The cost-effectiveness of thermal comfort in the house is ensured by the calculation of hydraulics, its high-quality installation and proper operation. The main components of a heating system are a heat source (boiler), a heat main (pipes) and heat transfer devices (radiators). For effective heat supply, it is necessary to maintain the original parameters of the system under any load, regardless of the time of year. Before starting hydraulic calculations, perform:

- Collection and processing of information on the facility for the purpose of: determining the amount of heat required;

- choosing a heating scheme.

- volumes of thermal energy;

If water heating is considered the best option, a hydraulic calculation is performed.

Calculating hydraulics using programs requires familiarity with the theory and laws of resistance. If the formulas below seem difficult to understand, you can choose the parameters that we offer in each of the programs.

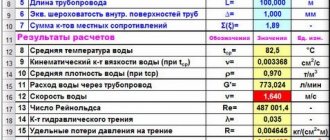

Calculations were carried out in Excel. The finished result can be seen at the end of the instructions.

A little about theory and tasks

The main task of the hydraulic calculation of heating networks is the selection of geometric parameters of the pipe and standard sizes of control elements to ensure:

- qualitative and quantitative distribution of coolant to individual heating devices;

- thermal-hydraulic reliability and economic feasibility of a closed thermal system;

- optimization of investment and operating costs of the heat supply organization.

You may be interested in: Pokrovsky Mine OJSC (Tygda, Magdagachinsky district, Amur region) - a primary gold deposit developed by open pit mining

Hydraulic calculation of heating networks creates the prerequisites for heating and hot water devices to achieve the required power at a given temperature difference. For example, with a T-graph of 150-70 °C, it will be equal to 80 °C. This is achieved by creating the required water pressure or coolant pressure at each heating point.

This mandatory condition for the operation of a heating system is implemented through proper configuration of network equipment in accordance with design conditions, installation of equipment based on the results of hydraulic calculations of heating networks.

Network hydraulic stages:

- Pre-launch calculation.

- Operational regulation.

- using calculations;

- measuring method.

The initial hydraulics of the network is performed:

You may be interested in: Metallurgical, St. Petersburg

In the Russian Federation, the calculation method is predominant; it determines all the parameters of the elements of the heat supply system in a single design area (house, block, city). Without this, the network will be misregulated, and the coolant will not be supplied to the upper floors of multi-story buildings. That is why the beginning of the construction of any heating supply facility, even the smallest one, begins with a hydraulic calculation of heating networks.

Metal heating pipes

These products have proven themselves in the construction market for quite a long time, since they have a number of very obvious advantages:

- any, even the most significant pressure drops in the system will not interfere with the normal functioning of these pipes;

- due to the fact that the metal takes a long time to heat up and at the same time gives off heat for a long time, such structures can serve as an additional heating device like a radiator;

- the service life of metal pipes is very long;

- the reasonable cost of such products distinguishes them favorably from other modern pipeline systems.

However, they also have some negative aspects that cannot be ignored:

- installing a metal pipeline is quite difficult. This work requires a large set of specialized construction tools, which are not always available to the average user. In addition, the entire installation process requires a lot of physical and time investment;

- the mass of metal structures is very large, so to hold them, very strong walls of the house are required, which cannot always be provided (for example, if the basis of the partitions is plasterboard);

- cast iron, which is usually the main material in a metal pipe, is prone to the formation of a corrosive coating on it both from the inside and outside, and periodic cleaning, which cannot be avoided, is a very problematic procedure.

Drawing up a diagram of heating networks

Before hydraulic calculations, a preliminary pipeline diagram is performed indicating the length L in meters and D of utility water pipelines in mm and the estimated volumes of network water for the design sections of the diagram. Pressure losses in heat supply systems are divided into linear, which arise due to the carrier rubbing against the pipe walls, and losses in areas caused by local structural resistance due to the presence of tees, bends, compensators, turns and other devices.

Calculation example: hydraulic calculation of heating networks:

Features of calculating the cross-section of metal pipes

For large heating systems with metal pipes, heat loss through the walls must be taken into account. The losses are not that great, but over a long distance they can lead to the fact that the temperature on the last radiators will be very low due to the wrong choice of diameter.

Let's calculate the losses for a 40 mm steel pipe with a wall thickness of 1.4 mm. Losses are calculated using the formula:

q = k*3.14*(tв-tп)

Where:

q is the heat loss per meter of pipe,

k is the linear heat transfer coefficient (for this pipe it is 0.272 W*m/s);

tw — water temperature in the pipe — 80°C;

tп — room air temperature — 22°С.

