Connecting a heating element in a heating system paired with a solid fuel boiler.

Installation of heating elements in the boiler.

As a rule, most manufacturers of solid fuel boilers provide for the insertion of electric heating elements, and often they are already supplied as a kit. The most common options are heating elements with a power of 6 kW (3 heating elements of 2 kW each) and 9 kW (3 heating elements of 3 kW each).

The boiler has a 1” threaded hole on the opposite side of the return in the lower part. The heating element is installed through a rubber sealing ring. Tightening is done with an adjustable wrench (be careful not to damage the terminals on the ceramic bushings)

Connection diagram for the heating element on the boiler:

Normal switching via AT is performed as follows: Parallel one end from each heating element by installing a jumper - this will be a common zero with its own machine. We supply phases to the remaining three outputs via AT. According to this connection diagram, each heating element can be powered separately at 220 volts. But even without zero, you can apply 380 Volts in series to two heating elements, obtaining a greater range in power selection.

Connecting the heating element via an automatic control unit:

An excellent option for automatically maintaining the operating temperature in the boiler. This is precisely why the heaters are provided in the boiler, to maintain the temperature at night or during the inspection process. Having a thermostat, the heaters are controlled by turning on from a set lower temperature and turning off at a set upper value. The heating elements are connected to the block, the temperature sensor is installed at the outlet of the boiler.

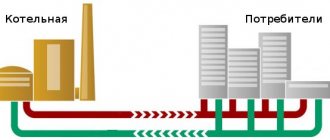

When deciding on the organization of heat supply, the correct choice of equipment occupies a central place. The heat generator is the center of any heating system, and the productivity of the entire heating circuit as a whole depends on the efficiency of its operation. The heating equipment market offers a lot of different solutions.

Solid fuel boilers still remain in demand and popular, largely due to the possibility of modification. Installing heating elements (tubular electric heaters) is a fairly simple and relatively cheap way to transform a solid fuel boiler into a combined device that produces heat using electricity. A solid fuel boiler with heating elements is essentially a unit in which there is the possibility of alternative or joint use of the main types of fuel and electricity.

Solid fuel heating boilers with heating elements

Currently, boilers operating only on solid fuel are rarely used. Instead, the domestic market offers a wide selection of combined and universal heating units that operate not only on solid fuel, but also on other types of energy carriers. A wide range of electric solid fuel heating boilers is offered to consumers.

This type of units is intended for heating residential, domestic, agricultural and other premises. A number of models can be used as both the main and backup sources of heat supply. They are also installed for use with other types of heating systems.

A heating element solid fuel boiler has the following advantages:

Radiator electric heating at home

Installation diagram of the heating element in the radiator

Before installing a heating element into the heating system, you need radiator parameters. The main one is the diameter of the connecting pipe. Currently, manufacturers produce products in two sizes - 1/2 and 3/4 inches. Then a comparative analysis of the heating parameters is carried out before and after installing the heating element.

Connecting the heating element to the existing heating

If it will be used as an additional method of heating water, you need to take into account the change in hydraulic pressure when passing through the radiator. Since the flow diameter of the system this month will be smaller, it is recommended to install a pump of higher power.

When connecting a radiator to the system, installing a heating element for heating the house will not be possible. To do this, you must either change the connection diagram to the top, or install a heating element on the top of the battery, which is not recommended by experts.

They are often installed in old cast iron batteries. Before performing work, you must first check the direction of the thread of the pipe (right or left) and also measure its diameter. Then you should follow this scheme:

- Coolant drain. It is prohibited to install a heating element into a heating radiator if there is water in it;

- Checking the battery level. Even at a slight angle of inclination, the likelihood of air pockets significantly increases;

- Installing the heating element into the pipe. To seal the holes, you must use the gaskets supplied with the heating element or make them yourself;

- Installation of a unit with a thermostat, if included.

An example of installing a heating element in a cast iron radiator

After this, you need to fill the system with water. Using the installed Mayevsky crane, possible air pockets are removed. Before switching on, to ensure safety, a tester is used to check any possible heating coil-battery circuit. If there is one, you need to dismantle the heating element and install it again, improving the sealing.

Radiator electric heating

When organizing heating using heating elements made by yourself, installation of a pipeline is not necessary. A heating element must be installed on each radiator. At the same time, it is possible to install models of different power depending on the thermal conditions in a specific room of the house. The advantages of such a system are as follows:

- Saving on the purchase of materials and reducing the labor intensity of installation work;

- If you use a heating element with a thermostat for heating and a temperature sensor connected to it, the degree of heating of the room will be adjusted automatically;

- Minimum system heating inertia.

But all these positive qualities can be offset by the total cost of service. Therefore, before heating with electric heaters, you need to calculate not only the cost of purchasing materials and components, but also the subsequent costs of electricity. Only after this should a heating system of this type be introduced.

It is recommended to purchase factory radiators with installed heating elements. Their operating efficiency is higher than that of homemade ones, since special oil is used as a coolant. Even when the heating element is turned off, it will give off heat to the room for some time.

When is it advisable to use heating elements?

Design of the heating element

First of all, it should be clarified that it is not recommended to make a homemade heating element for a heating battery. This is due to compliance with operational safety regulations. In such designs, it is difficult to prevent a short circuit when electric current penetrates the coolant. Therefore, do-it-yourself heating using heating elements should only be done using factory models.

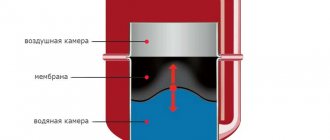

The heating element is a metal spiral with a high electrical resistance. It is enclosed in a metal shell, which is filled with oil. This ensures a better heat transfer coefficient during operation of the device. When connected to an electrical network, the coil begins to heat up, transferring thermal energy to the surface of the shell. It, in turn, is a heat exchanger between the heating element and water.

It is important to use heating elements for heating in the following cases:

- Creation of heating systems without a main line. To do this, you will need a heating element for a heating radiator with the ability to regulate power;

- Included in electric boilers. If factory models are too expensive, you can make an analogue with your own hands. It is recommended to use a special heating element for the heating boiler as the main heating device. It is characterized by increased power, in most cases it is designed for a network voltage of 380 V;

- For quick heating of the room. Unlike solid fuel for a gas boiler, heating with electric heaters has a minimum heating time for the coolant. If you need to quickly increase the temperature in the room, it is best to use this type of heating.

Comparison of heating costs for different types of energy carriers

In addition, electric heating devices are small in size. They are successfully integrated not only into boilers and heating radiators, but also directly into the pipe. Thanks to this, the dimensions of the entire system are reduced, which is important for small houses and apartments. The disadvantage of heating with self-made heaters is the high running costs. In a comparative analysis of various energy carriers, electricity will turn out to be the most expensive.

Is it really effective to use heating elements for heating radiators? Reviews often contain conflicting information. This is mainly due to the lifespan of the heater. The reason for this is improper installation and operation of the device.

You can install a heating element into the heating system yourself. Manufacturers often include installation instructions with the device.

Additional functions of electric heaters

Above we discussed the simplest designs of devices that do not have any built-in adjustment mechanisms.

But electric water heaters can be equipped with simple automation that provides the device with additional functions.

These include:

- Thermoregulation. Heating elements with a built-in thermostat for heating have a temperature sensor that is triggered when the working environment is heated to a certain level. The electric heater is adjusted from the outside of the flange.

