Placing a gas boiler in a house is not an easy task. There are serious requirements that can disrupt a home owner's plans. After all, in order to put a gas boiler into operation, it is necessary to obtain permits. It is prohibited to use it without them. Unauthorized switching on of the heating unit will lead to large fines. The thing is that a gas boiler is a fire hazardous equipment.

Basic regulatory requirements for placement

Placing gas boilers in a private home is a serious matter. There are strict regulatory requirements that must be complied with without fail.

Here are some of them related to accommodation in a private house:

- The boiler must not be installed close to the wall. This also applies to wall-mounted models, which are equipped with special factory fasteners and canopies. Structurally, they are made so that there is a gap between the equipment and the wall of the house. You cannot use homemade fasteners.

- All boilers with an open combustion chamber must be equipped with a chimney, the installation of which has its own requirements. First of all, it should be as vertical as possible. Minor deviations are permitted. If the need arises, horizontal sections with a total length of 3 m can also be used. Bends are also not prohibited, but their number should not exceed 3 pieces.

- The diameter of the chimney must correspond to the diameter of the outlet pipe of the gas boiler.

- If volatile equipment is used, then it is necessary to strictly follow the grounding installation rules. They are usually indicated by the manufacturer in the instructions.

- A gas analyzer is a necessary element for the safe operation of a gas boiler. It is triggered when the amount of gas in the room increases in the form of a leak. When it is triggered, the gas supply to the boiler firebox is turned off using a shut-off valve. The latter receives a signal from the gas analyzer.

- Installation of a gas meter in front of the equipment is a prerequisite.

Requirements for obtaining permission to place a gas boiler and for the equipment acceptance certificate:

- You need to obtain technical specifications from the Raygas department. They give the owner of the house the right to begin installation work, place and install gas equipment. Therefore, you need to submit an application to Raigaz and support it with documents for the house and the right to own it.

- Gas workers give a response within 30 days. During this period, technical conditions must be prepared that will specify the daily gas consumption. If the owner of the house was refused, then Raigaz must indicate the reasons. You can appeal the refusal or correct the shortcomings and resubmit the application.

- After receiving the technical conditions, a project is created, which indicates the route of the gas pipeline, the location of the boiler, the connection point, etc. The project can only be produced by a specialized design bureau.

- The finished project is being agreed upon with the gas industry. The law allows up to 90 days for this.

- If the documentation is agreed upon, you can proceed to installation work.

- After completion of the work, the Raigas engineer must check compliance with the project, seal the gas meter and write an acceptance certificate in which he signs.

- After this, you can open the tap and use gas.

Floor-standing

In order to save money, the owners themselves are trying to figure out how to install a floor-standing gas heating boiler in a one-story wooden house. Basic requirements include the following points:

- Strengthening the place where the boiler will be located. It is best to make a screed or carefully lay concrete slabs.

- A gap of at least 15 cm is left between the boiler and the wall surface.

- If the base of the house is not fireproof, then additional cladding with metal sheets is necessary. It is best to insulate the walls with roofing steel, which is laid on an asbestos sheet at least 30 mm wide.

- Using a building level, the condition of the floor is assessed, since the surface under the boiler must be perfectly flat.

- Connecting the chimney is prohibited without first checking the draft.

- Filters are installed that do not trap debris at the entrance to the heat exchanger.

- At the final stage, the prepared double-circuit boiler is connected to the water pipes.

The video provides up-to-date information about installing the boiler:

Required documents

To obtain technical conditions, the following documents must be attached to the application:

- passport of the gas boiler, which comes with it in packaging from the manufacturer;

- installation and operating instructions;

- quality certificate;

- a certificate stating that the boiler complies with the standards and requirements put forward by the state in relation to gas equipment.

For private houses, Raigas often offer to issue a technical certificate for the premises where the boiler will be placed. This document records the purpose of the room. That is, it is now either a boiler room or a furnace room. Separate buildings fit the definition of the first. For the second, premises built into the house or attached to it.

