There are dozens of ways to insulate attic floors, using hundreds of insulation models, but mineral wool is still the most popular material.

Insulating the ceiling with mineral wool from the attic side is considered the best option

The only problem is that not all amateurs know how to properly insulate an attic with mineral wool in a private home. Therefore, next we will analyze the technology and important nuances of the process.

How to calculate layer thickness?

To calculate the thickness of the required insulation layer, special calculations should be carried out.

This will not be difficult if you use an online calculator. In general terms, the calculation scheme is based on the physical parameters of the substances and established building standards. For example, in Moscow SNiPs establish that the insulation of all types of floors should provide resistance to heat transfer, R = 4.15 m2C/W. When polystyrene foam with a thermal conductivity of 0.04 W/mS is used, the required coating thickness is calculated as follows: 4.15 x 0.04 = 0.166 m. Polyurethane foam will require a layer thickness of 125 mm, and expanded clay should be 415 mm in height.

How thick should the attic floor insulation be?

The thickness of the thermal insulation layer does not depend on which attic floor construction using wooden beams or reinforced concrete is chosen. On the packaging of any insulation, the coefficient of thermal conductivity λ is indicated, and it has two values: λA - for a dry environment, and λB - for a wet environment. The lower this coefficient, the better the insulating properties of the material. It is on the basis of this value that the calculation of the insulation of the attic floor is made.

The thickness of the attic floor insulation is:

α = R0·λB

where R0 is the heat transfer resistance coefficient, which, according to standards, is equal to 4.15 m² °C/W.

2 Why is mineral wool used to insulate an attic?

In most cases, when insulating attic floors, the consumer's choice falls on mineral wool. Its advantage is that its installation does not require special skills.

Mineral wool has excellent thermal insulation properties. Its structure consists of thin glassy fibers, the length of which ranges from 2 to 60 millimeters.

Insulating the attic with mineral wool

High sound insulation characteristics are ensured due to the presence of a large number of air pores.

These pores are located in the space between the fibers and can occupy 95% of the total volume of the insulation. Mineral wool is presented in three varieties; it can be basalt glass and stone.

Basalt wool is made using molten basalt rocks, to which binding elements are added.

This may be a carbonate type rock, which regulates the acidity level of the substance, which entails an increase in the service life of the insulation. Glass wool exhibits high heat-resistant properties and can withstand temperatures up to +450 degrees Celsius.

2.1 Technology for insulating attic floors with mineral wool

When carrying out work related to mineral wool, it is important to comply with all safety requirements and regulations. This is due to the fact that in the process of cutting and laying such material, the air is filled with tiny particles that can enter the respiratory organs and thus cause harm to human health.

This is due to the fact that in the process of cutting and laying such material, the air is filled with tiny particles that can enter the respiratory organs and thus cause harm to human health.

During installation, be sure to ensure the availability of personal protective equipment. Goggles, a respirator and thick rubber gloves must be available.

The process of insulating attic floors begins with the selection of the necessary tools and additional materials. You can't do without:

Insulation

- Boards and plywood;

- Vapor barrier film;

- Mineral wool (excellent insulation for an attic roof);

- Waterproofing;

- Scotch tape;

- Roulettes;

- Knife;

- Construction stapler;

- Spatula.

The essence of insulation technology is that the insulation must be carefully laid in the space between the attic floors or beams.

To enhance the thermal insulation qualities, reliable vapor barrier protection should be used. Warm and moisture-saturated air will continuously rise from the living rooms and reach the top through the ceiling.

There, in the under-roof space, it will collide with a layer of insulation. Due to the fact that mineral wool is generally considered a vapor-proof material, it will absorb all the outgoing moisture inside itself.

If it is left without the necessary access to air and sunlight, it will gradually dry out and, ultimately, lose all its heat-insulating qualities.

Cold attic interfloor covering 20 cm min. wool

In order to avoid such destructive consequences, it is necessary to lay a vapor barrier material under a layer of mineral wool.

Before starting the main work, you will need to carefully calculate the required amount of insulation.

To do this, you need to calculate the total area of the entire surface of the attic, and then purchase the highest quality and most reliable insulation, which must meet all the necessary requirements.

The amount of cotton wool purchased depends on how many layers are planned to be used when covering the attic space. In addition, the thermal insulation thickness parameter directly depends on the climatic conditions in the region.

Useful insulation

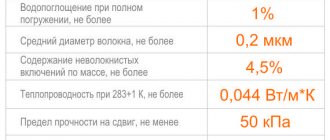

In practice, no construction innovation in the field of insulation can compete with mineral wool, which has already been proven over the years, which is ideal for insulating a country house. Due to the fact that mineral wool is made from hard rocks, its abilities reflect the thermal insulation properties of the stone. The meter-thick stone walls were replaced by brickwork insulated with stone wool. It has the following characteristics:

- thermal insulation;

- sound insulation;

- fire resistance;

- vapor permeability;

- environmental friendliness.

The thermal insulation coefficient of insulation is 0.038–0.045 W/Km, which is a rather low indicator. Thus, a protective layer of mineral wool with a thickness of 100 mm can be compared in terms of thermal insulation with brickwork with a thickness of 1170 mm. In this case, the sound insulation coefficient is 0.95 with a maximum value of 1.

Insulating a home with fiber insulation meets all fire safety requirements, since it does not burn at all and can withstand high temperatures.

For a wooden house, the vapor permeability of the thermal insulation material is also a very important indicator.