Substituting the values we get:

q = 0.272*3.15*(80-22)=49 W/s

It turns out that almost 50 W of heat is lost per meter. If the length is significant, this can become critical. It is clear that the larger the cross-section, the greater the losses will be. If you need to take these losses into account, then when calculating losses, add losses in the pipeline to reduce the thermal load on the radiator, and then, using the total value, find the required diameter.

Determining the diameter of heating system pipes is not an easy task

But for individual heating systems these values are usually not critical. Moreover, when calculating heat loss and equipment power, the calculated values are most often rounded upward. This gives a certain margin, which allows you not to make such complex calculations.

An important question: where to get tables? Almost all manufacturers' websites have such tables. You can read it directly from the site, or you can download it for yourself. But what to do if you still haven’t found the necessary tables for the calculation. You can use the diameter selection system described below, or you can do it differently.

Despite the fact that different values (internal or external) are indicated when marking different pipes, they can be equated with a certain error. Using the table below you can find the type and marking for a known internal diameter. You can immediately find a corresponding pipe size made of a different material. For example, you need to calculate the diameter of metal-plastic heating pipes. You did not find a table for MP. But there is one for polypropylene. Select sizes for PPR, and then use this table to find analogues in MP. Naturally, there will be an error, but for systems with forced circulation it is acceptable.

Correspondence table for different types of pipes (click to enlarge size)

Using this table, you can easily determine the internal diameters of the heating system pipes and their markings.

Applications of the normative method

You may be interested in: Steel X12F1: characteristics and application

Hydraulics of networks is carried out on the basis of tables of maximum hourly heat loads and a heat supply diagram for a city or region, indicating the sources, location of the main, intra-block and intra-house engineering systems, indicating the boundaries of the balance sheet ownership of the network owners. Hydraulic calculation of heating network pipelines for each section up to the above diagram is carried out separately.

This calculation method is used not only for heating networks, but also for all pipelines transporting liquid media, including gas condensate and other chemical liquid media. For pipeline heat supply systems, changes must be made taking into account the kinematic viscosity and density of the media. This is due to the fact that these characteristics influence the specific pressure loss in the pipes, and the flow rate is related to the density of the transit medium.

Parameters of hydraulic calculation of water heating network

Heat consumption Q and the amount of coolant G for areas are indicated in the table of maximum hourly heat consumption indicators for the winter and summer seasons separately and corresponds to the amount of heat consumption for the quarters included in the scheme.

An example of a hydraulic calculation of a heating network is presented below.

Since calculations depend on many indicators, they are performed using numerous tables, diagrams, graphs, nomograms, the final value of heat consumption Q for intra-house heating systems is obtained by interpolation.

The amount of liquid circulating in the heating network m3/hour, when calculating the hydraulic mode of the heating network, is determined by the formula:

G = (D2 / 4) x V,

Where:

- G—carrier consumption, m3/hour;

- D – pipeline diameter, mm;

- V—flow velocity, m/s.

Linear pressure drops in the hydraulic calculation of heating networks are taken from special tables. When installing heating systems, dozens and hundreds of auxiliary elements are installed in them: valves, fittings, vents, bends and others that create resistance to the transit environment.

The reasons for the drop in pressure in pipelines also include the internal state of the pipe materials and the presence of salt deposits on them. The coefficient values used in technical calculations are given in the tables.

Sequence of calculation steps

Speaking about the calculation of the heating system, we note that this procedure is the most controversial and important in terms of design.

Before performing the calculation, you need to perform a preliminary analysis of the future system, for example:

- establish a thermal balance in all and specifically each room of the apartment;

- approve thermostats, valves and pressure regulators;

- select radiators, heat exchange surfaces, heat-dissipating panels;

- determine areas of the system with maximum and minimum coolant flow.

In addition, it is necessary to determine the general scheme for transporting the coolant: full and small circuit, single-pipe system or two-pipe main.

As a result of the hydraulic calculation, we obtain several important characteristics of the hydraulic system, which provide answers to the following questions:

- what should be the power of the heating source;

- what is the flow rate and speed of the coolant;

- what is the required diameter of the main heating pipeline;

- what are the possible losses of heat and the mass of the coolant itself.

Another important aspect of hydraulic calculation is the procedure for balancing (linking) all parts (branches) of the system during extreme thermal conditions using control devices.

There are several main types of heating products: cast iron and aluminum multi-section, steel panel, bimetallic radiators and covectors. But the most common are aluminum multi-section radiators

The design zone of the pipeline main is a section with a constant diameter of the main itself, as well as a constant flow of hot water, which is determined by the formula for the heat balance of rooms. The listing of design zones starts from the pump or heat source.

