In the vast majority of situations, natural gas is the cheapest type of fuel for organizing autonomous heating and hot water supply. However, you must agree that this energy carrier is very explosive. If the boiler operating on it is installed and connected incorrectly, then disaster is not far away. Therefore, it is worth studying in advance the requirements for the room for installing a gas boiler, familiarizing yourself with the regulations and rules for installing this equipment.

Before you start installing a heating boiler, you should carefully study the requirements for the room for its installation. Only if these standards are observed will it be possible to talk about the safety of using gas appliances. Moreover, gas workers will not even connect you to the pipe if the gas equipment is not installed in proper conditions.

Regulations and design documentation

Absolutely all requirements for the installation of gas boilers are freely available in the following building codes and regulations:

- SNiP 31-02-2001;

- SNiP 2.04.08-87;

- SNiP 41-01-2003;

- SNiP 21-01-97;

- SNiP 2.04.01-85.

Further, data and figures taken from the relevant SNiPs are used.

1. You need to start by submitting an application for approval of technical conditions. The presence of this document gives the applicant the right to begin installation and connection of heating equipment to the central gas main. The application is submitted to the gas service, where it is reviewed by specialists within thirty calendar days.

To speed up the receipt of the above document and avoid possible delays, the application must indicate the estimated average daily volume of natural gas that will be required to meet heating needs. This figure is calculated individually according to the standards given in the first of the listed SNiPs.

- For a domestic gas boiler with a hot water supply circuit and used in central Russia, fuel consumption is 7-12 m3/day.

- A gas stove for cooking consumes 0.5 m³/day.

- The use of a flow-through gas heater (gas water heater) consumes 0.5 m³/day.

For a number of reasons, after the gas service has reviewed the application for permission to connect, it may be refused. At the same time, the responsible body is obliged to issue the owner of a private house a document that officially indicates all the reasons for the refusal. After they are eliminated, the application is resubmitted.

2. The next step after receiving technical specifications is an even longer but necessary process - creating a project. The main part of this document is a plan diagram, which indicates the location of the boiler, metering equipment, gas pipelines, as well as all connection points.

An appropriate specialist is always involved in drawing up the project. He must have permission to do this work. It will not be possible to develop a project on your own. In any case, the gas service will not accept for consideration a document prepared by a non-specialist.

After drawing up the project, it must be submitted for approval. This is done by the gas service department that controls gas supply in a specific locality or area. As a rule, it takes up to 90 days to approve the project, and only after receiving a positive response can work on arranging the boiler room and installing the heating unit begin.

The following documents must be attached along with the project and the application for its consideration:

- technical passport (available with the equipment);

- official operating instructions (a copy is possible);

- certificates;

- a document confirming the compliance of specific equipment with safety requirements.

It is also recommended to consult with a specialist drafting the project. He will provide the most up-to-date information on these issues, talk about possible innovations, changes in legislation and common pitfalls. This knowledge is guaranteed to save you a lot of time and nerves.

Approval of the project, just like receiving specifications, may result in refusal. At the same time, the owner is given an order indicating errors, shortcomings or inconsistencies that need to be eliminated. After corrections, the application is submitted and reviewed again.

What to look for when choosing a boiler

Boiler units operating with two heating circuits have high efficiency, since, consuming almost the same cubic capacity of gas, they provide a residential building with both heating and domestic hot water.

Wall-mounted and floor-mounted boilers have different thermal outputs, so they can be used in buildings with different heating volumes.

For small-sized objects, wall-mounted ones are preferred, for tall country cottages - floor-mounted ones, and the most complex large-sized structures.

In order to choose which gas boiler is better, you need to consider the following parameters:

- number of people living in the house;

- number of water points;

- distance of water intake points from the boiler unit;

- cottage area;

- rating of gas boilers.

The thermal power of the boiler system is the most important thing you need to know before purchasing. It is calculated using data on the heated area.