In this case, you cannot do without mineral wool. It has good vapor permeability and is used for installation of ventilated facades. And the last property of cotton wool is its environmental friendliness: the materials used in production do not have a harmful effect on humans and the environment.

Features of installation of different materials

The tactics of action depend on the chosen material and the location of its placement - from inside the room or from the attic.

Laying mineral wool

Installation of insulation is carried out along the attic floor.

When constructing a thermal insulation cake, it is important to meet two conditions:

- ensure protection of mineral wool from water vapor coming from inside a warm room;

- arrange ventilation of the outer surface to ventilate moisture from the insulation.

Mineral wool slabs are laid between beams or strips of prepared sheathing. Can be mounted on the ceiling surface.

Before starting work, it is necessary to check the boards for rot and treat the wooden elements with an antiseptic. Make sure the roof is not leaking

The surface is cleared of debris, and if necessary, a wooden frame is constructed.

Further actions:

- Install a vapor barrier membrane.

- Roll out rolls or place mats between beams.

- Install a wooden base, maintaining a ventilation gap between the insulation and the hard floor.

The last step can be missed. However, it will not be possible to walk in the attic or store things there, since mineral wool cannot be pressed.

Internal lining with expanded polystyrene

This thermal insulation option is suitable for concrete ceilings. Expanded polystyrene slabs are fixed to the surface with glue and secured with “fungi”.

At the preparatory stage, the ceiling is cleared of debris and old finishing, holes, cracks and gaps between the slabs are sealed.

Before installing the insulation, the ceiling is treated with an antifungal compound and primer.

The procedure for attaching polystyrene foam boards:

- Apply glue to the insulation, apply and press it to the ceiling.

- Cover the entire area with slabs, leaving no gaps between the elements.

- Use a hammer drill to drill holes for fasteners.

- Kill the fungi.

- Foam the joints and gaps between the plates.

- Cut off the remaining foam and fix the reinforcing mesh with adhesive.

- The surface should be primed and plastered.

After the layer has dried, clean the ceiling and apply the final decorative coating.

Filling the attic with expanded clay

The minimum layer of bulk insulation is 20 cm. To adjust the height of the backfill, you need to prepare a beacon - make the necessary mark on a piece of reinforcement, securing a piece of electrical tape.

If a wooden base is insulated with expanded clay, then the floor must first be covered with waterproofing extending onto the walls. Polyethylene film will do

There is no need to lay a water barrier on a concrete base.

Sequence of work:

- Pour in expanded clay and distribute the granules evenly.

- Check the thickness of the insulating layer. Its height should be 3-4 cm below the level of the flooring. If this norm is neglected, then when walking through the attic the sound of granules rubbing will be heard.

- Lay a layer of vapor barrier membrane and seal the joints of the panels with tape.

- Install a rigid base. Boards, fiberboard or OSB panels are suitable.

The floor on top of expanded clay makes it easier to move around the attic and increases the effectiveness of the insulation cake.

Application of Spray Insulation

It will not be possible to carry out the work yourself, since spraying will require expensive equipment - a high-pressure apparatus. In addition, skills in working with equipment are required to evenly distribute polyurethane foam.

To start the device, a voltage of 380 V is required. If there is a two-phase network in the house, a generator is connected that produces the required value of the electric field.

It is better to entrust the work to a specialized company and conclude an agreement with them for the provision of services. At the appointed time, a team arrives and extends a hose with a gun into the house.

Recommended work order:

- Install wooden joists on the attic floor. They will be needed for subsequent fastening of the flooring.

- Fill the device with components in the required proportions.

- Set the gun to the minimum foam supply force.

- Apply polyurethane foam between the joists in an even layer.

- Wait for the composition to dry. If the thickness of one layer is not enough, then the treatment must be repeated.

- Level the cured coating by cutting off the excess to the level of the joist.

- Mount on boards on a rigid base.

To insulate a small ceiling yourself, you can use a disposable foam spray kit.

The kit contains everything you need: cylinders with components for preparing foam insulation, a spray gun, hoses, personal protective equipment

Assembly and preparation takes a couple of minutes, no power supplies are needed - the device operates autonomously.

Glass wool

It is a type of mineral wool; glass and a small amount of sand are used as a base. The fibers have a larger diameter and thickness, which increases their mechanical strength. The main disadvantage of glass wool is the high fragility of the fibers; when they get on the skin and in the respiratory tract, they cause prolonged itching and irritation.

Features of application:

- Mandatory insulation of wool to prevent glass dust from entering living spaces;

- Short service life. Due to the fragility of the material;

- During installation, you must use personal protective equipment - work glasses, a respirator.

The advantage of glass wool is its lower cost compared to its basalt counterpart.

Brands: URSA GEO, Isover Warm Twin House, TeploKnauf.

Features of attic insulation with polystyrene foam

The method of thermal insulation with polystyrene foam depends on the purpose of the upper room:

- If the attic is very low or is not intended for use, only the floor is insulated with material, placing it on top of the structure or inside. The latter option is used at the stage of building a house, when sheets can be placed between the joists without any problems, and then covered with a finished floor on top.

- The sloping roof is insulated with slabs, placing them between the rafters. Positive temperatures will be maintained due to the entry of heat from below from living quarters.

- The pediment is finished with sheets fixed to the vertical surface on the side of the room.

Thickness calculation

In an individual house there are no requirements for thermal protection of structures, so the thickness of the insulation can be selected approximately. It depends on the climate of the area; for most cases, protection with mineral wool 100-150 mm thick will be sufficient.

To calculate a more accurate value, you can use the help of a specialist or the simple Teremok program. It can be found freely available on the Internet.

