If it is not possible to supply gas to the house, the problem of autonomous heating and water heating must be solved using alternative energy sources. You can install solar generators and heat with wood or pellets. However, the best solution may be a double-circuit electric boiler.

The article we presented describes in detail the operating principle and types of equipment that converts electrical energy into heat. Listed are guidelines that future owners of the unit should consider before purchasing it. Recommendations for economical operation are given.

How the device works

The design of a double-circuit boiler involves placing two heating elements in one device for heating water and coolant. The system works by converting electric current into thermal energy.

Design features of a double-circuit boiler

To heat the room, a closed-type heating circuit is connected to the boiler, through which the coolant moves. The second pipeline is designed to supply hot water, which is heated in a built-in storage tank or according to the flow-through principle.

During the warm season, the heating can be turned off and the boiler can only be used as a boiler.

Two circuits of an electric boiler can function either independently of each other or simultaneously, heating the house and heating water

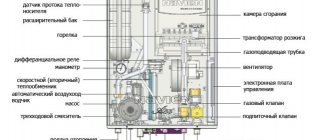

The device consists of the following main elements:

- housings with thermal insulation, inlet and outlet fittings;

- a heat exchanger through which the coolant circulates;

- control system and automation unit, which allows you to set temperature parameters and turn off/on the device;

- heating device;

- expansion tank for pressure relief;

- safety valve;

- air vent (automated or manual) to remove air pockets;

- circular pumps for hot water supply and heating systems;

- security groups with temperature sensors and relays.

The principle of operation of an electric boiler is heat exchange: a circular pump pumps water into the tank, which is heated to a certain temperature by a thermoelement and discharged either into the heating circuit or into the hot water system.

In fact, a dual-circuit electrical appliance, like its gas counterpart, can serve as both a home boiler room and an instantaneous water heater.

Advantages and disadvantages of electrical equipment

Electric heating is an environmentally friendly heating method, because it does not pollute the air with smoke and soot like a solid fuel boiler, carbon monoxide and other harmful wastes like gas equipment.

In addition, the peculiarity of electric heating operation practically eliminates emergency force majeure in the event of a water leak - if there is no coolant in the system, the equipment automatically turns off.

An electric boiler has an excellent efficiency indicator - 95-99%, but even such a high heat transfer does not compensate for the high electricity consumption, therefore, in comparison with a gas boiler, the electric appliance loses

Also, the general advantages of electrical equipment include:

- Simple installation - there is no need to equip a chimney, a forced ventilation system, connect a gas pipeline and apply for a bunch of permits, as when installing a gas boiler.

- Safety - the likelihood of an electric boiler leaking or boiling is very low, in addition, the design of the device does not provide for the use of open flames, flammable materials and explosive gas.

- Compact dimensions are an important point for small rooms. In addition, the device can be installed not only in places specially provided for by the project (like gas equipment), but in any convenient place where it is possible to connect to the electrical network and heating system.

- Silence - the electric boiler operates without vibrations, “exhausts” and other sounds that plague solid fuel and gas appliances.

- Affordable cost of both the device itself and its installation and maintenance.

As for the disadvantages, one of the most significant is the cost of energy consumed. If we are talking about electric heating and hot water for a large cottage, the amounts will be impressive.

Therefore, it would not be amiss to make at least an approximate calculation of consumption before purchasing, analyzing information about the area, water consumption and power of the device. And then decide whether the “game” is worth the cost.

The installation of special controllers, storage devices and differentiated meters operating in day-night mode will help to significantly reduce costs.

Other cons:

- Dependence on energy supply - in areas with constant power outages, installing such a heating device makes no sense. However, if outages are random and not the norm, purchasing a generator that stores energy will help solve the problem.

- Mains voltage surges have a detrimental effect on the sensitive automation of the boiler, so before installing the equipment it is worth purchasing good energy stabilizers.

- Sedimentation. Since running water is used for hot water supply, the heating elements gradually become covered with scale, which must be removed from the equipment. The solution may be to install filters at the cold water inlet and regular maintenance.

In addition, before installing an electric boiler, it is worth finding out whether your home network is designed for such a load. For example, for an area of 200 square meters you will need at least 16-20 kW.

And this is only for heating, without taking into account other electrical appliances. And if in new cottage villages such power is provided by connecting to a three-phase network, then for a summer cottage, no more than 10 kW is usually allocated.

Connecting a double-circuit boiler

First you need to choose where the equipment will be mounted - on a wall using brackets or on a special podium. In this regard, the work area is prepared.

