Beretta gas boilers have proven themselves as a source of thermal energy in autonomous heating systems. The units are equipped with a self-monitoring function for the processes occurring in units and parts during boiler operation. Equipment malfunctions can be identified by light signals.

We will analyze the typical malfunctions of the Beretta gas boiler and their elimination. Let's consider in what cases it will be possible to solve the problem on our own. Let's find out when you will have to call a gas service technician for repair operations.

We will talk about how to identify an error in the operation of the equipment, about which it independently warns the owner. We'll tell you what the combinations of letters and numbers that appear in the event of a problem with the built-in display or indicators mean. With this information, you can decide how best to proceed.

Common failures of Beretta boilers

According to gas technicians involved in the repair and adjustment of Beretta gas boilers, there are several main malfunctions that most often occur in equipment of this brand:

- There is no flame on the burner, resulting in the equipment being blocked. This problem can be caused by several reasons, ranging from a blockage to a lack of gas supply.

- Control board failure. Occurs due to the accumulation of condensation on the board, which leads to its failure. Also, board failure can occur due to burnout of parts on it.

- Increased flue gas pressure. Such a failure can be caused by ice in the chimney of a gas boiler, clogging with soot, or increased wind force. As a result, the operation of the equipment is blocked.

- Self-diagnosis sensor failure. It also causes the control system to shut down the equipment.

- Low water pressure when supplied to the heating circuit. The most common cause is a leak or problem with the expansion tank.

Statistics collected by experts do not mean that exactly such problems will occur in every Beretta boiler.

It is possible that problems will not appear at all for a long time, or completely different failures will occur for other reasons. Each problem or failure in Beretta gas boilers has its own code, which is displayed by the control system on the LCD display.

It is necessary to pay attention to failures and malfunctions during the operation of the Beretta gas boiler and correct them in a timely manner in order to avoid more serious breakdowns

Fault detection occurs thanks to a self-diagnosis system, which allows you to instantly identify problems when they arise and take appropriate measures.

Repair the board or replace it with a new one?

The electronic board of any boiler is an expensive device and replacing it with a new one in case of any malfunction is not advisable, especially since Beretta boards do not have the most complex circuit diagram.

We offer our clients board repair because it is, first of all, profitable, since the cost in most cases does not exceed 30% of the price of a new board. To carry out repairs, we have professional equipment, diagrams, original spare parts and experience.

To carry out diagnostics, special stands have been organized that simulate a real unit, on which the boards are checked after repair.

We don’t just repair boards, but we provide a significant warranty period for the work, because we have already repaired more than one such board and are confident in the result.

How does the self-diagnosis system work?

In Beretta boilers, the self-diagnosis system consists of a network of monitoring sensors located on the main working units of the units.

After turning on the boiler, the sensors begin to function in continuous mode; they do not require an additional special start. Using the same principle, it is impossible to disable the sensors without stopping or blocking the gas boiler.

All main components of the Beretta gas boiler contain sensors that send signals to the display with an error code when problems are detected

When the monitored parameters change or the operation of a particular unit is disrupted, signals from the sensors are sent to the control module, which blocks the equipment. At the same time, an error code is displayed on the display, allowing the boiler owner to determine the type of problem and take measures to eliminate it.

In addition to the display, malfunctions in Beretta boilers are signaled by special indicators located depending on the design features of different models of heating equipment.

#7 2017-01-15 21:31:53

- Answers: 1 Profile

- All messages

- Reputation 0

Re: Beretta 2012 boiler - error AO1

SOS. I have a Beretta City 24 CSI boiler. The boiler only works for 2 months. After calling the master, the board burned out - the board was replaced. But . The boiler stopped maintaining the temperature - it is always in the “swing” mode. The temperature reaches the set 55 and immediately drops to 30 degrees, freezes for 2-3 minutes and starts all over again. The batteries do not have time to heat up. What could be the reason?

Error codes on the boiler display

The LCD display, which is equipped with almost all models of Beretta gas boilers, displays information about the operating mode of the equipment, as well as error codes and malfunctions that arise during operation.

Most failures are resolved by rebooting the boiler. But if the problem does not disappear after rebooting, you need to check the parts and components listed below.

The LCD display is located on the control panel of the Beretta gas boiler; in case of failures and malfunctions, error codes are displayed on it, which can be used to determine which unit of the unit has problems

We tried to collect the most complete list of errors.

A01 - there is no flame on the burner, 5 unsuccessful attempts to ignite.

Check:

- presence of gas in the pipeline;

- boiler shut-off valve position;

- adjust the gas valve;

- clean the burner with nozzles;

- ignition electrode, if necessary, clean the contacts;

- ignition relay;

- change the slave board.

A02 - thermostat overheating.

Check:

- thermostat, integrity of wiring to it;

- clean or replace the circulation pump;

- If the pressure in the circuit is low, add fluid.

