The basement is an ideal place for a boiler room.

Our topic today is a boiler room in the basement: requirements for the room, choice of heating equipment and heating method. We will get acquainted with the regulatory documentation, compare different types of boilers in terms of efficiency and ease of use, and also select the optimal solutions for the heating system. So, let's go.

Freestanding furnace

A separate boiler room is intended for high-power units - over 200 kW.

But if you need to preserve the architectural appearance of the house, then building such a structure makes sense for a boiler of lower power. Modern polymer materials and technologies make it possible to lay underground communications for supplying heated coolant and hot water from the boiler room - a high degree of thermal protection will minimize the loss of thermal energy when transporting heated liquid.

A separate boiler room is built from:

- fire-resistant materials (building blocks of various types, brick);

- it is allowed to use metal sandwich panels with a non-flammable thermal insulator inside;

- fireproof roofing material is used;

- Reinforced concrete covering is used for the floor.

Premises requirements:

- the ceiling height in a separate building should be from 2.5 m;

- when calculating the volume of the room, 0.2 m2 is added to the minimum value (15 m3) for each kilowatt of heat generator power;

- for a boiler weighing more than 200 kg, a foundation is installed separately from the base of the building, the height of the podium above the floor level is up to 15 cm.

There are standard requirements for doors, ventilation and chimney installation.

How the boiler works

The design of the heater is quite simple. If you look at a boiler in cross-section, you can see the main element - a container inside which there is a heating element (this is a storage boiler with electric heaters), or a system of tubes through which liquid flows (this is a heat exchanger or an indirectly heated boiler). It can also be a regular tube surrounded by heating elements (flow type: gas or electric).

An interesting scheme is the layer-by-layer heating boiler - a relatively new device, the efficiency of which is significantly higher than indirect heaters. The container for layer-by-layer heating is needed only for accumulating and collecting hot water. Heating is carried out in a plate heat exchanger, from which hot water enters the container. As the hot liquid is taken from the upper part, new portions from the heat exchanger enter it.

Source

Economical

- Which boiler provides the cheapest heating (see Boiler in the basement: install it yourself)?

Here is the rating of heating equipment for this parameter in 2022 prices:

| Thermal energy source | Price per kilowatt-hour of heat, rubles |

| Main gas | 0,7 |

| Dry firewood | 1,2-1,4 |

| Coal | 1,5-1,7 |

| Pellets | 1,6-1,8 |

| Diesel fuel | 3,4-4,0 |

| Electricity | 4,0-5,5 |

If your house is gasified, you are provided with cheap heat

However, there are a couple of solutions that can significantly reduce costs when using expensive electricity for heating needs.

A heat pump uses electricity not for direct heating, but to operate a compressor that circulates coolant between two heat exchangers - an internal one, which transfers heat to the heating system, and an external one, located in the ground, under water or in the air. The highlight of the heat pump design is that it is able to extract thermal energy from a relatively cold environment to heat a hotter one.

Monoblock air heat pump

Moreover, the amount of heat transported into the house from a low-potential source is 3-6 times greater than the amount of electrical energy consumed to operate the compressor. This feature allows electric heating using heat pumps to successfully compete with solid fuel boilers.

You get most of the thermal energy for free

Another solution to reduce the cost of heating the basement with electricity is the use of a heat accumulator (a thermally insulated large-capacity water tank). When combined with a dual-zone meter, it can reduce the cost of a kilowatt-hour of heat to 1.5-2 rubles.

Heat accumulator in the basement

How does this scheme work:

- At night, the electric boiler operates at rated power, maintaining heating operation and heating the water supply in the accumulator;

- Night electricity consumption is paid at a lower night tariff;

Meter with separate accounting of day and night energy consumption

During the day, the boiler turns off, and the water continues to circulate between the heat accumulator and the heating devices, gradually releasing heat to them.

Heating circuit with heat accumulator

Sources

- https://ProPodval.ru/mikroklimat/uteplenie/mozhno-li-gazovyj-kotel-ustanovit-v-podvale-chastnogo-doma.html

- https://jsnip.ru/vodosnabzheniya/trebovaniya-k-gazovym-kotlam-v-chastnom-dome.html

- https://avtonomnoeteplo.ru/otopitelnye_kotly/384-mozhno-li-ustanovit-gazovyy-kotel-v-podvale.html

- https://ProfiTeplo.com/sistemy-otopleniya/110-kotelnaya-v-chastnom-dome.html

- https://bouw.ru/article/normativnie-trebovaniya-k-gazovoy-kotelynoy-v-dome

- https://v-teplo.ru/trebovaniya-k-kotelnoi.html

- https://obustroen.ru/inghenernye-sistemy/otoplenie/kotly/gazovaya-kotelnaya.html

- https://pogreb-podval.ru/planirovanie/kommunikacii/kotelnaya-v-cokolnom-etazhe-435

Selection of heating devices

- What devices are best for heating the basement?