For preliminary calculations of the power of the device for a standard room height of up to 3 m, you can use a simple ratio: multiply the heated area by 0.1 kW.

Requirements for the premises for installing a gas boiler

Comprehensive information on the correct preparation of the premises is contained in one of the above documents. Among other things, there are regulations on the dimensions of the boiler room, the arrangement of the entrance door, the height of the ceiling and other important parameters (see key requirements below).

It is immediately worth noting that if the maximum thermal power of a gas boiler is more than 30 kW, then it is necessary to allocate a separate room for its installation. Models with lower capacity and with a corresponding location of the outlet under the chimney can be installed, for example, in a kitchen area. Installing a gas boiler in a bathroom is strictly prohibited.

It cannot be installed in the bathroom, as well as in rooms that are considered residential. As an alternative, it is possible to install a boiler room in a separate building. At the same time, their own standards are taken into account, about which there is information below.

A boiler room in a private house can be equipped at the ground floor level, in the attic (not recommended) or simply in a room specially equipped for these tasks.

In accordance with the rules for installing a gas boiler in a private house, it must be equipped taking into account the following criteria:

- Area of at least 4 m2.

- One room is designed for no more than two units of heating equipment.

- The free volume is taken from 15 m3. For models with low productivity (up to 30 kW), this figure can be reduced by 2 m2.

- From the floor to the ceiling there should be 2.2 m (not less).

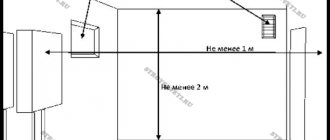

- The boiler is installed so that the distance from it to the front door is at least 1 m; It is recommended to install the unit near the wall, which is located opposite the doorway.

- At least 1.3 m of free space must be left on the front side of the boiler for setting up, diagnosing and repairing the unit.

- The width of the entrance door is taken around 0.8 m; It is desirable that it opens outwards.

- The room is provided with a window with an outward opening window for emergency ventilation of the room; its area must be no less than 0.5 m2;

- Surface finishing should not be made from materials prone to overheating or fire.

- A separate power supply line is introduced into the boiler room to connect lighting, a pump and a boiler (if it is volatile) with its own circuit breaker and, if possible, an RCD.

Particular attention should be paid to the arrangement of the floor. It must have a solid base in the form of a rough screed with reinforcement, as well as a finishing coating made of absolutely non-combustible materials (ceramics, stone, concrete). To make it easier to position the boiler, the floors are made strictly level.

On a curved surface, installation of the boiler may be difficult or impossible due to insufficient reach of the adjustable legs. It is prohibited to place third-party objects under them to level the unit. If the boiler is installed unevenly, it may not operate correctly, with increased noise and vibration.

To fill the water heating system and replenish it during operation, it is necessary to introduce a cold water supply into the boiler room. To drain the system during equipment maintenance or repair, a sewer point is installed in the room.

There are special requirements for the chimney and air exchange in the boiler room of a private house, therefore this issue is considered in a separate subsection below.

If the premises for installing a gas boiler are equipped in a building separate from a private house, then the following requirements are imposed on it:

- your foundation;

- concrete base;

- presence of forced ventilation;

- doors must open outward;

- the dimensions of the boiler room are calculated according to the above standards;

- no more than two gas boilers are allowed to be installed in the same boiler room;

- the presence of a properly equipped chimney;

- it must be provided with free access for cleaning and other operations;

- for powering individual lighting and heating equipment, a separate input with a circuit breaker of appropriate power is provided;

- The water supply must be organized so that the main does not freeze during the cold season.

Mini-boiler room mounted near the house.

The floors, walls and ceilings of a separately equipped boiler room must also be made and finished with materials that meet the class of non-flammable and heat-resistant.

Disadvantages of modern heating systems

As with any heating system, an autonomous one has its drawbacks. Although there are much fewer of them compared to the centralized one. Due to the fact that gas autonomous boiler houses are not widespread, it is quite problematic to obtain reliable equipment and all the components adjacent to it.

