It may be news to some that gas boiler equipment requires not only gas, but also electricity. And along with gas consumption, you should also take into account the power consumption of the gas boiler, which is the heart of your heating system.

Now there will definitely be a reader who will object and be right. But he is right in that there are still gas boilers without connection to the electrical network. These are classic floor-standing units with an open combustion chamber; they require a separate room and strict adherence to strict fire safety rules in it.

Non-volatile boilers are currently used in villages remote from cities, in dachas - where there are interruptions in the electricity supply. Or if you want to save on buying equipment. We will talk about modern gas heating equipment, and it only works if there is a high-quality, reliable power supply.

What does electrical power mean?

The operating manual for a gas boiler contains information about the amount of energy required to fully implement the functionality of the unit.

The power supply requirements indicate the power consumed from the network, expressed in W or kW.

There are no standards that regulate what information the manufacturer must include in the accompanying manual.

Therefore, information about power consumption is indicated in an arbitrary manner:

- total maximum power when all devices are turned on;

- electricity consumption in one or more modes and in any other combinations;

- value for each node separately (pump, ignition, fan, protection, sensors).

Thus, electrical power is the amount of work produced per unit of time.

How to find out how many kilowatts per day a gas appliance consumes

To find out how much electricity a gas boiler consumes, you need to do a regular calculation of energy consumption - it is used for any electrical appliances.

For the calculation, you will need the value of the electrical power of the boiler. Its value is indicated in the technical documentation; it is measured in watts (W or W) and kilowatts. Usually they indicate the maximum value of kilowatts consumed by the device - it significantly exceeds the average.

Let's say we have a Baxi Eco Four 24 double-circuit heater, its heating capacity is 24 kW, and its electric capacity is 130 W. To calculate daily electricity consumption, you need to multiply the power consumption by the number of hours during which consumption occurs.

If energy is consumed around the clock: 130 W x 24 hours = 3120 Wh

This is the maximum consumption of the Baxi Eco Four 24 model per day. Dividing the result by 1000, we get 3.12 kWh. To find out how many kWh the device consumes per month - and it is in these units that the consumed electrical power is indicated in payment receipts - you need to multiply the number of kilowatts consumed per day by 30:

3.12 kWh x 30 (days) = 93.6 kWh

This is the maximum value of consumed electrical power. It is clear that to calculate consumption for a year, you need to multiply the result by the number of months in a year during which the device operates.

For single-circuit models, their number is limited by the heating season - about 5. For dual-circuit devices switched to economical summer mode, consumption is calculated taking into account the summer months.

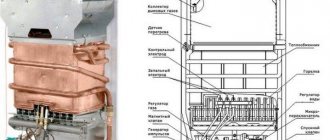

What is electricity used for?

In heating equipment connected to electrical networks, the lion's share of electricity is consumed:

- Circulation pump. It “eats” electricity more than others and consumes energy up to 200 watts per hour. Like any electric motor, the pump requires impeccable voltage parameters. Any non-compliance with the standards leads to a decrease in power indicators - it begins to work noisily and may even break down.

- Protective automation. It consumes little electricity - about 15-30 W. He is afraid of changes in the power supply - because of them, the controller may break, which will cause the equipment to turn off.

- Burners. They are extremely demanding on current characteristics. They require a three-pole connection so that the fire is recognized by the ionization electrode and the burner does not stop operating. Gas burner devices are characterized by a long starting current of the fan - the starting power increases. The fan motor is sensitive to the parameters of the electrical network - even with the smallest deviations from the correct sinusoid, it operates unstable.

Factors affecting electricity consumption

The equipment of a gas boiler with additional devices directly affects the level of energy consumption.

The main costs come from the following components:

- Circulation pump with power from 20 to 150 W. The exact value is determined by the operating mode (constant or switched), as well as the technologies and materials used, such as a magnetic rotor, a carbon fiber impeller, the use of a frequency converter, and an electronic performance control unit.

- Turbine consuming from 10 to 80 W. The exact value is determined by the volume of required gas exchange, the efficiency of the automatic component, the weather, and the boiler power.

- The burner and electric ignition make a small contribution, with the exception of the short moment of starting the boiler, when the power consumption increases to 100 W.

- Automatic control and regulation sensors. Despite the constant operating mode, they make a small contribution to energy consumption - up to 10-15 W.

