Today there are many options for heating your own home. And a lot of opportunities open up for owners of country houses and dachas. And more and more often you can notice that many people give preference to such a device as a diesel heating boiler. From a technical point of view, such boilers are liquid fuel. But among the people they got their name only on the basis of what they work on.

Diesel heating boiler

Advantages

One of the options for heating private houses is a diesel boiler. The system is attractive for several reasons:

- The equipment is inexpensive. Only boilers with heating elements can be cheaper, and even then not all of them. But only the simplest boilers with a single-stage burner are inexpensive. The cost of more complex models with high-performance simulated burners is already considerable. But such equipment is more economical and has a much longer service life.

- You can install a diesel boiler for your home without approval from the fire inspectorate (this is required, but practically never done, as is the case with solid fuel boilers).

- When installing, it is not necessary to make a full-fledged chimney. The specific design of a diesel fuel boiler is such that combustion products fly away into a low chimney under decent pressure. To remove smoke, it is necessary to lead the sandwich pipe from the boiler into the wall, then raise it a little, and equip the top with a metal umbrella to prevent precipitation from getting inside. That's the whole chimney.

Liquid fuel boilers are domestic and industrial

Modern boilers have automation that monitors the operation of the system. But you can leave such boilers unattended for 8-12 hours. A longer absence is possible with a configured warning system. Modern automation has such an opportunity. In this case, if an emergency occurs (the boiler goes out, etc.), an SMS message about the problem is sent to the specified phone number. This equipment costs a lot. In addition, if you plan to use a diesel boiler for your dacha, be prepared that you will have to visit the site several times during the heating season to start up the stopped system. Quite often, burners become clogged, electricity goes out, or other emergency situations occur that cause the boiler to shut down.

Varieties and classification

Manufacturers of heat generators divide them into 2 groups depending on the installation method:

- Floor-standing.

- Wall-mounted.

The former are characterized by increased requirements for the quality of the fuel mixture, which is why most people choose the second option.

Taking into account the characteristics of heat generation, boilers are:

- Classic.

- Condensation.

Diesel boilers are condensing.

According to the liquid heating technology, single- and double-circuit units (including those with an integrated boiler) are distinguished.

Disadvantages of diesel boilers

Boilers using light heating oil (as it is correctly called) have many disadvantages:

- Installation requires a separate room that meets certain requirements.

- You need a large tank for diesel fuel. It is advisable to fill it with the entire amount for the season before the season. Having some data, you can calculate the fuel consumption of a diesel boiler for heating. If we are based on generally accepted average standards for calculating the power of heating equipment, heating a building of 150 m2 requires a 15 kW boiler (in central Russia for houses with average insulation). If the burner power is 0.1 (data is in the boiler passport), then in one hour of operation at full power 1.5 liters of fuel will be consumed (15 kW * 0.1 = 1.5 liters). It will take 36 liters per day. If we take into account that for central Russia the boiler must operate at full capacity for 120 days, then the consumption per season is 36 * 120 = 4320 liters. A container of this volume will be required to meet the annual need for liquid fuel. But usually the tanks are taken with a reserve. In this case, you will need a capacity of 5000 liters. Another option is to install a smaller tank, but refill it more often.

One of the disadvantages of diesel boilers is high fuel consumption - From the above costs, one of the main disadvantages of diesel boilers is clearly visible: heating is expensive. Even if special diesel fuel is used and it is 20-30% cheaper than automobile fuel, but 4320 liters per year will cost a lot, very much. Even heating with electricity is cheaper, especially with new economical boilers. This problem is virtually eliminated if used diesel fuel is used, but then another burner is required.

- Liquid fuel boilers have another unpleasant feature: they make a lot of noise during operation. This is another reason why you have to install a separate boiler room (the first is the strong smell).

- Low efficiency is a fairly serious problem. Electric boilers usually have an efficiency above 90%, while diesel boilers, especially older models, have an efficiency of 75-85%. New models are much more productive and economical: manufacturers understand that such heating is far from the most profitable and are constantly improving the equipment. Thus, CTC Okotherm Unit boilers have an efficiency of 98%, but their cost is considerable.