Therefore, boiler room elements will cost customers a tidy sum. Despite the high level of comfort that the systems in question provide, not all developers are willing to pay a lot of money for it.

In the event of an emergency, the entire heat supply system completely fails. There is up to five cubic meters of boiling water above people's heads. If the pipes burst, the water will flow down. That is why there are so many requirements for gas equipment

In addition, gas boiler rooms must be located in separate rooms or buildings. To do this, you need to allocate an area near the house, bring the roof to the required technical conditions, or install a block structure on the roof. All of these solutions require an infusion of additional resources either from the developer or from a common fund created by residents.

Gas heating systems release polluting decay products into the environment. Therefore, when installing boiler rooms, it is necessary to provide for the installation of filtration systems. Cleaning devices must perform their functions sufficiently to comply with SNiP standards. This further increases the cost of purchasing equipment.

When building a new house, the developer has a choice: to build an autonomous heating system or connect to the central highway. In order to crash into a highway, you need to obtain a number of permits. Often, resolving a problem requires a large sum of money. In addition, you will need to wait more than one month until the papers are checked by all authorities.

The high cost of connecting to existing networks, difficulties in coordinating this procedure, as well as the presence of many obstacles that impede the rapid and efficient installation of heating networks reduce the attractiveness of autonomous systems for developers.

Often the installation of gas boilers on the upper enclosing structure entails the need to strengthen the ceiling. The total load created by the heating system can reach 15 tons. Such values can be avoided by installing flow-through equipment instead of capacitive

Installing autonomous heating is also associated with a number of bureaucratic procedures. Both the initial implementation of systems and reconstruction with redevelopment have their own characteristic features. This is mainly due to the fact that you are going to use gas as a heating resource. All work with gas is strictly regulated by law.

Modern engineering developments effectively combat a number of shortcomings. If you need to heat just one house, an excellent option would be to place a block boiler room in the attic of the house. The attic becomes heated, and residents of the top floor do not experience discomfort.

Such structures are developed in detail by engineers, are lightweight and are installed on load-bearing walls. For such options, a flat roof option is required. This subtlety is usually taken into account at the design stage. Designers carry out calculations and determine in advance the location for the boiler room on the roof of the house.

The law sets a limit on the power of equipment on the roofs of 3 MW. Some regions have a 5 MW limit. If such power is not enough to fully heat the entire house, then additional permits must be requested

However, despite all the shortcomings, ultimately, the residents of the house will significantly improve their living conditions and get rid of discomfort. In addition to all the obvious advantages, autonomous systems have an increased level of security.

The new systems are equipped with threat and emergency alarms. A variety of sensors for gas boilers monitor many indicators. In the event of a breakdown, the backup boiler and additional pumps are activated.

Requirements for the chimney and air exchange

The current standards for installing gas boilers in private homes provide for a number of requirements for organizing normal air exchange in the boiler room. In particular, you should be guided by the rule that the installed ventilation system must uninterruptedly provide three times the renewal of air in the room in one hour.

If ventilation standards are neglected, or an insufficiently efficient system is installed, correct operation of the boiler will be impossible due to lack of oxygen. An influx of fresh air is needed to prepare a combustible fuel mixture, and due to its lack, the boiler will not operate stably. Moreover, insufficient air exchange will cause the accumulation of carbon monoxide in the boiler room, which is deadly to humans!

For example, consider a low-power gas boiler with a rated thermal power of 23 kW. According to the manufacturers' instructions, modern models with such productivity burn about 2-2.5 m3 of gas in one hour. In order for this volume to burn completely, at least 30 m3 of fresh air must enter the boiler during the same hour. If it is less, the gas will not be completely burned, which will negatively affect the efficiency of the heating system of a private home. For other modifications, the rate of fresh air supply is usually indicated in the specifications and accompanying documentation for gas equipment.