A03 - violation of smoke removal.

Check:

- presence of traction;

- clean the chimney of the gas boiler, if necessary, chip off the ice at the outlet;

- clean or replace the fan, check the contacts;

- smoke sensor and its contacts.

A04 - decrease in water pressure in the system.

Check:

- presence of leaks;

- pressure sensor, its contacts;

- circulation pump;

- presence of blockages in the system;

- change the slave board.

A05 - failure of the NTC hot water supply temperature sensor.

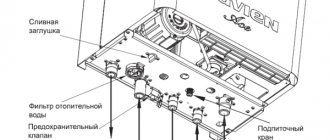

In order to better understand the reason for the malfunction of the Beretta brand gas boiler, it is advisable to familiarize yourself with the design features of the unit. The device diagram must be in the technical passport

Check:

- NTC sensor, its connections, replace the part if necessary;

- change the slave board.

A06 - failure of the NTC heating temperature sensor.

Check:

- NTC sensor, its connections, replace if necessary;

- change the slave board.

A07 - the thermal relay does not open.

Check:

- change the slave board.

A08-A10 - internal error of the slave board.

Check:

- change the slave board.

A11 - flame simulation (fire on a switched off burner).

Check:

- press Reset, reboot;

- contact service specialists.

A12, A15 - errors on the slave board.

Check:

- change the slave board.

A16, A18 - errors on the main board.

Check:

- replace the main board.

A20 - fire remains after closing the gas valve.

Check:

- gas valve, replace if necessary.

A24 - fan malfunction.

Check:

- fan connection, its contacts;

- if damaged, replace the fan.

ADJ - failure in min and max power settings.

Check:

- configure the necessary parameters.

E02 - NTC1 sensor is not connected.

Check:

- NTC1 sensor and its connections, replace if necessary.

E04 - NTC3 sensor is not connected.

Check:

- NTC3 sensor, its connections, replace if necessary.

E18 - short circuit of NTC1 sensor.

Check:

- NTC1 sensor connector;

- replace the part.

E20 - short circuit of NTC3 sensor.

Check:

- NTC3 sensor connector;

- replace the part.

E23-E26 - errors on the main board.

Check:

- replace the main board.

E32 - no slave (SALVE).

Check:

- position of two-pole switches on individual units, bring them to the ON state.

E33 - phase and neutral are incorrectly connected.

Check:

- reconnect in the correct order.

E34 - Reset button error when pressed more than 7 times within 30 minutes.

Check:

- wait 40 minutes for the error to disappear;

- replace the slave board.

E35 - pressure switch failure.

Check:

- check the water flow in each circuit, bring it to the norm of 2 m3/h;

- replace with a new part with a setting of 500 l/h.

E36 - error on the slave board.

Check:

- change the slave board.

E37 - failure when fire is detected.

Check:

- clean or replace electrodes.

E38 - smoke sensor short circuit.

Check:

- replace element.

E39 - no contact with the smoke sensor.

Check:

- smoke sensor connector;

- replace the part.

E40 - 50 Hz error.

Check:

- frequency in the electrical line;

- connect a voltage stabilizer.

E41 - error on the slave board.

Check:

- change the slave board.

E42 - short circuit of the sensor on the supply pipe.

Check:

- sensor connector on the supply pipe;

- replace the part.

E43 - no contact with the sensor on the supply pipe.

Check:

- sensor connector on the supply pipe;

- replace the part.

E44 - short circuit of the sensor on the return pipe.

Check:

- sensor connector on the return pipe;

- replace the part.

E45 - no contact with the sensor on the return pipe.

Check:

- sensor connector on the return pipe;

- replace the part.

E46 - overheating of the sensor on the supply pipe.

Check:

- measure the water flow in each circuit;

- bring the flow rate to the norm of 2m3.

E47 - overheating of the sensor on the return pipe.

Check:

- measure the water flow in each circuit;

- bring the flow rate to the norm of 2m3.

E48 - smoke sensor overheating.

Check:

- measure the water flow in each circuit;

- clean the heat exchangers on both sides.

Sometimes situations occur when errors are not shown on the display of a Beretta gas boiler, but other signs of equipment malfunctions appear.

Such signs include the appearance of gas or burning odors in the room with the boiler, delayed operation of the boiler burner, as well as a noticeable difference between the heating of the boiler and the temperature of the batteries. These manifestations of problems should be treated with no less attention than the codes on the display.

#12 2018-08-19 00:15:43

- Replies: 2539 Profile

- All messages

- Reputation 5

Re: Beretta 2012 boiler - error AO1

bsman writes:

A01 does not appear constantly, but periodically . Is this the problem with the board? Is it possible to repair it? There is a stabilizer.

