- Rules for placing a boiler room in a house

- Requirements for a boiler room attached to the house

- Boiler room area

- Dimensions of a boiler room in a private house

- Boiler placement

- Window in the boiler room

- Requirements for the boiler room door

- Wall requirements

- Ventilation in the boiler room

- Requirements for boiler houses using solid and liquid fuels

The room where heating equipment is installed in a private house is called a boiler room.

In accordance with current building regulations, very stringent requirements are imposed on this room, since powerful heaters operate on flammable fuel. In this article we will analyze the basic requirements for a boiler room in a private house and consider the rules for installing equipment in premises for various purposes.

Rules for placing a boiler room in a house

The main document regulating the rules for installing a boiler room in a house is SNiP 42-01-2002, in force since July 1, 2003. It contains all the basic requirements for the installation of a combustion chamber. And during construction it is necessary to focus on it.

Theoretically, the owner does not need to understand SNiPs, since according to current standards, the design of a boiler room in a house must be developed by a specialized enterprise. Design experts are well aware of all modern rules and can draw up design documentation in such a way that, in accordance with it, a boiler room that is functional and safe for residents is built in the building.

However, in practice, property owners would also benefit from knowledge of building regulations. Therefore, let us outline the basic requirements for a boiler room in a house for 2022:

- The minimum volume of the object must be 15 m3.

- The furnace room can be located on the first, ground floor, as well as in the basement.

- It is prohibited to build a furnace close to the bedrooms in the house.

- The shortest distance to the street exit should be no more than 12 m.

- Heating equipment can only be placed in rooms with a ceiling height of 220 cm or more.

- A door and window are required.

- A functional ventilation system is required.

Types of wall devices

According to their functional purpose, gas heating units are divided into two groups:

- Single-circuit. Intended for heating only. They are connected to the heating circuit and heat the coolant. The organization of hot water supply in this case is carried out by installing an electric or gas water heater of any type.

- Dual-circuit. They heat the room and provide hot water. An additional circuit for heating water is built into the boiler. The technological feature of the device is that it is impossible to simultaneously heat water and heat the room.

The priority action of dual-circuit units is to heat the water; heating operation stops at this time. Considering that water can be heated quickly, the boiler heats the building quite effectively.

If the tasks of the gas unit are planned to include both heating the coolant and supplying hot water, then it is better to purchase a double-circuit boiler. They come with one or two heat exchangers. When equipped with two, two circuits can be served simultaneously

According to the method of fuel combustion, all devices are divided into the following two groups.

Group #1 - devices with an open combustion chamber

Such devices are also called natural draft heating devices. They take the oxygen necessary for combustion from the room in which the device is located.

To remove combustion products, they need a traditional type chimney. Thus, a mandatory requirement for installing such a boiler is the provision of good ventilation.

If the heating device is installed in a residential area, it must be equipped with high-performance supply ventilation.

The best option for installing a heating device with an open firebox is the presence of a separate room, the so-called firebox, where it is placed.

Systems with natural ventilation are quite popular due to their low cost and energy independence.

The figure schematically shows boilers with open and closed type burners

Group #2 - devices with a closed combustion chamber

Turbocharged devices are equipped with a closed combustion chamber. They take the air, without which the combustion process is impossible, from the street. For this purpose, the devices are equipped with coaxial type chimneys.

Such a chimney is made in the form of a structure of two pipes, one of which is nested inside the other. The combustion products are discharged outside through the inner pipe.

At the same time, street air flows in the opposite direction through the gap between the two pipes. It is clear that boilers with a closed firebox do not in any way affect the composition of the indoor air, which makes it possible to install them even in living rooms.

In this case, it is necessary to equip a coaxial chimney system, which is higher cost and more complex installation compared to a separate traditional chimney.

Dimensions of a boiler room in a private house

The suitable area of the boiler room in a building must be calculated individually, taking into account several important factors. One of them is the type of heating equipment. Let's talk about the two most common options.

