A situation with a leaking heating circuit is not uncommon, since the heating system consists of many components and elements, the tightness of their connection with each other is sooner or later broken. In addition to joints, a depressurization zone can also be an entire span of pipe that is physically worn out or damaged due to the influence of some factor.

Sealant for heating pipes, available in different types and designs, helps solve the problem of a leak or ensure long-term tightness of the connections of its elements during installation of the system.

Why is sealing needed?

Sealing in a heating system usually means the elimination of open and hidden leaks that occur in any area. In fact, this problem falls into the category of emergency situations and requires an urgent solution, as well as strict adherence to technology when carrying out work. In addition to isolating cold or hot water leaks, sealing may be needed in the following cases:

- for laying water supply pipes;

- when installing threaded connections;

- for sealing the heating boiler lid;

- for installing heated floors;

- to strengthen the radiator connections after disassembling into sections.

CO sealant is a universal self-sealing solution that helps eliminate leaks in pipes and joints. Most sealants are suitable for interior and exterior work; they can be poured into the expansion tank and other areas of the water system.

The use of sealant allows you to restore the functioning of the CO in a short time, without compromising the integrity of the walls and floors. Sealants are especially often used when the pipes in the house are in a place inaccessible to open operations, as well as when it is impossible to eliminate the leak by soldering or applying a clamp.

What to look for when choosing?

- When heading to the store, you should already have an idea of what kind of work you need a sealing agent for. This is the first thing the seller will ask you.

- In addition, try to study in detail the instructions (it should be on the packaging) of what you will be offered.

- Determine whether the composition is for interior or exterior use.

- There must be an indication of the type of work (plumbing, roofing, etc.).

- Properties of the sealant - whether it has heat resistance or elasticity.

- Check if it suits your color.

- If there is an indication on the packaging that it belongs to the professional group, keep in mind that it is more difficult to work with, and additional knowledge of its features is required.

- Is it possible to use it in a pistol?

Basic requirements for compositions

The sealant can be used for polypropylene, bimetallic, and other heating system pipes. But before purchasing, it is important to clarify that its characteristics correspond to a particular pipe material, because compositions for plastic are not suitable for metal networks. You can get acquainted with such information on the packaging, where exact data on the composition and properties are always indicated.

In addition, the sealant must meet the following requirements:

- Resistance to adverse factors. The water in the pipes is under pressure, and it is also hot. Therefore, the product must be moisture resistant and not responsive to temperature changes or aggressive chemical environments. If the sealant is used in steam systems, it must be high temperature (heat resistant).

- Long service life. The operating time of the entire CO depends on this factor. If the sealant is reliable, the system will work for at least 5-10 years. The cost of such funds is usually quite high.

- Elasticity. Sealants against leaks after hardening must remain plastic. This way they will easily, without destruction or detachment, tolerate the expansion and contraction of the base material that inevitably occurs with temperature changes.

How to choose?

It is important not just to choose a sealant for the radiator, but also heat-resistant options to eliminate leaks. If you notice that a joint is leaking somewhere near the batteries, you need to decide which sealant will help, and reviews can help in this matter

The choice of sealant is made based on the problems that it must solve to eliminate leaks in the heating system. If it will be used to seal the joints of the heating system, then paste-type silicone sealant is perfect for these cases.

It can be drying or non-drying version.

Differences between sealants may include the following:

- Drying compounds. After the composition applied to the surface dries, it has the ability to shrink, but this happens if the drying technology is broken. Thus, deformation of the composition may occur, cracks and drips may appear.

- Non-drying compounds. Ideal for removing small cracks and can also be used to seal heating system joints. But such compounds can be squeezed out if the pressure in the system exceeds the normal value.

Aerobic-based compounds, which are considered a type of acrylic sealants, are used in some situations to eliminate defects and leaks in heating systems. This type of sealant is able to withstand temperature changes, is resistant to mechanical stress and is resistant to alkali and acid solutions. If you apply it to the site of a defect, it quickly fills the defect and dries.