Let's think a little. A special feature of the basement is the large area of surfaces in contact with the ground. This means that in winter the floor and lower part of the walls will become a source of cold.

If so, they need thermal insulation. The obvious solution for the floor is an insulated screed.

Preparing to lay insulated screed

But if we still have to lay the screed, why not place water heated floor pipes in it?

Installation of water heated floor

Here are the benefits of this solution:

- Uniform heating of air throughout the entire volume of the room;

Help: with convection heating using radiators, the temperature difference between the floor and ceiling levels can reach 6-8 degrees.

Temperature distribution for radiator and underfloor heating

- Subjective comfort. Walking on a warm surface is simply pleasant;

- Reducing heat loss by reducing the average temperature in the room. In the case of installing heated floors, there is no need to heat the air under the ceiling to excess temperature in order to obtain a comfortable +20 - +22°C above the floor.

If the idea of a heated floor does not appeal to you for some reason, aluminum sectional radiators are at your service. These devices combine reasonable cost (from 2,500 rubles for a 10-section radiator) with excellent heat dissipation (up to 210 watts per section).

The only disadvantage of aluminum batteries is their relatively low strength in relation to internal pressure, which is offset by the stability of heating parameters in an autonomous system.

Aluminum radiator BiLUX AL M

- What pipes should I use for heating installations with my own hands?

The stability of pressure and moderate temperature of the coolant allows the use of inexpensive polymer and metal-polymer pipes.

For laying water heated floors, the following are used:

| Image | Type of pipes |

| PEX (cross-linked polyethylene). Cross-linking is the process of joining long polyethylene molecules with cross-links formed during radiation or chemical treatment. Cross-linking makes the polymer more heat-resistant and durable. PEX pipes are connected with fittings that use shape memory: the stretched pipe is pulled onto the fitting and, returning to its previous dimensions, compresses it. For additional fixation of the connection, a sliding sleeve is used. |

| PERT (made of heat-resistant polyethylene). Unlike PEX, they can be joined with inexpensive socket weld fittings. |

| Metal-plastic. They are a composite of an aluminum core and shells (inner and outer) of PEX or PERT. Connected with compression and press fittings. |

Please note: all three types of pipes are supplied in coils 50-200 meters long, which avoids laying connections in a screed.

For radiator autonomous heating installations, polypropylene pipes reinforced with foil or mineral fiber are most often used. Reinforcement increases the tensile strength of the pipeline and, more importantly, reduces its elongation as the coolant temperature increases.

Radiator heating is made of reinforced polypropylene

Features of installing gas equipment in the basement

Placing a gas boiler in the basement is convenient for people living in a private house, but this is not always permitted. The exception has long been liquefied petroleum gas systems, which have long been widely used.

Boilers of this system operate on fuel extracted from oil. As soon as natural gas became widespread and special equipment for it was produced for residential buildings, restrictions on installation in basements were completely lifted.

Now SNIP requirements allow up to 4 gas units of any type, located in the basement, the total power of which should not exceed 200 kW. The degree of safety is so high that their location is possible even in the attic.

One of the main requirements before starting installation work on gas equipment is an approved boiler room design. This must definitely be done before starting the system, since its operation represents an increased fire hazard and, as a result, may be prohibited by the fire inspectorate. In this case, it even comes to dismantling the boiler room or rebuilding the system.

Installation of a wall-mounted boiler

There are wall-mounted and floor-mounted gas boilers for the basement of a house. Both have their advantages and disadvantages. Wall-mounted boilers are most often used, although they require a lot of labor to install.

The main condition for mounting the boiler is reliable fixation. A space of at least 20 cm must be left between the boiler and other equipment. A space of 2-3 cm must be made between the wall and the installation. The boiler can also be mounted above other existing equipment.

You should begin installing a wall-mounted boiler by collecting all the necessary elements: instructions, brackets, fasteners, pliers, screwdrivers and other tools. Boiler manufacturers are required to place a rating plate on the equipment. They should be compared with those written in the instructions.

If the wall to which the boiler is mounted is made of wood or other material that is easily flammable, then it is necessary to use thermal insulation material. Its thickness must be at least 3 mm.

The next stage is the installation of brackets. It is imperative to use dowels here. The instructions contain a diagram according to which all actions should be performed. Next you need to secure the strips to the boiler. Various manufacturers offer their own methods. You must act according to the instructions. In most cases, screws with self-tapping screws are used.