Mineral wool is a modern thermal insulation material that, if used correctly, will last a long time and reliably protect building elements. The material is suitable for working with all types of floors from basement to attic.

Why insulate?

For comfortable living conditions in winter, houses are heated, consuming a huge amount of coolant. Every year the cost of heating only increases. In order to save costs and reduce heat loss, energy-saving double-glazed windows are installed and walls, floors and ceilings are insulated with heat-insulating materials.

More than a third of a home's heat escapes through the roof as warm air rises. Through an uninsulated ceiling, warm flows leave the living spaces and rush into the attic, where, in contact with the roof covering, they form condensation on the floor beams and rafter system. High humidity leads to material deterioration and fungal growth, reducing the durability of the roofing structure.

If the attic space is actively used or serves as an attic, then the roof itself is insulated. When the attic is not in use, the attic floor is insulated. Installation is carried out on the beams of a cold attic.

In this case, you can achieve multifunctionality of the insulation:

- protection from hot hot air in the attic in the summer allows the living space to remain cool;

- sound absorption function: noise from howling wind and precipitation is reduced;

- retention of warm air indoors during the heating season is achieved by creating an insulating barrier.

Vapor barrier materials

The most popular vapor barrier material is a special film that protects wood and insulation from the effects of steam, which turns into condensation as a result of temperature changes. The negative impact of moisture on the elements of the roofing structure need not be mentioned once again - suffice it to say that it significantly reduces the service life of the roof and the effectiveness of the thermal insulation material.

The vapor barrier membrane is attached to the roof or ceiling before thermal insulation materials are laid. In rooms where heating is installed, a vapor barrier should be installed only under the finishing layer. To protect structures that are constantly exposed to temperature contrast, a vapor barrier layer must be placed on both sides. The exception is concrete floors, which do not require such protection.

To create a vapor barrier layer, a film with different characteristics can be used. The simplest option is a film made of non-woven material, but a much more effective option is a foil membrane. The latter option, as its name implies, has a thin layer of foil on one side, which prevents heat from escaping beyond the structure. The roof vapor barrier installed from the inside of the house is connected with special tape, ensuring a tight connection.

Insulating the attic in a private house

When insulating an attic with mineral wool, it is laid either in a continuous layer (see photo) or in cells with grooves, to obtain which a light frame is assembled from wooden blocks.

However, before laying the mineral wool, the surface on which it will be installed is reliably protected by a vapor barrier layer. Thus, the vapor barrier will prevent condensation from forming in the insulation due to the large temperature difference.

The vapor barrier material must be laid correctly (see the markings on it) and with a slight overlap, up to 10 cm. The vapor barrier layer must protect all protruding structures and cover the joints well.

Only after laying the vapor barrier layer can you begin to insulate the attic with mineral wool. To do this, if necessary, the slabs are cut to the size of the cells with a sharp construction knife, and then laid in them, without any gaps.

Also, it is imperative to ensure that the mineral wool has a free shape, is not compressed, etc., since otherwise its thermal insulation properties are greatly lost.

The final stage in insulating the attic of a private house with mineral wool is laying a waterproofing layer. If the attic space will not be used for any purposes in the future, then this is quite enough to complete all the work related to its insulation.

In another scenario, after laying the waterproofing layer, subfloors are laid on top of it, which subsequently serve as the base. At this point, the insulation of the attic in a private house is completed. Be sure to leave your reviews, wishes and advice on the website samastroyka.ru.

Final finishing

The material for the final finishing of the attic can be any sheet material that can protect the insulation from damage. Most often, plasterboard, chipboard or OSB boards, as well as wooden lining or plastic are used.

Installation is carried out on slats that secure the thermal insulation to the roof. You can assemble a separate metal frame from profiles, but this will require additional space in the attic and will once again compromise the tightness of the waterproofing.

Properly installed attic insulation will not only help conserve heat, but will also protect roofing and ceiling elements from premature aging.

The main advantages of attic insulation

Layers of insulation before laying the floor

The benefits of properly insulating your attic are well known. First of all, it is about maintaining heat in the house. There are also other factors to consider, such as the health of you and your loved ones.

Proper attic insulation can bring many benefits to you, your family and your home.

1. Save money on electricity and gas bills

Better attic insulation saves you money. After all, a poorly insulated house can lose a quarter of its heat through the roof.

The simple solution is to install appropriate insulation

If this insulation is the recommended thickness of 270mm, you could save up to 25% on your electricity or gas bills.

Good insulation increases the value of your home

Improving the energy efficiency of your home makes it more valuable. According to statistics from completed home purchase and sale transactions, real estate with energy-saving technologies was sold at an average of 14% higher price.

Properly installed insulation can improve your health

A damp problem can affect your health or the health of other family members

Poorly insulated attics and those where flooring is installed incorrectly can cause dampness and condensation. This can lead to mold which, along with dampness, means you are more likely to have respiratory problems, respiratory infections, allergies or asthma.

Problems often arise when insulation is compressed by improperly installed attic flooring. This will stop the air flow between the floor and the insulation.

It is important to lay a solid base on top of the insulation

This can lead to problems such as:

- The insulation loses its thermal efficiency.

- This causes cracks in the ceiling.

- Water vapor generated in the home rises until it hits the cool surface of the lower attic floor.

- This may cause condensation to form inside the insulation.

- The condensation then begins to seep down, creating dampness and affecting the ceilings.

If you want to use your attic space for storage, adequate air flow is essential. This should be considered an absolute necessity.

