Here you will learn:

- Scope of application of heating elements for heating

- Pros and cons of radiator heating elements

- How are they used for heating radiators?

- Types and methods of manufacturing heating elements

- Criterias of choice

- How to install and use heating element correctly

- Radiator electric heating at home

- Rules of operation and maintenance

Heating elements for heating are used in various devices, ranging from electric fireplaces to cast iron radiators. Installing a heating element is a simple and quick procedure; it is connected directly to the electrical network and has high efficiency. The downside is energy costs.

Types and methods of manufacturing heating elements

Modern electric heating elements have high strength and the ability to change shape and size under the influence of high temperatures without compromising their technical characteristics.

They are used not only in household heating appliances, but also in industrial ones. True, in the latter they install more powerful analogues with larger sizes. All modern heating elements have a high rate of long-term operation. Manufacturers produce two types of heating elements, which differ in the manufacturing method. There are products that are mass produced, and there are also those that are produced in small batches. They usually meet specific customer requests. They are used in special heating installations with specific requirements. By the way, the price of the latter is much higher than the former.

Tubular electric heaters

This is the most common type of heating element, which is used in almost all electrically powered heating devices. With the help of tubular analogues, heating of the coolant occurs according to the principles of convection, radiation and thermal conductivity as a result of the conversion of electrical energy into thermal energy.

This heating element has the following characteristics:

- Tube diameter 6.0-18.5 millimeters.

- The length of the heating element is 20-600 centimeters.

- The tube can be made of steel, stainless steel or titanium (a very expensive device).

- Device configuration - no restrictions.

- Parameters (power, performance, etc.) - as agreed with the customer.

Finned tubular electric heaters

Used to heat air or gas that heats the room

TEHPs are the same tubular electric heater only with ribs that are located in planes perpendicular to the axis of the heating tube. Typically, the fins are made of metal strip and secured to the tube with special clamping nuts and washers. The heating element itself is made of either stainless steel or structural steel.

This type of electric heating devices is used to heat air or gas that heats a room. They are often used in heating devices such as air curtains and convectors - where heating with heated air is required.

Electric heater block

TENB are used only if it is necessary to increase the power of the electric heater. They are usually installed in devices in which the coolant is liquid or any bulk material.

A distinctive design feature of the heating element is its fastening to the heating device. It can be threaded or flanged. Particularly popular today is a block-type heating element with collapsible flanges. Such a heating element can be used repeatedly for different devices. The burnt heating element can be removed and a new one put in its place.

Cartridge-type electric heaters

This type is not used for heating systems.

This type is not used for heating systems. It is used as a mold part to create any products, since it is a part of industrial equipment. They are not found in everyday life, but it is necessary to mention them, because this type of heating element is included in the category “tubular electric heaters”.

A distinctive feature of this analogue is the shell, made of stainless steel, which is polished to the maximum. This is necessary so that the heating element can enter the mold with a minimum gap between the tube and the walls of the mold. The standard gap should not exceed 0.02 millimeters. This is how tightly it should fit.

Ring electric heaters

This type of heating elements is also used only in industrial installations. Their purpose is to heat injectors, nozzles of injection units and injection molding equipment.

Electric heaters with thermostat

Heating element with thermostat TECHNO 2 kW

This is the most common heating element today, which is used to heat liquids. It is installed in all household electrical appliances that are associated with heating water. The maximum temperature of the released heat is +80C.

It is made from nickel-chromium wire, which is filled inside the tube with a special compressed powder. The powder is magnesium oxide, which is a good insulator of electric current, but at the same time has a high thermal conductivity.

Design and operating principle

Electric boilers have a fairly simple design. All devices are equipped with a heating element and a container for heat conduction. According to the type of heating element, electric boilers are divided into:

- devices with heating elements (tubular heaters);

- induction boilers;

- devices with electrode heaters.

Read more:

The coolant can be forced to move through the system by installing additional equipment (pumps). Also for this purpose, the elementary laws of physics and the force of earth's gravity can be used. With automatic circulation, the pump is installed at the return inlet.

