About the manufacturer

Since 2006, Keber gas boilers have been produced by the domestic company, which is part of the Tactical Missile Arms OJSC corporation. These heating devices are well adapted to Russian operating conditions; they operate smoothly even in places characterized by very low temperatures.

If necessary, such heating devices can be used for heating premises in the Far North.

Keber's product range includes both household and industrial models.

Single-circuit and double-circuit units are distinguished. The first are used exclusively for heating, while others provide the room not only with heat, but also with hot water.

Let's move on to cleaning the column

Turn off the gas supply valve to the boiler. Using wrench No. 10, unscrew the fastening screw under the boiler door and remove the door.

Disconnect the wire connecting the piezoelectric element and the ignition electrode.

Using key No. 10, unscrew the thermocouple clamp. Using wrench No. 9, unscrew the thermocouple from the valve.

Note:

It is necessary to ensure that the thermocouple does not turn while unscrewing.

We note the depth of insertion of the nozzle into the main burner so as not to disturb the boiler settings.

Using wrench No. 17, unscrew the nut securing the copper tube from the burner to the valve. Using wrench No. 10, unscrew the ignition electrode from the pilot burner and the copper tube from the pilot burner and valve. Using a flat-head screwdriver, unscrew the two screws securing the pilot burner.

The gasket installed under the pilot burner has become unusable. It will need to be replaced.

Remove the nozzle from the pilot burner.

Tip: if the nozzle is stuck, you can lightly tap the burner with a key.

We unscrew the four screws securing the main burner to the boiler body and the screw securing the housing to be able to remove the main burner.

Lowering the main burner down, remove the copper tube from the valve.

Remove the main burner.

Remove the thermometer sleeve from the boiler body.

Using wrench No. 10, unscrew the four screws securing the top cover of the boiler and remove it and the insulation sheet under it.

Unscrew the two nuts securing the flue to the boiler body.

Remove the terminals from the draft sensor.

We remove the gas duct.

We remove the swirlers from the boiler heat exchanger. We clean them with a brush. If necessary, use a metal brush.

Clean the outer part of the heat exchanger with a metal brush. We clean the heat exchanger channels with a brush to the full depth. Clean the bottom of the heat exchanger with a brush. We also clean the gap between the boiler body and the floor. We clean the loose debris using a vacuum cleaner.

Using wrench No. 13, loosen the screw that fixes the depth of insertion of the nozzle into the main burner and remove it.

We clean the burner with a brush and a brush, and clean its holes with a vacuum cleaner. We clean the flue of dust from the outside and inside.

We clean the outer surface of the nozzle with a brush, then clean the nozzle holes with a needle or wire.

Note: The needle should be smaller in diameter than the nozzle hole. Even a slight increase in the diameter of the nozzle hole can affect the combustion mode.

We install the main burner in place.

We install a copper tube with a nozzle and attach its nut to the gas valve.

Only after this do we secure the nozzle to the burner at the mark using wrench No. 13.

Note:

This sequence is necessary in order not to strip the threads in the valve body.

Finally tighten the nut of the copper tube with wrench No. 17.

Clean the pilot burner with a metal brush.

This is how the thermocouple should be installed in the pilot burner (the tip of the thermocouple opposite the flame).

We install the pilot burner on a new gasket.

Before installing the nozzle into the pilot burner, it must be slightly rubbed against the tip of the copper tube for better sealing. The nozzle should also be cleaned or purged.

We connect the copper tube to the pilot burner and to the valve using a number 10 wrench.

The remaining parts of the boiler are assembled in the reverse order. When connecting, the ignition electrode should not be clamped with a key; it is enough to do it by hand, since it is made of ceramic and can easily crack.

We carry out control washing of all compounds. It will be possible to check the tightness of the connections of the copper tubes to the main and pilot burners only when the boiler is turned on.

Technical characteristics and device

Keber boilers are distinguished by their reliable assembly and long service life. The manufacturer provides a 15-year warranty. Also, units of this brand are characterized by high efficiency.