Modern liquid fuel heating boilers have a special cylindrical combustion chamber and a heat exchanger made of stainless steel or cast iron. For better heat transfer and increased efficiency, heat exchangers are designed so that the coolant for water boilers or air for air heaters passes through heated chimney pipes several times.

Advantages

Let's start right away by considering the winning aspects (we'll discuss those that aren't so good later) that characterize heating a country house with diesel fuel. This question is relevant for many owners of private housing, because diesel fuel is not cheap; frankly speaking, a lot of it is required for the heating season.

The rating of this equipment in European countries is quite high, thanks to its advantages. Let's list the main ones.

The efficiency of the equipment under discussion is high, reaching 95% under the following conditions:

- correct installation of the boiler;

- furnace installations in accordance with all rules and regulations;

- high-quality insulation of the house;

- installation of double-glazed windows;

- proper storage of fuel reserves;

- using high-quality fuel;

- timely maintenance;

- competent choice of equipment power, manufacturer, model.

The efficiency can reach up to 98% when using a condensing type boiler, but more on that later.

- Wide range of model range, manufacturers, power characteristics, etc.

- Economical consumption of electrical energy.

- Environmental friendliness, which is a fairly current trend in modern European society. When burned, almost no harmful substances or gases are formed.

- High level of safety compared to gas boilers.

- Autonomous, automatic operation that does not require constant human intervention.

- Inertia is not typical for the design of diesel boilers (unlike solid fuel analogues). Productivity decreases immediately.

- Liquid fuel takes up much less storage space than solid fuel (peat, firewood, coal).

- Possibility to use used engine oils, which are cheaper. At the same time, the issue of recycling waste material, which is completely burned in a diesel unit, is resolved. Again, a reference to environmental friendliness.

Don't miss: Hot water temperature in the tap according to the 2022 standard

Operating principle

They work in almost the same way as with gas: fuel is supplied under pressure into the nozzle, which sprays and ignites. The nozzle design is different.

Internal structure of an oil-fuel boiler

Main structural elements:

- The combustion chamber. Their forms are developed by each company. They strive to achieve higher efficiency, but the vast majority of domestic diesel boilers have a cylindrical firebox.

- Heat exchanger. Here the forms can be varied. There are heat exchangers made of stainless steel, cast iron, copper, and steel.

- Diesel burner. Determines the efficiency of the boiler and the completeness of fuel combustion.

- Automation. Regulates the level of heat transfer, coordinating the operation of all components and monitoring the specified parameters.

- Fuel pump – supplies fuel to the burner.

If the combustion chamber, heat exchanger and automation are selected at the time of purchase and then either not changed at all (furnace) or very rarely (automation), then the fuel pump and diesel burner can be changed to improve the efficiency of the system. With pumps everything is more or less clear. It must provide the required pressure and be reliable.

Diesel burners are complex devices that ensure the functionality of the entire system. They can be changed and products from different companies can be installed. Let's look at how they work and how they differ.

Operating principle of the burner

The burner is, as a rule, a removable unit and you can install any unit whose parameters correspond to the power of the boiler. It is recommended to take the burner power with a margin of 10-15% relative to the boiler power. This will make it possible to regulate its operation more smoothly.

With the help of this unit, fuel is sprayed into small droplets. The nozzle is responsible for the size of the droplets and their direction. Next, the fuel suspension is mixed with the air supplied by the fan, and then fed into the combustion chamber. It turns out that it is the burner that is responsible for maximum fuel use.

If we consider the combustion process in detail, everything happens as follows:

- The pump supplies fuel to the burner. Moreover, only the required amount is taken, and the excess is returned to the tank.

- Before being supplied to the nozzle, the fuel is heated (not all models have this stage), then it is filtered and supplied to the atomizer itself.

- A flow of air and a fuel suspension are simultaneously supplied to the combustion chamber.

- The intensity of the process is adjusted using specially shaped blades that create vortex flows of suspended fuel and air.

- Electrodes located in front of the heating pad ignite the mixture.

Diesel boiler. Operating principle of the burner

Burner types

Burners can be of three types: single-stage, two-stage and adjustable. The simplest ones are single-stage. They operate constantly in one mode - at 100% power. Two-stage can operate in two positions: full power and half power.

