This is a classic mechanical pump for pressure testing. They can fill the outline

In country houses and where the heating circuit is turned on only from time to time, ordinary water cannot be filled. It freezes, which leads to rupture of pipes and batteries, and the boiler may break down. Therefore, in such cases, special antifreeze compounds are used, which are popularly called by a beautiful foreign word - antifreeze. We talked about whether it is possible to pour antifreeze into the heating system in one of our articles. In short, you can, you can read more here.

Today we will talk about how to add antifreeze to the heating system. Let's look at the technique step by step. We will help you determine which pump to use and where to connect it. There are some tricks that you can use to cope with the task yourself.

How to pump coolant

Pumps for filling the circuit with antifreeze can be different. Any water pump that is used in water supply is suitable for this purpose, since antifreeze can be properly poured into the heating system using any pressure blower of sufficient power. This includes manual and electric pumps, which can pump liquid in different ways. Some of them are immersed in the coolant, while others are not.

Submersible pump

Vibrating submersible pumps operate when completely immersed in antifreeze. Such devices include the well-known “Baby”. It should be said that there is no special pump for filling the heating system with antifreeze. All units have a wide range of applications on the farm. So, for example, “Malysh” can not only pump antifreeze into the circuit, but also lift water from the well.

“Baby” – submersible rotary pump

Advantage of submersible pump:

- inexpensive;

- compact;

- economical;

- portable.

With this pump you can do everything - from watering garden beds to supplying water from a well. It has a metal body, which makes the device reliable and durable. Characteristics:

- capable of pumping 430 liters per minute;

- distance from the power source is up to 40 m;

- two types of fluid intake (upper, lower);

- lifts a column of liquid to a height of 40 m;

- consumes no more than 250 W per hour.

Liquid from ten meters creates a pressure of one atmosphere, it turns out that “Kid” is capable of pumping up to four atmospheres. This power is more than enough for an autonomous heating system. As you know, the pressure in it does not exceed two atmospheres; the norm is considered to be a pressure gauge reading of one and a half atmospheres.

Taking into account the high pumping speed, such a pump will pump up an ordinary system containing up to 100 liters of coolant in a few minutes. The principle of operation is that antifreeze enters directly into the pump through holes in the housing and is supplied to the circuit through a hose.

To roll antifreeze into the heating circuit, you will need a barrel into which it will be poured. Then the pump is placed in the barrel, and the hose is connected to the recharge pipe.

Drainage pump

Drainage submersible pump

Drainage pumps also belong to submersible pumps, but only their main purpose differs from the same “Baby”. This type of blower is designed specifically to pump out water from basements or even from plots of land. A special feature of this unit is its ability to pass large particles, the size of which varies up to 35 mm.

It does not have a filter element that would protect the circuit from contamination, so this must be taken into account before pumping the heating system with antifreeze. In addition, you will need to make sure that the pump does not turn off automatically when there is a minimum amount of coolant left in the tank. The fact is that the submersible drainage pump has a special float switch that responds to changes in the liquid level.

The principle of pumping antifreeze into the heating system with a drain pump is the same as that of other submersible

The only thing you should pay attention to is the dimensions of the device. It may not fit into the neck of a small barrel, so the inlet hole should be enlarged

Surface pump

Surface pumps are not immersed in liquid. They are installed separately, antifreeze is supplied through a hose. These are undoubtedly more powerful units, but they also cost more. Such pumps can pump very high pressure into the circuit, which allows them to be used for pressure testing of heating systems and hydraulic tests. Surface pumps are either mechanical or electric.

Rotary Type Electric Surface Pump

According to the principle of action they can be:

- membrane;

- rotary;

- piston

The first two types are electrical devices, and a piston pump is a manual unit with a liquid reservoir. Antifreeze is poured into the reservoir, which is pumped through low and high pressure cylinders. The device is equipped with a pressure gauge. When pumping antifreeze into the system, a lot of effort will be required. You will need to press very hard on the handle. How to pour antifreeze into the heating system video:

To summarize, we note that you can fill the heating system with antifreeze using any pump that you have on the farm. If there is none at all, then the purchase will not be one-time. Such a unit is always useful in a private home. It can be used to water a garden, pump water from an artificial lake, fuel a heating system, and much more. The principle of filling the heating circuit does not depend on the selected supercharger. The main thing is to monitor the pressure gauge readings and bleed the air.