Gas

Despite the permitted area of 5 m2, for a boiler room it is best to use a room of 8 m2 or more. If you place all the equipment necessary for the safe operation of the system along one wall, it will take up more than 3 meters in length and about 1.7 meters in width. If the equipment is moved slightly so as not to place it under one wall, it will occupy approximately 2.5 x 2.5 meters of space.

At the same time, the surrounding space itself must remain accessible even with open doors and windows. In addition, additional equipment can be placed here, for example, a washing machine or dryer.

Pellet

Pellets are bars of compressed sawdust measuring 0.8x3 cm. They are often used as the main fuel for boiler houses in situations where it is impossible to connect the facility to the gas supply system.

A pellet boiler room requires two rooms at once. The first will house a bunker for storing pellets, and the second will house the combustion chamber itself.

The size of the bunker in most cases is about 6 m2. It is recommended to allocate a room of about 7-8 m2 for the boiler room itself.

Flue gas removal

Channels and pipes designed to remove gas combustion products must ensure normal combustion in the boiler furnace. Due to this:

- the cross-section of the smoke exhaust duct should not be less than the dimensions of the boiler connecting pipe;

- it is allowed to reduce the cross-sectional area of the chimney if the design of the heating unit provides for the forced removal of combustion products and air supply;

- channels can be located inside capital walls and partitions of appropriate thickness or be attached to them;

- the material for the manufacture of chimneys must be fireproof and not subject to active corrosion;

- the design of the chimney must include a special hatch for cleaning the channel from soot and a device for draining the resulting condensate;

- the height of the chimney is higher than the ridge of the roof or a line at an angle of 15° when moving away from it.

All butt connections of elements are made airtight and exclude not only the release of combustion products into the premises, but also the possibility of air leaks and a decrease in draft.

Boiler placement

Today the heating boiler can be placed inside the building itself in existing rooms. Let's look at the most popular options.

Kitchen

In buildings with an area of less than 350 m2, for which a 50 kW boiler is sufficient for heating, there is no need to organize a separate boiler room. The necessary equipment can be placed in the kitchen, the main thing is that the area of the room is at least 7 m2 with a total volume of at least 21 m3.

There will be no difficulties in coordinating the installation of a boiler in a combined kitchen with a dining room. But in this case, the dimensions of the room should be larger: volume - 36 m3, area - 12 m2.

Additional requirements for the room include the presence of a window, as well as a natural ventilation duct with access to the roof of the house.

In addition to the boiler, the heating system may have other equipment:

- faucets;

- pumps;

- boiler;

- collector;

- expansion tank.

To place it in the room, you can use a special cabinet measuring 1x1.5 meters. The main thing is that all elements of the system are available for scheduled maintenance and repair.

Pantry

The requirements for the pantry when installing heating equipment are similar to other internal non-residential premises. That is, if the room meets the permitted criteria in its area and volume, you can place a gas boiler here without any problems.

However, it will not be possible to install a boiler in all non-residential premises. The law prohibits the installation of such heating equipment in bathrooms and toilets.

Corridor

It is unlikely that it will be possible to place a boiler in the corridor, as well as in the hallway, veranda and other similar rooms. Such premises almost always cannot meet current building codes and regulations. Either the volume/area is insufficient, or the living rooms are too close, or there is no window, etc.

Maintenance

Preventive measures for routine inspection of gas boilers include the following types of work :

- Checking the valves of the external and internal gas pipelines (disassembling, applying lubricant).

- Inspection of thermostats on floor-standing boilers.

- Washing or replacing filter elements.

- Inspection of nozzles , checking the tightness of the door, the operation of the igniter on floor-standing devices.

- draft control

- ice build-up in winter .

All components that have been subject to wear during operation must be replaced.

On a note! After completion of the repair and before starting the heating system, the gas service worker checks the tightness of all connections in the line. Usually a soap solution is used for this.

A competent preventive inspection will not only increase the service life of the equipment in use, but will also reduce gas consumption.

Repair and maintenance of gas equipment Source sanmaster62.ru

Window in the boiler room

The requirements for a gas boiler room in private houses stipulate the mandatory presence of a window. Not every window can meet the standards. It must comply with GOST R 56288-2014.