The most expensive, but also the most effective and economical are adjustable. Under automatic control, they consume the amount of combustible mixture that is necessary to maintain the set temperature. When used, they significantly reduce fuel consumption in a diesel boiler.

To create fine dust, fuel must be supplied to the atomizer under high pressure - this is provided by a pump. On the other hand, a fan operates, forcing air flow and ensuring the required level of saturation of the fuel suspension with oxygen.

Burners are also distinguished by the type of device that provides the required pressure:

- fan burners use a fan to create pressure;

- supercharged - powerful turbines are used, due to which the pressure increases, the droplets are smaller and the fuel burns more completely.

Nozzle selection

But that is not all. You need to choose the right nozzle for the burner. For the correct and efficient operation of a diesel boiler, the correct selection of nozzle is very important. The efficiency of the thermal unit and the completeness of fuel combustion depend on the quality of atomization. After all, the nozzle sprays fuel before feeding it into the combustion chamber.

The passport for the boiler contains a spray angle, which is determined by the shape of the combustion chamber, the power of the unit and several other parameters. It may differ in each boiler design and model. The nozzle is selected for this value. The main thing is that at the outlet the fuel is sprayed in the form of a cone, and its angle corresponds to that indicated in the boiler passport.

The efficiency of the boiler largely depends on the burner

If the burner does not operate properly, the fuel is burned inefficiently, and some of it settles in the form of soot on the walls of the heat exchanger. Soot is an excellent heat insulator and a small amount of it significantly reduces operating efficiency. So a layer of soot of 1 mm reduces the efficiency by almost half.

If you have soot inside the firebox, blue smoke comes out of the chimney, fuel consumption has increased, and the temperature has dropped, the most likely reason is that the nozzle is clogged. To restore the previous operating efficiency, it is necessary to remove the spray assembly, remove the nozzle filter and wash it with non-abrasive detergents. After drying, put the filter and then the entire burner in place. If the boiler is still not working efficiently enough, the nozzle most likely needs to be replaced (on average, once a year).

What is taken into account

- Location of the house, prevailing winds, climate features.

- The degree of deterioration of the structure, the material of the walls, the quality of insulation.

- Building design, heating system diagram, possible heat loss.

And that's not all that is needed to calculate the required power of the installation; can't do it yourself.

Are you convinced that a diesel boiler is a good solution to your home heating problem? There is no need to look for a liquid fuel unit - the online store alfatep.ru has an impressive assortment of units from leading manufacturers. Thanks to direct deliveries, prices are at the factory level and fast delivery to regions of the Russian Federation. Our specialists will help you make thermal calculations and purchase the optimal version of boiler equipment; telephone number 8 (495) 109 00 95. We offer full service to residents of the Moscow region: project development, professional installation of the boiler, configuration and commissioning. At the request of the client - subsequent technical support of the product (repair/maintenance).

Installation of a diesel boiler

Installation of a diesel boiler is simple.

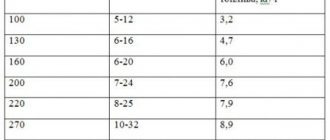

It is important to correctly set and ensure fire safety rules. The requirements for the premises where the diesel fuel boiler will be located are quite strict, but not prohibitive. When installing a device with a power of up to 150 kW (on average 1500 m2 can be heated), the room must have the following dimensions:

- volume not less than 15 m3;

- ceiling height not lower than 2 m.

The room must have ventilation and at least one window. The interior decoration of the boiler room must be non-flammable (both walls and floor). If the room is located in the basement, an equipped fire exit is additionally required.

The fuel container can be located in the same room, or buried outside. The boiler and container are connected by pipes, usually copper.

There are a few more points to consider when using liquid fuel. The boiler room must be heated, since when the temperature drops below +5oC, diesel fuel begins to thicken. It flows worse, paraffins thicken, which instantly clog the burner, stopping the system. The outputs are:

- heat the boiler room;

- install a filter at the burner inlet;

- use winter fuel or add special additives yourself.