- Antifreeze. This function is provided by a simplified thermostat, which operates only when the temperature drops to 0-2°C. It prevents water from freezing in heating pipes, consuming a minimum of electricity.

- Turbo heating, which provides forced heating of the working environment during the initial start-up of equipment. It must be remembered that the electrical wiring of the room must withstand a short-term increase in power.

There are not many devices that support additional functions, because the operation of heating devices as a whole is often regulated using a separate automation unit.

Scope of application of heating elements for heating

Electric heating elements have gained popularity due to their versatility and high efficiency. All the electricity they consume is used for its intended purpose - heating the surrounding space.

The main heating devices where heating elements are used are:

- Portable and stationary oil electric heaters.

- Water heating radiators.

- Bathroom heated towel rails.

- Electric fireplaces.

- Electric convectors.

- Electric boilers.

The specified equipment can be used as a main or additional heating source. It is inexpensive, easy to install and does not require special skills to operate.

You can connect the heating element to a cast iron central heating radiator after disconnecting the common riser. This device can be used for main and additional heating

How big is the benefit from heating elements?

If you have an old battery, then why not use a heating element to turn it into a heating system for a small utility room - a chicken coop, a workshop, a garage.

There are even myths that heating with heaters is beneficial. But “dreams are shattered by harsh reality” - heating with electricity is the most expensive. Since the most expensive energy carrier is used.

It doesn’t matter whether there is a proprietary programmable electric boiler, or a barrel with a heating element lowered into it on a wire, the efficiency of such electric heaters is about 97%. And then we pay according to the meter...

Heating element and single-phase network. What to screw to what?

This case is typical for dachas and old-built village houses. First you need to generally understand what we are talking about and the easiest way to do this is by looking at the following figure:

So, a single-phase electrical network has two conductors - zero and phase. The picture itself shows two ways to turn on the load - parallel and serial. These methods differ in how the initial voltage is divided between the elements. In most cases, heating elements are connected in parallel so as not to lose useful power; a series circuit is suitable only for various specific cases. A block prepared for connection to one phase will look like this:

It is also worth paying attention to the choice of cable, but we will touch on this point a little later, and now let’s move on to the three phases

Device and connection diagrams of heating elements | For home, for family

Room thermostats can be divided by device, by method of device and by functionality.

Based on their technical design, room thermostats can be divided into 3 types:

- Electromechanical.

- Electronic.

- Mechanical.

According to the method of installation, room thermostats are divided into two types:

- Wireless thermostats. Using periodic signals, communications between the executive unit and the controller are carried out. Wireless thermostats have a big advantage: there is no need to make holes for wires. But there is also a small drawback: the signal power is reduced due to reinforced concrete walls.

- Wired thermostats. Contacts between blocks are maintained using wires. Such a thermostat can transmit data over a distance of more than 50 meters. The power source can be a household electrical network.

Based on functionality, the following types of room thermostats can be distinguished:

- Programmable thermostats. They can set the desired regime for several days in advance.

- Simple thermostats. They only maintain the required temperature.

- Room thermostats cannot create a harmful electromagnetic field. They only transmit a small impulse.

How to connect a thermostat to an infrared heater

Electrical wiring can be open or hidden.

Is it possible to use one thermostat in several rooms?

When installing a thermostat, it is necessary to take into account that the set temperature will be maintained only in the place where the sensor is located. Cables laid in several rooms must be connected in parallel, as when one heating cable to the thermostat

You should not use one thermostat when the operating conditions of the premises are different (bathroom and kitchen), and also when the rooms have different heat loss rates (room and balcony).

Choosing an electric boiler for your home

To choose the right electric boiler for heating your home, you need to consider many factors. including the material and thickness of the walls, glazing area, outdoor air temperature in winter in your region, ceiling height and many others.

Often, such calculations are entrusted to specialists who make a home heating project that takes into account all the necessary characteristics of the system, including the type and power of the electric boiler; often they even offer a specific model or several to choose from.

When independently choosing the required power of an electric boiler for heating, it is usually customary to use the following formula: 1 kW of power is required to heat 10 sq.m. Houses.

The rule is relevant for single-circuit boilers used only for heating rooms, but if there are two circuits, one of which is used to heat water in the hot water supply system, the calculation must be changed, the same should be done if the ceiling height is higher than the standard 2.5-2.7 m and in some other cases.

So, in our example, the area of the house is 120 sq.m. Therefore, an electric boiler with a capacity of 12 kW was chosen . model ZOTA - 12 series "Econom".

After all the theoretical calculations, we will determine whether this boiler is suitable for the permitted (allocated) power for the house. For us it is 15 kW, with a three-phase input, so a 12 kW boiler is suitable for us in terms of power.

Of course, if the electric boiler operates at its maximum capabilities, only 3 kW of the permitted amount will remain for the remaining consumers of the house, which is quite small. But since the boiler will be a backup one and will only turn on when the main gas boiler is faulty, this decision was made acceptable.

Flaws

Fragility is the main drawback of heating elements for heating with a thermostat.

Firstly, the tubular heater itself interacts with salts dissolved in water. As a result, scale grows on the tube, which leads not only to a decrease in efficiency, but also to damage to the heater. As a means of protection against plaque, some models install an additional rod - a magnesium anode.

Since magnesium is a chemically more active substance, salts preferentially interact with it, and the heating element is provided with protection against scale. And again, the disadvantage is that the protection rod slowly decomposes in a chemical reaction and eventually requires replacement.

And although replacing the anode is not a complicated process at all, which, like automation, does not require disassembling the entire structure, the inconvenience is the need to constantly monitor the presence of the reagent.

Inserting heating elements into the home heating system

If you want to replace or find a backup heat source for your solid fuel boiler, such as, for example, Don, Cooper, Evan, Breneram Aquaten or Teplodar, this option is perfect because it is not very labor-intensive and financially expensive.

When carrying out such a procedure, observe safety measures, since any activities using electrical energy are extremely unsafe.

Let's take a closer look at how to connect the heating elements on the boiler. When using it as a backup heating method, be aware of changes in pressure level; it is recommended to use a pump to equalize it.

Let's look at how to install such a device step by step:

- You need to check the direction of the thread in the pipe and measure its diameter.

- Drain the coolant.

- Check the level of the radiator, since at the slightest inclination there is a high probability of air pockets accumulating. Air lock in the heating radiator

- Install the heating element into the pipe. To ensure that the hole is sealed, use the gaskets that come with the kit; if they are not available, make them.

- Connect the heating element and thermostat to the radiator.

- If you have not previously installed a Mayevsky faucet, install it. Because it will be necessary to bleed air from the system.

Then fill the system with liquid, using the Mayevsky tap to release the accumulated air. Using a tester, check that the heating element is isolated from the battery to avoid electric shock; if a breakdown is still present, check the serviceability of the heating element. If its insulation is broken, it needs to be changed. Then perform the installation again.

Connection diagram of an electric boiler to a 380 V three-phase electrical network

The general electrical diagram for connecting a 380 V electric boiler is as follows:

As you can see, the line is protected by a three-phase residual current circuit breaker; grounding is necessarily connected to the boiler body.

As usual, according to tradition, I am posting a connection diagram for a three-phase electric boiler with a combination of an automatic switch (AB) plus a residual current device (RCD) in a circuit, which is often cheaper and more accessible than Diff. machine.