Keber gas boilers are equipped with gas burners, which ensure:

- stable heating of the coolant;

- maximum complete combustion of fuel.

In addition, these elements are distinguished by high anti-corrosion properties.

Due to the fact that Keber boilers have gas burners, the size of their fuel chambers is smaller than that of similar heating devices produced by other manufacturers. Thanks to the special design of the Danko automation, fuel burns as efficiently as possible, even if the flame height reaches 7 cm.

The Danko nozzle is a certified design, which is in no way inferior in quality to its European counterparts.

Also included in the package is the Arbat automatic system, which is responsible for regulating the operation of heating equipment and its safety. There are five levels of protection. If the pressure in the water or gas supply system decreases, the unit will turn off automatically. The design of the automation is simple, which has a positive effect on its reliability, and in case of problems, repairs will be simple.

It is worth saying that, if desired, users can order from the boiler manufacturer Keber a model with a more expensive, but at the same time more reliable and high-quality Italian Eurosit automation. Such units can operate practically without third-party intervention.

You can read about the types of automation for gas boilers here.

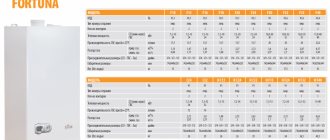

The assortment of the company that produces Keber boilers includes a wide selection of models of different powers: 10, 12.5, 16, 20 kW, etc.

Let's look at the technical characteristics of the device using the example of the Keber 12.5 floor-standing model:

- type of execution - floor-standing;

- combustion chamber - open;

- power - 12.5 kW;

- Efficiency - from 85%;

- mechanical control;

- gas consumption - 1.62 m³;

- weight - 39 kg;

- heated area - 125²;

- The maximum water pressure in the heating system is 3 bar.

Gas non-volatile boiler KS-G Keber 12.5 with EUROSIT automation

Peculiarities

The ATEM brand has invested all its efforts in the development and production of high-quality devices for autonomous heating. For more than 27 years, the company has been providing heat to its consumers in the form of Zhytomyr gas boilers. Since the introduction of the first boiler, a huge rebranding has been carried out, the device has received changes from the internal base of spare parts to the external design. Today, the Zhitomir boiler is a neat, small-sized unit with switching instructions that even a child can handle. The main quality inherent in boilers of this brand is the quality and reliability of the device. Product specifications have also changed as new technologies emerge. Not only these components, but also many other facts allowed the ATEM brand to receive the European Quality award.

Malfunctions of Keber gas boilers

Of course, any equipment can fail. Keber boilers are no exception. Let's look at the most common problems that owners of such equipment have to face:

- Unstable operation of the igniter. This problem is usually solved by cleaning the nozzle. In some situations, it is necessary to check the meter, since it may not allow gas to enter the system in the required quantity.

- The gas burner goes out a few minutes after being turned on. There can be many reasons that lead to this, but most often it is due to the failure of the traction sensor. It is best to contact specialists.

- There is no gas supply to the injectors. If you purchased a boiler with an Arbat automatic, then most likely the stem is jammed in the middle part of the structure. You can drop a little machine oil yourself, then check the automation for gas leaks. If the above steps are unsuccessful, then you should contact a specialist.

Review of the Keber KSG 10K-01 boiler

For what reasons does a gas boiler go out?

To summarize all of the above, it is worth saying that the Keber gas boiler is an effective heating device. User reviews indicate that the unit is economical, easy to use and has a long service life.

Design Features

The main elements of the Zhitomir boiler are:

- a housing in which the main components and equipment are installed;

- gas burner unit located in the firebox. Here gas combustion occurs and heat flow is released;

- recuperative heat exchanger, in which heat exchange occurs between combustion products and coolant;

- gas exhaust system, its responsibilities include removing combustion products outside the boiler and releasing them into the chimney.

In order to increase the efficiency of heat transfer, the gas boiler Atem Zhytomyr 3 has the following design features.

- The heat exchanger pipes made of heat-resistant steel have a rectangular cross-section; this device allows you to increase the contact area of the flue gas and the coolant.