What you need to know to fill antifreeze correctly

Let's start with the fact that it is impossible to mix coolants with different properties, since such a mixture can result in an insoluble precipitate. This will cause the radiator passages and other sensitive parts of the system to become coked over time. To avoid such situations, you only need to fill the car with antifreeze approved for use by the manufacturer of the particular car, and add a similar composition that complements the existing liquid.

The behavior of the cooling composition when water is added to it is an open question. To a certain extent, a diluted mixture can show excellent qualities, provided that distilled water is used. Regular tap water will not work here.

It is worth recalling that the color of the coolant does not depend on its composition. For example, blue and red refrigerant may be absolutely compatible, while two different green liquids will ultimately have different bases and additive compositions.

Many car owners make the mistake of not knowing where to pour antifreeze. And out of ignorance, they always use the radiator socket for this. This hole is indeed present in this device, but only in its collapsible models. Liquid should not be poured or topped up directly into a radiator system with a solid body. Antifreeze enters the radiator and other components of the cooling system through the expansion tank.

If the old fluid is completely replaced with a new one or its brand is changed, the existing refrigerant is drained from the collapsible radiator through an individual hole. The remaining liquid flows out through an additional plug, sometimes covered with a protective panel on the bottom.

A universal instruction will not always help here, since some car models are equipped with non-standard cooling systems with individual drain and fill circuits. This significantly differs the products of English automakers. The standard procedure for filling coolant is simple and consists of several steps that can be performed independently without the help of specialists.

How to fill the heating system in an apartment building

Scheme of water heating with associated movement of water: 1 – boiler; 2 – main riser; 3 – expansion tank; 4 – air collector; 5 – supply risers; 6 – return risers; 7 – return line; 8 – expansion pipe; 9 – pump; 10 – direction of pipe slope.

The water valve located in the house should be closed, and the water discharge on the coolant supply pipeline is gradually opened. At this time, the discharge on the return line is blocked. Then you need to very slowly open the valve on the return line until it is completely open

Caution must be exercised because if the high-pressure water supply of a general heating system is suddenly opened, this can lead to sudden changes in pressure, causing water hammer. The push can be so powerful that one will be enough to break the system in the most vulnerable places. It will take some time for the heating system to fill

Reset should be monitored continuously. When water flows without any admixture of air bubbles, and this can be understood by the cessation of the characteristic hissing sound, close the discharge valve. Now it’s time to open the water supply valve to a specific room. At the final stage, all that remains is to bleed the air from all heating circuits. This method of filling the system with water is intended for heating with bottom wiring

It will take some time for the heating system to fill. Reset should be monitored continuously. When water flows without any admixture of air bubbles, and this can be understood by the cessation of the characteristic hissing sound, close the discharge valve. Now it’s time to open the water supply valve to a specific room. At the final stage, all that remains is to bleed the air from all heating circuits. This method of filling the system with water is intended for heating with bottom wiring.

A system with top piping looks much easier to use

In this case, you should simultaneously, with the same caution, open both dampers at once, while the discharge should be closed. To bleed air, go up to the attic of the building and open the air valves provided by the design

Video description

Video on how to install the make-up valve:

- If replenishment is carried out through the return, then the boiler must be turned off. Otherwise, cold coolant entering a heated heat exchanger can lead to thermal deformation of the latter. This is especially true for cast iron models.

- Automatic make-up for a floor-standing boiler with a cast-iron heat exchanger is best done through a direct manifold.

- If possible, it is better to make replenishment through a hydraulic arrow so that the cold coolant quickly mixes with the hot one and eliminates thermal shock for the heat exchanger.

- On condensing-type boilers, it is advisable to install the make-up in the return line - to increase the efficiency of the system.

- If there is indirect heating in the boiler system used for hot water supply to the house, it is allowed to supply heated water from it for replenishment through the return line.

Reference! Modern boiler models from official manufacturers are equipped with technical documentation, which includes important technical information. This is, first of all, a diagram of the correct piping indicating the location of the recharge unit.

How to pour water into the heating system through the expansion tank, that is, from above

Thus, if you have an open system, then we take a bucket or hose, go up to the attic or where the expansion tank is located, remove the lid from it, insert a large watering can into the neck of the tank, or stick the end of the hose directly into the tank. After that we add water. There should be a device on our tank, usually a simple transparent tube that shows the water level in the tank. We have to know when to stop! In addition, at the very top of the tank, there must be an outlet for excess water. Roughly speaking, this is a pipe to which a hose leading into the sewer is connected.