It is convenient to select protective automatic ratings and cable cross-sections for three-phase electric boilers of various capacities using the following table:

In three-phase electric boilers, three heating elements are usually installed at once, sometimes more. Moreover, in almost all household boilers, each of the tubular electric heaters is designed for a voltage of 220 V and is connected as follows:

This is the so-called star connection. For this case, the neutral conductor is connected to the boiler.

The heating elements themselves are connected to the network as follows: one end of each of the tubular electric heaters is connected by a jumper, the remaining three free phases are alternately connected: L1, L2 and L3.

If your boiler has heating elements designed for a voltage of 380 V, their connection diagram is completely different and it looks like this:

This connection of the heating element of an electric boiler is called a “triangle” and at the same voltage of 380 V, as in the previous “Star” method, the boiler power increases significantly. In this case, a neutral conductor is not required, only phase wires are connected, and the electrical connection diagram looks like this:

Do not deviate from the connection diagrams permitted for your electric boiler. if there are heating elements for 220V with a three-phase connection, do not convert the circuit to a “triangle”. As you understand, theoretically you can reconnect them and get a voltage of 380 V on the heating element, respectively, increasing their power, but in this case they will most likely simply burn out.

How to determine the correct connection diagram for heating elements with a star or triangle and, accordingly, what voltage they are designed for?

If the instructions for connecting your electric boiler are lost or there is simply no way to refer to them, you can determine the correct connection diagram at home as follows:

1. First of all, inspect the terminals of the heating element; most likely, the manufacturer has already prepared the contacts for a specific circuit. So, for example, for connecting a star and heating elements for 220V, three terminals will be connected by a jumper.

2. The very presence of the zero terminal - “N”, indicates that the heating elements are 220 V and they must be connected according to the “Star” circuit. Moreover, its absence does not mean that the heating element is 380 V.

3. The most reliable option to find out the voltage of the heating element is to look at the markings. indicated either on the flange to which the tubular electric heaters are attached

Or, on the heating element itself, its parameters are necessarily extruded:

If you cannot find out for sure the voltage for which your electric boiler is designed and the connection diagram for its heating element, but you “really need to” connect it, I advise you to use the “Star” circuit. With this option, if the heating elements are designed for 220 V, they will work normally, and if they are rated at 380 V, they will simply produce less power, but most importantly they will not burn out.

In general, there are different cases, and it is very difficult to cover them all in the format of one article. ,

Connecting heating elements of an electric boiler

The first thing you need to pay attention to is the rated power of the heating element. By installing a device with low power, you will receive less thermal energy while consuming a large amount of electricity

And by setting an unacceptably high power, there is a high probability of constant overheating of the device, and an explosion is possible.

As for its location, it must be completely immersed in water, otherwise it will overheat; as a rule, it is installed at the bottom of the radiator. This makes it possible to isolate it from places where air accumulates. In order for it to last longer and less plaque to accumulate on it, which leads to a significant loss of efficiency, as well as to corrosion, you need to use distilled liquid.

It is very important, when you insert a heating element or a block of heating elements into the heating system, to properly seal the end joints, because if liquid gets on the heating element (coil), there will be a threat to the residents of the house. Let's consider the option of connecting to electrical networks with different numbers of phases. If you have one phase, often this option is most typical for cottages or old buildings, you need to install a fuse

It is characterized by the presence of two conductors: phase and zero. There are two connection methods - parallel or serial, the difference is in dividing the original voltage between the components

If you have one phase, often this option is most typical for cottages or old buildings, you need to install a fuse. It is characterized by the presence of two conductors: phase and zero. There are two connection methods - parallel or serial, the difference is in dividing the original voltage between the components.

More often, the connection is made in parallel to minimize the loss of useful energy. The sequential circuit is used extremely rarely, as it involves energy losses. For any of the selected circuits, it is necessary to choose a wire with a large cross-section, since it will carry a large load.

Connection to three phases - the first method is the so-called star, it involves feeding from a 220 V network with a neutral wire supplied from the panel. One jumper is used, connected to zero, and the remaining three free ends are connected to the phases.

Triangular connection, the incoming voltage in this case is 380 V. By connecting heating elements intended for use at 220 V here, you risk damaging them because they will burn out. The difference between a triangle and a star is the absence of a neutral conductor.

Prevention of breakdowns of heating elements

Needle heating element without the ability to adjust power

Even after you have managed to professionally install the heating element of heating systems, you must follow the operating rules. First, the ability of the electrical network to withstand maximum loads is checked. To do this, you need to sum up all the power of electrical appliances in the house and add a factor of 1.2 to the resulting figure for the power reserve. The cross-section of the electrical wiring must withstand the rated power without overheating or short circuiting.

The operation of the heating elements in the device consists in the gradual destruction of the heating spiral. Therefore, heaters intended for radiators must have a maximum service life of at least 10 years, which is confirmed by the manufacturer. In addition, you must follow these rules:

- Do not add tap water to pipes or heating radiators. This can lead to scale formation on the surface of the heating element. Use only distilled water;

- Installation of an RCD (residual current device) is required. You can connect one or more heating elements to it. When an emergency occurs, this device will cut off the power supply;

- Frequently turning the heater on and off when heating a house reduces its service life;

- If static electricity is observed on the surface of the battery, you urgently need to check the tightness of the heating element;

- Installing a heating element into a heating boiler or radiator without grounding is prohibited.

Guided by these simple recommendations, you can create not only an effective, but also a safe heating system for a private house or apartment using electric heating devices.

You cannot install a heater in a heating system without first checking the grounding. To do this, it is best to use the services of an electrical laboratory.

Types of electric heaters for heating

TENs were invented at the end of the nineteenth century in America. A patent for this was received in 1896. The very first products were a spiral insulated with ceramic material and inserted into a metal tube. Such electric heaters for heating were practical products, but unsafe to use. Mass production of these devices began 50 years after their invention. Since that time, TENs began to be widely used and became one of the most popular heating devices operating from the electrical network. Since then they have changed a lot, they have become more perfect - you can see what they look like now in the photo. Modern devices differ markedly from the very first models, but the principle of their operation remains unchanged.

Pros and cons of radiator heating elements

Tubular-type electric heaters make it possible to assemble a practical and fairly efficient heating system for main or additional heating.

The advantages of the devices include:

- Extreme ease of installation. Every novice master can handle this job.

- The low cost of the device, however, refers to the price of one heating element, without additional equipment.

- Greater reliability compared to oil radiators. In addition, batteries with heating elements are repairable. If the equipment fails, it will be enough to replace the heater.

- Availability of additional options and functionality.

- Possibility of automatic control of the heating system, but this will require additional equipment.

We have listed the main advantages of radiator heating elements; we will consider their significant disadvantages. There are quite a lot of them. First of all, these are impressive operating costs, which is explained by the high cost of electricity. They can be reduced if the heating system control is fully automated.

In this case, the heating elements will be switched on only after the room temperature drops to a certain minimum value. And turn off when the temperature defined as comfortable is reached. Working in this mode is as economical as possible.

The simplest radiator heating elements in design are not equipped with automatic control. To automate such a system, you will need to purchase additional equipment

However, automation equipment will require financial investment. If we consider purchasing a heating element complete with a radiator and automation, the cost of such a kit will be much higher than the price of an electric convector or an oil radiator.

But at the same time, in terms of the level of comfort provided, the latter are in no way inferior, and in some ways even superior to radiators with heating elements. For example, the latter require permanent installation, while electric convectors and oil radiators are more mobile and compact.