Repairing the board is possible, but in order to find out whether the board is at fault or not, you need to know whether the fault can be cleared and at what point in the operation process the fault occurs. It happens that the pressure switch is to blame, and sometimes there is not enough gas in the line.

What do the indicator signals mean?

In some models of Beretta gas boilers, for example Beretta City, the occurrence of malfunctions in the operation of the units can be judged by the signals of the red, yellow and green indicators.

The indicators are two or three light diodes located on the central panel, which begin to blink with different intensities when a particular failure occurs.

In some models of Beretta gas boilers, signals about errors and malfunctions are provided by light indicators located on the control panel

A blinking green indicator may mean the following:

- 1 time/3.5 sec - the equipment is switched to standby mode, the fire is extinguished;

- 1 time/0.5 sec - the boiler is stopped due to a breakdown;

- 1 time/0.1 sec - the unit is switched to the auto-regulation system;

- the indicator is on and does not blink - the boiler is working normally, the fire is burning.

Beretta City can stop on its own due to a breakdown if it receives a signal from pressure and smoke sensors.

The boiler may pause operation for 10 minutes, during which the correct parameters must be restored. During this time, the system will automatically scan. A detailed guide on how to check the sensor readings of a Beretta gas boiler should already be included in the self-diagnosis system.

The indicators on the Beretta boiler panel can produce signals in different combinations and with different intensities. The type of light signal depends on what error occurred during the operation of the unit

The red indicator turns on in the following cases:

- the indicator is on and does not blink - if after stopping the boiler operation is not established, the unit goes into emergency mode;

- the indicator is flashing - the limit temperature sensor is triggered. Sometimes you can eliminate the error using the operating mode switch.

Simultaneous flashing of the red and green diodes occurs in the event of a breakdown of the NTC sensor.

The yellow indicator lights up and stays lit when preheating of the coolant in the circuit is turned on.

If you are not confident in your abilities and knowledge, it is strongly recommended to invite a qualified specialist to repair your Beretta gas boiler

To eliminate all the above-described problems with Beretta gas boilers, it is strongly recommended to use the services of specialists from authorized service centers and organizations with which an agreement has been concluded for the maintenance of gas units and the supply of blue fuel.

Independent intervention in the complex design of boilers can lead to an even more serious breakdown, which will result in expensive repairs and a long shutdown of the autonomous heating system.

Beretta CIAO 24 CSI

The Beretta brand is the property of one of the leaders in the European heating industry - the Italian company Riello, which is approaching its 100th anniversary.

Beretta boilers are manufactured using modern technologies and fully comply with European requirements for safety, economy and efficiency. The CIAO 24 CSI model is manufactured in accordance with the most advanced technical developments and is capable of meeting the needs of a modern residential building.

The units are manufactured in a wall-mounted design, have a compact and visually attractive body, which allows them to be installed directly in the kitchen and without having to allocate a separate room for the boiler room.

NOTE!

The successful combination of price and quality of the Beretta CIAO 24 CSI model is highly appreciated by specialists and users, which confirms the steady demand and relevance.

#13 2018-08-19 08:37:47

- Answers: 3 Profile

- All messages

- Reputation 0

Re: Beretta 2012 boiler - error AO1

The alarm is cleared when switched to off mode and back to DHW. An accident occurs when you turn on hot water, just turn on any faucet in the house to hot and A01, but not every time after 3-5 times. The alarm is cleared when switched to off mode and back to DHW. Yesterday the A01 alarm popped up 2-3 times in a row. I barely ran hot water. When I turned it on, the hot water runs normally and takes a long time to fully heat up. But it turns out to be a lottery to launch) Maybe take off the lid and look at something else? What to look for?

#15 2018-08-25 10:17:47

- Answers: 3 Profile

- All messages

- Reputation 0

Re: Beretta 2012 boiler - error AO1

There was a master who installed the boiler. Since the boiler had been working for 5 years, I blew out and washed everything that could be blown out and washed. I was sure that the pressure sensor was to blame. We replaced the boiler, turned on the water three times, heating approx. At 4 again A01)) further suspicions about the board and stabilizer. We have a private sector, an old area, power surges due to 2 home service stations nearby. I agreed with the master that I would buy a voltage relay and install it to check the output stabilizer to see if it is allowing surges. I checked the stabilizer and it gives 210-225V during surges. The cut-off relay may work 1-2 times a day. But the error pops up more often. I even tried trying on a different stabilizer, but the error keeps popping up every once or twice. So the problem is with the board? Should I change the relay on the board? The boiler starts up, hums, all stages go until ignition and the boiler should start flaming when an error pops up. A couple of times it has already happened that it didn’t get to ignition: it’s humming (the fan and the pump probably) but the error doesn’t pop up, the water goes on and on, the temperature drops down because the heating didn’t start. Could it be something with the lighter?