Device with thermal electric heater

Such devices are considered the most popular due to their simple design and low cost. The heating element (heating element) is installed in a container, where the heat conductor is heated to the desired temperature. When current passes through the heating element’s spiral, it heats up to a high temperature, due to which the liquid is heated.

The heating element is protected from overheating, as water constantly circulates and cools it. To maintain a constant temperature level of the heat conductor, a thermostat is installed that turns off the heating element if the set temperature is exceeded. The device turns on again when the indicators are reduced to the minimum.

It is not difficult to make an electric boiler for heating with your own hands, if you compare its production with other types of heating equipment. It will not have the advantages of purchased analogues, but it will still perform the function assigned to it.

To make your own device, you only need heating tubular elements and a container. But such a boiler should not be considered ideal, since its efficiency will be below 80%. Much also depends on the quality of heating elements, on which scale forms due to salts dissolved in water. It often leads to equipment failure due to overheating. As practice shows, scale with a layer of 1 mm reduces efficiency by 10-15%. But even taking this into account, electrical designs for heating rooms are very popular.

Induction devices

Such devices, unlike heating element models, have an efficiency close to 100%. Plus they are durable. Their service life is about 25-35 years, and in addition they can serve as a boiler, heating water. Thanks to energy conversion with virtually no losses, induction boilers have the highest energy efficiency.

However, this type of equipment has not become popular among home craftsmen, since it is very difficult to make a homemade induction electric boiler for heating a home. This is due to the need to use electronic voltage converters.

The design of such a device consists of a coil (inductor) that is mounted on a metal core. The latter is a coil of pipes through which the coolant moves.

An induction boiler differs from heating element devices in that the area of contact of water or antifreeze with the heating element is several times higher. Therefore, the efficiency of induction units is 99-100%. There is several times less scale formation in them, since microvibrations are created that prevent such a process. Electric boilers also have protection against overheating of the electrical element, since water is constantly circulating.

Electrode unit

The electrode-based design is somewhat reminiscent of an “army” boiler. It consists of two blades, between which there is a gap of 1-2 mm. Water with dissolved salt is used as a coolant.

The electrode boiler includes a piece of metal pipe. There is an electrode inside, which is closed with bushings. There must be a good grounding to the pipe, which is connected to the boiler body.

When preparing a heat conductor, it is necessary to correctly calculate the amount of salt, since the current strength in the circuit, that is, the power of the device, will depend on this indicator. A thermostat is used to adjust the temperature. The device is also equipped with an automatic shut-off system.

Scope of application: is it suitable for electric boilers and registers?

The devices are recommended for heating buildings with a small area that are rarely used in the autumn-winter period. To do this, the element is inserted into a radiator of impressive dimensions. Heating elements are mainly used for heating garages, country houses and other premises.

Photo 1. Heating element for a radiator with a regulator, power 1.5 kW, Ukraine.

They are also used for heating private one-story buildings, but extremely rarely due to the high cost of electricity. Here they are often installed not as the main, but as an auxiliary source of heating in case of gas outage.

Such batteries are connected not only to a gas autonomous heating system, but also to a circuit operating on solid fuel. This is especially true when the inhabitants of the house do not have the opportunity to regularly add coal or firewood to the firebox, as well as monitor the pressure and temperature inside the system.

Important! To save electricity, it is recommended to install a two-tariff meter. Then at night, when the cost of electricity is lower, the system operates from heating elements, and during the day - from solid fuel

Design

Device design:

Frame. It is made of electric welded or seamlessly drawn tube. Material - stainless steel or carbon steel, coating - chrome or nickel, cross-section - round or flat. The diameter of the tube depends on the model of the device.

- Filler. It is quartz sand or a mixture of crystalline magnesium oxides.

- Spiral. This is the heating element of the device. It is made of nichrome wire.

- The contact rod is sealed.

- Sealant.

- Insulator.