Helps the environment

A properly insulated private home can reduce CO2 emissions by up to 80kg per year. Reducing CO2 emissions means you are doing your part to reduce global carbon emissions. And therefore the consequences of climate change.

Reduced wear and tear on your boiler

- If your boiler has to produce more heat than it needs, consider it won't last as long as it could.

- Having proper attic insulation means that you will create a stable living environment inside your home.

- This will help extend the life of your boiler, which is another way to save money!

Which mineral wool is better for the ceiling?

When the question arises about varieties, it becomes clear that stores provide more than just one type of mineral wool. Indeed, there are several different products. Which one to choose when the goal is to insulate the house?

Important! Mineral wool is made from a variety of “bases”, the main ones being stone and glass. Among these there is no universal one. Different purposes and compositions of surfaces for insulation will prompt you to choose the right one.

Glass wool is a type of construction wool. The name says that it is made of glass. To make the glass variety, many operations are performed on glass chips, among them melting the sand in the source material. Thanks to the melted grains of sand, the roll or slab has a yellowish tint and a rough structure.

The advantages of this option include the following:

- Ease. Working with heavy elements is always more difficult. There is no need to involve additional labor for installation and transportation of glass wool.

- Elasticity. Glass is resistant to deformation, stretching, tearing, bending.

- Fire resistance. There is a percentage possibility of fire. Carriers who reset it are considered unscrupulous. However, in fact, in most cases the glass version does not burn.

Attention! The best glass wool is made in Germany. You should pay attention to German products.

With the second variety, things are worse - the stone version has more disadvantages than advantages. Stone wool is used as insulation or for its long service life.

There is a third, modern option - ecowool. It is expensive, but it is also used.

Modern methods

The industry is developing every year. Modern thermal insulators are increasingly entering the market. Therefore, insulation of the attic space can be carried out using the latest technologies and materials. This primarily includes:

- ecowool;

- polyurethane foam.

Ecowool has been used for insulation of the attic of a private house not so long ago. This modern material is suitable for both brick and wooden buildings. Ecowool is produced from pulp industry waste. To protect against insects, moisture and fire, the material is impregnated with special solutions. The result is a loose, lightweight and effective means for insulating the attic and other elements of a private home.

How to use this material correctly? The attic is insulated with ecowool using a special blow molding unit. The material is loaded into it and “sprayed” directly onto the desired surface. In this case, no preliminary actions are necessary. Ecowool penetrates all openings under high pressure, which makes the attic insulation reliable.

You can use another method. Ecowool is mixed with a special paste. After this, it is applied in a liquid state to the desired area. After drying, a reliable layer of attic insulation is obtained.

This material has one more advantage. A couple of weeks after the attic is insulated with ecowool, a crust forms on its surface. It has the scientific name lignin. This additional layer protects the insulation from moisture and other external influences. If you want the crust to form faster, then just spray a little water over the ecowool.

Insulating the attic with polyurethane foam is the most modern way to protect your home from the cold. This material has many undeniable advantages, namely:

- This kind of attic insulation will be the thinnest. The material has the lowest thermal conductivity. This means that its layer can be made small.

- Insulating the attic with polyurethane foam means getting rid of “cold bridges” one hundred percent. The material is sprayed in liquid form under high pressure. As a result, it penetrates into everything, even the smallest cracks. In addition, polyurethane foam has good adhesion. It securely attaches to any surface.

- Another advantage of this method of insulation is that the material is not afraid of moisture, rodents, insects, mold and other external influences. This means that there is no need to make additional protective layers.

But there are also disadvantages. Insulation with polyurethane foam is carried out using special equipment. It is quite expensive. Therefore, purchasing it for a one-time job of insulating the attic of one private house is unprofitable. That is why a special team is invited to perform such a task, and funds must also be spent on paying for its services. But this minus also has a positive side. All work will be performed by professionals. This means that the thermal insulation of the house will be at a high level.

Video on the topic:

Arrangement of the attic

The roof of the finished attic has the appearance of a layer cake. Exterior covering is a roofing material designed to protect a home from precipitation. From the point of view of thermal insulation, it does not provide any effect. The top waterproofing barrier is roofing material or a special film that is capable of retaining water, but is vapor permeable. It is laid in such a way that water flows through it to the outside. Next comes a layer of insulation, which forms a thermal insulation barrier.

The vapor barrier is designed to completely protect the installed insulation layer from moisture and steam. This polyethylene film is truly completely vapor and waterproof. Everything ends with a decorative coating to give aesthetic appeal and protection from mechanical damage.

The greatest difficulty in insulating an attic space is installing a waterproofing layer on insulation of a complex shape. The difficulty lies in bypassing all the load-bearing elements of the roof and organizing its exit under the roof to discharge water

It is very important here to maintain the integrity of the layer. Joints and fastening points must be taped, and secured between the rafters with staples or vertically nailed slats

The insulation is placed tightly between the rafters and, together with the hydrobarrier, is secured with slats, which will later serve as a support for the finishing. It is recommended to insulate with mineral wool formed into sheets or slabs, since it is more resistant to caking and shedding during operation compared to rolled wool.

Insulation of gables

Now all that remains is to insulate the gables, if, of course, they exist. It must be said that it is more expedient to insulate them from the outside in parallel with the insulation of the entire facade. However, if the facade will not be insulated, then thermal insulation must be done from the inside.

For this we will need the same materials as for finishing the roof. The only thing besides them is to prepare beams or boards. Their width should correspond to the width of the insulation.

The insulation work is similar to the thermal insulation of ordinary walls:

- In order to provide ventilation space between the walls and the insulation, the slats must be secured to the gables in a horizontal position. The vertical step should be about half a meter, and the horizontal step should be several centimeters.