In addition, like any other electrical device, heating elements generate a magnetic field during operation. Its danger to the body has not been proven, nor has its safety. Therefore, it is worth attributing the presence of such a field to the negative qualities of devices, because they are mounted in radiators, that is, they are in close proximity to people.

In other heating systems powered by electricity, this disadvantage is to some extent leveled out. For example, electric boilers are located in non-residential premises where human presence is short-term.

One of the most significant disadvantages of radiator heating elements is their relatively low efficiency. If we compare it with the efficiency of traditional systems operating with liquid coolant, it will be significantly lower.

This is due to the fact that in the first case the coolant moves at a fairly high speed. Thanks to this, the radiator warms up quickly and completely.

To increase the heat transfer of radiators equipped with heating elements, you can cover the wall on which the device is mounted with a reflective screen made of foil. Thermal radiation will only move into the room

The functioning of the heating element is not able to provide such a high speed. As a result, the heating of the battery case will be uneven. The temperature at the bottom will be much higher than at the top.

Considering that, for safety reasons, the battery should not be allowed to heat up above +70ºС, such a temperature will only be present in the lower part of the radiator, where the heating element is located. Consequently, in order to prevent overheating of the equipment, it will be necessary to reduce its power by about a third.

Finned tubular type electric heaters

Finned heaters also belong to the tubular type of elements, but they also have ribs that are located in planes perpendicular to the axis of the heater tube. Such ribs are made from metal tape, and they are attached to the tube using washers and clamping nuts. The device itself is made from stainless steel or structural steel.

This type of heating elements are used in heating devices that heat air or gas. They are often found in devices such as thermal curtains or convectors (read: “Electric heating convectors: how to choose - little tricks”). They are used to heat rooms using thermal air mass.

Broken heating element in the boiler or boiler

Replacing a heating element in a heating boiler

Despite its reliability, failure of heating electric heating elements is quite common. If this is a factory model, you can do independent repairs only if you have confidence in your own abilities. It is best to contact a specialized company, since in addition to the heating element, other important parts of the system can be damaged during unqualified repairs.

If you decide to restore the boiler’s functionality yourself, you first need to familiarize yourself with its design. To do this, you can use the data from the passport or look at the data on the manufacturer’s website. Before dismantling the heating element, the device must be secured. Then the coolant is drained. You can check the performance of the heater using the indicator. The passport must indicate the resistance value when closing the circuit. If the indicators do not coincide with the original ones, a new heating element is installed. The best option is to install a similar device from the same manufacturer.

Before installing a heating element into the heating system, you need to make good thermal insulation in your apartment or house. This will reduce ongoing electricity costs, which in turn will increase the life of the heating element.

To check the performance of the heating element, it is recommended to familiarize yourself with the video material.

Features of the Kupper OK boiler

- Manufacturers, in the Kupper OK series, in addition to the standard water jacket, proposed a single-tube heat exchanger design, which increased efficiency and was able to improve thermal removal.

- The heat exchanger pipe system was arranged in a checkerboard pattern. We equipped the unit with a removable plate, which acts as a flame arrester, with its help we increased the flame stroke and were able to completely extinguish the high flame in the boiler. Thus, it was possible to prolong combustion and significantly increase the efficiency of the boiler.

- By means of a specially placed automatic traction regulator, it is possible to set the power of the device within a range from 30 to 100%.

- As the solid fuel burns out, a built-in 6 kW heating element unit is put into operation. Such support delays the cooling of the coolant temperature in the system circuit, and under certain conditions can work for heating during periods that are not very frosty.

- The device is equipped with accessories that allow you to clean the firebox. In addition, the kit includes a rotary gate and a thermal thermometer for monitoring the temperature of the boiler.

Solid fuel boiler Kupper: how to select and install

The Kupper boiler is a solid fuel universal heating unit produced by the Novosibirsk company Teplodar. Despite the fact that the model entered the Russian boiler equipment market relatively recently, it was able to gain well-deserved popularity among buyers.

There is quite an explanation for this - heating units combine all the best achievements in the operation of modern solid fuel boilers, becoming a universal unit. It is difficult to find a similar model on the domestic market today.

Features and Benefits

Cooper solid fuel boiler has a simple operating principle and versatility in the use of solid fuel. It is loaded through a special door. Ignition is performed from below.

Water is supplied to the combustion boiler, made in the form of a water jacket. The efficiency of heating the coolant in this design is ensured by the multi-row design of pipes located in a checkerboard pattern, thereby ensuring the maximum possible contact of flue gases with the heated medium.

Fuel burning in the firebox transfers its heat to water, which at a temperature of 90-95 C is sent to the radiators. The movement of hot water can take place either according to the principle of natural circulation or forced circulation, using a circulation pump.

Flue gases, having given up their temperature to the network water, are released into the atmosphere through a smoke exhaust system consisting of a flue and chimney. The diameter of the exhaust gas outlet pipe for OK models is 150 mm, and for OVK – 120 mm.

Advantages of Kupper units operating on solid fuel:

- Multi-fuel - works not only on wood and coal, but also on electricity, main gas and pellets.

- Optimal ratio “cost - consumer quality”, lower price threshold from 20,000 rubles.

- Expanded functionality, food preparation permissibility for a number of models.

- A distinctive design solution and high quality paint coating.

- Optimal thermal insulation.

However, like absolutely all thermal power equipment, the Cooper PRO boiler has a number of disadvantages, which users include:

- Low level of brand awareness.

- A combustion heat exchanger made of steel has a shorter service life than cast iron.

- The package does not include a thermostat or control panel for heating elements; they must be ordered additionally.

- Single-circuit model, there is no possibility of obtaining hot water for domestic needs. To obtain hot water, it can be used in a circuit with an indirect heating boiler, which must be purchased separately.

Models and characteristics table

The Kupper line is quite wide, it includes both basic OK boilers and the “PRO” series. All models differ in design and technological parameters.

https://www.youtube.com/watch?v=XqgY8ZMogfMu0026t=309s

Consumers are offered multi-purpose configurations, long-burning modifications and standard solid fuel units.

Kupper units are presented on the market in the following basic versions:

- Boiler Cooper Praktik 8.

- Boiler Cooper OK 9.

- Boiler Cooper Praktik 14.

- Heating boiler Cooper Expert 15.

- Heating boiler Kupper OK 15.

- Boiler Cooper Carbo 18.

- Boiler Cooper OVK 18.

Classification of boilers “OK” stands for heating boiler, and “OVK” - additionally has a hob for food preparation.

In addition to the basic options, the Teplodar company produces a series of boiler units “PRO”:

- Boiler Cooper PRO 22.

- Boiler Cooper PRO 28.

- Boiler Teplodar Cupper PRO 36.

- Boiler Teplodar Cupper PRO 42.

These are multi-purpose units with the principle of long burning, a large loading chamber and a long period of operation on one load of firewood up to 8 hours. These solid fuel boilers are equipped with an additional chamber that produces pyrolysis gas.