- The counter movement of coolants was organized, this solution made it possible to increase the efficiency of the heat exchange device to 92%;

- To increase the area of interaction between combustion products and the coolant, as well as to prevent the accumulation of soot on the surface of the steel pipes of the ATEM boiler heat exchanger, turbulators are installed. Soot accumulates on the lower surface of the turbolizers, while the pipe walls remain clean. To remove soot, you need to periodically remove the turbolizers and clean them of soot.

- Gas double-circuit turbocharged boilers in Zhitomir have a coil of copper pipelines around the heat exchange heating pipes.

To organize a stable gas combustion process, a POLIDORO gas burner device is used. Its distinctive feature is a single-stage atmospheric burner. The edges of the burners themselves are made of heat-resistant steel, which allows you to maintain the combustion mode at different gas supplies to the firebox. Even at low gas consumption, the heating of the edges is sufficient to maintain stable combustion.

The gas supply mode is regulated by the EUROSIT gas valve. This device automatically switches the gas supply to the burners depending on the temperature of the coolant. The user independently sets the temperature of the coolant, focusing on the temperature in the open air. As the ambient temperature decreases, the temperature of the coolant increases.

Sources

- https://www.stroy-podskazka.ru/otoplenie/kotly/zhitomir/

- https://ProfiTeplo.com/gazovye/56-kotly-zhitomir.html

- https://SpetsOtoplenie.ru/gazovoe-otoplenie/gazovye-kotly-evropejskogo-proizvodstva/chto-nado-znat-pro-gazovyj-kotel-zhitomir.html

- https://teplospec.com/gazovoe-otoplenie/kak-zapustit-gazovyy-kotel-vpervye.html

- https://microklimat.pro/otopitelnoe-oborudovanie/kotly/kak-vklyuchit.html

Varieties

Today, several types are involved in the production of Zhytomyr boilers - parapet (wall-mounted) and floor-mounted. In turn, floor products also have divisions into single-circuit and double-circuit.

Floor-standing

If a gas boiler is needed only for heating purposes, attention should be paid to single-circuit models. They are unpretentious, practical and economical

The equipment of the single-circuit boiler “Zhitomir” primarily involves imported components. Thanks to them, the device can be turned on and off if necessary. And if there is a need, in addition to heating, to have hot water in direct access, you will need to choose from dual-circuit options.

In terms of their technical characteristics, floor-standing boilers mostly have the following similarities:

- the maximum temperature limit is +90 degrees;

- efficiency is 92%;

- gas pressure – 635 Pa.

But when choosing a model you definitely like, you need to consider its specific characteristics and capabilities.

Wall mounted

The same separation as in floor-standing boilers is also present in wall-mounted boiler models. They can also be single-circuit or double-circuit. The efficiency of all devices is the same. The same applies to gas pressure.

But it’s still worth considering their characteristics p>

- the power of parapet boilers must be no less than 5 kW and no more than 20 kW;

- the coolant in the device is no more than 17.5 liters;

- depending on the chosen model, natural gas consumption is considered; according to the standard - 0.56–1.67 cubic meters per hour;

- profitability due to imported automation.

For its part, the manufacturer provides a wide range of boilers to choose from, but the Zhitomir-3 KS-G-020 SN model is still in great demand. This device differs from its counterparts not only in terms of availability in terms of price, but also has clear technical data. The design of the device is designed in a minimalist style; the appearance of the boiler looks like a cabinet. It should only be placed on the floor. On the front of the model there is a small door behind which hides a button for turning on and adjusting the device settings. In the same part there is a control window, with the help of which you need to monitor the performance indicators of the boiler.

The basic package includes a housing, which also includes heat exchanger elements. On the outside, it is covered with heat-insulating material and a casing made of steel. The burners are presented in two pieces: one is the main one, and the second is the ignition one. The package includes a gas duct and an automatic gas valve, which is responsible for safety during operation.