Water, theoretically, should drain down the pipes and fill the system. But this is only theoretical. The fact is that water, going down, forms bubbles. The water compresses the air at the bottom of the system. The air needs to come out. The air should come out again upwards. Through the same pipes through which water is poured. And this is the big problem. While water moves down through the pipes, air cannot move up through the same pipes. This means that we cannot refill constantly. We can pour water and then wait. First, wait for the bubbles to start. Then wait until they stop walking. And only after that we can pour a new portion of water into the tank. Thus, we fill, as it seems to us, the complete system. At least there is water in the tank and it doesn’t go anywhere. But believe me, it’s still very early to turn on the heating! We need to go to each radiator and bleed the air from each one. Each radiator is a kind of air trap. There is simply nowhere for it to escape from the radiator! At the same time, we need to make sure that the water does not completely leave the tank. After all, if it leaves there, then empty pipes will form, which means that when water is poured into them, new air cavities and bubbles will form, which will have to come out.

So, we go down to the radiators. Do we have air bleeders on our radiators? If there is, then good, if not, then everything becomes very complicated and the issue of filling the heating acquires the status of not a big, but a very big problem. We need to spin something to drain the water and, quite possibly, this will not be enough to release air from the radiators. But let's not talk about sad things! We will assume that on each radiator we have so-called Mayevsky taps, or air bleed valves. We unscrew them one by one and bleed the air until water flows out. As already mentioned, do not forget to add water to the expansion tank.

After all the radiators have been bled, you can try to start the boiler. If at the same time the boiler heats up, but the pipes do not heat up, then we can only wait. How many? Maybe a day. Or maybe a week. And during this week there may be cases when we, like, wake up at night and hear a bubble inside our heating suddenly begin to move upward with a characteristic gurgling sound. Here they are - the delights of an open heating system!

Pipe slope

In order for the air to escape from the heating system on its own, all pipes must have a slope. Tilt towards the expansion tank. The bubbles should rise up. They will also gradually rise through gentle pipes. It is only necessary that the pipes have a slope in the desired direction and that there are no depressions or loops. It is quite possible to lay the pipes in such a way that air will collect in them, which will never come out of them, which means there will never be circulation in the system. Moreover, most often in the entire system, or in the entire branch.

But the slope of the pipes is important not only for an open heating system! Unfortunately, other articles about heating are written in such a way that it begins to seem that in a closed system the slope of the pipes is unimportant and unnecessary. This is wrong! The slope of pipes in a heating system is always necessary. Where should the slope be in a closed system? There is no open expansion tank at the highest point!

The slope of the pipes in a closed heating system must be exactly the same as in an open one. Ideally, the pipes should rise steeply from the boiler to the highest point, and then smoothly descend to the last, furthest radiator. An air release valve must be installed at the highest point. When draining water from the heating system, water should not stagnate in any place. It should pour out completely, and by gravity. And this is also due to the slopes of the pipes.

Replacing a three-stage pump

If we need to replace an old non-functional pump, the situation is different and we usually have to choose a suitable replacement. It is possible to purchase the same type of pump and simply replace it, however, it is often the case that the original pump is no longer made. This usually happens if we have an old three-speed pump.

These pumps are no longer in production and have been replaced by new models with electronic power control. New electronic pumps can save up to 90% energy compared to older non-regulated pumps, so this change saves you money.

If one old non-regulated pump consumes 500-800 kWh per year, then new booster pumps consume about 50 kWh per year, meaning that the price of a new electronic regulator could come back to you in about a year.

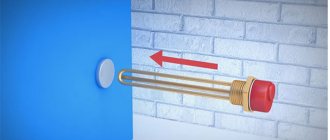

Pressure testing of heating system with air

In most cases, developers, before starting interior decoration of residential premises, first complete the installation of the heating system and check it for leaks. This is done so that after expensive repairs you don’t have to do it again because the pipes simply leaked. This whole process is called pressure testing of the heating system and its essence is to check the tightness of pipe connections under the operating pressure of the system, which is 1.8 - 2.0 atm.