A window in the boiler room is needed to protect living quarters and their users from additional danger in the event of emergencies and explosions.

The requirements for the window directly depend on the area of the combustion chamber. For a room of less than 9 square meters, the glass area should be 80 cm2 or more.

Features of energy supply

The power supply of a gas boiler unit must be of two types: a separate power line from the subscriber panel and an emergency power supply, from batteries or a backup line. In addition, the boiler room power supply circuit must fulfill the following conditions:

- Mandatory installation of a boiler grounding system.

- Connecting the unit through a voltage stabilizer or uninterruptible power supply.

- The socket for the heating device must be located nearby in order to connect directly.

- The use of carriers is not permitted.

Requirements for the boiler room door

All attached furnace rooms must have a door leading to the street. If the heating equipment is located in the interior, it is not necessary to make an exit from them to the outside.

However, this requirement applies only to gas boiler rooms in a private home. If the furnace operates on a different fuel, for example, pellets, regardless of its location, there must be an exit from the room.

In internal gas boiler rooms, the door may not lead outside, but to other rooms of the house, for example, to a corridor or to a staircase. The main thing is that the distance from it to the exit from the house is no more than 12 meters.

Main requirements:

- must open outwards;

- width is 0.2 m larger than the size of the heating equipment;

- must comply with fire safety type 3 with EI15 (standard for steel doors with non-combustible basalt fiber filling).

It is allowed to have several doors leading to the corridor/veranda/street. The main thing is that each of them meets the specified standards.

Fire safety

The combustion area must be kept clean, and there must be sufficient artificial lighting inside the room to provide good illumination for work and public areas. Storage of any flammable materials in such premises is prohibited. When pipes freeze, they can only be heated with steam or hot water. The use of open flame is prohibited.

Special requirements are imposed on the operation and maintenance of smoke ventilation systems; they must be checked and cleaned periodically:

- Every year in August – cleaning of smoke channels from soot contaminants and checking draft.

- Quarterly - cleaning of brick chimneys.

- The integrity of the ventilation ducts is inspected annually.

The entrance doors of the furnace room must open outwards. Windows - must have easily removable packages. At the entrance of the gas pipeline in the combustion chamber, a protective electromagnetic valve, a fire alarm and indoor gas sensors are installed.

Requirements for boiler houses using solid and liquid fuels

Such furnaces are subject to special requirements, which do not differ too much from the standards relating to gas equipment. Let's look at the main ones:

- mandatory presence of a door to the street, regardless of the location of the room;

- protection of surfaces from exposure to high temperatures and the risk of fire;

- installation of heating equipment at a distance of at least 10 cm from the walls;

- presence of a window;

- the width of the doorway from the room should be at least 80 cm;

- mandatory arrangement of a fuel storage warehouse, which must be covered, but not heated.

Render House specialists are engaged in the construction of houses with boiler rooms according to standard and individual projects. For more detailed advice, you can contact the phone number indicated in the header of the site.

You asked, we answer

Despite the large amount of available information, many questions arise from users related to the installation and subsequent startup of gas boilers.

How to properly install the device in a wooden house. Are there special standards?

Installation of a gas boiler in a wooden house can be carried out subject to a number of norms and rules.

They are united by a certain code:

- installation of a gas boiler in the basement (basement) of a wooden house is prohibited;

- for the boiler room it is necessary to allocate a separate room where there is natural light and ventilation;

- the size and height of the ceilings meet the requirements;

- staying in living rooms (kitchen-living room), bathroom is prohibited;

- prevent contact of the boiler with wooden surfaces;

- the boiler area is perfectly flat, lined with non-flammable material, there is a layer of asbestos between the wall and the rear wall;

- Individual fire extinguishing equipment is located in close proximity to gas equipment.

Avoid starting the boiler on its own. This is possible only with permits and in the presence of specialists from the company supplying gas to housing construction.

At what distance can the socket be installed?