The next step is to connect the outlet leading from the internal water supply to the lower pipe, which is responsible for the supply of cold water. The top connector, through which hot water is distributed, is connected to the manifold serving the hot water supply.

Next, a branch coming from the heating pressure branch is fixed on the upper branch pipe of the coil. The lower branch pipe, in turn, is combined with the return branch; to do this, it is necessary to insert a tee behind the expansion tank and pump.

The final stage comes down to connecting the boiler to the electrical network using an automatic fuse and an RCD. All work can be done without the involvement of professionals, but it is important to make sure that the unit is securely fixed if the choice falls on a wall-mounted modification.

Types of electric boilers

Modern electric boilers are equipped with heaters with different operating principles. But only devices with a heating element design can be used simultaneously for both heating and hot water supply.

Connecting an electric boiler to a heating and hot water system most often involves installing a boiler with a heat exchanger or a container for storing hot water

Other types of equipment can be used for domestic hot water only if an indirect heating boiler is connected to the heating circuit.

Electrical appliances with heating elements

The most common models of electric boilers have built-in heating elements - heating elements, which are made of ceramic or metal, have the shape of rods, a spiral or a hollow rod bent by an arc, inside which a thread of a certain resistance is placed. They act as “intermediaries,” heating up when an electric current passes and transferring heat to the water.

Diagram of a double-circuit electric boiler. The number of elements depends on the power of the device and its internal volume, but additional heating elements not only increase the heating rate, but also the cost of electricity and maintenance

The main disadvantage of the device is the rapid formation of scale on the heating elements, which impairs its performance. For example, with a limescale thickness of only 0.5 mm, the efficiency of the device decreases by 10% of the nominal, and with 2 mm - by 35-40%!

As a result, the device heats the water more slowly, so electricity consumption increases. Therefore, the boiler needs constant cleaning and periodic replacement of failed heating elements.

To extend the service life of the heating element, it is recommended to use a system of cleaning filters or add special softening agents to the coolant, and pour distilled water into the heating circuit.

In addition, boilers with heating elements require regular maintenance, because we are talking about the safe use of the equipment. The heating element gradually wears out and may burn out.

If this happens with depressurization of the housing, it’s not so bad. In this case, heated nichrome will simply crumble upon contact with water and does not pose a danger to humans. But if the disconnected element remains in the undamaged case and continues to work, the entire metal case, thanks to the water conductor, will be energized.

Induction heating equipment

The operation of an induction boiler is based on magnetic induction, which allows you to convert electricity into thermal energy. Inside the housing there is a primary circuit with an inductive coil, which, when voltage is applied, creates an alternating magnetic field.

As a result, so-called Foucault (or eddy) currents arise, which heat the metal, and it transfers its heat to the circulating carrier.

Time-tested heating element boilers can be safely installed even in a living room, but for induction devices it is better to provide a separate room - despite the advertising statements of manufacturers, medicine has not confirmed the harmlessness of electromagnetic fields for humans

Advantages of induction boilers compared to heating elements:

- The highest level of efficiency is 98-99%.

- Large heating area and, accordingly, faster heat transfer.

- Scale does not form on the heating element.

- Completely autonomous and do not require maintenance.

- In addition to water, petroleum products and oil can be used as a coolant.

The main disadvantage of such devices is the high price and the need to connect an indirect heating boiler or storage tank to provide the home with hot water. Therefore, despite a number of advantages of induction equipment, the leadership of consumer demand is firmly held by double-circuit heating element boilers.

Boilers with electrode heaters

The operation of an electrode boiler is based on the high thermal conductivity of water. Inside the housing there are negative and positive electrodes that generate electric current, and coolant circulates between them.

Heating occurs due to the energy that is released when molecules split into charged ions and their movement towards the electrode of the appropriate polarity. Thanks to this, heating of the water in the boiler chamber occurs almost instantly.

A prerequisite for an electrode boiler is good grounding, since the devices are potentially dangerous devices and the housing can “pierce” with a strong current charge

Advantages of electrode boilers compared to heating elements:

- Heats water 10 times faster.

- They spend 20-30% less electricity.

- They have compact dimensions even with high productivity (most often models are presented in wall-mounted versions).

- They do not fail during power surges.

But due to significant shortcomings, electrode boilers have not yet become widespread. They are mainly used for heating, but it is possible to organize a second circuit for hot water supply if the system is retrofitted with an indirect heating boiler.

These devices are very demanding on the composition of the liquid that serves as the coolant. Ordinary tap water is excluded; it is recommended to use a special liquid with a balanced salt composition. In addition, the electrodes gradually dissolve during operation and require replacement.

