in heat transfer through the surface of the stove to the dishes, the heating spot exactly matches the size of the pan, the tightness of the seal does not matter. In heating boilers, the coolant is immediately heated; there are no intermediate elements. There are no advantages, the efficiency of the boilers is the same. The rest of the “arguments” regarding reliability and safety are also made up. Disadvantages: increased winding wear due to interturn short circuits, increased insulation aging, vibration when heating, labor-intensive repairs.

Induction heating systems are by no means new; they have been used in industry for more than 70 years, but only a few domestic Kulibins offer their use for heating buildings

Electric boiler on heating elements, fully equipped, adequately controlled

Slobozhanka

The oven has a rather complex design. The body consists of several casings, which are fastened together according to a special scheme. There is an air gap between them. As a result, the air flows that come from below move correctly. When heated, they rise upward, which provides heating to the room.

The solid fuel unit is capable of operating on wood and wood industry waste. Fuel is loaded into a equipped fuel tank. If logs are used for the firebox, it is recommended to place them vertically. This arrangement will ensure efficient and long-lasting burning of the bookmark. Combustion starts at the top and gradually goes down.

The Slobozhanka has a fireproof lid and a blower, which allows you to regulate the strength of the flame. During the combustion process, the ash falls into the lower pan, and the smoke enters the chimney pipe. Air supply is carried out in different ways:

- Installation of an L-shaped pipe. Air is supplied into it and rises through a perforated channel, which is located on the side of the screen. Thus, oxygen is supplied directly to the combustion site.

- Using a pipe that is located in the center of the firebox. Air enters from below and gradually flows upward to the unit.

- A pipe that is installed at the bottom of the equipment. Air from the environment rises along it.

Slobozhanka has a number of advantages, which explains its popularity. The main advantages include:

- High level of efficiency, which is close to 90%. The rest comes out through the chimney. Thanks to this productivity, the equipment heats up quickly, which allows you to heat the room in a short time. Unfortunately, after the fuel burns, the structure cools down in a short time.

- Easy to manufacture. The equipment has a simple design, which makes it easy to manufacture the unit yourself. To do this you will need a minimum set of materials and tools.

- Economical. A small fuel load ensures long-term operation of the equipment. At the same time, it is possible to add firewood during combustion.

- Mobility. The equipment is small in size and weight, which allows it to be moved to another location if necessary.

As for the disadvantages, it is worth noting the rapid clogging of the system if household garbage and waste are used for heating. You will have to regularly clean the pipeline from carbon deposits.

When choosing, the power of the unit is taken into account

How to choose boilers for greenhouses - advice from farmers

When choosing between solid fuel, electric, coal, or steam boilers, you need to take into account the area of the greenhouse, financial capabilities, type of covering and types of plants grown.

Recommendations from experienced farmers will help you navigate and make the right decision:

- If there is a gas pipeline on the site, it is more profitable to install a gas boiler. This statement is true for buildings of any size.

- For year-round heating of areas over 50 square meters. m and if you have available firewood, it is better to choose a solid fuel unit with long combustion. The costs of purchase and installation will pay off within two to three years. Payback in small greenhouses (15-20 sq. m) is about 10 years.

- When heating is turned on seasonally (in early spring), it is advisable to use a low-power hanging electric boiler without a chimney outlet. However, during severe frosts they are not effective, since they heat the air above, but the soil remains cold - this is fraught with freezing of plants.

Homemade solid fuel stove

Some gardeners consider direct combustion solid fuel models like potbelly stoves to be the optimal heating boilers for small greenhouses. The efficiency of the system can be significantly increased by connecting a water circuit and installing a pump for pumping coolant.

Requirements and heating scheme

When installing solid fuel boilers for greenhouses, you should pay attention to the following parameters:

- construction area;

- calculate the system power;

- presence of insulation;

- the ability to control the operation of the system;

- material opportunities.

If you take all these factors into account, you can choose a truly effective system that will allow you to heat the greenhouse without much expense. It is worth carefully considering all available options.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

About boiler power

Forgive me, but your post is akin to the question “I want to go for a walk, what clothes should I wear”? To recommend panties or a sheepskin coat, you need to know whether it’s winter or summer outside, hot or cold, sun or rain. It's the same with the greenhouse. Where do you live, in the Krasnodar region or in the Northern Urals? What type of cellular polycarbonate is used to cover the greenhouse? Is the cheapest 4 mm (thermal conductivity 3.8 W/(m K)) or 25 mm (1.6 W/(m K))? How are you going to heat it: just in the spring to drive out the seedlings or do you want to have fresh vegetables all year round? What temperature should be maintained? What is the average height of a greenhouse? After all, we heat not the area, but the volume? What are its proportions, the floor area does not matter, heat is lost through the external walls - it is their area that you need to know. How is the structure oriented to the cardinal points, does it receive direct sunlight in winter? Since we don’t know any of this, we can’t give you any advice on boiler power.

Internal thermal insulation

To make heating more efficient and cheaper, you need to pay attention to thermal insulation.

The base can be sheathed with a suitable material - penoplex or polystyrene foam. Then polycarbonate is mounted on top, which is covered with foil-isolon or simply foil.

Decorating walls in a greenhouse with foil

The frame part can be thermally insulated using double glazing. It would be optimal to use polycarbonate. The inside can be additionally covered with bubble wrap.

Source of the article: https://mrdachnik.com/proekty-otopleniya-teplicy