Technical characteristics

Let's look at the boiler parameters, presented for convenience in table form:

| Characteristics | Meaning |

| Power | 24 kW |

| Heated area | 240 m2 |

| Dimensions | 730 : 400 : 299 mm |

| Weight | 33 kg |

| Power consumption | 10.6 kW |

| Efficiency | 92,9 % |

| Gas consumption | 2.73 m3/h |

| Exhaust temperature | 30-80° |

| DHW temperature | 35-60° |

| Allowable pressure | 19.1 bar |

| Chimney | Coaxial 60/100 mm |

| Power supply | 230 V, 50 Hz |

Is it possible to reduce the electricity consumption of a gas boiler?

The later heating equipment is released, the higher its energy efficiency, even with an expanded set of functions. Otherwise, it is only possible to radically reduce electricity consumption by completely updating the installation.

The following methods are also used:

- reduction of operating time of electrical components;

- saturation of the heating system with control sensors that will maintain the minimum required operating time;

- disabling unused functions;

- replacing obsolete components with new ones that have greater efficiency;

- reducing the number of boiler shutdown and ignition cycles;

- transfer (programming) of equipment to “quiet” operation with a smooth change in the temperature of the medium while installing a heat accumulator;

- controlling the performance of the circulation pump using a set of temperature sensors and room thermostats;

- introduction of remote monitoring and control methods.

The reduction in electricity consumption can be carried out to a certain threshold, after which the system will not be able to maintain a comfortable temperature in the rooms. In this regard, there is no need to abuse savings on relatively small, up to 150-250 W, power consumption.

Measures to reduce electricity costs should be additional, auxiliary in nature.

Initial data

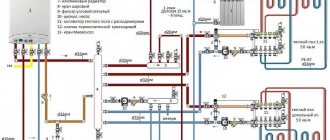

First, a few general notes to help you understand the proposed schemes:

Part of the time the boiler is idle or operates at reduced power. Its rated power is selected to match the peak energy consumption of the house, which occurs on the coldest days of winter. When the thermometer rises, the need for heat decreases;

During the thaw, the home's need for heat decreases.

To reduce non-target heat losses, the boiler heat exchanger is insulated with mineral wool or teplovol (foil insulation based on heat-resistant foamed polymer).

Having heated the water to the desired temperature, the boiler turns off the heating and waits for the coolant to cool.

Why do you need to install a UPS?

When there are interruptions in the electrical network, the well-functioning algorithm for the functioning of heating equipment is disrupted. Operation in emergency mode leads to additional costs, threatens the breakdown of expensive components and even freezes the entire system. To prevent adverse consequences, you should provide electricity from a backup source, such as a UPS.

Criterias of choice

An important factor is the availability of free space. It is more difficult to provide power to a wall-mounted unit in a small kitchen. The easiest way to place a floor-standing unit is in the boiler room.

Selecting a power source for a heating system always begins with determining the required electrical power and the duration of its expected emergency shutdown.

You cannot use UPS designed for computer equipment, since they do not produce the sinusoidal voltage required for analog devices - fans and pumps. Also, these pulse devices are designed to stabilize voltage for a short period of time, while UPS heating systems must provide several hours of operation or more.

Among the latter, the best are devices with double conversion, on-line UPS. Their advantage is the shape of the output voltage, which is as close as possible to a sinusoid.

Charging time

The UPS, in addition to stabilizing the voltage, monitors the fill level of the backup battery. If the design provides for the connection of an external battery, then its capacity should be selected based on the average duration of the emergency shutdown. If the heating system consumes 200 W, then to maintain operation for 5 hours you will need a 12 V battery with a capacity of at least 80 A/h.

For longer outages, it is worth purchasing a gasoline generator. The battery charging time is not critical, since UPSs with on-line operating mode constantly check and maintain the supply of electricity in the battery.

How to choose the most economical model?

Of the three existing models of electric boilers, the most widespread are cathode and heating element boilers. Of these, ionic ones are considered the most economical. Their efficiency reaches 98%, so the use of such models in a two-pipe heating system will give an economic effect of at least 35%, compared to other electrical devices.

Achieving such results is possible not only because of the method of energy transfer, but also because of the entire operating principle of the device. In a heating system that is configured correctly, the cathode apparatus starts working with less than 50% power.

Experts recommend choosing exactly this model of electric boiler for a private home.

Why is a power outage dangerous?

Non-volatile boilers are designed to operate without external power sources. Interruptions are not dangerous for them: the circulation pump in the systems resumes operation of the device when voltage is applied. If there is automatic ignition, the coolant will not freeze.

For complex systems, a power outage results in the inaction of automatic control and safety sensors, a violation of the logic of operation of shut-off and control valves, and water pumps.

The list of potential threats does not end there:

- In boilers with an atmospheric burner, the automatic component does not turn off the gas, the pump does not work, so overheating of the coolant, its boiling, and destruction of boiler components or pipelines are possible.