Specifications

| Model | PRO – 42 | OK – 30 | OK – 20 | OK – 15 | OVK – 18 | OVK – 10 |

| Heated area, m2 | 420 | 300 | 200 | 150 | 180 | 100 |

| power, kWt | 42 | 30 | 20 | 15 | 18 | 10 |

| Dimensions, mm | 540820970 | 1000645422 | 745645422 | 740500340 | 745645422 | 740500340 |

| Heating range (°C) | 60/95 | 60/95 | 60/95 | 60/95 | 60/95 | 60/95 |

| Power of the heating element block (kW) | 3x3=9 | Zx2=6 | Zx2=6 | Zx2=6 | Zx2=6 | Zx2=6 |

| Type of fuel | WoodCoalPelletsBriquetsCokeGas Fuel OilPatSawdust | WoodCoalPelletsBriquetsCokeGas Fuel OilPatSawdust | WoodCoalPelletsBriquetsCokeGas Fuel OilPatSawdust | WoodCoalPelletsBriquetsCokeGas Fuel OilPatSawdust | WoodCoalPelletsBriquetsCokeGas Fuel OilPatSawdust | WoodCoalPelletsBriquetsCokeGas Fuel OilPatSawdust |

| Heat exchanger | Steel | Steel | Steel | Steel | Steel | Steel |

| Efficiency, % | 88 | 80 | 80 | 80 | 80 | 80 |

| Price, thousand rubles | 44.080 | 33.320 | 25.940 | 22.820 | 27.560 | 22.420 |

| Warranty, year | three | three | three | three | three | three |

| Weight, kg | 178 | 145 | 115 | 98 | 125 | 85 |

Accessories

Buyers, purchasing Kupper heating boilers, receive multifunctional, combined units capable of operating according to the schemes: “coal - electricity” or “main gas - electricity”, this allows you to evenly maintain the temperature in the rooms throughout the day.

All Kupper OK boilers are equipped with electric heating elements - 6 kW, and models over 30 kW - 9 kW. Particularly promising for the use of such devices is the use of a diphtariff electricity metering scheme, when at night it can be switched to electric heating with the lowest tariff.

Be sure to check the boiler delivery package

For comfortable controllability of a group of heating elements of the unit, there is a control panel (CP) with temperature sensors that control water heating and internal air temperature in the room. The system operates automatically and can turn on heating elements alternately depending on the set mode.

Cooper boilers can operate on main gas fuel or pellets. The buyer can order a gas injector AGG-13/26/40K with a power from 13 to 40 kW or a pellet injector APG-25/42. Both are mounted in the area of the fire door.

Installation procedure

The installation of the unit, piping of the heat supply system, flue, and gas burner device must be carried out by highly qualified craftsmen who have a license to perform such work.

The validity of the warranty for the device and the auxiliary equipment that comes with it will depend on this fact.

All work on installing the unit must comply with the Rules for the safe operation of water boilers with a coolant temperature not exceeding 115 C.

Basic requirements and installation procedure for Cooper boilers:

- The boiler is installed at a safe distance from flammable materials: from the walls - 50 cm, from the ceiling - 120 cm, and in front - 125 cm.

- A safety valve must be installed at the outlet pipe of the hot coolant DN 40 mm to protect the structure from high pressure.

- The heating system must be equipped with air vents and an expansion tank.

- The boiler is connected to the heating system using pipe threads.

- Connections to the power supply line must be carried out by a licensed organization with qualified, certified personnel and comply with the requirements of the Electrical Installation Rules. Each electric heating element must be connected with a copper cable higher than 1.5 mm2 and 16 A circuit breakers. Parallel connection of 3 electric heating elements through a 30 A circuit breaker and a cable with copper conductors of at least 4 mm2 is allowed.

- To remove flue gases from the boiler, it is recommended to install stainless steel thin-walled pipes supplied by the same manufacturer. The best option for such devices is the installation of ready-made blocks with sandwich thermal insulation.

- It is allowed to use a brick chimney with a channel cross-section of at least 200 cm2, which must be uniform along the entire length.

- The height of the flue, starting from the grate, is at least 5 m.

Tips for use

Cooper boilers are classified as objects of increased fire danger; boiler owners must maintain the units in full compliance with factory instructions and fire safety rules.

It is allowed to ignite the boiler only after filling the heating system with water. Preliminarily check the presence of draft in the gas path. To do this, light the paper and bring it to the ash pit; if the fire is drawn into the boiler, then the draft is normal.

Requirements for the operation of a solid fuel boiler Kupper:

- Kindling begins with dry firewood, filling the firebox up to 1/2 of the height. Subsequently, when the flaming coals cover all the grates, load the coal.

- Loading of coal is carried out in small parts of 5 kg, and the door should not be left open for a long time, so as not to allow a large amount of cold air to enter the combustion chamber.

- During the combustion process, the intensity of the process can be controlled by regulating the air supply by rotating the screw and providing draft with a rotary gate.

- The temperature of the flue gases is controlled, which should be at least 150 C. This mode will guarantee the absence of bitumen deposits on the inner surface of the chimney and maintain stable draft.

- During operation, it is necessary to ensure the cleanliness of the heating surfaces and prevent soot from growing more than 1-2 mm. Since such deposits lead to a sharp decrease in heat transfer and efficiency of the unit.

- Boiler owners must conduct an annual inspection of their equipment before the start of the heating season.

- To reduce scale formation in internal heating surfaces, it is recommended to soften the make-up water.

- The Cooper boiler is not allowed to be operated at a return coolant temperature below 60C. Because in this mode, condensate is intensively created in the flue gases, which contributes to corrosion damage to the heat exchanger and chimney system.

A fairly wide range of models, budget price, attractive design and excellent build quality set Cooper solid fuel boilers apart from the list of similar units.

They already have many modern technological innovations and continue to improve, which in turn delights customers.

Criterias of choice

When choosing heating equipment, any consumer is guided by its ability to heat the home and utility or technical rooms as efficiently as possible. The main indicator of any heat generator is its power. As a rule, the required power is calculated through complex calculations, taking into account the heated area of the premises, the characteristics of wall and roof materials, the number of door and window openings and dozens of other parameters.

A simplified calculation is made based on the area and volume of the premises. In the most simplified form, it is generally accepted that 1 kW of the declared boiler power is enough to effectively heat 10 m² of room area. In practice, for a house with an area of 150 m², a 15 kW boiler will be sufficient. Ideally, a heat generator with parameters higher than the calculated ones by 10-15% is selected.

When choosing, you should also consider:

- materials for manufacturing the housing and heat exchangers;

- linear dimensions of the boiler;

- possibility of connecting electrical equipment and characteristics of the electrical network;

- location of connection points for pipes and shut-off valves;

- features and shape of the gas outlet;

- the need for arrangement and power of supply ventilation;

- price and brand authority.

On practice

If you buy a ready-made boiler and do not assemble it yourself, then you will have a boiler control unit that will have terminals for connecting the power supply.

The only thing you need to do is to correctly calculate the cross-section of the power cable and the rating of the circuit breaker for the boiler.

I wrote about this in the articles How to select a cable in an electrical network and Calculation of cable cross-sections and circuit breakers.

Let me briefly remind you that these calculations are carried out based on the boiler power using tables 1.3 of the PUE. Since aluminum will soon be returned to electrical installations, I will provide summary tables from which you can select the cable cross-section according to the power of the device for copper and aluminum wires (cable cores).

This table for selecting cable cross-sections and protection devices for Protherm Skat boilers will also help.

TT piping diagram for a boiler with natural circulation

Power outages are not uncommon in our country, and they usually happen in the worst weather. Therefore, in many villages and villages they prefer to make heating systems with natural circulation - gravity. They work regardless of the availability of electricity, so the house will not be left without heat.