Types of sealants for heating systems

The choice of sealant is determined not only by the material of the pipes, but also by the type of coolant used and the presence of a heat exchanger. If you choose the wrong product, pipes can become clogged anywhere in the heating system. Various substances can be used as a coolant, and the sealant should not react or be destroyed by contact with them. Based on this criterion, agents are divided into those that can come into contact:

- with water (regular, softened with complexons or magnetized);

- with antifreeze;

- with oils;

- with gas or steam.

A separate line includes sealant for cold water pipes, which is also applied to the threads of faucets and is used to seal joints. The consistency of sealants can be fluid or paste-like. Pipe sealant can also be classified according to its physical properties:

- Drying compounds. As they polymerize, they become completely dry. If the application and drying technology has been violated, the products may shrink and quickly crack.

- Non-drying compounds. Ideal for removing small leaks and sealing threads, although they can be squeezed out at joints under pressure.

Among the popular brands of sealants are Aquastop 2100, BCG, Block Seal 100. Based on their composition, the products are divided into several groups, which are described below.

Oligomer based

Depending on the functional group used in production, such products are divided into polysulfide and polysiloxane. Sealants made from polysulfide oligomers are used much more often for heating systems. They have a unique set of properties: oil resistance, gasoline resistance, gas impermeability, weather resistance, and the ability to operate for a long time in different temperature ranges.

Acrylic

Most acrylic products are not suitable for repairing CO in a private house or apartment. Only some brands are able to withstand temperature changes and boast heat resistance. For example, anaerobic sealants are suitable for sealing pipes and radiators - a type of acrylic compositions that, when released into an airless environment, fill the entire closed volume (crack, chip) and form a homogeneous polymer mass.

Such products can withstand high temperatures, they are very durable and elastic. Seams and joints can subsequently be cleaned with acidic and alkaline substances, since sealants are sufficiently resistant to chemicals. And yet they have one drawback: dismantling the structure will be very difficult, since it becomes monolithic.

Thiokols

Such materials can be used at temperatures of -20...+40 degrees, that is, they are not heat-resistant. Therefore, they are used only in construction for sealing interpanel joints, double-glazed windows, plumbing equipment and are not used for repairing CO.

Silicone

Such funds are considered universal and most in demand. Most silicone sealants are high-temperature and therefore suitable for work in CO environments. They can be liquid or paste-like, the latter having thixotropic properties (do not flow after application). The technical characteristics of silicone compounds are as follows:

- possibility of operation at -60…+300 degrees;

- penetration even into the smallest cracks and depressions;

- adhesion to any surfaces;

- hardening at room temperature;

- resistance to moisture and aggressive chemicals;

- elasticity;

- environmental Safety;

- strength;

- durability.

When purchasing silicone sealant, you need to pay attention to its specific type. The products are neutral and acidic, and the latter can cause corrosion of metals, so they are not suitable for metal pipes.

Polyurethane

Polyurethane-based products are produced in one- and two-component forms. The first ones are inexpensive, but they dry much longer. The latter, after reacting with the hardener, quickly undergo polymerization, resulting in the creation of a strong, elastic connection. Polyurethane compounds are suitable for all types of materials, including metals; they do not provoke corrosion; on the contrary, they protect parts from damage. Sealants are durable, resistant to aggressive chemicals and mechanical stress, and are characterized by low consumption.

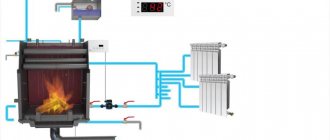

Liquid sealant for heating system

Liquid sealant has to be used where there are hidden leaks and there is no access to the place where the defect appears. The material is poured into the damaged pipe along with the coolant. In the area of the crack, the sealant inevitably comes into contact with air and begins to polymerize, sealing the defect. Among the liquid options there are those that work in water, antifreeze, and are suitable for metal or plastic pipes.

Results

As with all building materials, sealants also need to be understood. High-temperature sealants are a very narrow and specific segment, but even here there are many nuances, ignorance of which can lead to errors and insufficient tightness of products.

The choice of building materials for installation and repair work with brick fireplaces is strictly limited by such parameters as heat resistance, adhesion, and environmental safety. The need to use such substances arises even at the stage of construction of fireplaces or stoves. The difficulty lies not only in the high temperature of the working unit, but also in the difference in the coefficients of thermal expansion for different elements.