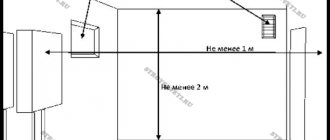

Modern energy-dependent boilers have a strictly regulated cord and socket. The use of extension cords is prohibited. The electrical cord should easily reach the nearest power source without tension. This is also regulated by regulatory documents. The distance is no more than 50 cm. It looks approximately as shown in the figure.

What should the doors be like?

We have already discussed above what the parameters of the boiler room and its entrance doors should be. It wouldn't hurt to remind you. The door width is from 80 cm. It opens outwards. There must be a small slot at the bottom to ensure normal functioning of natural ventilation. The presented diagram will help answer this and many other questions.

.

You should not assume that your own knowledge is enough to install gas equipment yourself. To avoid problems with launching and obtaining permits, it is better to coordinate the purchase of equipment for a boiler room or other premises with the company supplying blue fuel. Receive a project for installation. This is important because even a new boiler may not match the capacity of the gas distribution network.

We recommend reading: How to get a gasification project for a private house and How to replace an old gas boiler with a new one (2021 rules).

Step-by-step installation of equipment

Before installation, you need to unpack the new boiler and check the completeness of the delivery. The availability of parts is checked according to the operating instructions, which must be included with the device.

If any item is missing, please contact the supplier immediately. One more nuance. The boiler must have an ideal appearance without dents, chips or signs of repairs. If this is not the case, you need to call the sellers.

It is important to make sure that the technical data specified in the technical data sheet of the heating device exactly matches those printed on the device itself. In addition, they must correspond to the numbers specified in the operating instructions for the device.

Immediately before starting installation, you need to flush the boiler pipes, which may contain various debris that got inside during the manufacture of the device and its transportation.

Installing a gas boiler involves connecting heating pipes, water supply and gas mains, as well as installing a chimney

It is also advisable to flush the heating system lines. After the preparation is completed, you can begin installation.

The specifics and procedure for its implementation are determined by the characteristics of the equipment: the number of circuits involved and the type of combustion chamber.

Most often, double-circuit appliances with a closed firebox are installed in houses. Let's take a closer look at the installation of just such a modification.

Stage #1 - preparing the wall mount

To secure gas boilers, a special bracket is used, which should be included in the delivery of the device. Reliable fasteners are used for mounting it on the wall. They should be selected according to the material from which the wall is made.

It is quite possible that those that the manufacturer packaged with the heating device will not be suitable. Then you will need to choose and purchase others.

The purpose of the bracket is to support the weight of the boiler and additional equipment, as well as to provide it with an even, clearly aligned position without distortion.

To accurately mark the wall, you can use a paper stencil, which usually comes with the boiler. With its help, you can easily mark holes for fasteners.

Once this is done, the bracket is secured in place and the boiler is hung onto it.

Heating pipes are connected to the corresponding pipes of the gas equipment. You can determine their location from a photograph.

Stage #2 - connecting the heating system pipes

Depending on the type of heating system, and it can be single-pipe or two-pipe, the number of pipes connected to the boiler may vary. In any case, we start by removing the plugs from the device’s pipes.

To protect the boiler from the ingress of dirt particles from the heating line, it is recommended to install a mesh filter at the return inlet.

If the water in the system is hard or in other respects does not meet the requirements stated by the heating device manufacturer, you should take care of installing additional treatment equipment.

These could be, for example, polyphosphate dispensers. If this is not done, the device will quickly break down. All connections must be made in compliance with all rules and regulations.

Sealing is required. For this purpose, special sealants are used: traditional paint or tow, or modern thread sealants. In addition, experts recommend the mandatory installation of shut-off valves for supply and return.

This is necessary to facilitate repair of the boiler if it fails. In addition, the fittings will help prevent possible airing of the radiators.

A water filter is an element that must be installed when connecting a gas boiler to a water circuit

Stage #3 - connection to the water circuit

This work is almost the same as connecting heating pipes. The main difference is the taps used and the diameter of the pipes.

The cold water supply must be equipped with a filter, which will eliminate the possibility of contaminant particles entering the heating device. Otherwise the equipment will be damaged.

The taps used to isolate the boiler from the water supply must have detachable connections.