Pressure testing of the heating system using a compressor

To do this, we connect a simple device to the drainage point of the system, consisting of a union nut, a pressure gauge and a fitting for connecting the hose from the pump. Before this, you need to weld an adapter with a thread at the drain site to connect our entire device. Next, screw the nut to the system outlet (drain) adapter and connect the hose from the pump to the fitting. In this case, you can use the pump that is used to inflate tires in a car, either a foot pump or an electric one. In the latter option, you will need to provide a voltage of 12 V, which is not always possible. Therefore, we will focus on the foot pump.

The inlet valves to the boiler, as well as the heating radiators, can be closed since we are interested in connecting the pipes of the heating system. Next, we pump air into the system to 2 atm and leave it in this position for a day, having first closed the drain valve, that is, we close the connection of the device to the heating system. After a day, open the drain valve and look at the pressure gauge of the device. If the pressure has not dropped, then everything is in order and the heating system can be filled with coolant.

Standards according to SNiP

Building codes and regulations (SNiP) are based on statistical research, testing theoretical calculations in practice - that is, the ease of use of plumbing fixtures in the bathrooms of apartments and public institutions. At the same time, collections of rules standardize the basic requirements for the design of certain building structures.

According to SNiP 3.05.01-85, the installation height of a sink in a bathroom (regardless of whether it is a private bathroom or a public one) is 800...850 mm from the floor, the permissible deviation is +/-20 mm. For schools, kindergartens, hospitals and clinics, places of visit for the disabled or people with temporarily limited mobility, the parameter may vary. Data on other plumbing fixtures are presented in the table.

Important: when installing a joint mixer for a sink and bathtub, its position is determined by a higher-lying plumbing fixture, usually the sink. Thus, the height of the sink in the bathroom from the floor (standard) along the top of the side and the installation height of the faucet in the bathroom (along the bottom edge of the body) are the same.

The RF standard is focused on devices installed by builders during mass construction

Thus, the installation height of the bathtub from the floor in the table is given for a typical cast iron or steel product with legs. For acrylic, modern cast iron and steel bathtubs, glass models, the position is determined individually, in accordance with the geometry of the model and the method of its installation. If the product is installed on a podium, the distance from the finished floor to the top of the side is calculated from the top plane of the podium. Thus, the height of an acrylic bathtub is determined by the height of the podium, the type of supports and linings under the bowl

The RF standard is focused on devices installed by builders during mass construction. Thus, the installation height of the bathtub from the floor in the table is given for a typical cast iron or steel product with legs. For acrylic, modern cast iron and steel bathtubs, glass models, the position is determined individually, in accordance with the geometry of the model and the method of its installation. If the product is installed on a podium, the distance from the finished floor to the top of the side is calculated from the top plane of the podium. Thus, the height of an acrylic bathtub is determined by the height of the podium, the type of supports and linings under the bowl.

In addition to the height of the bathtub from the floor (standard) and the position of the sink side, the required free area in front of the plumbing fixtures and the distance between them are standardized.

It is important to understand: the standards for the placement of plumbing fixtures are justified, but are not indisputable. If there are no other options, you can change the relative position of the devices so as to provide users (taking into account their physical characteristics) a comfortable stay in the bathroom.

How to add water to a closed heating system with and without plumbing

Arkady How to fill water into a closed heating system?

No heating system will function without coolant. after all, it directly ensures the transfer of energy to radiators and subsequent heating of the air in the room. So after installation and repair work, you will inevitably need to pour new water into the equipment. For many, this procedure seems overwhelming. Especially if you need to fill a closed system. Indeed, the task is troublesome, but at the same time absolutely achievable if you do everything according to the rules - they will be discussed further.

Preparatory operations

Before you start pouring coolant into a closed heating system, prepare it for operation. In particular, the following procedures should be followed:

- Hydraulic test - before filling the system, it must be pressurized. This is done using a special device that builds up pressure and fills all pipes and batteries with compressed air. Pressure testing is performed at a pressure 25% higher than the base pressure for a specific heating system.

- Checking for problems - after completing the pressure test, you should check all joints of the heating equipment for depressurization and leaks. If there are any problems, they need to be corrected.

- Shutting off the valves - to avoid unplanned water consumption when filling, shut off the shut-off valves that drain liquid from the system.

When the preparatory work is completed, you can start pouring water. It can be run from a centralized water supply or, in the absence of the latter, from another source of water - we will consider both options.

Hand pump for pressure testing the heating system

Filling water from the water supply

If your home is connected to the water supply network, there will be no problems filling the heating system. First, you need to determine which fittings are closest to the heating boiler - it is through it that the coolant should be introduced.