Connecting a solid fuel boiler to a gravity heating system

The piping of a solid fuel boiler for a gravity system shown in the diagram is the simplest possible option. The system must have an expansion tank. It is necessary to compensate for thermal expansion: during heating, the volume of coolant increases and it is forced into the expansion tank. In systems with natural circulation, the expansion tank is installed in an open type. This is a regular container that contains a certain amount of coolant (about half the volume or less). To prevent the coolant from evaporating less, a lid is placed on the tank. And in order to simultaneously remove air from the system, they raise it to the highest point of the system.

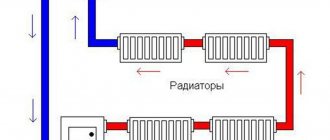

The principle of operation of a heating system with natural circulation

In systems of this type, the coolant moves due to the slope of the pipes. To ensure circulation, the boiler must be at the lowest point, all heating devices must be above it. In addition, it is necessary to use pipes of large cross-section to reduce resistance when the coolant moves.

The pipe rises from the boiler, then, gradually lowering, the supply pipe bypasses all heating devices. The return line is connected with a reverse slope - to the boiler. The scheme works like this: the heated coolant, due to the high temperature, rises up a vertical pipe, with a slight slope (slightly above the level of the radiators). This part is called the acceleration loop. Further along the inclined supply pipe, due to the force of gravity and the accumulated speed, it bypasses all heating devices.

The basic principle of natural circulation is the difference in elevation and temperature difference

As the coolant passes through pipes and radiators, it cools down. The cooled coolant has a greater mass than the hot one. The colder coolant tends downward, creating pressure. Due to this, circulation occurs - the heated coolant tends upward, the cold fluid - downwards. But the system only works with the correct pipe diameter and slope.

What else is needed

The above scheme has a lot of disadvantages:

- There is no safety valve - this device is installed at the boiler outlet. With its help, excess coolant is discharged when it boils. If this valve is not installed, rupture of pipes, radiators, heat exchanger, expansion tank (if it is closed) is possible.

- There is no air vent. If the system is open (the expansion tank in this case is simply a container with a lid), air can escape through the expansion tank. But with a branched system, additional devices are needed to remove air from the radiators.

The above two devices are required, but a pressure gauge and a thermometer are also desirable. They are needed to monitor the system. It is advisable to have two thermometers - at the outlet and at the inlet of the boiler. So that you can evaluate the efficiency of the system, adjust and adjust the heat transfer of radiators.

Flaws

The main advantage of the gravity piping scheme for a solid fuel boiler is its independence from the availability of electricity. There are many more disadvantages:

- Low efficiency and inability to adjust. The coolant movement speed in such systems is low. Therefore, it is not possible to achieve high efficiency. There is also no way to regulate it. So it is impossible to adapt to weather conditions.

- Every time the system warms up (in the morning, for example), the temperature of the coolant in the return is very low. Because of this, condensation forms, corroding the heat exchanger. And there is no way to fight this.

- Unaesthetic performance. To ensure circulation, the supply pipes must be located above the radiators. The piping of a solid fuel boiler in a gravity system is done with a pipe of 32 mm or more. Sometimes the feed is pulled above them - at the level of a meter (or slightly higher) from the floor, sometimes - they are sent under the ceiling. And the pipes have a considerable diameter, so the appearance is different.

All these disadvantages lead to the fact that heating systems with natural circulation are being made less and less often. People prefer to make a redundant power supply (install batteries and/or a generator) and have a more convenient and adjustable heating system.

About traffic jams and small bubbles

It is clear that air can occupy the entire pipe along some of its length. This is an air lock. It is irresistible for natural circulation and for small (ordinary) circulation pumps. But there may also be small bubbles that travel through the system along with water. Such bubbles can simply circulate, or they can unite when they meet. If there is a place in the system to collect these bubbles, then during operation of the heating system an air lock will collect in this place. After this, circulation will stop. Bubbles can also collect in traps (radiators). In this case, the part of the radiator in which the air has collected becomes cold.

If the circulation in our system is quite fast, and there are no obvious humps or traps, then the bubbles circulate through the system and create gurgling sounds. It’s as if water is flowing in a thin stream from one container to another. I regularly hear this kind of noise in one of my bathrooms, which has a beautiful, but not very well-configured heated towel rail. The bubbles run through it so actively that some parts of the heated towel rail are either cold or hot.

Connecting the heating element to a single-phase network

This case is typical for dachas and old-built village houses.

First you need to generally understand what we are talking about and the easiest way to do this is by looking at the following figure:

Connection of heating elements diagram

So, a single-phase electrical network has two conductors - zero and phase.

The picture itself shows two ways to turn on the load - parallel and serial.

These methods differ in how the initial voltage is divided between the elements.

In most cases, heating elements are connected in parallel so as not to lose useful power; a series circuit is suitable only for various specific cases.

A block prepared for connection to one phase will look like this:

Connecting the heating element block

Connecting electric heating elements

It is also worth paying attention to the choice of cable, but we will touch on this point a little later, and now let’s move on to the three phases

Conclusion

As you can see, electric heating elements are easy to connect and connecting the heating element itself does not cause problems. A more complex issue is connecting the automation and temperature sensor. More on this in the following articles.

©Obotoplenii.ru

More articles

- Heating scheme for a house up to 100 meters

- Glass heaters

- Baseboard heating: description, application

- Heating the house with an electric boiler

- Electric heating boiler (electric boiler): device, connection to power supply

Heating element blocks (TENB) with star connection

This connection is intended for units with 220V heating elements, with the ability to connect to both 220V and 380V. Install the jumper as shown in the photo.

Then we install the neutral wire on the middle pin and stretch all the contacts well.

We install power wires (phase) on the contacts on the opposite side; the cross-section of the wires must also correspond to the power of the heating element unit.

This connection is made at 380V; to connect to 220V, it is enough to install the same jumper on the opposite side and connect the power (phase) wire in the center, or install a jumper on the terminal block of the electric boiler or control panel.

How are they used for heating radiators?

The main function of tubular-type electric heaters for radiators is to heat liquid in an autonomous or centralized heating system. The device is used as a secondary or main heat source.

As an autonomous system and the only coolant heater, heating elements are used in the following cases:

- The need to heat rooms where there is no other type of heating. This could be a workshop, garage or agricultural building. The main condition for installing a radiator electric heater is the small size of the building. It is more effective to fill batteries with oil of low viscosity, since it has a fairly low freezing point.

- Subject to periodic heating of the room. Most often, such structures are dachas with no main heating system. At the same time, the number of installed heating elements, their power must correspond to the volume of the room.

As an additional device to the main heating, a tubular electric heater can be installed:

- In multi-storey buildings. Heating elements are installed in radiators in apartments if the main heating is not particularly efficient. The device helps create and maintain the necessary indoor microclimate. But its installation requires limiting the access of water that circulates through the heating system of the entire house. In this case, the use of a heating element is completely impractical, since you end up paying twice for heating - for the operation of the electric heater and to the housing office for the use of the coolant.

- In private homes. A heating element is installed if it is not possible to regularly add firewood to a solid fuel boiler. In such a situation, the tubular heater does not allow the coolant to cool completely and the required temperature is constantly maintained in the room.

The heating element for the radiator is installed in both private and apartment buildings

Using heating elements for gas boilers does not make sense, since such units cope well with heating due to an automated system.

Heating with heating elements, how to do it, is it worth using

A heating element is an electric liquid heater in the form of a metal tube, inside of which there is a spiral. There are many designs and varieties. Heaters are manufactured for both large and small industries.