Advantages and disadvantages

Advantages of the devices:

- environmentally friendly circuit, since the device does not require any fuel, the combustion of which releases harmful substances into the environment;

- creates an autonomous heating structure that does not depend on gas and solid fuel;

- compact dimensions;

- a large selection of devices of different power;

- simple installation;

- operational safety;

- There are models with a thermostat, which automates the heating process.

Cons of the elements:

- high cost of heat source (electricity);

- the device cannot be repaired if the spiral fails.

How does an electrical appliance work?

The design of the device is practically no different from other types of heating elements. The body of a tubular electric heater is made of a seamless or electric-welded thin-walled metal tube. Its diameter can vary, and its cross-section can be flat or round.

Carbon steel is most often used as the material for the manufacture of the case, but stainless steel can also be chosen if the working surface of the device will be heated to temperatures above +45°C.

To protect the metal from corrosion and extend the service life of the heating element itself, the steel body is chrome or nickel plated. A spiral of nichrome wire is used as a heating element.

The element has a high resistivity, due to which it heats up quickly. The spiral is placed inside the body, and the remaining free internal cavity contains filler.

The design of a radiator heating element necessarily contains a spiral, which is responsible for heating the device. It has high resistance, so when current passes, it heats up quickly (+)

The housing has high electrical insulating properties and at the same time transfers heat well. Purified quartz sand or periclase can be used as a filler - this is the name of a mixture of crystalline magnesium oxides.

After the body is filled with filler, it is pressed and bent to give the required shape. All insulators are coated with an organosilicon moisture-proofing compound.

Such a device can be installed in any type of radiator: copper, cast iron, bimetallic, etc. The device is capable of generating up to 2.5 kW of power. Models intended for industrial use produce up to 6 kW.

The design of the electric heating element is such that the device completely converts all incoming electrical energy into heat, with virtually no losses.

The operating principle of the device is extremely simple. When activated, it begins to heat up quickly, warming up the coolant located in its immediate vicinity. According to the laws of physics, a heated liquid is lighter than a cold liquid, so it begins to move upward.

A cooler coolant is lowered in its place. Having risen to the top of the radiator, the heated liquid gives off its heat there, cools down and falls down.

The main enemy of heating elements of any type is limescale. It inevitably forms on the heating element and gradually leads to the device failing

The cycle is repeated many times. Thus, the electrical device creates a unidirectional flow of liquid inside the battery. The higher the power of the device, the higher its speed.

Based on practice, transformer oil is considered one of the best types of coolant. The liquid heats up quickly and does not cool down for a long time, gradually giving up its heat to the radiator body.

Selecting a heating element

When choosing a heating element, you need to pay attention to some details. Only in this case can you count on a successful purchase, high-quality heating, long service life and compatibility of the selected model with the water heating tank. boiler or radiator

boiler or radiator.

Shape and size

There are dozens of heating element models available for buyers to choose from. They have different shapes - straight, round, figure-eight or ear-shaped, double, triple and many others. When purchasing, you should focus on the use of the heater. For installation in sections of heating radiators, narrow and straight models are used, since there is quite little space inside

When assembling a storage water heater, you should pay attention to the volume and shape of the tank, and based on this, choose a suitable heating element. In principle, almost any model will fit here. If you need to replace a heating element in an existing water heater, you need to purchase an identical model - only in this case can you count on it fitting into the tank itself

If you need to replace a heating element in an existing water heater, you need to purchase an identical model - only in this case can you count on the fact that it will fit into the tank itself.

Power

If not everything, then a lot depends on power. For example, this could be the heating rate. If you are assembling a small-volume water heater, the recommended power will be 1.5 kW. The same heating element will be able to heat disproportionately large volumes, but it will do this for a very long time - with a power of 2 kW, heating 100-150 liters of water can take 3.5 - 4 hours (not to a boil, but on average by 40 degrees).

If you equip a water heater or water tank with a powerful 5-7 kW heating element, the water will heat up very quickly. But another problem will arise - the house electrical network will not withstand it. When the power of the connected equipment is above 2 kW, it is necessary to lay a separate line from the electrical panel.