Types of homemade stoves in development

Engine oil contaminated with impurities will not ignite itself. Therefore, the operating principle of any oil stove is based on the thermal decomposition of fuel - pyrolysis. Simply put, to obtain heat, the waste must be heated, evaporated and burned in the furnace firebox, supplying air in excess. There are 3 types of devices where this principle is implemented in different ways:

- The simplest and most popular direct combustion design with afterburning of oil vapors in an open perforated pipe (the so-called miracle stove).

- Drip furnace using waste oil with a closed afterburner;

- Babington burner. How it works and how to make it yourself is described in detail in our other publication.

The efficiency of heating potbelly stoves is low and amounts to a maximum of 70%. Note that the heating costs indicated at the beginning of the article are calculated based on the indicators of factory heat generators with an efficiency of 85% (to get acquainted with the full picture and compare oil with firewood, you can go here). Accordingly, fuel consumption in home-made heaters is much higher - from 0.8 to 1.5 liters per hour versus 0.7 liters for diesel boilers per 100 m² of area. Take this fact into account when starting to manufacture a furnace for testing.

Design and disadvantages of an open-type potbelly stove

The pyrolysis stove shown in the photo is a cylindrical or square container, one-quarter filled with used oil or diesel fuel and equipped with an air damper. A pipe with holes is welded on top, through which secondary air is sucked in due to the chimney draft. Even higher is an afterburning chamber with a partition for collecting heat from combustion products.

The principle of operation is as follows: the fuel must be ignited using a flammable liquid, after which the evaporation of the waste and its primary combustion will begin, causing pyrolysis. Combustible gases entering the perforated pipe flare up upon contact with the oxygen flow and are completely burned. The intensity of the flame in the firebox is controlled by an air damper.

This stove has only two advantages during testing: simplicity and low cost and independence from electricity. The rest is all downsides:

- stable natural draft is required for operation; without it, the unit begins to smoke into the room and die out;

- water or antifreeze that gets into the oil causes mini-explosions in the firebox, causing fiery drops to splash from the afterburner in all directions and the owner has to put out the fire;

- high fuel consumption - up to 2 l/hour with low heat transfer (the lion's share of the energy flies into the chimney);

- The one-piece housing is difficult to clean from soot.

Although the potbelly stoves look different, they operate on the same principle; in the right photo, fuel vapors burn out inside the wood stove

Some of these shortcomings can be leveled out with the help of successful technical solutions, which will be discussed below. During operation, you should adhere to fire safety rules and prepare used oil - settle and filter.

Pros and cons of IV drips

The cardinal difference of this furnace is the following:

- a perforated pipe is placed inside a steel casing made from a gas cylinder or pipe;

- fuel enters the combustion zone in the form of drops falling to the bottom of a bowl located under the afterburner;

- To increase efficiency, the unit is equipped with air pressurization using a fan, as shown in the diagram.

Diagram of a dropper with bottom supply of fuel from the fuel tank by gravity

The real drawback of the drip stove is the difficulty of execution for a beginner. The fact is that you cannot rely entirely on other people’s drawings and calculations; the heater must be manufactured and configured to suit your operating conditions and the fuel supply must be properly organized. That is, repeated improvements will be required.

The flame heats the body of the heating unit in one zone around the burner

The second negative point is typical for supercharged stoves. In them, a jet of flame constantly hits one place in the body, which is why the latter will burn out quite quickly if it is not made of thick metal or stainless steel. But the listed disadvantages are more than offset by the advantages:

- The unit is safe to use because the combustion zone is completely enclosed by an iron casing.

- Acceptable waste oil consumption. In practice, a well-tuned potbelly stove with a water circuit burns up to 1.5 liters in 1 hour to heat 100 m² of area.

- It is possible to wrap the body with a water jacket and convert the exhaust furnace into a boiler.

- The fuel supply and power of the unit can be adjusted.

- Undemanding to the height of the chimney and ease of cleaning.

Boiler with pressurized air, burning waste engine oil and diesel fuel

What can be repaired without gas workers?

There are several main causes of malfunctions. This is the incorrect operation of gas equipment, the presence of an unacceptable microclimate in the boiler room, untimely maintenance of all systems or low-quality components.