- If a breakthrough occurs inside the boiler, the flame goes out. The incoming gas has nowhere to go and begins to accumulate in the room, which can lead to a fire or explosion if the device is not regularly supervised.

- In boilers with a closed burner, the likelihood of such a development is less, but it is not completely excluded.

In this regard, before purchasing gas equipment, you should study how design solutions ensure the safety of the device, what happens to the fuel supply in an emergency, how overheating of the coolant in the boiler is prevented, etc.

The best European electric boilers for heating houses of 50, 100 and 150 sq.m.

Europe is known to be a supporter of high-quality, safe, but short-lived devices. A rare product can last more than 10 years. Moreover, often it simply turns off and that’s it - resuscitation will no longer help. But over these 10 years, the quality of work will always remain at its best.

Ferroli ZEWS 9

Wall-mounted boiler designed for forced circulation heating. The device can be connected to a boiler or underfloor heating system.

Ferroli ZEWS 9

Specifications:

| power, kWt | 9 |

| Recommended heating area, sq.m | 100 |

| Heater type | heating element |

| Voltage, V | 380 |

| Power adjustment, kW | multi-stage |

| Dimensions, cm | 44x74x26.5 |

| Weight | 28,6 |

| Coolant temperature, °C | 30-80 |

| Maximum water pressure in the circuit, Bar | 3 |

It can be connected to a single-phase or three-phase network with a maximum current of 41 A for one phase, and 14 A for three. There is a self-diagnosis system - the boiler itself will notify you if something has failed or the condition is critical. Find the error code in the instructions and decide whether to fix it yourself or have it repaired by a professional.

Among the advantages of this model from the Italian manufacturer, it is worth highlighting the presence of a circulation pump in the kit, the ability to connect to a boiler and a heated floor. The full-fledged protection system is captivating:

- from overheating,

- avoiding freezing

- safety valve,

- air vent,

- anti-blocking pump.

The average cost of the device will be 34,500 rubles.

Operating instructions Ferroli ZEWS 9

Protherm Skat 18 KR 13

Single-circuit electric boiler, which is able to provide heat to a room measuring 180 square meters. meters. The heat exchanger is made of stainless steel; a boiler can be connected to the device.

Protherm Skat 18 KR 13

Specifications:

| power, kWt | 18 |

| Recommended heating area, sq.m | 200 |

| Heater type | heating element |

| Voltage, V | 380 |

| Power adjustment, kW | multi-stage |

| Dimensions, cm | 41x74x31 |

| Weight | 34 |

| Coolant temperature, °C | 30-80 |

| Maximum water pressure in the circuit, Bar | 3 |

Connection to a three-phase network with a maximum current of 32 A. There is a self-diagnosis system - the boiler itself will notify you if anything has failed or the condition is critical. The instructions explain the error codes.

The kit includes a circulation pump and an expansion tank. It is possible to connect to a boiler and heated floor.

The Protherm Skat 18 KR 13 model is distinguished by simple and convenient controls; when using room regulators, the process will become even simpler. Built-in automation guarantees protection against overheating of the coolant and excess pressure in the boiler. The main advantage of the device is economical energy consumption, frost protection and the possibility of self-diagnosis.

The average cost of the model is 39,900 rubles.

Operating instructions for Protherm Skat 18 KR 13

Too lazy to read? Then watch!

If you want to make your country house warm and cozy... or heat any other object... You can leave a request for a consultation

PS For Moscow and Moscow Region, Kaluga region, Tula region, Ryazan region, Vladimir region, Yaroslavl region, Tver region, Smolensk region

SKGAZ Company was with you

Thumbs up and subscription is invaluable support for our work.

You can SUBSCRIBE to our Telegram channel

If the article was useful, be sure to share it.

Leave your opinion in the comments!

Real gas consumption: reviews from gas tank owners

We have selected examples of using autonomous heating on the ForumHouse forum. Owners have different experiences. In the project, the insulation of the house, the climate, the needs of the residents and the quality of the boiler are important.

Case 1. The user actively spends LPG - permanent residence with regular showers. A 2,300 liter refill lasts for almost 2 years at a room temperature of at least 21°C. Costs are reduced by using the fireplace 6 times a month - 3 hours of burning and 9 hours of smoldering.

Accessories for temperature control

The latest self-diagnosis system, with errors displayed on the LCD display, allows for precise adjustment of the boiler’s thermal processes.

An electronic chip using primary sensors will analyze the condition of the boiler for compliance with the established temperature conditions and adjust the operation.

The electronic system is able to remember the latest failures. The temperature regime in the house and the heating level of the hot water supply can be set directly on the remote control unit.