Is it possible to install it yourself?

You can install a wall-mounted gas boiler with the simplest modifications with your own hands. Such, for example, as single-circuit devices with an open combustion chamber.

To install them, you will need to connect the heating system, supply gas and organize a chimney. However, some boiler manufacturers indicate in the technical documentation for their products that installation should only be carried out by specialists.

Installing and connecting a gas boiler is a responsible and quite complicated job. Many heating equipment manufacturers require that this be done by professionals.

In this case, independent installation of even the simplest models is prohibited. Thus, if you plan to install the equipment yourself, you should make sure that the manufacturer allows this before purchasing it.

Checking the correct installation and connecting the device to the gas main should only be carried out by a specialist with special permission.

In addition, the gas service representative must issue a permit to operate the installed equipment. Without this, the owner of a self-installed and running device will face serious fines.

Thus, without inviting specialists, you can only connect the device to the heating system and to the water supply. Moreover, it is advisable to do this only if you have some experience.

Wall-mounted gas boilers are installed in autonomous forced-type heating circuits with natural coolant circulation

Place and characteristics of the premises for accommodation

The requirements are strictly checked by representatives of Raigaz:

- A gas boiler for heating must be placed in a specially designated room. It can be located anywhere in the building: attic, basement, utility room, extension.

- It is prohibited to construct suspended ceilings and false floors in the boiler room. The reason is to avoid creating voids where gas can accumulate.

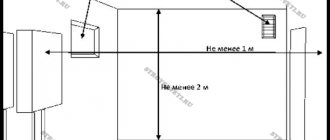

- The volume of the room is at least 8 m³, its area is at least 4 m², and the ceiling height is at least 2.5 m.

- A window in a boiler room is a mandatory attribute. Its size is 0.5 m². If the volume of the room is more than 15 m³, then the window area increases by 0.03 m³, taking into account each added cubic meter to the volume of the room.

- The width of the entrance door to the boiler room is 0.8 m. There should be a gap of 2.5 cm below between the door leaf and the floor.

- The boiler room must be built and finished only with fire-resistant materials.

All these rules for placing a gas boiler in a private house are necessary to ensure air exchange in the boiler room, which is equal to three times the volume of the room. The fire safety of the facility is also taken into account.

If a gas boiler with a closed combustion chamber is placed in the house, then some of the above requirements for the equipment do not apply. This mainly concerns the volume of air exchange and the room itself. Indeed, in units of this type, air is supplied using a fan directly from the street.

The principle of operation of a wall-mounted gas boiler

The installation and connection of the heating device depends on its type. Therefore, you need to understand exactly how the device works and which of its varieties you will be dealing with.

Any wall-mounted gas boiler is a compact device, the maximum power of which is limited to 42 kW.

Wall-mounted gas boilers are powerful compact devices that provide the room with heat and hot water

The main elements of the system include:

- Gas burner . It supplies gas to the chamber where the combustion process occurs. With the help of nozzles, fuel is distributed as evenly as possible. Modern modulated burners can maintain a given temperature and regulate the flame strength.

- Heat exchanger through which the coolant moves. The best efficiency is for a copper device. In condensing boilers there may be two such elements.

- Expansion tank . Designed to compensate for excess water resulting from heating.

- Circulation pump . Powerful models may have two such elements.

- Boiler automation or a system of devices whose task is to maintain a set temperature in a heated room. May include devices powered by electricity or non-volatile.

- Devices that control and regulate the operation of the boiler.

- Fan . Only used in turbocharged models.

- Security system . Stops the boiler operation when dangerous situations occur.

Modern models are additionally equipped with self-diagnosis systems that can detect about 90% of boiler faults. The display shows the number of the diagnosed breakdown, which is promptly corrected by a service technician.