Installation diagram of slats on gables for arranging a ventilation gap

Keep in mind that the slats must form a smooth vertical plane. Therefore, if the gables are uneven, the slats must be leveled during installation;

- then a vapor barrier membrane is attached to the slats. During installation, make sure that the film does not sag;

- then vertical posts (beams or boards) are installed. To fix them, you can use self-tapping screws and metal corners. Make the distance between the posts a couple of centimeters less than the width of the mats;

An example of laying mineral mats in the space between the racks

- Now the space between the racks must be filled with insulation. If the racks are installed correctly, the mats will fit tightly and no additional fixation will be required;

- then attach a vapor barrier to the racks;

The photo shows an example of the sheathing of an insulated pediment

- At the end of the work, install the sheathing.

Now all that remains is to complete the finishing. The choice of finishing materials depends on the purpose of the home and the attic itself. If the house is used for permanent residence, and the attic will be heated, you can cover it with plasterboard and use any finishing materials.

Finishing a cold attic should be done with materials that are not afraid of low temperatures. Therefore, it is better to avoid using wallpaper and plastic panels.

Main nuances of the procedure

- The wood rots, therefore, the steam rising from the house must pass freely. If you install a vapor barrier or use a material that does not “breathe,” the tree may soon collapse.

- Insulation with foil should be laid with it (foil) down to protect the wood from moisture.

You can see examples of correct and incorrect installation in the image below.

But here is a universal scheme - insulating the attic floor using any of the materials.

Video - thermal insulation of attic floors

As a result, we note that the thermal insulation of the attic floor will be most effective if the attic itself is reliably protected from moisture penetration from the outside. In other words, you also need to properly arrange the roof. Good luck with your work!

Steam and thermal insulation of a cold attic

For a roof with a cold attic, it is most important to minimize heat loss through the attic floor. For both wooden and reinforced concrete floors, a vapor barrier is mandatory. It is laid on the ceiling itself and protects the insulation from vapors that can condense in the heat insulator after passing through the ceiling of the living room

Slab and bulk materials can be used as insulation. The ceiling pie consists of a vapor barrier, floor beams and insulation

It is laid on the ceiling itself and protects the insulation from vapors that can condense in the heat insulator after passing through the ceiling of the living room. Slab and bulk materials can be used as insulation. The ceiling pie consists of a vapor barrier, floor beams and insulation.

The following types of heat insulators are often used in ceiling coverings:

:

- expanded polystyrene and foam boards;

- mineral wool slabs or mats;

- expanded clay granules;

- fuel or granulated slag;

- sawdust with lime or clay;

- pumice.

The thickness of the required insulation layer is selected depending on the estimated winter temperature using the table below.

Winter temperatures are calculated according to SNiP 2.01.01-82 (building climatology and geophysics) or selected by regions of the Russian Federation from the corresponding climate maps.

The insulation is laid between the joists or ceiling beams, and a boardwalk is made on top for the attic passages. Joists are usually 50 mm thick, and decking boards are 25-35 mm thick.

Attic waterproofing device

Waterproofing roofs with a cold attic, according to many experts, is a controversial issue. Some say that waterproofing must be present under the roofing material, while others categorically recommend that it be abandoned. Here, a lot depends on the type of roofing material and the angle of inclination of the roof slopes.

Metal roofs are most susceptible to corrosion, which occurs due to possible small leaks or condensation

Therefore, we once again draw your attention to the fact that ventilation plays one of the main roles in the fight against condensation.

For flat metal roofs, experts recommend installing superdiffusion membranes. It will prevent moisture from entering the outside of the roof when snow or rain blows in. No matter how well the roof is laid, there is always the possibility of minimal leaks. That is why, by paying a little extra, you will receive additional protection from moisture getting on the insulation in the ceiling of a cold attic.

If, for example, slate is used as a roofing material, then waterproofing can be abandoned. There is also corrugated sheeting with an anti-condensation coating on the market, which can hold up to 1 liter of water per 1 m2. For our part, we recommend always using waterproofing membranes, because this is the cheapest and easiest additional way to protect your roof from possible leaks

.

When installing waterproofing membranes, a counter-lattice is used. It serves as a fixing strip and, due to its height, provides the necessary clearance for ventilation of the under-roof space. The installation of lathing in a cold attic is no different from insulated roofs. The dimensions of the sheathing and its pitch determine the type of roofing being installed.

Cold attic temperature

To prevent ice and icicles from forming on the roof, it is necessary to maintain the correct temperature and humidity conditions in the attic. If the thickness of the thermal insulation material is insufficient, significant heat losses occur through the ceiling. Warm air, heating the roof covering, causes snow to melt and ice dams to form. By choosing the right insulation layer, this can be avoided.

The effectiveness of a heat insulator can be assessed by measuring the temperature of the top layer of insulation. The electronic thermometer is immersed in insulation by 10-20 mm. The temperature readings taken should correspond to the values in the table below.

As you can see, the design of a cold attic pie is not particularly complex in design. The main task is to ensure the necessary intensity of ventilation and the thickness of the thermal insulation layer in the ceiling.

We will install copper roofing quickly and efficiently

Ceiling-side insulation technology

If, for technical reasons, insulation from the side of the cold attic is impossible, then thermal insulation systems are installed from the side of the room, i.e. put on the ceiling. This option is more difficult to implement, but sometimes it is the only possible one.