Electrode boilers are very compact, but do not have high power, so for heating large areas, modules with several devices connected in series are provided

For safe use, it is recommended to equip the electrode boiler with an additional automation kit, which is sold separately and often costs more than the device itself. First of all, this is a circulation pump and an electronic temperature controller that controls the heating temperature.

A current controller is also needed to regulate the current strength, with the ability to turn off the equipment to prevent water from boiling.

Functions of unit controls

The usual set of functions for the controls of double-circuit boilers with a power from 7.5 to 45 kW includes the following options:

- Smooth control of boiler power in small steps (2.5 kW) for electric boilers up to 30 kW and 5 kW for electric boilers from 30 kW to 45 kW. The current per phase cannot be higher than 12 A.

- Possibility of connecting boilers to a thermostat or OpenTherm + controller, for example using a socket controller. This provides the possibility of remote control via SMS messages sent using a smartphone.

- Weather compensated control, when the power of the unit can be changed depending on the room temperature or outdoor temperature.

- Control of the maximum current consumption, which is carried out regardless of the capabilities of the circuit breaker installed in the house.

A further development of the control and control functions of double-circuit boilers is the modularity of their connection, when up to 32 devices of the same type can be included in the configuration of an intelligent cascade boiler. This allows you to optimize the total load power when indoor heat exchange conditions differ significantly. A diagram of such a connection for a wall module is shown in the figure. The success of the modular connection is guaranteed if all double-circuit boilers include an external expansion tank, the filling of which is carried out depending on the volume of coolant in the system, as well as on its temperature.

With proper operation, the equipment considered provides complete comfort to any home.

What to look for when purchasing?

When you have figured out what type of device you want to buy, it’s time to think about its size and technical parameters.

Most often, electric boilers are installed in the kitchen, but you can also equip a mini-boiler room, which will allow you to hide unattractive communications and additional equipment (storage tank, indirect heating boiler, etc.).

Selecting a device by installation method

Regardless of the type of construction, all double-circuit boilers can be divided into two large groups - wall-mounted and floor-mounted. The dimensions and choice of model directly depend on the area that you need to heat, and also on the amount of free space for the device itself.

A wall-mounted boiler differs from a floor-mounted boiler in its small size - if necessary, it can be hidden in a wall cabinet or cabinet, but even an undisguised device does not look bulky and harmonizes perfectly with other household appliances

Attachment units are designed for heating relatively small areas - up to 100 m2, therefore they are most often installed in apartments or small country houses. They are attached to special brackets to any vertical surface that can withstand such a load.

Floor-standing boilers are rather bulky devices, but they can provide a house with an area of up to 200 m2 with heat and an uninterrupted supply of water, and storage tanks can either be built into the device itself (which significantly increases its dimensions) or mounted separately

If the cottage area exceeds 200 m2, you can equip a boiler room with several electric boilers or use additional heating sources - solid fuel equipment or solar panels.

Calculation of required power

The simplest way is to divide the heated area by 10. It is believed that when heating 10 m2, 1 kW will be spent, but the resulting figure will be very arbitrary, because such a calculation makes sense only for rooms with a height of no more than 3 meters.

In addition, heat costs largely depend on the presence of insulation, the quality of windows and their sizes, the climatic features of the area and the materials used in the construction of the house.

If the house has high ceilings, you must first determine the volume of the room (multiply the area by the height). Then calculate the required power on the basis that 1 m3 will require 35 W.

When purchasing, consider models whose power is 15-20% higher than your calculated values - it is better to set the boiler to a weaker mode than to freeze in the cold winter with the equipment working at its limit

To the obtained result you need to add a “margin”:

- 10% - with a large glazing area (panoramic windows, veranda, etc.).

- 15% - in the absence of house insulation.

- 10-15% - for areas with cold winters.

- 20% - for additional load when DHW operates in flow-through heating mode.

When calculating the required power for boilers with built-in storage, you need to rely on the data specified by the manufacturer in the technical documentation.

The method of feeding it also depends on the technical parameters of the boiler. Appliances up to 10 kW can be connected to a regular 220 V network, and more powerful boilers can be connected to a three-phase network (moreover, this may require permission from local power grids if a 380 V line is not supplied to the house).

Other important nuances

Based on the principle of heating water, double-circuit electric boilers can be divided into flow-through and storage. The first is a good option for a small house and family; it can easily serve 1-2 water points in addition to heating. But despite its compactness and ease of use, the 2-in-1 device has a significant drawback - a high load on the electrical network.