From the experience of using diesel boilers, we can recommend the following improvements that improve the quality of system operation:

- If your boiler does not have a function for heating the fuel before feeding it to the burner, you should carefully insulate the fuel tank and ensure its heating. There is no need to heat to high temperatures. All that is required is to maintain the temperature at +5oC. With normal insulation, this one consumes about 100 W per hour. Very little.

- If you buy an imported boiler, either install an additional filter at the inlet, or change the “native” one. Those that come with the kit are designed for European fuel, not domestic. They just get clogged very quickly and the system stops.

Installation and connection of the structure to the heating system

To install a diesel unit, no special permits are required. It is enough to equip a safe boiler room and a reservoir for raw materials, and also connect it to the heating system.

Since a lot of soot accumulates when the working mixture burns, it is necessary to install a jumper between the forward and reverse supply. Other stages of connecting the boiler are performed according to the same algorithm as connecting other heating systems.

It is better to place the expansion tank, safety equipment and circulation pump in the boiler room, but this is not a mandatory requirement.

Review of manufacturers

There are many manufacturers of diesel boilers. There are domestic ones, from near and far abroad. There are so many offers that it is difficult to choose. In this case, it is customary to focus on the most popular ones.

Diesel boilers Kiturami (Kiturami)

Convenient for heating cottages and houses with irregular residence. They operate autonomously and use a tubrocyclone burner - one of the latest developments that saves fuel. It is possible to control both the room temperature and the coolant temperature; a self-diagnosis system is built-in.

The power of boilers using Kiturami diesel fuel is from 10.5 to 34 kW, fuel consumption is from 1.13 liters/hour to 4.3 liters/hour. There are dual-circuit models, with a possible supply of hot water from 3.8 liters/min to 20 liters/min.

Diesel boilers Kiturami (Kiturami)

Buderus boilers

The Buderus company produces diesel boilers made of steel and cast iron. Cast iron boilers of the Logano G model (Logan) are popular. There are powers from 25 kW to 95 kW. In another line there are more powerful ones up to 1200 kW.

They run on standard diesel fuel or fuel with low sulfur content. They are interesting because in the Unit modification, the burners optimize the fuel mixture, achieving almost complete combustion of gas, which reduces soot formation and emissions. These units have simple controls and easy setting of the required operating parameters. It may be interesting to expand the functionality of the automation by installing additional modules (you do not need to change the automation unit as a whole, but just purchase an additional unit that provides the functions you are interested in).

Boilers "Buderus" on diesel fuel

Buderus Logano S steel boilers are produced only in industrial capacities - from 450 kW of power. These industrial units can operate on two types of fuel - gas and liquid fuel.

Navien

Korean diesel boilers Navien (Navien) are made in the form of a rectangle. Their design is more similar to European ones. A distinctive feature is its small dimensions.

Boilers marked Navien KG have fuel preheated before being supplied to the nozzle. The pressurized fan supplies fuel at a sufficiently high pressure, which also ensures the effective removal of combustion products into the chimney. A stainless steel heat exchanger and a filter adapted for Russian fuel, which has replaceable cartridges for easy and quick cleaning or replacement. The control panel is Russified, the automation is protected by a special microcircuit at the input, which allows the boiler to operate without failures with network parameters of 230 V ±30%.

That’s why Navien liquid fuel boilers are quite popular: manufacturers have taken into account many of the features of our country’s networks. Power from 13 kW to 40 kW, fuel consumption from 1.46 liters/hour to 4.65 liters/hour, hot water capacity - up to 22.9 liters/min

Diesel boilers Navien

Saturn

Saturn boilers are units from another Korean company. They run on diesel fuel and kerosene; manufacturers do not recommend using spent fuel. They are distinguished by the presence of a copper heat exchanger (pipe 20 meters long and 15 mm in diameter). They delight owners with quiet operation and minimal size. They can be placed in a living space. The power of Saturn diesel boilers is from 13.5 kW to 35 kW, fuel consumption is from 2.01 liters/hour to 4.54 liters/hour.

Liquid fuel boilers Saturn (Saturn)

When compared with Navien boilers, there is greater fuel consumption for heating with almost the same equipment power.