Technology and methods of using sealant for heating systems

To begin with, it is important to choose the appropriate composition and accurately calculate its quantity, which directly depends on the volume of coolant. Typically, 1 liter of sealant is used for 60-80 liters of liquid.

External treatment

External operations include work on sealing joints and threaded connections. They need to be done in this order:

- drain the liquid from the CO;

- find the damaged area;

- clean the defect area from dust, dirt, old sealant;

- degrease;

- apply a new composition;

- wait for it to dry;

- pour coolant into the system.

Internal processing

If you need to fill the sealant inside the CO, you need to purchase a liquid product. Water from the heating system is drained into appropriate containers, and the sealant is diluted with water. The Mayevsky valve is unscrewed from the radiator, and a pump is attached in its place. The system is filled with liquid with sealant, the pressure is increased to 1.5 atmospheres. After 6-8 hours the sealant completely hardens.

Then the coolant is drained again, and a new one is introduced instead (without sealant). In this way, another 2-3 repetitions of operations are performed, which is required to remove the remnants of uncured sealant from the pipes. After 3 days, check for defects and cracks. If necessary, the process is repeated again. If the water leak is more than 30 liters per day, sealing is pointless: only a major overhaul by replacing a piece of pipe will help.

About the pros and cons of glycol antifreeze

The main advantage of artificial coolants based on glycols is the preservation of the liquid phase at subzero temperatures. We list other positive aspects of using antifreeze in closed water heating systems:

- coolants do not contain calcium and magnesium salts, which form scale inside the heat exchangers;

- due to the penetrating ability of glycols, the effect of lubrication of moving parts occurs, ball valves and thermostatic valves do not sour, the fittings last longer;

- the boiling point of antifreeze 103-106 °C delays the moment of vaporization and airing in case of overheating of a solid fuel boiler;

- When the temperature drops below the freezing threshold, glycol solutions turn into a gel mass.

When glycol mixtures freeze, they form a slurry that is unable to rupture pipes and heat exchangers.

Let us explain the last 2 points. Ordinary water, often poured into the heating system of country houses, begins to boil at 96-98 ° C, actively releasing steam. If the circulation pump is on the TT boiler supply, the steam phase penetrates the chamber with the impeller, water pumping stops, and the boiler completely overheats. A higher boiling point of antifreeze will delay the moment of the accident.

Unlike water, glycol hardened in the cold does not expand and does not destroy pipe walls. In the event of freezing, the only unit that will suffer is the forced circulation pump. The crystallizing gel will jam the impeller and the motor will burn out.

Unfortunately, there are plenty of disadvantages to non-freezing substances:

Ethylene glycol is poisonous and requires careful handling and disposal of the solution. Glycerin and polypropylene glycol are harmless. The heat capacity of the “anti-freeze” is 15% less

To deliver the required amount of heat to the batteries, the liquid flow will have to be increased. The viscosity of antifreeze creates additional hydraulic resistance. You will need a more powerful and expensive circulation pump. Good turnover is a double-edged sword. Glycols penetrate through the slightest leaks, from which plain water cannot flow.

Coolants and additives decompose during operation, losing their frost-resistant properties and forming flakes of sediment. The maximum service life of 1 refill is 5 years, then the heating is flushed and replaced. When using antifreeze, many gas boiler manufacturers void the warranty of the purchased product.

Glycol liquids are poorly compatible with electric boilers. Instructions for the use of various antifreezes categorically do not recommend filling systems operating in conjunction with electrolysis heaters with antifreeze. That is, for electrode boilers of the “Galan” type, a special coolant developed by the specified company is needed.

Under rare circumstances, antifreeze can release flammable gas that breaks through the automatic air vent. Example: the heat source is an electric boiler, the heaters are Chinese-made aluminum radiators. Heating glycol causes a complex chemical reaction and gas formation. The fact is demonstrated in the video:

Preparatory work before using sealant

To prepare the system, all taps are unscrewed and filters are removed. This is necessary to bleed air and water (antifreeze). To find a leak, the pipes should not be wet: for this purpose, a pump is installed on the first radiator, which will remove remaining air and heat the inner surface of the pipeline to +50...+60 degrees.