Protection against corrosion and scale

When choosing heating elements for heating water with a thermostat, we recommend paying attention to modern models equipped with scale protection. Recently, models with enamel coating have begun to appear on the market. It is this that protects heaters from salt deposits.

The warranty on such heating elements is 15 years. If you don’t find similar models in the store, then we recommend purchasing electric heaters made of stainless steel - they are more durable and reliable

It is this that protects the heaters from salt deposits. The warranty on such heating elements is 15 years. If you don’t find similar models in the store, then we recommend purchasing stainless steel electric heaters - they are more durable and reliable.

The presence of a thermostat

If you are assembling or repairing a boiler or want to equip a heating element with a heating element, choose a model with a built-in thermostat. It will save on electricity by turning on only when the water temperature drops below a set point. If there is no regulator, you will have to monitor the temperature yourself by turning the heating on or off - this is inconvenient, uneconomical and unsafe.

TOP 1: S-TANK AT PRESTIGE -500

Advantages

The model has enough of them:

- simple maintenance and installation;

- fast heating of water, independent of conditions;

- protection against overheating, so operation is permitted even in commercial buildings;

- unique parameters and versatility, the choice of which is determined by the size of the heated room;

- continuous heat accumulation thanks to built-in heat exchangers;

- compatibility with heat supply sources of any type.

Additional thermal insulation can improve efficiency. The insulation can be polyurethane foam or mineral wool, which slow down the cooling of the coolant.

Characteristics

- Manufacturer – Belarus;

- Weight – 105 kg;

- Size in diameter – 78 cm;

- Height – 157 cm;

- Tank volume – 500 l.

Installation stages

Regardless of the manufacturer, heating elements are installed in heating radiators according to a single principle. To install the heating element yourself, just follow the instructions:

- The device where installation will be carried out must be de-energized.

- The supply of working fluid to the batteries is stopped, after which it is drained.

- Instead of the bottom plug, a heating element is installed, which must go into the water supply pipe.

- The fluid supply is restored, and then the radiator is checked for leaks.

- The heating element is connected to the electrical network.

Precautionary measures

When using heating elements for radiators of a heating system, you must adhere to certain safety requirements. When installing heating, it is important to check the reliability of the ventilation. Also, when performing work, it is necessary to move flammable and explosive substances to a protected, hard-to-reach place at a safe distance from the heating device. Before connecting a heating device with a heating element and a thermostat, it is worth checking once again how well the electrical wiring can cope with the load placed on it

Exceeding the permissible power is fraught with overheating of the wires, short circuits and fires.

- When connecting heating devices with heating elements, you should avoid using ordinary household carriers. The best option is to use network filters. This solution allows you to automatically de-energize the device during voltage surges in the system.

- It is absolutely unacceptable to use batteries with an electric heating element to dry things.

- When the heating element operates, the working fluid is intensively heated. Its operation for a long time leads to the burning of oxygen. Therefore, staying in such a room for a long time poses a health hazard.

Safety precautions and operational points

A heating element is a mains-powered heater

When using the device, it is quite important to follow some rules that will ensure safe use and significantly extend its service life:

In order for the device to operate for a long time with full heat transfer, the scale that forms on its surface should be cleaned once every three months. If a large layer of white deposits forms, it can damage the device. The intensity of scale formation can be reduced by using distilled water as a coolant. Do not allow the electric heater to overheat. The temperature of the radiator in the place where the electric heater is installed should not reach seventy degrees above zero

Therefore, it is quite important to choose the correct power of the heating element. The heater can only be turned on in a battery filled with coolant. Water entering an already heated electrical appliance can lead to a thermal explosion.

As a result, not only the radiator, but the entire heating system may be damaged. If static electricity appears on the surface of a tubular device, it must be immediately turned off and all connections and the device itself checked for leaks. The heater power should not be higher than the thermal rated power of the battery. A load of no more than 3.5 kilowatts is allowed in one outlet.

The temperature of the heating element for the radiator cannot reach 70 degrees

Installation of a heating element in a heating battery is carried out only using grounding. To avoid voltage drops, it is best to connect the electric heater to the network through a stabilizing device.