These heaters are widely installed, for example, in electric boilers and electric boilers, and therefore are also produced by well-known manufacturers.

But in any market you can find heating elements intended for installation in heating radiators. These devices are often manufactured in Poland, Ukraine, and China. They can be equipped with built-in temperature sensors, i.e. work in semi-automatic mode, monitoring the degree of heating.

Based on such electric heaters, you can easily create a heating device with your own hands. This is what home craftsmen use, constructing the simplest heating and, as they think, “saving” a fair amount of money.

But is it really profitable to use heating elements? Where and in what situations are these electric water heaters usually used? How to install and use heating elements...

How to choose heating elements

Heating element for heating with plates

How to choose the right heating element for a heating system? Currently, there are many manufacturers who offer similar products. However, both the quality and technical parameters do not always correspond to the required ones. Therefore, before purchasing, you need to pay attention to the following operational characteristics of the heater:

- Rated and maximum power. If a heating element is needed for a heating boiler, its power should be sufficient for the system to operate. The simplest method of calculation is per 10 square meters. at home you need 1 kW of thermal energy;

- Electrical network type. For models with power up to 3 kW, you can use a 220 V home network. If you plan to install a heater for a heating system of higher power, you should install a three-phase 380 V network. This may be due to difficulties in completing the documentation;

- The presence of a thermostat. For a radiator electric heating system, this is the main selection factor. If you purchase a heater without the ability to adjust the power, it will constantly work at maximum mode. This will dramatically increase electricity costs;

- Price. The average price of a 2 kW model starts from 900 rubles. The cost of more powerful ones can be up to 6,000 rubles. They are often made to order.

The appearance of the heating element can also affect its performance and efficiency. The best option would be to purchase a finned heating element for a heating boiler. It differs from conventional ones in that additional heat exchange plates are located on the protective shell.

Thanks to them, the heating area increases. This design is typical for heating elements in heating radiators of larger diameter. Reviews about them indicate increased heat transfer even at minimum operating mode. But their overall dimensions do not always make it possible to install them in a battery. Therefore, simple tubular type heaters are most often purchased. To increase efficiency, you can buy a block of heating elements with a thermostat. It differs from traditional ones by the presence of several heating elements on one base.

Site headings

- DC-DC (4)

- Automatic pumping of water from a drainage well (5)

- Automatic (34)

- Car (3)

- Antennas (2)

- Assembler for PIC16 (3)

- Power supplies (28)

- Well drilling (6)

- Life (11)

- Generators (1)

- Signal generators (6)

- Sensors (4)

- Engines (6)

- For the garden (11)

- Chargers (14)

- Radio protection (6)

- Winter water supply for a bath (2)

- Measurements (29)

- Indicators (5)

- Indication (10)

- As my grandfather used to say... (1)

- Switches (5)

- Logic circuits (1)

- Feedback (1)

- Lighting (3)

- Programming for Beginners (12)

- Programs (1)

- Works by visitors (7)

- Radio transmitters (2)

- Radio stations (1)

- Regulators (5)

- Repair (1)

- Homemade products (12)

- Homemade mobile sawmill (3)

- Homemade water supply (7)

- Self-calculations (36)

- Welding (1)

- Alarms (5)

- Directory (12)

- Stabilizers (15)

- Construction (2)

- Timers (4)

- Thermometers, thermostats (24)

- Technologies (21)

- ULF (2)

- Signal conditioners (1)

- Electricity (4)

- (12)

Types and methods of manufacturing heating elements

Modern electric heating elements have high strength and the ability to change shape and size under the influence of high temperatures without compromising their technical characteristics. They are used not only in household heating appliances, but also in industrial ones. True, in the latter they install more powerful analogues with larger sizes. All modern heating elements have a high rate of long-term operation.

Manufacturers produce two types of heating elements, which differ in the manufacturing method. There are products that are mass produced, and there are also those that are produced in small batches. They usually meet specific customer requests. They are used in special heating installations with specific requirements. By the way, the price of the latter is much higher than the former.

Tubular electric heaters

This is the most common type of heating element, which is used in almost all electrically powered heating devices. With the help of tubular analogues, heating of the coolant occurs according to the principles of convection, radiation and thermal conductivity as a result of the conversion of electrical energy into thermal energy.

This heating element has the following characteristics:

- Tube diameter 6.0-18.5 millimeters.

- The length of the heating element is 20-600 centimeters.

- The tube can be made of steel, stainless steel or titanium (a very expensive device).

- Device configuration - no restrictions.

- Parameters (power, performance, etc.) - as agreed with the customer.

Finned tubular electric heaters

Used to heat air or gas that heats the room

TEHPs are the same tubular electric heater only with ribs that are located in planes perpendicular to the axis of the heating tube. Typically, the fins are made of metal strip and secured to the tube with special clamping nuts and washers. The heating element itself is made of either stainless steel or structural steel.

This type of electric heating devices is used to heat air or gas that heats a room. They are often used in heating devices such as air curtains and convectors - where heating with heated air is required.

Electric heater block

TENB are used only if it is necessary to increase the power of the electric heater. They are usually installed in devices in which the coolant is liquid or any bulk material.

A distinctive design feature of the heating element is its fastening to the heating device. It can be threaded or flanged. Particularly popular today is a block-type heating element with collapsible flanges. Such a heating element can be used repeatedly for different devices. The burnt heating element can be removed and a new one put in its place.

Cartridge-type electric heaters

This type is not used for heating systems.

This type is not used for heating systems. It is used as a mold part to create any products, since it is a part of industrial equipment. They are not found in everyday life, but it is necessary to mention them, because this type of heating element is included in the category “tubular electric heaters”.

A distinctive feature of this analogue is the shell, made of stainless steel, which is polished to the maximum. This is necessary so that the heating element can enter the mold with a minimum gap between the tube and the walls of the mold. The standard gap should not exceed 0.02 millimeters. This is how tightly it should fit.

Ring electric heaters

This type of heating elements is also used only in industrial installations. Their purpose is to heat injectors, nozzles of injection units and injection molding equipment.

The minimum twisting diameter is 8 millimeters, the maximum is not limited. The tube can be wound with the same or variable pitch. Typically this type is made only from stainless steel.

Electric heaters with thermostat

Heating element with thermostat TECHNO 2 kW

This is the most common heating element today, which is used to heat liquids. It is installed in all household electrical appliances that are associated with heating water. The maximum temperature of the released heat is +80C.

It is made from nickel-chromium wire, which is filled inside the tube with a special compressed powder. The powder is magnesium oxide, which is a good insulator of electric current, but at the same time has a high thermal conductivity.

Radiator electric heating at home

Installation diagram of the heating element in the radiator

Before installing a heating element into the heating system, you need radiator parameters. The main one is the diameter of the connecting pipe. Currently, manufacturers produce products in two sizes - 1/2 and 3/4 inches. Then a comparative analysis of the heating parameters is carried out before and after installing the heating element.

Connecting the heating element to the existing heating

If it will be used as an additional method of heating water, you need to take into account the change in hydraulic pressure when passing through the radiator. Since the flow diameter of the system this month will be smaller, it is recommended to install a pump of higher power.

When connecting a radiator to the system, installing a heating element for heating the house will not be possible. To do this, you must either change the connection diagram to the top, or install a heating element on the top of the battery, which is not recommended by experts.