Next, the heating boiler must be connected to a centralized water supply and a special shut-off valve must be installed between them. Filling is carried out precisely thanks to this valve: when it is opened, water begins to flow from the water supply into the boiler, which is then poured into the pipeline.

Important! Water must enter the heating system at a minimum speed - this will allow the air that remains in the pipeline to be removed without consequences through special Mayevsky battery-powered taps. If the house has more than one floor, the system can be filled not at once, but in parts: starting from the lower radiators and ending with the upper heating points. If the house has more than one floor, the system can be filled not at once, but in parts: starting from the lower radiators and ending with the upper heating points

If the house has more than one floor, the system can be filled not at once, but in parts: starting from the lower radiators and ending with the upper heating points.

Filling water without running water

If the source of coolant is not a centralized water supply, but a well, a well or a reservoir, auxiliary equipment will be required to fill a closed heating system. This could be a powerful pump or an expansion tank.

Heating system diagram

In the first case, you will need a manual or electric pumping unit. With its help, filling is performed according to the following scheme:

- Connect the pump hose to the drain pipe.

- Open the special valve on the pipe.

- Open the Mayevsky taps.

- Start the pump and begin running water into the system.

In the second case, use a membrane tank with a partition in two parts and a regular bicycle pump:

- Connect the tank to the heating system pipeline and fill it with water.

- Unscrew the nipple at the top of the expansion tank and bleed the air from the tank.

- Connect the bike pump to the nipple and begin pumping air into the tank, creating pressure to force water into the system.

Advice. Pump the tank until the pump pressure reaches 1.5 atm.

Now you know that you can pour water into a closed-type heating system either from a water supply or without it. The main thing in both cases is to carefully prepare for the procedure and observe all the technical details of the work. So, if you follow the rules, filling the system will not be an overwhelming task for you.

Briefly about the main thing

An autonomous heating system is based on the principle of transferring heat with a coolant heated in a heat exchanger to radiators, and then returning it through the return line in a cooled state to the boiler for reheating and restarting the system. There are open or natural systems and closed or forced ones. In the first, the coolant moves by gravity, in the second, under pressure using a pump.

They can use water, antifreeze, propylene glycol and brine as a coolant. Each liquid has its own characteristics and recommendations for use. When choosing a coolant, the following characteristics are considered:

- Specific heat.

- Operating temperature range.

- Viscosity.

- Corrosive activity.

- Lubricity.

- Chemical activity.

- Environmental safety.

A decrease in coolant level can occur due to reasons such as leakage, evaporation, losses from air vents and repair or maintenance of filters, reset by an emergency sensor. Feeding open and closed systems has its own characteristics and algorithm of actions. The open one is fed through an expansion tank located at the top point of the system, the closed one through the valve - from the bottom position, most often through the return line. At the same time, special requirements are imposed on the choice of location for installing the recharge unit.

Advantages and disadvantages

In addition to the fact that oxidation in a closed system occurs more slowly, they have several other advantages:

- the coolant does not evaporate, there is no contact with the external environment, which makes it possible to use not only water, but also special compounds that increase heating efficiency and improve its characteristics;

- higher pressure and circulation speed of the coolant, therefore its silent movement through the pipes.

With proper heating organization, the difference between the return and supply temperatures is small, which has a positive effect on the duration of operation of the boiler (with the exception of condensing boilers, but there is a different operating principle).

Single-pipe open-type circuit - the expansion tank is installed at the top point

- for efficient operation, active movement of the coolant is required, which is achieved either by installing a pump or by creating natural circulation with sufficient slopes;

- with a large system volume, a large tank is required, a place for which is not easy to find (its volume should be 10% of the coolant volume).

Glycerin

Reviews about coolants of this group are the most contradictory, from the most enthusiastic to the sharply negative.

Positive characteristics of glycerin antifreeze:

- Complete safety for the human body and the natural environment. This is the safest coolant for the heating system of all antifreezes.

- Significant range of operating temperatures. The lower limit of crystallization is 30 degrees, the boiling point is the same as that of water (sometimes higher). Freezing of glycerol is not accompanied by its expansion. An increase in temperature not only liquefies, but also completely restores all the characteristics of the substance.

- Resistant to zinc. In this regard, it is one of a kind among other antifreezes.

- No aggressive effects on the sealing gaskets of the system are observed.

- Absolute fire safety.