Such models are also called “American”. They significantly simplify installation, and in case of unforeseen situations, they make it possible to quickly replace a worn-out faucet.

It must be remembered that the pipes supplying cold water are located on the heating device on the left side relative to the center, and those supplying hot water are located on the right.

Stage #4 - connection to the gas main

This part of the work should only be carried out by a qualified specialist, since the cost of an error can be very high. In any case, upon completion of the connection, its correctness must be checked by a representative of the gas service. He will also conduct the first start-up of the equipment.

All operations when carrying out work independently must be performed with the utmost care. They start by connecting the branch of the gas main with the corresponding pipe on the boiler.

When connecting the boiler to the gas main, you can only use tow to seal the threaded connection, otherwise it will not be possible to achieve the required tightness

A special filter must be installed on the tap that cuts off the gas supply from the main line. Experts strongly recommend not to skimp on this detail.

A cheap, low-quality filter will not work for long, which can cause the gas boiler to fail. When arranging a connection, special attention should be paid to its sealing.

You must understand that the weight of gas is much less than air, and if the connection is not tight enough, it will leak out of the pipeline. The consequences can be the most dire. Therefore, careful sealing is mandatory.

The main materials for sealing a threaded connection are paint and tow; the use of sealants such as fum tape is unacceptable.

A special flexible connection is installed after the filtration element. You need to know that using rubber hoses for its installation is strictly prohibited.

This is due to the fact that over time, the material from which the part is made dries out and becomes covered with cracks through which gas begins to leak. Therefore, the best choice for arranging such a connection is a corrugated hose.

A corrugated hose is a good choice for connecting the device to the gas main. It is quite strong, durable and does not collapse under the influence of gas

For its manufacture, high-quality durable stainless steel is used. This is a very strong and durable material, particularly resistant to high humidity and the adverse effects of gas.

The hose is secured to the heating device pipe using a union nut. In this case, a paranitic gasket must be used, which provides the necessary sealing of the connection.

Stage #5 - connecting to the electrical network

This operation is only necessary for appliances with a closed firebox that require electricity. It powers the fan that removes combustion products and the automation that controls the system.

Typically a standard three-wire connection diagram is used. Experts recommend connecting the boiler to the network only through a stabilizer, which will make it possible to avoid power surges and thereby extend the life of the boiler.

If you live in an area where there are frequent power outages, then it is additionally advisable to purchase an uninterruptible power supply - this will protect your equipment from sudden power surges

Stage #6 - arrangement of the chimney outlet

The easiest way is to connect a heating device with a closed firebox to the chimney. For them, special coaxial pipes are used. In apartment buildings, the boiler must be connected to the collective chimney.

In individual buildings, a coaxial type chimney is led out to the street through a wall. The height of the pipe suspension in this case is not particularly important, since the necessary draft is created by the built-in fan.

Appliances with an open firebox must be connected to an individual chimney. The boiler is connected to it by a pipe of the required cross-section.

The material for its manufacture is selected so that the part is resistant to combustion products, high temperature and mechanical wear.

You can check the tightness of the gas pipe connections using a soap solution. A gas leak will manifest itself as bubbles

Before starting work, you need to make sure that there are no soot residues, installation debris, etc. in the chimney. When installing a chimney pipe, it should be positioned with a slight slope towards the gas boiler.

A vertical section of pipe is installed at the outlet of the device; its length before turning must be equal to at least two pipe diameters. The total length of the connection section to the chimney should be minimal.

Stage #7 - preparation for the first launch

Before the test run, the heating system is filled with water. The liquid is pumped until a pressure of 2 atmospheres is reached. Pumping water is carried out as slowly as possible in order to remove the maximum amount of air collected inside.

In addition, the system is checked for leaks. All leaking connections must be sealed immediately.

To identify insufficiently tight connections on the gas main, you need to dilute a soap solution and lubricate all connections with it. Then watch.

Air bubbles will appear in poor quality areas. Any faults found should be corrected and re-checked. The first start-up of the equipment should be carried out only in the presence of a gas service representative.