Safety

It is believed that a radiator heating element with a built-in thermostat is an absolutely safe heating device: turning it off when the coolant reaches the set temperature will avoid dangerous overheating or boiling of water.

However, not all potential buyers of the device know that safety and operational efficiency are ensured not only by the design of the device, but also by proper installation.

- In a central heating system, when the heating element is turned on, the radiator shut-off valves must be closed. In this case, a jumper must be mounted in front of them on the supply line, which will allow the coolant to circulate through the riser when it starts. In the absence of valves, your heating element will heat the batteries throughout the riser; in the absence of a jumper, after an unsuccessful attempt to start the heating, a sad locksmith will come to you and say a lot of offensive words.

- Heating the coolant in a closed volume will turn your radiator into a full-fledged miniature boiler room and... sharply increase the pressure in it. Thermal expansion, you know. Hence the need to install on the supply line after the shut-off valve either a small expansion tank (its volume is taken equal to 10% of the radiator volume) or a safety valve.

A small expansion tank will be able to accommodate excess expanded coolant.

Note: the second scenario is undesirable, since when heated the valve will periodically eject streams of hot water.

- The cross-section of the power cord must be at least 1 square millimeter per 8 amperes of current. With a heating element power of 2500 watts and a supply voltage of 220 volts, the current will be 2500/220=11.36A; the minimum cross-section of the wire core, therefore, is equal to 11.36/8 = 1.42 (rounded to the real value - 1.5 mm2).

- The maximum load per outlet should not exceed 3500 watts.

- Grounding is highly recommended.

The grounding contacts in the socket must be connected to the electrical panel housing.

The power of the heating element without a thermostat should not exceed the rated thermal power of the radiator. For one aluminum section it is taken equal to 200 watts, for cast iron - 160 watts. Heating elements for heating radiators with a thermostat can be installed without power restrictions.

Benefits of the latest technology

Infrared film is used not only for heating window sills; it is used in systems of heated floors and baseboards. Installation of this device is simple, and no special tools or skills are required.

The heating film has the following qualities:

It heats up in a very short time: one or two minutes, and it is in the operating temperature range. It warms up efficiently, evenly, affecting the entire area. Electricity consumption is striking in its economy - 20 W. Three window sill plates - three 20 W each - the energy consumption is equal to one incandescent light bulb. Excellent aesthetic appearance. It does not damage the base at all, since it does not require either a cement screed or an adhesive solution for installation: it is applied to the surface using a dry method

This is very important: if it fails, there is no need to do “dirty” work. Replacement will require about an hour of free time

Sold in kits that include all the necessary accessories and elements for its installation: special tape, mounting wires, an insulating block, several clamps. To control such a heating system, a convenient electronic control has been created

There are both simple hand-held devices and programmable ones with an LCD display. Invisible to prying eyes. It is more convenient to measure thickness not in millimeters, but in microns.

Prevention of breakdowns of heating elements

Needle heating element without the ability to adjust power

Even after you have managed to professionally install heating elements for heating systems, you must follow the operating rules. First, the ability of the electrical network to withstand maximum loads is checked. To do this, you need to sum up all the power of electrical appliances in the house and add a factor of 1.2 to the resulting figure for the power reserve. The cross-section of the electrical wiring must withstand the rated power without overheating or short circuiting.

The operation of the heating elements in the device consists in the gradual destruction of the heating spiral. Therefore, heaters intended for radiators must have a maximum service life of at least 10 years, which is confirmed by the manufacturer. In addition, you must follow these rules:

- Do not add tap water to pipes or heating radiators. This can lead to scale formation on the surface of the heating element. Use only distilled water;

- Installation of an RCD (residual current device) is required. You can connect one or more heating elements to it. When an emergency occurs, this device will cut off the power supply;

- Frequently turning the heater on and off when heating a house reduces its service life;

- If static electricity is observed on the surface of the battery, you urgently need to check the tightness of the heating element;

- Installing a heating element into a heating boiler or radiator without grounding is prohibited.