Outdoor temperature sensor

When an outside temperature sensor is connected to the unit, the weather-compensating automation integrated into the electronic board of the device is activated.

The boiler will independently regulate the temperature in the supply pipe according to the specified control schedule. In this option, the internal thermal regime will correspond to maximum comfort and efficiency, since real atmospheric conditions will be taken into account.

The outdoor temperature sensor modifies the temperature regime of the supply coolant in the heating system in accordance with the outside air temperature outside. The device is designed to maintain a constant sanitary regime in the house.

The group use of external and internal air temperature sensors in the electronic control board implements self-adaptation of the equipment. In this way, the temperature relationship adjustment curve will be calculated automatically.

Room programmable thermostat

Such a thermostat is designed to guarantee a stable temperature in the house. It operates on the principle of turning off the equipment when the required ambient temperature is reached and turning on when it drops. Thus, a simple and safe means of regulating climatic conditions in the house is implemented.

The simplest adjustment system can save up to 15% of gas fuel used for heating needs. This is achieved by maintaining the temperature conditions more accurately and reducing the number of unit turns on/off.

The use of such devices is mandatory according to EU requirements and domestic standards for the operation of gas equipment.

What electrical requirements should you pay attention to?

Before connecting the electric boiler, you need to pay attention to the electrical requirements

- How many watts of voltage can your home's current network handle? In particular, the voltage in rural areas is not 210-230 V, but only 150-180 V. Specific types of imported boilers at this voltage may simply not start.

- What power is allocated to your series of houses or to the village in which you live. For example, if your dacha community includes 60 houses, and electricity is allocated at the rate of 5 kW per house, then in the process of installing a boiler with a power of 30 kW you will certainly have disagreements with your neighbors. How much power is allocated to your home? Modern dacha communities very often install a 10-12 kW automatic machine in order to avoid quarrels with their neighbors.

- It is worth checking the current condition of the transformer installed in your village. In some cases, it is necessary to pull certain wires for.

- Find out what powerful electrical appliances your neighbors have installed and whether their total power will drop below that allocated for the house.

If all requirements are met, you can either use a convector. The energy consumption to ensure heating of 1 m3 of volume is used by an electric boiler and a convector approximately equal.

The simplest calculation of planned costs

Theoretical background

Electricity, the only one of its kind, is capable of providing 100% efficiency when converted into a thermal component. This indicator remains stable for the entire period of equipment operation.

It is not difficult to find out how much electricity an electric boiler consumes if you are guided by generally accepted data:

- In order to heat a unit volume of a building with a heat generator, an average of 4-8 Wh of electrical energy will be required. The specific figure depends on the result of calculations of heat losses of the entire structure and their specific value for the heating season. They are performed using a coefficient that takes into account additional losses through parts of the walls of the house, through pipelines passing in unheated rooms.

- When making calculations, the duration of the heating season is 7 months.

- When determining the average power indicator, we are guided by the rule: to heat 10 square meters. areas with well-insulated structures, up to 3 meters in height, 1 kW is sufficient. Then, for example, to warm up a house 180 sq. m. A boiler power of 18 kW is sufficient. It should be remembered that a lack of “capacity” will not allow achieving the required microclimate parameters, and their excess will lead to unnecessary waste of energy.

- Calculation of the monthly heat value of an average building will be the product of the boiler power and the number of hours of its operation per day (with continuous operation).

- The resulting value is divided in half, taking into account that at a constant maximum load the boiler will not work for all 7 months: thaw periods are excluded, heating decreases at night, etc. The result obtained is considered the average indicator of energy consumption for the month.

- Multiplying it by the time of the heating season (7 months), we get the total energy consumption for the heating year.

Based on the cost of one unit of power, the total needs for heating the house are calculated.

A clear graphic example of the operation of an electric boiler: the dependence of electricity consumption on the temperature outside the window

Using the Power Formula

In a simplified version, the thermotechnical calculation of power can be performed using the formula:

W = S x W beats /10 sq. m.

From the equation it is clear that the desired value is the product of the specific power per 10 m2. and the area of the heated room.

Liquefied gas consumption per month and year

Let's go over the costs of refilling a gas tank for houses of different sizes. We use the LPG price current at the beginning of 2022 - 17.80 rubles/l. This is the cost of refueling in our company.

House area (m2)

Gas consumption per month (l)

Gas price per month (RUB)

Gas consumption per year (l)

Gas price per year (RUB)

gas consumption for heating a house of 100 m2 - 68 thousand rubles per year;

gas consumption for heating a house of 150 m2 - 101 thousand rubles per year;

gas consumption for heating a house of 200 m2 is 136 thousand rubles per year.