In a boiler room with a gas boiler, a supply and exhaust ventilation system is always installed, which provides not only the supply of fresh air, but also the forced removal of carbon monoxide in the event of a disruption in the normal functioning of the chimney. It is best to install the supply channel on the opposite side of the boiler, near the front door. For maximum efficiency it should be located as low as possible.

Boiler room ventilation diagram.

The area of the ventilation supply duct is calculated based on where the fresh air is taken from. If it comes directly from the street, then the channel cross-section should be 8 cm2 for each kW of boiler thermal power. For example, for a 30 kW boiler, the area of the ventilation duct must be at least 240 cm2 (this is a square with sides approximately 15 cm long).

If air is taken from the next room, the cross-section of the supply channel increases to 30 cm2 for each kW of boiler thermal power (in our example this is already 900 cm2, which corresponds to a square with sides of 30 cm). It is for the latter reason that it is recommended to organize an influx of fresh air from the street.

It is recommended to install the boiler in close proximity to the chimney. Gas boilers with a closed combustion chamber are equipped with a coaxial chimney. A coaxial chimney consists of two pipes of different diameters, which are inserted one into the other.

Coaxial chimney.

In this way, the boiler can take in oxygen from one pipe and remove combustion products through the second. This design feature allows such boilers to be operated without additional ventilation.

Types of coaxial chimney:

Horizontal coaxial chimney.

Vertical type coaxial chimney.

For boilers with an open combustion chamber, a regular (traditional) chimney is required. For such boilers, supply ventilation is required.

Construction of a traditional chimney:

There are many ways to arrange such a chimney:

The cross-section of the channel for the chimney pipe must correspond to the diameter of the outlet hole on the boiler. This value can be found in the technical description of the purchased boiler model. Along with this, it should be borne in mind that for boilers with an open combustion chamber and a thermal power of up to 30 kW, the diameter must be at least 13 cm, and for a 40-kilowatt boiler - 17 cm.

On the way from the boiler to the wall, the chimney pipe should have as few bends and turns as possible (but no more than 3). It is best if there are no them in the room at all. To do this, many modern gas boilers have two outlets - one on top, the other on the back.

The chimney pipe must be made of stainless or carbon sheet steel. The use of an asbestos pipe is also allowed, however, from its beginning to the boiler outlet there must be a minimum distance of 50 cm. Connecting such a pipe directly to the boiler is strictly prohibited.

There are also a number of requirements regarding the location of the chimney outside a private house:

- Above the roof without a ridge, the pipe should rise 0.5 m.

- The pipe facing the slope at a distance of up to 1.5 m from the ridge should rise 0.5 m from the ridge.

- If, with a similar configuration, the pipe is removed from the ridge at a distance of 1.5 m to 3 m, then its upper cut should not be lower than the level of the ridge.

- If the pipe extends into the slope further than 3 meters from the ridge, then its upper cut should be no lower than a conventional line drawn from the top of the roof at an angle of 10° relative to the horizon.

Standards for liquefied and natural gas

Various models of domestic heating boilers can operate on methane and a mixture of propane and butane. In both cases, the requirements for the minimum volume of the boiler room for a gas boiler, as well as other room parameters, are identical. However, there is one nuance in the issue of ventilation.

Methane is lighter than air and, when leaking, rises to the ceiling, while propane-butane is heavier and sinks to the floor or into the basement/cellar

If you plan to place equipment in a boiler room or kitchen using main methane fuel, then the natural ventilation openings in the room should be located under the ceiling. In this case, their distance from the ceiling should not exceed 20 cm.

If the gas appliance will be powered by a gas holder or cylinder, then the room must have ventilation vents at a height of 10–15 cm above the floor.

Natural ventilation should be arranged so that when the boiler goes out or there is another gas leak, the gas goes outside. The accumulation of methane or propane in a room is a direct path to an explosion and fire.