Before hanging the boiler on the brackets, you should wash the pipes of the unit. A stream of cold water is used for this. This eliminates particles that enter the system when equipment is being built or transported.

The boiler is hung on brackets using a special strip. This point is also stated in the instructions. After installing the equipment in place, you must make sure that it is in a horizontal position, without distortions.

To prevent the boiler from clogging during operation, it is necessary to find the pipe leading to the heat exchanger and connect a filter element to it. There are ball valves on both sides of this filter element that allow you to shut off the water.

The most important thing is that only licensed company employees are allowed to put such equipment into operation. Therefore, even if the installation can be done independently, the connection must be carried out by a specialist.

Provide heating for your private home and basement

Ventilation system of the boiler room

In order for the heating device to function as efficiently as possible (and the principle of its operation, we remind you once again, is based on the combustion of gas and the subsequent release of heat), it is necessary that fresh air constantly enter the room, which is extremely necessary to remove the products of fuel combustion. In most cases, in order for the air exchange in the boiler room to reach the required level, ordinary natural ventilation is sufficient. Dilapidated doors and window frames, as well as a number of other places where there are cracks for one reason or another, provide an ample amount of fresh air. But if all this is not enough, since the room is sealed, then it is advisable to take a closer look at the possibility of installing an additional ventilation system. And if this is not done, then the combustion products will remain inside the room, leaving behind traces in the form of soot and soot on all surfaces. Moreover, the unattractive appearance of the furnace is only the least of the problems that will befall you in the absence of proper ventilation.

Expansion tank requirements

The hot coolant leaves the boiler into the distribution manifold and is pumped into the heating system by a circulation pump. As required by safety standards, an expansion tank must be installed in the system to compensate for water intake and an emergency pressure relief valve. A water replenishment device for the main heating circuit is also installed into the system.

Recently, double-layer polypropylene pipes with an aluminum amplifier have been used to construct the heating circuit. SNiP allows the use of certified plastic pipes for heating systems, provided that the requirements for the coolant are met: pressure no more than 3 bar and temperature no more than 105 ° C.

The operation of a gas boiler is ensured by a gas supply system, burners and automation that controls the combustion process of natural gas. One or two electric fans supply air to the combustion chamber.

Often, two boilers are installed in gas boiler houses - the main one, designed for the design heating power, and the auxiliary one. The smaller one is in demand for producing hot water during periods of no heating.

Is it possible or not?

- Is it allowed to place a boiler room in the basement?

Yes. SNiP 2-35-76, which is still in force today, directly states that it is permissible to design built-in boiler rooms in residential buildings, provided that they heat water to a temperature not higher than 115°C.

- Is it possible to place gas boilers in the basement?

In the case of a single-family home, yes. It does not contradict the above excerpt from SNiP: the temperature of the coolant at the boiler outlet is usually kept within 70-80 degrees.

A nuance: according to the text of the same SNiP, in the basement you cannot use heating equipment using gas or liquid fuel with a flash point (the minimum temperature at which vapors of a substance can ignite in the air upon contact with an ignition source) below +45 degrees. Natural gas has a flash point of -187.8°C. However, this restriction does not apply to basement floors.

Definition of flash point

Please note that we are talking only and exclusively about private homes. Another SNiP - number 42-01-2002 - directly prohibits the placement of gas-using equipment in the basements and ground floors of buildings, with the exception of blocked (low-rise adjacent to each other) and single-apartment buildings.

Requirements for the basement with boiler room

Boiler rooms in the basement of a residential building are subject to certain installation requirements, in accordance with which the following requirements must be met:

- The room must be more than two meters high. Optimal is 2.5m;

- The boiler room must be isolated from the living rooms of the house, in which the installation of gas equipment is strictly prohibited;

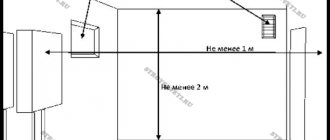

- To place one boiler there must be a minimum of 4 square meters of space, moreover, the system must be located at a distance of one meter from the wall of the building;

- Access to the boiler must be free from either side in order to be able to quickly turn it off or repair it;

- The boiler room must have a window with an opening of at least a quarter of a square meter. The recommended size is 0.03 sq.m. per cubic meter of basement;

- The door to the basement must be comfortable and safe, with an opening width of at least 0.8 meters;

- The floor covering can be a cement screed, but not linoleum or laminate. All flammable materials are strictly prohibited. It is recommended to finish the floor with tiles or tiles made of fire-resistant materials;

- All wall and ceiling surfaces must be treated with fire-resistant materials and covered with tiles or tiles. If there are things around the boiler room that are vulnerable to burning, they must be covered with special shields with insulation;

- At the entrance to the boiler room, ventilation ducts must be made, usually punched in the lower part of the door;

- A boiler room with a gas unit requires the installation of a supply and exhaust air exchange system;

- Access to the premises is restricted to unauthorized persons, except for repair crews or maintenance personnel. Children and animals are strictly prohibited from entering the boiler room.