The figure shows a diagram of a double-circuit wall-mounted gas boiler with a closed combustion chamber

Chimneys and ventilation

Properly installed ventilation is the key to the boiler room being accepted into operation. The question of whether a window in a boiler room is sufficient or whether the placement of a hood is necessary worries many. It should be noted that it is better to install a hood.

Fire safety rules and regulations change every year. All the time, some additions are being made that will have to be implemented anyway, sooner or later.

Therefore, it is recommended to install an exhaust device opposite the gas boiler, closer to the ceiling. This can be regular natural ventilation or forced. The main thing is to accurately match the size of the hood with the power of the gas boiler for the home. Here the ratio is: for every 1 kW of power there is 8 cm² of exhaust vent.

The requirements for the placement and location of the chimney were discussed above. If the flue pipe passes through the ceilings, then a fire-retardant coupling must be installed in the passage section. For example, this could be a tunnel through the ceiling through which a chimney passes, filled with fire-resistant material: expanded clay, asbestos, etc. It is important here that the pipe does not touch the flammable material of the house floor.

Technical requirements for equipment

There are no special requirements for the gas equipment itself. If the boiler has a quality certificate, then you can safely install it in the house. Sometimes representatives of Raygaz may make claims regarding certain characteristics. For example, to power. For small private houses, a boiler with a capacity of 30 kW is the maximum permissible limit. There is no point in installing more than this.

About the gas duct

The cross-sectional area of the house flue for it depends on the required boiler power (see below). At any power, the diameter of the flue must be at least 110 mm and not less than the diameter of the exhaust pipe. The dependence of the flue diameter on the boiler power is as follows:

- up to 24 kW – 120 mm.

- 30 kW – 130 mm.

- 40 kW – 170 mm.

- 60 kW – 190 mm

- 80 kW – 220 mm.

- 100 kW – 230 mm.

Installation features

If this is a wall-mounted option, then only on factory mounting structures. If it is a floor model, then on a solid base: level, without flaws. This can be a pure concrete floor or covered with a fire retardant durable finish such as ceramic tiles.

The gas pipe is only steel. It is connected to the boiler through a flexible metal insert. But here you need to choose a corrugated hose designed specifically for gas, and not for water.

Piping the heating system, as well as connecting to the water supply network, can be made from different types of pipes, where polypropylene is the priority today.

The temperature in the boiler room, both during installation of equipment and during its operation, should not fall below 0º.

If the unit is volatile, then an outlet should be placed near it.

Dual-circuit

In order to correctly install a powerful gas factory boiler with two circuits in a classic private country house, you need to take into account several nuances. With the traditional connection scheme of a double-circuit unit, one heat exchanger heats the coolant fluid inside the system, and the second provides consumers with hot water. These resemble an autonomous high-tech boiler room.

Compact gas boiler

Boiler room preparation

First, work is carried out to improve the furnace room, radiators are attached, water supply and heated floors are installed. Before fixing the main unit, electricity and sewer pipes are installed. Heating is installed after laying a solid floor based on cement screed. The walls, floor and ceiling are finished with fireproof materials.

Installation of high-quality heating devices involves the installation of auxiliary equipment. It is necessary to use the boiler diagram to provide for all the nuances of the arrangement. The locations of the mounting holes are marked on the wall and floor, and all missing elements are installed. The heating boiler is installed last.

Correctly connected boiler in the living room

Commissioning

When the location of the boiler is chosen correctly and all parts are in place, you can perform a test run of the installation. For units with a closed firebox, all wires are connected to the electrical network. For this you need a stabilizer. Then the system is filled with coolant.

This must be done slowly in order to have time to displace unnecessary air from the pipes. The liquid is pumped until the pressure reaches 2 atmospheres. After this, you no longer need to install any parts, since it is necessary to inspect the quality of all connections. It is best to coat the joints with soapy water. If no bubbles appear and everything is done hermetically, then you can start the system.

A lot of interesting information on this topic is presented in the video:

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...