Preparing the sealant

The rate of adding a sealing compound may vary depending on its type and brand. The concentration of the product must be calculated as accurately as possible, otherwise the effectiveness will be low. For this purpose, you must carefully read the instructions and determine the volume of coolant. You can perform the calculation using the following methods:

- Direct freezing. Take containers of a known size, pour water from the pipes into them, and determine the total volume of liquid.

- Indirect freezing. Calculate the total length of the pipes, multiply by their cross-sectional area, add the volume of the boiler and radiators to the indicator (they can be viewed in the product data sheets).

Afterwards, you need to determine the amount of sealant according to the instructions for the specific product. Usually it does not exceed 1 liter per 80 liters of coolant. The two-component sealant must be mixed immediately before use, combining the two substances according to the proportion indicated in the instructions.

Setting up a heating system for filling

To prevent the sealant from hardening in the pipes prematurely, without reaching the leak site, it is important to completely remove air from the CO. After removing the filters and unscrewing the taps, the automatic pump is turned on for 2 hours - this is enough to remove the remaining gas.

Pouring sealant

A solution of water and sealant is prepared in a large container and mixed well. The liquid is immediately introduced into the heating system using a pump - a high speed of work will help reduce the risk of contact with air. After CO it starts in normal mode with a water temperature of about +50 degrees.

Control measures are carried out after 3-5 days - they help to check whether the sealing was carried out efficiently. It is also advisable to carry out pressure testing - launching CO under pressure, for which it is better to invite an experienced specialist.

Heat-resistant (silicone) pastes

The maximum temperature limit of 250-300°C allows the use of such compositions in external finishing, restoration of the outer layer of the portal, in joining sandwich pipes and when processing them in places where they pass through the ceiling. The main substance here is silicone. Depending on the impurities, the maximum temperature for which the paste is designed may have different values.

Typically, silicone sealants have a red tint. This indicates that it contains iron compounds.

In their variety, heat-resistant sealants are divided into acid-containing and neutral. In the kiln business, neutral pastes are used, since the acid released when the substance hardens has a strong, unpleasant odor. Crystallization of neutral sealants is accompanied only by the release of water or alcohol. In addition, acid has a detrimental effect on sealed seams.

In order to resolve the issue of the applicability of silicone sealant, its main properties should be highlighted.

- The finished composition is not subject to destruction by ultraviolet radiation. This allows this type to be used not only indoors, but also on the streets.

- Bonds well to various types of surfaces. The only condition is their preliminary preparation (removal of dust, wetting).

- Waterproof properties make this type of sealant an indispensable option when sealing the outlet of a chimney pipe through the roof.

- The plasticity of the finished substance will not allow destruction during thermodynamic changes. The sealant is excellent as an adhesive element when facing fireplaces.

- Possibility of use in mechanized devices.

In order for the heat-resistant sealant to efficiently perform its functions, it is necessary to wait until the paste has completely hardened before lighting the fireplace. This may take up to several days. Detailed information is provided by the manufacturer.

How to eliminate leaks in hidden wiring pipes

To quickly seal hidden heating pipelines, use mustard powder or a ready-made special sealant. The existing substance is added to the expansion boiler and the system is put into operation. After a few hours, the sealant (or particles of mustard powder) will seal the damaged area, eliminating the leak.

Such repairs will give time to prepare for a complete restoration of the heating circuit. However, if a large damage has occurred in a hidden area, then the internal sealant is unlikely to help. The heating circuit will have to be drained and repaired immediately.

Affordable repairs begin with the correct design and installation of the heating system. All detachable connections must be accessible for inspection. Hidden areas must be made of high-quality, durable materials and not have detachable connections. Timely replacement of worn-out equipment will allow you to live peacefully in cold weather, enjoying warmth and comfort.

Plumbing thread

Plumbing threads , advertised in large quantities, seal threaded connections well, but with a large number of connections, and in the heating system of a private house or cottage there are dozens of threaded connections, they will be too troublesome and expensive sealing material.