These requirements are dictated for reasons of safety of people living in the house. In addition, this allows you to use the equipment in the most optimal mode. Failure to comply with these requirements leads to fires and accidents, since the small size of the room with a gas boiler is very favorable for the emergence of a fire source and its subsequent spread.

All restrictions on room volumes apply to boilers with an open combustion system. Almost all modern models are equipped with a sealed firebox, but if old equipment is in operation, then the room dimensions can be 7.5 cubic meters, 13.5 or 15 cubic meters for boilers with a power of 30.30-60 and 60-200 kW, respectively.

All modern models can be located in any volume of the basement, but if located in the basement, it is necessary to equip a separate exit to the street. All exits are immediately made of fireproof materials.

After the building is put into operation and the boiler room is not equipped, living spaces should not be allocated for these purposes. It is recommended to build a separate building, an extension to a residential building, but in this case it is necessary to provide for all the requirements for the arrangement of the boiler room.

Requirements and rules for installing a gas boiler room in a country house

Let's start with the fact that the requirements for the premises of a gas boiler room are distributed by type of premises. So, if the heat output of the boiler is ≤ 30 kW, then it can be installed directly in the house - in the kitchen, for example, in the basement or in an extension. If the power of the heat generator is ≥ 30 kW, it will need to be allocated a separate room, equipped in accordance with all fire safety rules.

There are separate requirements for boilers installed in kitchens, and the main points are listed below:

- If the kitchen is gasified, then its minimum area should not be less than 15 m2, and the ceiling height should not be less than 2.5 meters;

- The kitchen ventilation system or hood should provide hourly air exchange in the volume of 3-5 kitchen volumes. So, if the room has a volume of 15 m2 x 2.5 m = 37.5 m3, the minimum volume of air moved per hour should be 113 m3;

- The glazing in the kitchen should be such that the proportions of 0.3 m2:1 m3 are maintained, and the window (or windows) must have a window or a turning frame. To ensure air flow from the street and between rooms, a grille or gap of any shape with a cross-section of ≥ 0.025 m2 is installed at the bottom of the door leaf.

Additional requirements for kitchen premises with gas heating installed in them from a fire safety point of view are the following:

- Under the entrance door to the kitchen it is necessary to equip a narrow opening for air exchange with the rest of the rooms in the house;

- The distance from objects made of flammable materials to gas equipment must be at least 10 cm;

- If a load-bearing wall or interior partition is too close to gas devices, then a metal or other sheet of non-combustible material is mounted between them.

Boiler types

There are different heater designs made for different heat sources or fuel types.

The choice of type is determined by the availability of a certain type of energy or fuel. If there are several options, the most economical option is usually used.

The most common types of heaters are:

Depending on the type of heater, the devices are:

Let's take a closer look at them.

Indirect water heaters

Indirect heating is used in heat exchangers. The principle of its operation is to transfer thermal energy from one medium to another without mixing. The design of an indirect type boiler most often consists of a container into which cold water is supplied. It is located inside another larger container through which hot coolant is passed. The cold liquid absorbs the energy of the coolant and heats up.

The flow rate of the coolant is adjusted so that it does not cool down too much and is suitable for heating rooms.

Instantaneous electric water heaters

Instantaneous water heaters are devices in which a section of pipe with water passing through it is heated . In order for the temperature to rise to a normal value during the flow of liquid through a relatively small area, a sufficiently powerful heater is required. It needs the appropriate network and wiring. This point is the weakest point of electric heaters, since not everywhere it is possible to install a powerful device without the risk of destroying the power line.

In addition, with high water consumption, it simply does not have time to heat up. This option is good when space is limited, since instantaneous water heaters are compact in size and can be installed in small rooms.

Instantaneous gas water heaters

Gas water heaters are commonly referred to as “gas water heaters”. They are more efficient than electric ones and do not require large expenses. The dimensions of such devices are very compact, which also speaks in favor of gas equipment.

Boiler room in the basement of a private house requirements, standards, features

Installing a gas boiler in the basement is an obvious solution, since such equipment cannot be located in residential premises, and building a separate structure is too expensive.