- Before pouring glycerin antifreeze, the heating system does not need to be thoroughly rinsed, even if another substance was poured into it before.

- Durability. If you follow the operating rules, coolants of this type can last up to 10 years.

- The level of thermal characteristics here is comparable to propylene glycol. At the same time, glycerin coolants are 20-25% cheaper.

Disadvantages of glycerin:

- Outdated version. Glycerin antifreezes are the most “ancient”: it was in order to improve their performance characteristics that all of the above substances were developed.

- High density and viscosity. Pumps experience significant difficulties pumping glycerin coolant through the heating circuit. As a result, equipment wears out much faster.

- Low heat capacity. In this regard, glycerin is inferior not only to water, but also to propylene glycol.

The heat resistance and environmental safety of the substance deserve special consideration:

- Upon reaching a temperature of +90 degrees, significant foaming of glycerin is observed. To reduce this effect, special additives are usually used.

- The same temperature level triggers the process of chemical decomposition of the liquid. As a result of precipitation, the solid substance gradually layers inside the pipes, and the gas released, acrolein, has a very unpleasant odor, being a weak carcinogen.

- When overheated, water evaporates from glycerin, which makes the liquid very viscous. As a result of this, it loses its characteristics, turning into a jelly-like substance already at a temperature of +15 degrees. It is clear that normal operation of the heating system in such conditions is impossible.

As studies have shown, the main component of counterfeit antifreeze coolants for heating systems is most often glycerin. This is explained by its cheapness, which gave unscrupulous manufacturers the idea to use the material instead of propylene glycol, passing off their products as environmentally friendly high-quality propylene glycol antifreezes

Therefore, when purchasing non-freezing coolants, it is necessary to exercise some caution, requiring quality certificates. It should be noted that in Europe, coolants based on ethylene glycol have long been discontinued, but local companies are in no hurry to return to glycerin.

What to look for when buying - main characteristics

Productivity or feed

This is a value showing how much liquid the pump moves through itself per hour. Measured in m3/h. These data can be found in the technical document for the pump.

Multiply the volume of liquid in your pipes by three - and you will find out the approximate value of productivity.

Those. an approximate figure for a small village house will be 1 - 2 m3/h.

Performance of circulation pump Askoll ES2 70

A more accurate calculation is made using the formula:

Q=Qn/Dt

Q - desired feed

Qn – how many kilowatts of energy are needed for a given area (in kW)

Dt is the temperature difference between the boiler outlet and return.

Pressure

The second, no less important indicator. The more complex and longer the pipeline (the more turns, radiators, fittings and taps it has), the greater the pressure the pump should have.

It is clear that if there is insufficient pressure, the pump simply will not perform its functions, and if there is excessive pressure, noise will appear in the system from the rapid movement of liquid.

Pressure and flow characteristics of the pump

The pressure can be calculated using the following formula:

Hpu =R x L x ZF / 10000

R – losses caused by pipe friction (Pa/m)

L – pipeline length

ZF – coefficient for valve (1.7), fittings (1.3)

If all these calculations seem too difficult and confusing to you, there is a plan B. Buy a pump with a reserve of pressure and flow (which, of course, leads to unnecessary expenses), but you can always simply switch the unit to a lower speed if it is working too hard.

Connection size

The diameter of the pipes and the diameter of the inlet holes on the pump may not match. This, of course, can be corrected with the help of adapters, but it will be less troublesome if the section sizes are chosen to be the same. In the specifications for heating circulation pumps, the diameters are indicated in inches.

Power

Remember that your heating circulation pump will be turned on quite often and for a long time, so high power can be ruinous. Nowadays they make very economical units that consume electricity like a regular light bulb.

Selection of a circulation pump based on power parameters

Other nuances

Automation for the heating circulation pump (automatic regulator) will help save electricity. Then the pump will work “according to the needs” of the system.

When buying an imported pump on the Internet, it is a good idea to make sure that it operates on a 220 V network (and not 380, for example).

And look at the service life of the pump - it should not be less than 10 years.

How to create pressure in a closed heating system

For rapid movement of the coolant through the pipes, a certain pressure must be created. Its value is determined by the type of system - for natural circulation the pressure should be only slightly higher than atmospheric pressure, and this will be sufficient, but for forced circulation its value is required as high as possible, but not exceeding 2 Bar.