They are often installed in old cast iron batteries. Before performing work, you must first check the direction of the thread of the pipe (right or left) and also measure its diameter. Then you should follow this scheme:

- Coolant drain. It is prohibited to install a heating element into a heating radiator if there is water in it;

- Checking the battery level. Even at a slight angle of inclination, the likelihood of air pockets significantly increases;

- Installing the heating element into the pipe. To seal the holes, you must use the gaskets supplied with the heating element or make them yourself;

- Installation of a unit with a thermostat, if included.

An example of installing a heating element in a cast iron radiator

After this, you need to fill the system with water. Using the installed Mayevsky crane, possible air pockets are removed. Before switching on, to ensure safety, a tester is used to check any possible heating coil-battery circuit. If there is one, you need to dismantle the heating element and install it again, improving the sealing.

Radiator electric heating

When organizing heating using heating elements made by yourself, installation of a pipeline is not necessary. A heating element must be installed on each radiator. At the same time, it is possible to install models of different power depending on the thermal conditions in a specific room of the house. The advantages of such a system are as follows:

- Saving on the purchase of materials and reducing the labor intensity of installation work;

- If you use a heating element with a thermostat for heating and a temperature sensor connected to it, the degree of heating of the room will be adjusted automatically;

- Minimum system heating inertia.

But all these positive qualities can be offset by the total cost of service. Therefore, before heating with electric heaters, you need to calculate not only the cost of purchasing materials and components, but also the subsequent costs of electricity. Only after this should a heating system of this type be introduced.

It is recommended to purchase factory radiators with installed heating elements. Their operating efficiency is higher than that of homemade ones, since special oil is used as a coolant. Even when the heating element is turned off, it will give off heat to the room for some time.

Types and design, as well as operation

Structurally, a heating element for heating a house is a metal tube with a wire spiral inside, made of a material with high electrical resistance. When energy is supplied from the network, the coil heats up and transfers heat to the shell of the heating element, which in turn heats the coolant in the radiator.

The heating element is installed in a specialized socket of the heating battery, be it aluminum, metal or cast iron. The heating element is also used as the main heating element in electric boilers.

Most tubes use stainless steel or carbon steel. If low-quality metal was used in production, the heating element can quickly “burn out”. The power of the spiral and the shape of the tubes are determined by the purpose of the device and in which radiator or boiler it will be used.

Models are available with fins and additional plates around the tube to increase heat transfer. The ribs significantly increase the dimensions of the product, so they cannot be used in all cases.

In addition to devices that heat water, space heating with an electric heating element can be carried out using an air device that heats air instead of water. But due to their low efficiency, they are little used.

The thermostat included in the heating element measures the temperature of the surrounding coolant in the radiator and, if necessary, supplies power to the coil. After reaching the specified temperature parameters, it breaks the circuit. And as the water cools, it reconnects the coil to the network and heats the water. The presence of a thermostat allows you to set temperature parameters that are most comfortable for those present in the room. In its absence, the heating element will operate at maximum power, constantly consuming electricity, which will sharply increase the bills for it.

Some models of electric heating elements for heating a home are equipped with additional functions: “turbo mode” (turns on the device at maximum power for a short time) and “anti-freeze” (prevents the coolant from freezing, maintaining its temperature at a minimum).

Radiator electric heating at home

Installation diagram of the heating element in the radiator

Before installing a heating element into the heating system, you need radiator parameters. The main one is the diameter of the connecting pipe. Currently, manufacturers produce products in two sizes - 1/2 and 3/4 inches. Then a comparative analysis of the heating parameters is carried out before and after installing the heating element.

Connecting the heating element to the existing heating

If it will be used as an additional method of heating water, you need to take into account the change in hydraulic pressure when passing through the radiator. Since the flow diameter of the system this month will be smaller, it is recommended to install a pump of higher power.

When connecting a radiator to the system, installing a heating element for heating the house will not be possible. To do this, you must either change the connection diagram to the top, or install a heating element on the top of the battery, which is not recommended by experts.

They are often installed in old cast iron batteries. Before performing work, you must first check the direction of the thread of the pipe (right or left) and also measure its diameter. Then you should follow this scheme:

- Coolant drain. It is prohibited to install a heating element into a heating radiator if there is water in it;

- Checking the battery level. Even at a slight angle of inclination, the likelihood of air pockets significantly increases;

- Installing the heating element into the pipe. To seal the holes, you must use the gaskets supplied with the heating element or make them yourself;

- Installation of a unit with a thermostat, if included.

An example of installing a heating element in a cast iron radiator

After this, you need to fill the system with water. Using the installed Mayevsky crane, possible air pockets are removed. Before switching on, to ensure safety, a tester is used to check any possible heating coil-battery circuit. If there is one, you need to dismantle the heating element and install it again, improving the sealing.

Radiator electric heating

When organizing heating using heating elements made by yourself, installation of a pipeline is not necessary. A heating element must be installed on each radiator. At the same time, it is possible to install models of different power depending on the thermal conditions in a specific room of the house. The advantages of such a system are as follows:

- Saving on the purchase of materials and reducing the labor intensity of installation work;

- If you use a heating element with a thermostat for heating and a temperature sensor connected to it, the degree of heating of the room will be adjusted automatically;

- Minimum system heating inertia.

But all these positive qualities can be offset by the total cost of service. Therefore, before heating with electric heaters, you need to calculate not only the cost of purchasing materials and components, but also the subsequent costs of electricity. Only after this should a heating system of this type be introduced.

It is recommended to purchase factory radiators with installed heating elements. Their operating efficiency is higher than that of homemade ones, since special oil is used as a coolant. Even when the heating element is turned off, it will give off heat to the room for some time.

Rules for installation and operation of heating elements

One of the main parameters for each electrical appliance is its rated power. Correct installation of the heater in the heating system is carried out only after calculating this value. To do this you need to use a simple formula:

P=0.0011*m(Tk-Tn)/T

Where m is the mass of the energy carrier, kg, Tk and Tn are the value of the water temperature after and before heating, T is the required time for raising the temperature to the optimal Tk .

For a 6-section aluminum radiator, m will be equal to 0.45 * 6 = 2.7 kg . Let's assume that Тк=80°С and Тн=20°С . The heating time should be 10 minutes. In this case, the optimal power that electric heating elements for heating radiators should have will be:

Р=0.066*2.7(80-20)/10=1.06 kW

It is taken into account that the coolant is water. With the use of antifreeze, the rated power of the heater for the heating battery must be increased with an adjustment of 1.44 - 1.06 * 1.44 = 1.52 kW .

Then you need to familiarize yourself with the rules for installing electric heating elements for heating your home.

The outer shell must always be in water. If this is not done, the heat from the coil will not be compensated by the low water temperature. As a result, the heating element will quickly fail due to overheating. Therefore, the heater for heating a house is mounted at the lowest point of the radiator. In this case, it will not be in the possible zone of formation of air jams.

Coolant quality

Failed heating element

It is best to use distilled water, as it contains a minimal percentage of impurities. When heated, they form a layer of scale on the surface of the protective shell. This not only leads to loss of efficiency of the device, but is also the main cause of corrosion.

Sealing joints

When installing the heater into the heating system, you must first read the instructions from the manufacturer. If it states that the end joints of the electrodes must be additionally sealed, this must be done. Otherwise, if water gets on the surface of the heating coil, the danger for those living in the house increases. After familiarizing yourself with these rules, you can begin installing a heating element.

Not every heating element is suitable for a heating radiator. Only special models with the appropriate mounting diameter should be selected.

Types of tubular heaters for radiators