We will talk about what requirements for a boiler room in the basement of a private house are put forward by state standards and building codes, and also answer frequently asked questions.

The photo shows a boiler room in a private house in the basement.

Is it possible or not?

A gas boiler room can be installed in the basement or ground floor of a residential private house.

The question is often asked: “Is it possible to install a gas boiler in the basement?” The answer is clear and categorical: you can.

The exception is systems whose gas supply is made from liquefied petroleum gas (LPG) extracted from oil.

The history of this issue stretches back to the times when the location of boiler rooms in basements and ground floors was actually prohibited due to the widespread use of LPG.

However, with the transition to natural gas and boilers with a closed firebox, this ban was lifted, and now in basements and basements, as well as in the attics and roofs of single-family houses, up to four heating or water heating gas boilers with a total capacity of up to 200 kW can be located.

The heating boiler can even be placed in the attic.

Important! This permit applies only to those boiler houses that are built and equipped in accordance with the requirements of GOST, SNiP and other regulatory documents and norms. In general, taking into account the specifics of the Russian bureaucratic apparatus, it is better to draw up a project for the future boiler house and approve it in all instances in advance

In general, taking into account the specifics of the Russian bureaucratic apparatus, it is better to draw up a project for the future boiler house and approve it in all instances in advance.

Interaction with officials is an art.

This will allow you to demand truly exorbitant bribes, because it will be easier to give even a decent amount than to rebuild the boiler room or build it again.

On the other hand, if you bring a project for a future building, then there will be nothing to blackmail you with; the official can only make reasoned corrections and comments, after taking into account which he will have no choice but to approve your project.

Premises requirements

A gas boiler in the basement of a private house is a common occurrence.

In order to place a boiler room in a particular room, it must be brought into compliance with certain requirements.

Regardless of where exactly the room is located, it must meet the following parameters:

- The distance from the floor to the ceiling of the basement (room height) must be at least 2 meters, the optimal height is from 2.5 meters;

- The room must be separate; placing equipment in rooms adjacent or combined with living rooms is strictly prohibited;

- The area of the boiler room is taken at the rate of 4 square meters per boiler, and the minimum distance from the front of the equipment to the opposite wall should not be less than one meter;

- The equipment must be provided with free access from all sides for normal and convenient maintenance and repair of all parts of the system;

- The boiler room should have windows facing the street, the area of which is taken at the rate of 0.03 square meters. meter per cubic meter of room volume, but not less than 0.25 sq. meters;

- The width of the doorway should not be less than 80 cm;

- The floor must be level and durable, made of non-combustible materials. It is best to make a cement-sand screed, which can then be covered with tiles or other waterproof and fireproof material;

- Wall and ceiling structures should be made of non-combustible materials, finishing - plaster or tiles. Near the firebox, wall coverings that can catch fire or deteriorate under the influence of high temperatures should be covered with special shields made of non-combustible materials with a heat-insulating lining;

- The entrance door must have a basement ventilation hole at the bottom or a gap between the door leaf and the floor of at least 0.02 square meters. meters;

- The room must have supply and exhaust ventilation;

- It is better to limit access to the boiler room to the circle of persons who are directly involved in the maintenance or repair of equipment. Children and unauthorized persons are not permitted to enter the boiler room.

Important! All these requirements are dictated by objective reasons and are aimed at maintaining your safety and normal operating conditions of heating equipment. https://www.youtube.com/embed/BV10ePz3DgQ

The cost of neglecting these rules can be too high, even leading to emergencies, accidents and fires.

Communications

The room equipped for the boiler room must have all the required communications for optimal operation of the system. The boiler room of a private house must fully meet fairly strict requirements: it is necessary to supply not only gas and water supply, but also sewerage and electricity. In addition, when connecting communications, the following requirements must be observed:

- It is necessary to install a single-phase electrical network with a standard rated voltage and a maximum current of 20 A. Grounding must also be carried out and an automatic circuit breaker must be installed. In addition, do not forget about high-quality insulation on the wires.

- If one boiler is installed, then installing one shut-off unit, which is placed on the gas main, is sufficient. When there are 2 or more boilers, each one needs to install its own shut-off unit.

- The water supply in the boiler room must work in the same system with the building’s hot water supply and heating system. The boiler room in this case becomes a room in which you can install not only a boiler, but also perform any work.

- In water supply and ventilation systems, as well as in chimneys and boilers, it is necessary to provide a device for eliminating condensate and other moisture. This is a very important point for an instant water drain system.

- State standards clearly regulate communication indicators for boiler rooms on the ground floor, so it is advisable to familiarize yourself with them before starting work.