The gravity flow system is single-pipe with vertical distribution into two wings (circuits). A slope is required for normal operation

To create the required pressure drop in schemes with natural circulation (NC), it is necessary to maintain a slope of 1 cm per 1 meter of pipeline length. On the supply line the slope goes down from the boiler. On the return side, on the contrary, the pipes go down to the boiler with the same height difference. When using pipes of insufficient diameter, this value may not be enough, then the slope can be increased to 5% (5 cm per meter of pipe). In general, for a normal gravity system, careful selection of pipe diameters and slope is necessary - only then will it work normally.

Two-pipe horizontal system with forced circulation

The EC scheme requires the mandatory installation of a safety group, which includes a pressure gauge and a blast valve set to the operating pressure. As the pressure increases, the valve will operate, preventing the “weakest” element from rupturing. This situation can happen when using a boiler without automatic control, in particular a solid fuel boiler, which either gets very hot or almost goes out. This group also helps out in case of automation failures.

The best pumping units to increase water pressure

Grundfos

The Grundfos UPA_15-90(N) is rightfully considered the most convenient, high-quality and reliable, simply the best wet rotor pump. Made in Denmark, Grundfos has a durable cast iron stainless steel body and can operate with different pressures. There are several operating modes available in the control, which can be selected by the consumer at will. Grundfos can raise water to a level of eight meters. In this case, the minimum inlet pressure will be 0.2 bar, and the electricity consumption will be high - only 0.12 kilowatts.

Grundfos pump Source valves-msk.ru

The noise level is an important point for a pump installed inside a small apartment. For Grudfos it is no more than 35 decibels. The pump is lightweight, easy to install, durable (can operate for at least ten years, according to the established official service life).

Selection of energy carrier and heating system

If you do not take into account the cost of energy, but approach it from the point of view of independent heating, then electricity will confidently take first place. It is also more convenient to use than any hydrocarbons, and if a private house has a multi-tariff meter, then the price becomes acceptable

An important advantage of electricity is that to use it it is not necessary to install water heating

Advice. An excellent solution for southern regions is an inverter air conditioner or a split system with heating mode. It is capable of operating down to -15 °C in winter and delivering 3 kW of heat for every kW of electricity consumed.

The combustion of other types of fuel requires the presence of a single heat source - a boiler or furnace. And from them the heat spreads throughout the rooms through water (coolant) or heated air. It is difficult to carry out traditional water (they used to say steam) heating yourself, since you need to correctly calculate the pipes, radiators and select shut-off and control valves. The same is with air distribution - you need air ducts and fans, taken according to calculation. All these systems will not be cheap.

An exception is gas convectors, which are placed near the outer walls of rooms and heat the air in each room directly. There are no particular difficulties in installing them yourself; usually the installation process is well covered in the product documentation. The only problem is connecting the convectors to the gas main; this can only be done by specialists from a licensed company who have all the permits.

In a small one-story house, it is possible to independently install a steel wood-burning stove; it will be enough to heat 2-3 rooms. True, you will also have to install a chimney with good natural draft. Such solutions are good for dachas or country houses with periodic residence of the owners.

It turns out that the most affordable option for independent implementation is heating a wooden or stone house with electricity, which will be discussed further.

Selection of coolant

First, a few words about what liquids can be used to fill the heating system. Here are the key properties of popular coolants.

- Price. minimal (when pumped from a water supply with a water meter installed at the entrance to the house - from 20 rubles per cubic meter);

- Heat capacity. high (4183 J/(kg deg) at +20°C);

- Viscosity. low (which means little load on the circulation pump);

- Corrosive activity. medium (steel in contact with water rusts only in the presence of oxygen);

- Toxicity. absent;

- Expansion coefficient when heated. 0.03%/deg.

For heating, it is better to use distilled water, which does not conduct electricity and has minimal corrosive activity.

Antifreeze was developed several decades ago as a winter filler for water cooling systems of automobile engines. Nowadays, it is often used as a winter coolant. The numerical designation in the marking of antifreeze (30, 40 or 65) means its freezing temperature.

- Price. from 40 rubles per kilogram for wholesale supplies and from 60 for retail sales;

- Heat capacity. average (3520 J/(kg deg));

- Viscosity. high (the load on the pump increases due to an increase in the hydraulic resistance of the system);

- Corrosive activity. low due to anti-corrosion additives;

- Toxicity. high (the original antifreeze contains poisonous ethylene glycol);

- Expansion coefficient when heated. 0.05%/deg. The higher the expansion coefficient, the larger the expansion tank must be in a closed heating system. It is this that compensates for the expansion of the coolant as the temperature rises.