Liquid fuel boilers Ferroli

Ferroli produces dual-fuel boilers. They run on gas and/or liquid fuel. The body and heat exchanger are cast iron. The body is insulated with a layer of temperature-resistant material. The GN2 N model is available with power from 106 kW to 252 kW, weight from 360 kg to 780 kg.

Liquid fuel boilers Ferroli

Cast iron boilers of the GF N model operate on solid and liquid fuels. The power of boilers in this line ranges from 12.7 kW to 27.5 kW. Equipped with an overheating protection system and a safety valve, you can burn both large and small pieces of wood in the firebox and switch it to “liquid fuel” mode. These models are single-circuit only (they do not heat water).

In principle, from these brands you can choose equipment for any conditions and needs, and there are still more than a dozen of them on the market, and maybe more than one hundred. So arm yourself with patience and choose. Good luck!

User reviews

Andrey, Moscow, 35 years old:

“I purchased a boiler 3 years ago for my dacha. The unit is small and compact, with a steel heat exchanger and an automatic unit for convenient operation settings. There were no complaints during this time. I maintain it regularly, changing filters and cleaning internal elements from soot.”

Victor, Saratov, 56 years old:

“After viewing dozens of reviews, I chose a small 17-kilowatt boiler for my dacha. I liked the quiet operation and quick heating of the room. But in severe frosts, the coaxial chimney begins to vibrate and make a lot of noise.”

Irina, 30 years old, Kirov:

“We have Kiturami at our dacha. Glad you installed it. Now you can stay outside the city even in the cold season. Fuel costs are low, and maintenance doesn’t cause any problems for my husband.”

Types of chimneys

The chimney is one of the most important thermal parts, which is necessary for its normal functioning.

The chimney must ensure the removal of fuel combustion products from the combustion chamber of a diesel boiler. There are internal and external chimneys. Internal ones are constructed inside the building to the top and lead out through the ceilings and roof. External ones are mounted along one of the walls of the house. In addition, there are individual and group chimneys. The first serves one boiler, the second, accordingly, works with several boilers.

Since many modern diesel boilers, during the combustion process, produce a low gas temperature at the boiler outlet, this feature places special demands on chimneys. One of them is that the diameter of the chimney must be no less than the outlet neck of the boiler. The chimney should not have bends or barriers to the exhaust gases. Also, condensation should not form in the chimney during operation. To prevent the formation of condensation, the chimney pipe must be insulated. A container for collecting condensate must be installed at the lowest point of the chimney. Chimneys with a height of more than 4-5 m are made of stainless steel. However, this material is quite expensive. Due to the formation of condensation, brickwork will not last long.

A new development has appeared on the market of products for heating systems - a universal chimney system with ventilation. It does not contain metal parts, therefore, is not subject to corrosion. This chimney system consists of lightweight concrete blocks, inside of which there is a ceramic insert. During installation, the blocks are placed on top of each other to the required height and glued with a special sealant. If we talk about cost, then such a chimney system is close in cost to a good quality stainless steel chimney.

Fuel storage tanks

Just as carefully as the diesel heating boiler itself, you need to choose a container for storing liquid fuel.

Since diesel fuel for heating purposes is purchased in large quantities, it is necessary to decide on the space where to store it, and most importantly, in what. Today, consumers often use special plastic containers to store liquid fuel. They have a rectangular shape, which makes their placement compact. As a rule, the width of the wall of the fuel container is about 75 cm, and its height is no more than two meters. The most popular among factory-produced containers are vertical tanks designed for a volume of 700 to 2 thousand liters.

Special manufacturing technologies allow you to make the container without seams, which is more reliable and will serve you for many years. Thanks to the anti-corrosion layer inside the container, large amounts of fuel can be stored for a long time, regardless of weather conditions. In addition to plastic containers, stainless steel storage facilities are also widely used.

Stainless steel metal containers can also provide all the necessary conditions for storing liquid fuel, since the metal from which they are made is resistant to aggressive environments and does not corrode, which ensures long-term trouble-free operation of the containers. Tanks designed specifically for storing diesel fuel are made from metal that has high corrosion resistance.