When thermally insulating the ceiling from the ceiling side, the following are used:

- Styrofoam. Non-extruded polystyrene foam panels are simply glued onto a pre-lined ceiling. Silicone sealant or polyurethane foam is injected into the gaps between the elements, the excess of which should be removed immediately.

- Extruded polystyrene foam. They also stick it on. Most often, Penoplex is used with a mounting edge, which eliminates the possibility of cold bridges. The thickness of the insulation can be accurately calculated according to the climatic data of the area and a material with the appropriate characteristics can be selected.

- Cork. The simplest option is a cork sheet used as a flooring for heated floors. Panels glued to the ceiling will also work, but the cost of the insulation system will ultimately be much more expensive.

Gluing while holding the material in a canopy is, of course, much more difficult and complex than pouring it from above. In addition, these options are not applicable without external finishing. They just need to be decorated.

Masking of the ceiling insulation system is done by installing frame structures: suspended and slatted ceilings. To install them, a fixing profile is installed around the perimeter of the room, located below the glued insulation by at least 1-2 cm.

If you plan to install ceiling lights and exhaust ventilation ducts, then the distance between the plane of the decorative ceiling and the thermal insulation system increases. As a result, you may end up with an excessively low, as if “pressing” ceiling, which negatively affects the interior design and the well-being of the home owners.

Options actively used in practice also include single- and multi-level plasterboard structures. The rigid GVL option is a priority due to the fact that if the heat-insulating board gets wet and peels off, it will freely hold the separated part.

In the field of installing an insulation system from the inside of a room, heat-insulating plasters stand apart. Materials for their implementation have been developed relatively recently. The pioneers in their use were progressive industries: the military space complex, civil aircraft construction.

The heat-insulating plaster material applied to the ceiling contains tiny ceramic balls, which contain air inside. This is the most effective insulator.

A valuable advantage of heat-insulating plasters is the ability to apply a thin layer of 1 mm, the effectiveness of which will be equal to the efficiency of a foam plastic board 5 cm thick. The disadvantage is the considerable cost and complexity of application, which requires special equipment.

What shouldn't happen

Do you know how a greenhouse works? To explain it in a primitive way, a film is stretched over the frame, providing insulation of the space from the external environment. We noticed that with a sealed shell, drops of water condense on the film. In the absence of ventilation, high humidity has a detrimental effect on plant growth and the condition of retaining structures. Therefore, the greenhouse must be equipped with ventilation, which allows maintaining the necessary microclimate. To eliminate the greenhouse effect when insulating the attic, it is necessary to use hydro- and vapor barrier in conjunction with thermal insulation.

Requirements

When choosing a material, it is necessary to pay attention to a number of characteristics that certain materials have. What is suitable for a concrete floor will not be suitable for a beam floor. Therefore, it is necessary to consider:

- resistance to moisture accumulation;

- thermal conductivity;

- dimensions (thickness, weight per 1 m3) of the material;

- fire resistance;

- resistance to decomposition and attack by mice, fungus and mold;

- environmental indicators (toxicity);

- vapor permeability;

- maintaining shape when pressed and during operation;

- simplicity in the installation process (release form).

A combination of insulation materials is also used in practice to compensate for the shortcomings of a particular material. For example, crumbly material can be foamed so as not to install an additional frame to hold it. Or the lack of density of mineral wool is compensated for by polyethylene or polystyrene slabs , which also serve as waterproofing.

Moisture absorption

Insulation materials are initially produced in such a way that they absorb moisture as little as possible or not at all, that is, they have water-repellent properties.

Foam insulation materials that do not have natural components cope best in this regard, especially if their cells are closed, like polystyrene foam. When liquid accumulates, the material immediately loses its basic properties by up to 50%, not to mention the fact that it begins to rot and transfer water to the wooden elements of the roof.

Thermal conductivity

The lower the thermal conductivity indicated on the packaging, the warmer the insulation. The average insulator value hovers around 0.04. Some manufacturers indicate the degree of thermal conductivity in 3 states :

- in dry form;

- at a temperature of 10-25°;

- in rooms of categories A and B (+28° and above).

The price depends on the thickness of the insulation and its properties. A thin product, but with a lower thermal conductivity, is more expensive. However, when insulating the attic floor, the thickness of the material does not matter.

If there is no planned residential area in this room, where every centimeter of space is important, then there is no point in buying thin insulation. You can insulate a floor with 1-3 layers of thick material, saving significant money.

Table of coefficients of thermal conductivity, density and vapor permeability of insulation:

Thickness and weight

For wooden floors, the weight of the insulation is important because it is limited. You must not create too much pressure on the floor beams, so that over time they do not begin to sag. At the same time, a thin layer of insulation will not provide the necessary heat retention properties.

To understand what thickness of a particular insulation will be required for a house, you need to use a special table that takes into account the average temperature of the region, the weight of the insulation per 1 m3 and its thermal conductivity.

For example, the owner decided to use mineral wool to insulate the ceiling; he lives in a zone where the average winter temperature is -20°. For his attic it is necessary to lay at least 7 cm of such material. A slab of mineral wool, meter by meter, 7 cm thick, will weigh 14 kg.

In this table you can see the thickness and weight of mineral wool, polystyrene foam and polyurethane foam:

Resistant to fire and decay

When a fire starts in a house, everything starts to burn, even bricks. The insulating material must be resistant to fire and have self-extinguishing properties in case of short circuits and other factors.

In this case, mineral wool, or rather basalt wool, which begins to smolder only at a temperature of 600°, wins. Polystyrene foam or ecowool, which is essentially cut paper, as well as sawdust take first place in terms of flammability.