When making repairs yourself, be sure to observe safety precautions and strictly follow the instructions. First of all, the user should decide which parts of the gas boiler can and cannot be repaired on their own.

When repairing gas equipment, the main danger is a possible gas leak.

Therefore, it is necessary to carry out all manipulations for installation and dismantling of units and parts of the device with caution.

Particular attention should be paid to replacing components related to the fuel supply system.

Knowledge of typical malfunctions of gas boilers and methods for eliminating them allows you to make simple repairs yourself. It is worth remembering that serious repairs can only be carried out by gas workers, but there are procedures available to independent home craftsmen

Boiler manufacturers strongly recommend calling gas service employees to correct problems associated with breakdowns of the gas supply system and built-in electronic devices. An inexperienced person will not be able to independently configure, repair and restore the functions of specific automation in a gas boiler.

There are three main elements in the design of a typical gas boiler:

- Gas burner closed/open type;

- Specific security blocks;

- A heat exchange system consisting of one or two internal devices, the number of which is determined by the number of circuits served.

If all the components involved in the operation of the boiler are classified according to their functional purpose, then they can be divided into the following groups: control system devices, hydraulic system devices, burner and gas supply unit, smoke exhaust, boiler operation control devices, multi-level safety systems.

Most often, users have the following problems: the boiler emits an unpleasant odor of gas, does not turn on, turns off during operation, does not heat the pipes or smokes

Most of the listed elements cannot be changed or repaired yourself. In case of tampering with the boiler design, its owner loses the right to restore operability at the expense of the manufacturer during the warranty period. But you definitely need to know what and how the craftsmen from the organization with which the contract for servicing the unit and supplying gas are repaired.

However, the owner of gas equipment, seeking to extend its service life, can independently produce:

- Chimney cleaning. It is performed in cases where traction is weakened by mechanical manipulation or using chemicals.

- Checking the tightness of water supply connections, gas supply lines, and heating circuit branches.

- Installation of a voltage stabilizer.

We warn you once again that all actions that require removing the casing from the boiler must be performed by a gas service representative.

However, if the guarantee is not important to you, then you can do it yourself:

- Manual external cleaning and internal flushing of the heat exchanger/heat exchangers. They are easy to dismantle, carry out the necessary procedures, and then install them back. In this case, it is effective to use homemade water solutions of citric acid (100g/1l) or suitable household chemicals that can dissolve calcium deposits.

- Supercharger fan maintenance. Replace the fuse or the fan itself, check the electrical circuit connected to it, and lubricate the bearings with technical fluid.

- Cleaning the injectors. Clogged nozzles cause a weak burner flame. They need to be periodically cleaned to remove any deposits with fine sandpaper and dirt removed with a rag containing household chemicals.

- Adjusting the pressure in the system.

- Finding a problem due to which the boiler does not turn on.

In order to decide how and how to repair a gas boiler, you need to visually inspect it and, if necessary, carry out a series of diagnostic procedures. Self-repair is possible in cases where the manufacturer’s warranty has already expired.

If you smell gas, you should immediately forget about manual intervention. It is necessary to turn off the gas supply, immediately carry out burst ventilation and call an emergency. The rules for operating gas equipment are described in detail in the following article, the contents of which we strongly recommend that you familiarize yourself with.

Consumer Opinion

Despite the fact that Keber boilers are one of the cheapest brands of heating equipment in Russia today, they have earned quite good reviews from consumers. Owners of houses and apartments attribute, first of all, their impeccable operation to the poles of these units. For the first few years, boilers of this brand usually do not require any special maintenance at all. Some problems with their operation may begin to arise for owners of country houses, judging by reviews, only approximately 5-7 years after installation. At this time, it is recommended to clean the previously purchased Keber boiler from limescale. This is due primarily to the fact that the water in Russia in most regions, unfortunately, is quite hard.

Reviews about Keber gas boilers on the Internet are therefore mostly positive. The only thing is that sometimes owners of country houses still criticize the work of domestic automation of these models. It happens that after several years of operation, Keber boilers, for example, deteriorate in the operation of the switching function. The burners in them light up only some time after pressing the “Start” button.