Guided by these simple recommendations, you can create not only an effective, but also a safe heating system for a private house or apartment using electric heating devices.

Types of tubular heaters for radiators

Despite the simplicity of the design, you can find various variations of radiator heating elements on sale. First of all, the power of heating devices varies. Models with a minimum power “produce” about 0.3 kW, with a maximum – 6 kW.

The devices differ in the design of the housing. Considering that the configuration and location of radiators can be different, there are heating elements with left-hand or right-hand threads.

The diameter of the device may also vary. This is due to the cross-section of the radiator plug plug, in the place of which the device is mounted. Standard size is 40 mm.

There is no fundamental difference between devices intended for installation in radiators made of different materials. Their design is similar, only the diameter may differ. You can find single and double heating elements on sale.

Double heating elements are more convenient to use. They allow you to significantly increase the rate of heating of the coolant, but at the same time they differ from single analogs at a higher price

The latter is more convenient to use. At the moment of switching on, both elements are activated at once, due to which the coolant heats up as quickly as possible. After this, one of the elements is turned off, which allows you to save energy resources. Some models are equipped with additional functionality.

The manufacturer uses only two functions:

- Turbo heating. Makes it possible to maximize the increase in temperature in the room. A thermostat is necessarily built into the device, which allows you to change the heating intensity.

- Antifreeze. This mode allows you to prevent possible defrosting of the entire system when the temperature drops to negative values. The heating element automatically maintains the minimum permissible temperature, while consuming a small amount of electricity.

In addition, radiator heaters vary in length and the presence or absence of a thermostat.

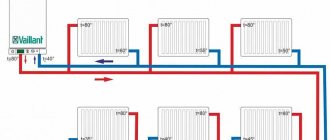

Radiator electric heating at home

Installation diagram of the heating element in the radiator

Before installing a heating element into the heating system, you need radiator parameters. The main one is the diameter of the connecting pipe. Currently, manufacturers produce products in two sizes - 1/2 and 3/4 inches. Then a comparative analysis of the heating parameters is carried out before and after installing the heating element.

Connecting the heating element to the existing heating

If it will be used as an additional method of heating water, you need to take into account the change in hydraulic pressure when passing through the radiator. Since the flow diameter of the system this month will be smaller, it is recommended to install a pump of higher power.

When connecting a radiator to the system, installing a heating element for heating the house will not be possible. To do this, you must either change the connection diagram to the top, or install a heating element on the top of the battery, which is not recommended by experts.

They are often installed in old cast iron batteries. Before performing work, you must first check the direction of the thread of the pipe (right or left) and also measure its diameter. Then you should follow this scheme:

- Coolant drain. It is prohibited to install a heating element into a heating radiator if there is water in it;

- Checking the battery level. Even at a slight angle of inclination, the likelihood of air pockets significantly increases;

- Installing the heating element into the pipe. To seal the holes, you must use the gaskets supplied with the heating element or make them yourself;

- Installation of a unit with a thermostat, if included.

An example of installing a heating element in a cast iron radiator

After this, you need to fill the system with water. Using the installed Mayevsky crane, possible air pockets are removed. Before switching on, to ensure safety, a tester is used to check any possible heating coil-battery circuit. If there is one, you need to dismantle the heating element and install it again, improving the sealing.

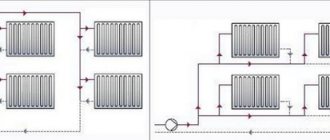

Radiator electric heating

When organizing heating using heating elements made by yourself, installation of a pipeline is not necessary. A heating element must be installed on each radiator. At the same time, it is possible to install models of different power depending on the thermal conditions in a specific room of the house. The advantages of such a system are as follows:

- Saving on the purchase of materials and reducing the labor intensity of installation work;

- If you use a heating element with a thermostat for heating and a temperature sensor connected to it, the degree of heating of the room will be adjusted automatically;

- Minimum system heating inertia.

But all these positive qualities can be offset by the total cost of service. Therefore, before heating with electric heaters, you need to calculate not only the cost of purchasing materials and components, but also the subsequent costs of electricity. Only after this should a heating system of this type be introduced.