Exposure to mold, mice

The fewer natural components in the insulation, the less attractive it is to mold. Synthetic materials win in this regard, mineral materials lose, and natural ones, for example, sawdust and husks, are the most suitable for mice and fungi.

However, if waterproofing is installed correctly so as not to create a warm and humid climate for the reproduction of certain organisms, then such incidents can be avoided.

Toxicity

During combustion and normal operation, the insulation should not emit toxic substances. As you know, in the event of a fire, most people die not from burns, but from carbon monoxide and chemicals that the product releases during the combustion process. For example, synthetic materials are the most toxic not only during combustion, but throughout their entire life .

Plastic-based insulation (polyurethane, polystyrene) during normal operation at normal temperatures emit a number of substances, including benzenes, formaldehyde, toluene, acetophenone and others.

Mineral heat insulators are not much better. Although they consist of 80% natural components (basalt, fiberglass), the substances used to combine them are quite toxic (phenols, formaldehyde, etc.). The most environmentally friendly insulation is flax and sawdust, but they are the most flammable. Therefore, the choice will have to be made by the developer himself, which is less dangerous for him.

Vapor permeability

This indicator is only relevant for a wooden house.

Since wood is fibrous, it allows steam to pass through it, and it needs an outlet. Mineral insulation works well for this task.

Water does not accumulate between the attic floor and freely comes out through the mineral wool, and especially through the glass wool. For concrete floors, high vapor permeability is not so important.

Shape stability during operation

Over time, some insulation tends to shrink by a small fraction of a percent, but this fraction is enough to create an air corridor through which heat will begin to escape from the room. EPP (expanded polystyrene) has the best performance in maintaining shape.

It is also the most durable material from the group of lightweight insulation materials, that is, you can walk on it and it will not bend. Mineral wool has the worst performance in terms of shape retention and strength , but it can be compacted for future use, which cannot be said about other heat insulators.

Easy to install

It is best if the insulation can be laid without the use of special equipment and the creation of additional frames. In this case, all hard, medium-hard, tile insulation or mats are suitable.

And although crumbly materials can be laid on the attic floor without difficulty due to the flat horizontal surface, compacting them manually will be difficult and not always of high quality. For example, ecowool is laid both manually and using a sprayer. In the second case, the work will be of the highest quality, without gaps and cracks, but quite expensive.

How to choose?

When choosing thermal insulation materials, the type of floor and the characteristics of the insulation are taken into account. The characteristic qualities of the heat insulator become the decisive criterion.

A number of factors are taken into account:

- Thermal conductivity level. The best insulation has low thermal conductivity and a small layer thickness.

- Weight. The load on the floors depends on the weight.

- Fire resistance and frost resistance. The material must not ignite.

- Ease of installation.

- Durability. The insulation must be durable, not collapsing under the influence of adverse conditions.

- Ecological cleanliness. The more natural the composition of the material, the safer it is for human health.

- Price. In private construction, price often becomes the main criterion.

What types of insulation are suitable for use in the attic?

Typically, this kind of insulation is necessary in little-used rooms

It is also important to note that they must be equipped with properly equipped roof ventilation

The attic, together with its ceilings, performs a very important function, namely, it acts as a boundary between heat and cold. A large amount of condensation accumulates here and this occurs as a result of intense exposure to moisture in the attic.

And this must be taken into account when insulating your private home.

Many firms and companies offer similar services, but it often happens that the prices for their services are too high and many people think about insulating the house themselves. You can insulate your house with your own hands

However, for this it is important to take into account all the installation features of this or that insulation.

Below we describe in more detail all the materials that can be used as insulation for the attic. All the advantages, as well as their disadvantages, will be discussed here, so that in the end you can choose the most optimal option for yourself.

But first you need to determine the main types of insulation:

- bulk;

- slab;

- roll;

- sprayed.

It should be noted that each of the options has its own characteristics and can be used as insulation for the attic

It is important to understand that only the main materials that have received the largest number of positive reviews are listed here.

Average cost of materials in the Russian Federation

The table shows average prices in the Russian Federation in rubles:

| Insulation | Release form | Volume, mass | Price | |

| Mineral wool | Basalt | Plates 12 pcs/pack. | 800x600x50 (1 piece) | 900-950 |

| Glass wool | Roll | 20 m2, 50 mm | 1100-1200 | |

| Ecowool | Package | 0.12 m3 | 100-110 | |

| Expanded polystyrene | Styrofoam | Plates | 100 mm | 300-320/m2 |

| EPPS | Plates in packaging | 13 pcs., 30 mm | 1400-1500 | |

| Polyurethane foam (spraying service) | Powder | Density 45-60 kg/m3 | 1200-1300/ m2 | |

| Foamed polyethylene (foil) | Roll | 5 mm, 1.2×25 m | 850 | |

| Wood sawdust | Shavings | car | 3500-5500 | |

| Fractional expanded clay | Fractions 10-20 mm | bag | 1800/m3 | |

| Foam glass | Plates | 1 m3 | 10100 | |

| Rice husk | Husk | ton | 1000 | |

| Metallurgical slag | Granules | ton | 600 | |

| Jute | Roller 20 m | 5-6 mm, | 130-190 | |

What you need to know before starting work

Where to start?.. The topic is quite extensive, and work related to insulation requires, if not professional, then at least basic knowledge about the materials available on the market, their properties and methods of their use.

If you do the work without having this knowledge, you can, at best, waste time, effort and money, so to speak, in the wind, which is what makes it cold, and at worst, provoke a fire due to neglect of fire safety rules and improper installation of insulation material. Yes, insulation is needed to keep warm, but a fire is clearly too much in every sense.