But the storage unit takes up much more space due to the additional tank in which the supply of hot water is stored. The advantage of this type of equipment is that it can supply water in large quantities and allows you to save up to 10% on electricity, since it does not waste energy on constant heating, but only maintains its temperature.

Thanks to the insulating casing, the heat loss of water in the tank per hour will be no more than 0.5 degrees. The technical data sheet of a device intended for connection to a hot water supply system must indicate its throughput - minimum and maximum temperature, volume of water and the required time for heating it.

Modern electric boilers allow you to control the device and control the heating temperature in the room using smartphones or a smart home system

Additionally, the boiler can be equipped with:

- Automation unit for remote control from a remote control or via a network.

- Frost protection, which will allow you to maintain a minimum temperature in the system, which is important for country houses and country houses where there are no permanent residents.

- Sensors that monitor weather changes turn the device on when temperatures drop and turn it off during sunny hours.

- Equipment that lowers the water temperature for connection to the “warm floor” system.

- Sensors with the ability to program the microclimate in the entire room or individual rooms at your discretion.

Of course, “bonuses” from the manufacturer increase the cost of the device, but with their help it is much more comfortable to operate the boiler.

How to choose an electric boiler for heating a private house

A double-circuit wall-mounted or floor-standing boiler can perform the function of a double-circuit water heater or heat a room. At the selection stage, you first need to determine the optimal type of installation.

You should also familiarize yourself with the following equipment characteristics:

- Heated area - to estimate this parameter, you may need to perform some thermal calculations.

- DHW capacity and operating characteristics. You can clarify them in the relevant documentation, which displays the permissible operating parameters: maximum and minimum heating, coolant volume and other information.

- Additional features - advanced boiler models are equipped with remote control elements, a GSM unit and multifunctional automation.

To choose an electric boiler for heating a private home, it is important to take into account all the listed parameters and your own needs. Only after this can you determine which model to choose.

How to calculate power

When choosing an electric boiler for heating a house (220V), it is important to correctly calculate its power. Such calculations are carried out according to the following principle:

- For complete heating of a residential building, the performance of a 2-circuit unit is measured according to this principle: 1 kW = 10 m². At least 15% of the reserve is added to the finished results.

- After this, the DHW calculation is performed - a traditional double-circuit electric boiler, which is used for heating and water supply, needs to be added to the calculated power by another 15-20% of additional reserve.

- If it is necessary to determine the power of a boiler with a built-in boiler installation, it is important to take into account the manufacturers’ recommendations and technical documentation.

When performing calculations, you should consider the amount of electrical energy consumed.

Leading brands market 2 types of electric heaters:

- Single-phase.

- Three-phase.

Representatives of the first group can have a power of up to 8 kW and operate from a 220V network. In technical information, single-phase models are called simple water heaters, so when installing them there is no need to obtain additional permits or allocate a separate voltage branch

If the power consumption exceeds 8 kW, you will need to install a three-phase system. For uninterrupted operation of the equipment, you need to install a separate 380V branch. In the absence of a centralized line, the consumer needs to make a request to increase energy consumption.

Ways to save money during operation

To reduce energy costs when using an electric boiler as a heating device and water heater, you need to reduce the overall heat loss at home.

First of all, it is worth replacing old wooden frames with modern windows with 2-3 air chambers and taking care of insulating the walls (preferably external) with polystyrene foam, mineral wool or other materials with low thermal conductivity

Other saving options:

- An additional connection or separate devices running on alternative energy (solar panels, wind generators, wood fireplace) will significantly reduce electricity consumption.

- A multi-tariff meter will allow you to pay less for night heating, and during the morning and evening “peak hours” the device can be turned off (the most expensive electricity is consumed in the intervals of 8.00 - 11.00 and 20.00 - 22.00). And if you supplement the system with an external heat accumulator, you can accumulate “cheap” energy at night in order to use it during the day.

- A recuperator in the ventilation system will help retain heated air inside the house.

- The weekly programmer will collect data on the operation of the system for a specified period of time in order to select the most comfortable and economical operating mode with minimal energy consumption.

- Room thermostats will monitor changes in the microclimate of the house and transmit data to a sensor built inside the boiler, which will turn the heating off/on, protecting against air overheating and unnecessary heat loss.

With proper organization of the operation of an electric boiler, you can reduce electricity consumption and associated costs by up to 40%.

The following article, which examines this very interesting issue in detail, will introduce you to energy-saving heating options for country property.