It is recommended to purchase factory radiators with installed heating elements. Their operating efficiency is higher than that of homemade ones, since special oil is used as a coolant. Even when the heating element is turned off, it will give off heat to the room for some time.

DIY electric boiler

Design of an electric boiler

Is it possible to make a boiler that uses electric heaters to heat a house yourself? First you need to familiarize yourself with the design of factory models.

They consist of a block with an installed heating element, a control and safety system. Unlike traditional boilers, it is small in size and can be installed almost anywhere in the system. For manufacturing you will need the following tools and materials:

- Block of heating elements. It is best to use this type of heaters, as they have maximum power;

- Thermostat and temperature sensor;

- Steel body divided into two zones. In one there will be an electric heating element with a thermostat for heating, and in the second a control and protection unit will be installed.

Since the heating element in the heating system must be constantly in the water, it is recommended to install a liquid level sensor. Liquid circulation occurs through the inlet and outlet pipes. To improve this process, a connection block for the circulation pump is provided. But it should be noted that it is not recommended to make such boilers with a power above 9 kW for a private home. This is due to the maximum load on the power grid and high overhead costs.

An additional heating element installed with a thermostat in the heating can be used as a way to prevent the coolant from freezing. To do this, the device can operate at minimum power.

Features of choice

Electric heaters designed for radiators may differ in several parameters. Therefore, you should approach the choice wisely

Below we will consider what you should pay attention to when choosing a heating element

Power is one of the most important parameters, since the heat transfer of the device depends on it. Therefore, first of all, you need to calculate the required power for comfortable heating of the room.

On average, 1 kW of power is required for every 10 m2. For a more accurate calculation, it is necessary to take into account the region and heat loss of the room. However, if the heaters are used as an additional heating element, then half the power is sufficient.

Note! It makes no sense to use a heater more powerful than 75 percent of the heat output of the radiator itself, since its capabilities will not be fully used

Bimetallic radiator with electric heating element

Radiator type

Heating elements for aluminum heating radiators and bimetallic batteries are structurally no different from heating elements for cast iron appliances.

However, the differences are in the following points:

- The shape of the outer part of the body.

- Plug material.

The heating element for an aluminum radiator has a plug with a diameter of one inch. The diameter of the plug for standard cast iron batteries is 1¼ inches.

Therefore, before purchasing a heater, you should pay attention to what types of batteries it is intended for. This information is usually contained in the instructions that come with the kit.

Heating element length

An important selection parameter is the length of the heating element. As you might guess, the uniform heating of the battery and the circulation of liquid depend on this. Accordingly, the length is selected depending on the number of sections of the device.

Ideally, the heating element should be 10 cm shorter than the battery. In this case, the liquid will be heated as evenly as possible.

Automation

Automation can be built-in or external. It should be noted that a radiator heating element with a built-in thermostat is cheaper than the components separately. However, outdoor electronics tend to be more functional.

The choice depends on the purpose of the heater. If it is to be used as the main heat source, external electronics can be installed to ensure maximum heating comfort. If the device is planned to be used as an additional one, a heating element for heating radiators with a thermostat in one housing is also suitable.

Inexpensive heating element with thermostat for cast iron radiator

Efficiency mark

A heating element for a radiator is not a heating device that can be constantly used to heat a large area. One kilowatt of electrical appliance power is converted into one kilowatt of thermal energy, which is completely used to heat the room.

When using cast iron batteries, a heating element equipped with a thermostat with a heating power of 100 Watt/m² can heat no more than 25 m² of space. Electrical energy consumption for twenty-four hours will be 36 kW/h, which approximately corresponds to 167 rubles. This takes into account the average power consumption of 1.5 kW. If the heating system is well organized, installing a tubular type electric heater does not make sense.

A heating element for a radiator is most effectively used as an emergency device. If the heating system is unstable, such a device will allow you to maintain the required level of heat in the room even in severe frosts. Installing a tubular heater makes sense if its power is correctly selected and all safety rules are observed.