Now we will look at the most popular materials, and also find out how to create a cold attic using common types of insulation. We'll find out what the advantages and possibly disadvantages of each are.

Thermal insulation of tiled floors

The principle of insulation of prefabricated reinforced concrete slabs or monolithic floors is similar to a similar process in the case of beam type. True, since the vapor permeability of reinforced concrete slabs is quite low, performing a vapor barrier on the “warm” side is not necessary. The thickness of the thermal insulation layer is calculated taking into account the type of supporting slab. A tiled floor with a flat surface can bear a large load.

Preparatory work

Ceiling insulation with mineral wool should be carried out on an already prepared base. For concrete floors with insulation from below, the following work must be done:

- remove the lighting, insulate the wires using terminals or electrical tape;

- remove finishing: whitewash, paint or liquid wallpaper;

- tap the joints between the floor slabs. Remove loose plaster;

- prime twice and then seal the seams with gypsum plaster;

- repair cracks and chips with repair mortar;

- remove dirt, soot and volatile fats;

- prime the ceiling twice. The first layer of primer, diluted by 30-40%, is applied generously, in 2 passes. The second time the surface is primed after a day - it takes time for the first layer to set;

- a sheathing made of wooden slats or a metal profile is installed.

You can see how to properly mount the frame in the article “Do-it-yourself suspended ceiling made of plasterboard.”

A metal profile sheathing is installed.

The scope of preparatory work when insulating a concrete floor is reduced to cleaning the surface from debris and dust, eliminating the sharp ends of nails and screws of the rafter system and applying a primer in 2 layers.

Preparing to insulate a wooden ceiling is easier. During new construction, beams are treated with a fire-retardant solution. When carrying out repair work:

Fire protection.

- overhead lighting is being dismantled;

- old finishing is removed;

- dirty and sooty stains are removed. Fatty areas are treated with acetone or gasoline;

- the wood is treated with antiseptics and fire retardants;

- the bottom of the ceiling is primed;

- if necessary, the lathing is filled or a frame made of metal profiles is mounted.

Attention: many experts consider vapor barrier work to be a preparatory operation. In this article they are classified as the main technology, which does not change the essence.

Insulation with mineral wool

Insulation with mineral wool is another, no less popular method. Mineral wool is widely used for insulation of apartments, houses, balconies, loggias. Moreover, both ceilings and facades. The range of its applications is no less wide than that of polystyrene foam.

Just like polystyrene foam, mineral wool has its own advantages:

- relatively low cost;

- it is unsuitable for rodents and insects;

- it is quite easy to work with;

- the material is considered to be highly flammable.

But, among other things, mineral wool also has its own characteristic disadvantages, associated, for the most part, with its structure, with the nature of the material itself:

- when wet, it loses its valuable qualities. Of course, if a few drops of water get on it, nothing bad will happen, but if your roof leaks with enviable regularity, dampness will accumulate in the wool - then it will not only cease to perform its functions, the main of which is heat preservation, but also with Over time it will become a place of residence for fungal formations. But growing such “mushrooms” in the attic is unlikely to be part of your plans;

- cotton wool cannot be pressed for the same reasons. No, this won’t cause mold to grow in it, but its effectiveness will decrease by about 30–40%, depending on how hard you try;

- People with diseases of the respiratory system (for example, asthma) should not look at mineral wool at all. But if you happen to work with it, then you need to use personal protective equipment - of course, not a gas mask, but at least a gauze bandage.

I would not say that the disadvantages of mineral wool are significant so as not to consider it as a possible option. I repeat, mineral wool is an affordable, reliable and widespread insulation material.

The main thing is to follow safety precautions and not violate operating rules.

As for the thickness, then, again, the thicker the layer, the warmer the room will be. Taking into account natural conditions, a layer of mineral wool from 15 cm to 30 cm or more is usually laid in attics.

Another important point: if you use several types of insulation (yes, this is also possible), then the bottom layer should be the least vapor-permeable. In other words, it is possible to lay mineral wool on polystyrene foam, but it is impossible to lay polystyrene foam on mineral wool. If there is a need for sound insulation, it is recommended to use mineral wool with a density of 40 kg/m³.

Here we come to the essence of this section. Let's get started:

- Be sure (!) to check the boards for rot. Outwardly, they may look intact, but if you hear a dull sound when you hit it with a hammer, it is most likely rotten inside. It should be replaced with a new fragment treated with an antiseptic. In general, the preparation is the same as when using polystyrene foam;

- checking the roof. If it leaks even a little, the mineral wool will not forgive you for it. Therefore, be sure to fix the leak;

- checking communications. Even though mineral wool is a highly flammable material, it’s still worth being safe;

- clean the surface of debris;

- we build a wooden frame;

- We lay vapor barrier material. Just in case, I will say that vapor barrier cannot be laid on both sides. If you suddenly want to spread it on top, resist this destructive desire. The condensate will have nowhere to evaporate, and then the mineral wool will begin to slowly but surely melt;

- we roll out the rolls between the beams (or lay the tiles);

- install a wooden base;

- We enjoy the work done.

You can do without installing a hard floor. This is not necessary, but, again, you will not be able to walk on the surface or place anything on it (remember that the cotton wool cannot be pressed).

We have already looked at two popular methods of insulating a house with a cold attic. Now let's look at other options. I’ll say right away that they are more labor-intensive, but at the same time, more economical from a financial point of view. One of these methods is the use of expanded clay.