Selecting the best products

It is impossible to give a clear answer, but if all the requirements are taken into account, the picture will be clearer. When purchasing a main heating boiler, you should pay attention to its economical characteristics.

Italian and German models succeeded better than others in this component. Manufacturers have taken care to equip their products with modern technologies. Therefore, the equipment is able to use energy economically. Double-circuit electric boilers from foreign manufacturers are in great demand. Read also: “Which electric double-circuit heating boiler is better to choose.” When purchasing backup equipment, it is recommended to opt for cheap systems. Their power will be sufficient to replace the main boiler if the latter fails.

Conclusions and useful video on the topic

We recommend that you familiarize yourself with a selection of reviews and practical tips on the use of electric boilers of various designs for heating and hot water supply at home.

Nuances of electric heating - boilers and other electric heating devices, calculation of equipment power and costs for the heating season:

Although double-circuit electric boilers seem very comfortable to use, before you go shopping, calculate your electricity costs for the cold season or contact a heating engineer.

Perhaps they will advise you on a more economical system with a single-circuit boiler with an indirect heating boiler, or they will design a combined heating system, where the “gluttony” of the electrical appliance will be compensated for by additional energy sources.

Please write comments in the block below. Tell us what was the decisive argument for you in choosing a double-circuit boiler model. Share useful information that will be useful to site visitors, ask questions.

Distinctive features of the equipment, advantages

Electric boilers, despite the high cost of the energy source, have a number of attractive features:

- This is the only boiler of all that does not need to build a chimney.

- There is no combustion process, which means everything is much simpler with installation - you don’t need a special room, you don’t need to do forced ventilation.

- No flame - no soot, which means the boiler works “cleanly” and will not be ruined by expensive repairs;

- The boiler does not need to be cleaned.

- They work silently.

- Compactness and light weight allow the device to be mounted on any suitable wall;

- You will not have to coordinate anything and obtain permits (except for units over 10 kW or 380 V).

- Electric boilers are complex on the inside, but simple on the outside - it’s very easy to understand the controls.

To install a unit with more than 10 kW of power, you need to notify the electricity supply organization. Since this is a large load on the network, you need to be sure that the line can handle it.

Popular models

Among the variety of brands, the leading positions in the ranking are occupied by the following manufacturers:

- Protherm (Slovakia),

- Vaillant (Germany),

- Kospel (Poland),

- Buderus (Germany).

Among Russian brands, buyers give preference to 4 brands, including:

- "TEPLODAR"

- "EVAN"

- ZOTA,

- "RusNIT".

The best models from the category of medium-power boilers that are suitable for apartments, based on user reviews:

- Teplodar Sputnik 6 (8.1 thousand rubles);

- RusNit 208M (average price - 16 thousand rubles);

- EVAN Warmos-IV-5 (16.5 thousand rubles);

- ZOTA 12 Lux (RUB 21.4 thousand);

- Kospel EKCO L2 12 (37 thousand rubles);

- Protherm Skat 12 KR 13 (32.5 thousand rubles);

- Vaillant eloBLOCK VE 12 (35 thousand rubles);

- Buderus Logamax E213-10 (9.3 thousand rubles).

Teplodar Sputnik 6 in black

Teplodar Sputnik 6 in white

Power

The power of the boiler is its most important characteristic, which means you need to choose it correctly. Sometimes it is tied to the footage and calculated based on the value of 1 kW per 10 m2. This formula is only suitable for a very rough estimate.

USEFUL INFORMATION: What types of electrical outlets are there?

In fact, you need to focus on heat loss. If, for example, they are 8 kW, then you need a boiler of the same power. The calculations take into account:

- area and height of the room;

- degree of insulation of walls, floors, ceilings;

- the number of external walls and their location according to the cardinal directions;

- number, dimensions and type of windows;

- battery connection diagram;

- region of residence and other parameters.

To correctly calculate the boiler power, it is recommended to use special calculators or seek advice from a heating engineer.

Electric boilers with heating elements (tubular heaters)

Such boilers work on the same principle as most household electrical appliances - kettles, boilers, irons. They are most in demand among consumers and are presented in a wide variety of models. There can be several heating elements, and they are turned on together or alternately.

Pros:

- simplicity of design;

- reliability of the circuit, ease of repair.

Minuses:

- high inertia of boilers - slow heating at startup;

- demands on the quality of the coolant. The tendency for scale to form, which reduces heating efficiency, forces special measures to be taken. You can install anode rods that will collect salt deposits on themselves, and change them at certain intervals, just like the heating elements themselves. But it is better to use specially prepared water or a special coolant.