Antifreeze is antifreeze for water cooling systems of engines.

Due to zero corrosive activity, antifreeze creates leaks at the slightest violation of the tightness of the heating circuit. Water and other coolants quickly clog small leaks with rust and crystallizing mineral salts.

Propylene glycol

Non-freezing coolants are produced on the basis of propylene glycol, designed specifically for heating systems.

Packaging of coolant based on propylene glycol.

Propylene glycol is used in the form of an aqueous solution. Mixing with water increases its heat capacity to the level of antifreeze (3500-4000 J/(kg deg) depending on the proportion of the mixture).

- Viscosity. high;

- Corrosive activity. low due to additives;

- Toxicity. zero (canisters with coolant are marked green and marked “Eco”);

Polypropylene glycol mixed with glycerin is used as a cosmetic product.

Expansion coefficient when heated. approximately 0.05%/deg.

A concentrated solution of table salt, calcium chloride and other salts can also be used as a coolant: its freezing point is inversely proportional to the salt concentration. These are a typical budget solution, which is limited to use only in open systems with natural circulation.

- Price. from 5 rubles per 1 kg of table salt;

- Heat capacity. low (at 30% concentration - 2700 J/(kg deg);

- Viscosity. low;

- Corrosive activity. extremely high. Salt literally corrodes steel pipes;

This is how steel is affected by contact with sea water - brine with a small concentration of salts.

At high brine concentrations and slow movement of the coolant in the system, excess salts will gradually be deposited on the walls of the pipes, reducing their cross-section. In a forced circulation circuit, brine has a detrimental effect on the pump. the shaft and impeller become overgrown with crystals, which leads to a drop in performance.

The instructions for choosing a coolant are quite obvious:

- If you have the opportunity to maintain a positive temperature in your house throughout the heating season, it is best to fill the heating circuit with water. It’s better to use distilled water, but you can also use drinking water or even well water;

- If the cottage is periodically left without heating, your choice is non-freezing coolants based on propylene glycol.

The freezing point of antifreeze depending on the concentration of the solution.

Antifreeze reaction to overheating

One of the characteristics of all antifreezes is the operating temperature range. This factor is very important - this type of coolant has a very negative attitude towards overheating, as a result of which the material begins to collapse. The boiling point of antifreeze, depending on the type, can vary from 106 to 116 degrees Celsius. This difference largely depends on the amount of water in the coolant.

Exceeding the maximum permissible temperature leads to obvious consequences - first of all, anti-corrosion additives stop working, then boiling glycols begin to decompose into tiny particles, which settle on the internal walls of the heating system in the form of scale, clogging the working channels.

To prevent overheating of the coolant, it is necessary to increase its circulation rate - in this case, the system elements will be protected from high temperatures. Considering that most antifreezes have a relatively low heat capacity, thermal conductivity and high viscosity, for their normal movement it is necessary to select sufficiently powerful circulation pumps and heating devices.

All types of antifreeze are very fluid and easily find various microcracks in which leaks form over time. In addition, heating with antifreeze in a private house does not allow the effect of swelling of the seals to occur, so the smallest gaps for the coolant present under them look like the widest channels for leakage. To get rid of this factor, and at the same time increase the quality of the heating system, you will have to tighten all existing connections well.

The tightness of heating is a very important point, especially when using antifreeze as coolants. It's all about the susceptibility of ethylene glycols to oxidation upon contact with air. The intensity of oxidation increases many times with increasing coolant temperature. Lack of tightness even in a single section of the heating system always leads to a significant reduction in its service life.

The operation of antifreeze has some features related to their physical properties. Unlike water, which begins to crystallize very quickly when the temperature drops, antifreezes change state very smoothly, first becoming more viscous, and only after some time they begin to harden. This rule works both ways - when starting a frozen system filled with antifreeze, you need to increase the boiler temperature gradually so that the coolant has time to react to changing operating conditions.

Antifreezes that are in a frozen state increase in volume so slightly that you don’t have to worry about any danger to the heating system. As the temperature rises, the coolant returns to its original properties. For normal operation, antifreeze poured into the home heating system must be diluted with water in the proportion specified by the manufacturer of the specific type of coolant. In addition, some substances can work independently, without adding water.