In fact, a plumbing thread from any manufacturer is a FUM tape reduced to the thickness of the thread, albeit from other materials, but the principle is the same. Like FUMka, the thread is wound onto the thread, and then the connection is assembled.

Popular brands

The market offers sealing materials for stoves, fireplaces and chimneys. They are selected according to their composition and operating temperature. It is recommended to use products from reputable manufacturers.

Soudal

Soudal (Saudal) is a Belgian company that specializes in the production of sealing compounds. Soudal sealant for stoves and fireplaces is the Soudal series.

Sealant for Soudal ovens

Calofer, heat-resistant compounds in black. Materials based on sodium silicate do not emit toxic substances when heated and can be painted. Suitable for sealing cast iron elements of boiler units. One of the advantages of Belgian products is their resistance to cracking and crumbling.

Penosil

An Estonian company produces silicate paste for Penosil +1500 ovens. The material has high heat resistance and is black in color. Foam is cheaper than the products of the famous Belgian manufacturer, but is not inferior in quality. This makes Estonian sealant widely in demand among professionals and home craftsmen. The company's product line also includes the silicone sealing compound Penosil Hight Temp, suitable for use for moving joints due to its elasticity.

Oven sealant Penosil Premium

Tytan

Under this brand, sealing compounds are produced by the Selena Group, a group of Polish manufacturers of professional materials for construction and finishing. The sealing paste contains fiberglass, which provides the sealed seams with increased gas tightness. The material is designed to be heated to high temperatures (1250 degrees), which makes it suitable for sealing seams and cracks in fireplace and stove masonry, and for installing chimneys. Products of the Tytan brand, as well as sealants with similar properties, which are produced under the Baumaster brand, belong to the middle price category. In terms of price and quality ratio, this is the best option for a wide range of consumers.

Silicate sealant for fireplaces Tytan

Makroflex

A well-known Estonian manufacturer of sealing materials supplies the market with fire-resistant silicate composition Makroflex HA147. It can withstand short-term heating up to a high temperature of +1500 degrees and exposure to an open flame. The advantages of the paste of inorganic materials include adhesion to most materials used in construction and the absence of shrinkage upon drying and under the influence of temperature fluctuations.

Fireproof silicate sealant Makroflex

Krass

The Russian manufacturer offers the refractory composition “Krass fireplaces and stoves”. Using this material, fireclay masonry and fireproof masonry can be installed in the furnace firebox. The composition can withstand sudden increases in temperature, is not afraid of open fire, and is suitable for repairing brick stoves and fireplaces, as well as heating boilers. This is a non-shrinking material made on the basis of liquid glass. Thanks to its paste-like consistency, it is easy to apply.

High-temperature silicate sealant Krass

The need for compaction

Sealing sewer pipes, like sealing all water pipes, is a very essential step in the pipeline installation process.

It is especially important to perform high-quality sealing of joints

To prevent the pipeline from leaking, since the appearance of unpleasant odors in an apartment or private house depends on this, it is necessary to choose the right seal for sewer pipes.

This means that you need to know which sealant is best for sealing plastic, polypropylene, cast iron, steel and other products. You also need to have information about how to seal threaded connections of a water supply system, couplings, and flanges.

You need to familiarize yourself with other materials necessary for the repair or installation of heating systems, gas supply, repair of sewers designed for draining acids and alkalis, and other systems, so that, if necessary, you can do such work yourself.

Now let’s talk about how to seal any pipe in order and in more detail.

Peculiarities

Thanks to sealing compounds, the construction and renovation process becomes simple and fast. With their help, you can reliably fasten various surfaces together without nails or a hammer, use them as a sealing agent and for sealing cracks and cracks. When installing windows or troubleshooting minor problems in everyday life, they are indispensable, saving money and time. Their use allows pipes to be repaired without opening walls or removing plumbing structures.

Liquid sealant is currently stronger than glue, but not as “heavy” as mortar.

The sealing liquid has a number of properties:

- does not change its characteristics under the influence of high temperature;

- is moisture resistant;

- withstands heavy loads.

The liquid solution is one-component, comes in tubes and is ready for use. The product for larger-scale work is available in canisters of various sizes.