Choosing doors to the boiler room

If the boiler room is located inside a residential building, then the doors to this room must be made of fire-resistant material that can withstand fire for 15 minutes. As a rule, these conditions correspond to doors made of metal, and they can be either factory-made or home-made.

If the furnace room is equipped with doors facing the street, then they should be loosely secured. This will allow, in the event of a gas explosion, to protect the boiler room from destruction by the blast wave, which will soften its blow after the doors with the frame are pushed out onto the street. The advantage of such doors is that gas can freely exit the boiler room.

In projects you can find an additional condition, which refers to the presence of a grille at the bottom of the door that covers the through hole. This hole will allow fresh air to flow freely into the boiler room.

List of necessary actions

If it becomes known that the installation of individual heating is allowed in the house, a long visit to the authorities cannot be avoided:

- Data regarding the purchased meter and boiler are reported to the design organization. Then the completed documentation is collected. It is not worth purchasing equipment in advance, since permission to install a gas boiler in an apartment building cannot always be obtained.

- Then, at the Gorgaz branch, a contract for servicing the unit is concluded, and the gasification project is submitted for approval.

- After receiving the signed project, you can begin to disconnect from the heating network. In this case, you will need to drain the water from the heating system of the entire house.

- Next, the apartment owner must install an individual heating system. The boiler is installed without connecting to the gas main, the system is checked for leaks and readiness for operation.

- Gorgaz is finding out the date when a gas boiler can be installed in an apartment building in a specific apartment. Its employees will connect pipes and equipment according to the project, seal the meter, and put the stove and unit into operation.

- In order for the guarantee for a gas boiler to be valid, adjustment and first start-up will be required, followed by a mark in the passport. Regarding this type of work, you should contact the department where the device was delivered for service. The technician will adjust the boiler, start the system and put a stamp in the passport. Now you can use the installed equipment.

The entire process described above, in compliance with the requirements for installing a gas boiler in an apartment building, will take from 1.5 to 2.5 months. Therefore, it is advisable to start the procedure in spring or at the very beginning of summer.

Some nuances

Important! There are SNiPs and there are requirements of regional gas companies. SNiPs are uniform throughout the country, but the requirements of regional gas workers sometimes differ quite greatly.

And if the requirements of SNiP will affect the operational characteristics of the boiler room, then the requirements of gas workers will affect approval, specifications and the actual launch.

You can build a gas boiler house in accordance with all the requirements of SNiP, but it is the local gas workers who decide whether to connect you to the main gas or not.

Second point. We are talking, first of all, about connecting to the main gas. Yes, a boiler room using liquefied gas, as well as equipment using it, are sources of increased danger and all mandatory requirements must be observed.

However, when connecting your equipment to a gas tank, all work and acceptance are carried out by specialists from a commercial company that is implementing this project on your site.

But the local branch of RAO Gazprom Distribution works with main gas. This means that the requirements will be more stringent, and acceptance will take place in a completely different way.

Types of ventilation for operation of gas heating equipment

Convection can be natural or forced. Spontaneous air flow is ensured by the presence of windows, vents, doorways and an exhaust duct, the outlet of which is mounted in the room with the boiler.

The natural ventilation system consists of an air duct that connects the outlets from the kitchen, boiler room and bathroom to a pipe on the roof. The width of the box is not calculated, but selected according to SNiPs, because For an accurate calculation, it is necessary to take into account the direction and speed of the wind, atmospheric pressure and other parameters. A 30 kW gas boiler must have an air duct 150 mm wide, for 100 kW - 230 mm.

The hood is mounted directly above the device, and the pipeline is mounted behind the fuel chamber.

Forced ventilation is organized by pumping air and creating an area of low pressure. The local vacuum provided by the fan stimulates the suction and rapid removal of the air mass.

To calculate the blower parameters, you need to multiply the volume of the room by the loss and air change coefficients. The cost of resistance during the passage of the chimney is about 40%, therefore, with room parameters of 4x2x2.2 m, the fan power should be at least 74 m³/h.