Standard Methodology and Process Steps

According to the method of hydraulic calculation of heating networks, it is carried out in two stages:

The first to carry out calculations for the main highway is the costs established according to the scheme. In this case, reference data on specific pressure losses in networks are used.

Next, having calculated the diameters of the pipes, calculate:

Pressure losses are calculated using formulas and nomograms. Then, having this data for the entire network, they calculate the hydromechanical regime of individual sections from the point of flow splitting up to the end subscriber.

Calculations are linked to the choice of branch pipe diameters. Inconsistency no more than 10%. Excess pressure in the heating network is extinguished at elevator units, throttle nozzles or automatic regulators at in-house control points.

You may be interested in: Airplane propeller: name, classification and characteristics

Given the available pressure of the main heating network and branches, first set the approximate resistivity Rm, Pa/m.

The calculations use tables, nomograms for the hydraulic calculation of pipelines of heating networks and other reference literature, which is mandatory for all stages; it is easy to find on the Internet and in specialized literature.

Determination of coolant flow and pipe diameters

First, each heating branch must be divided into sections, starting from the very end. The breakdown is done by water consumption, and it varies from radiator to radiator. This means that after each battery a new section begins, this is shown in the example presented above. We start from the 1st section and find the mass flow rate of the coolant in it, focusing on the power of the last heating device:

G = 860q/ ∆t , where:

- G – coolant flow, kg/h;

- q – thermal power of the radiator in the area, kW;

- Δt – temperature difference in the supply and return pipelines, usually 20 ºС.

For the first section, the coolant calculation looks like this:

860 x 2 / 20 = 86 kg/h.

The result obtained must be immediately plotted on the diagram, but for further calculations we will need it in other units - liters per second. To make a translation, you need to use the formula:

GV = G /3600ρ , where:

- GV – volumetric water flow, l/sec;

- ρ – density of water, at a temperature of 60 ºС is equal to 0.983 kg / liter.

We have: 86 / 3600 x 0.983 = 0.024 l/sec. The need to convert units is explained by the need to use special ready-made tables to determine the diameter of a pipe in a private house. They are freely available and are called “Shevelev tables for hydraulic calculations.” You can download them by following the link: https://dwg.ru/dnl/11875

These tables show the diameters of steel and plastic pipes depending on the flow rate and speed of the coolant. If you open page 31, then in Table 1 for steel pipes the first column shows the flow rate in l/sec. In order not to make a full calculation of pipes for the heating system of a private home, you just need to select the diameter according to the flow rate, as shown in the figure below:

Note. In the left column, under the diameter, the speed of water movement is immediately indicated. For heating systems, its value should be in the range of 0.2–0.5 m/sec.

So, for our example, the internal passage size should be 10 mm. But since such pipes are not used in heating, we can safely accept a DN15 (15 mm) pipeline. We put it on the diagram and move on to the second section. Since the next radiator has the same power, there is no need to apply formulas; we take the previous water flow and multiply it by 2 and get 0.048 l/sec. We turn to the table again and find the closest suitable value in it. At the same time, do not forget to monitor the water flow speed v (m/sec) so that it does not exceed the specified limits (in the figures it is marked in the left column with a red circle):

Important. For heating systems with natural circulation, the coolant movement speed should be 0.1-0.2 m/sec.

As can be seen in the figure, section No. 2 is also laid with a DN15 pipe. Next, using the first formula, we find the flow rate in section No. 3:

860 x 1.5 / 20 = 65 kg/h and convert it to other units:

65 / 3600 x 0.983 = 0.018 l/sec.

Adding it to the sum of the costs of the two previous sections, we get: 0.048 + 0.018 = 0.066 l/sec and again turn to the table. Since in our example we are not calculating a gravitational system, but a pressure one, then in terms of coolant speed, a DN15 pipe is suitable this time too:

Following this path, we calculate all the areas and plot all the data on our axonometric diagram:

Transporting hot water

The algorithm for the calculation scheme is established by regulatory and technical documentation, state and sanitary standards and is carried out in strict accordance with the established procedure.

The article provides an example of a hydraulic calculation of a heating network. The procedure is performed in the following sequence:

The numbering system should clearly separate the types of networks: intra-block main lines, inter-house ones from the thermal well to the boundaries of the balance sheet, while the section is established as a section of the network, enclosed by two branches.

The diagram shows all the parameters of the hydraulic calculation of the main heating network from the central heating substation:

- Q - GJ/hour;

- G m3/hour;

- D – mm;

- V - m/s;

- L is the length of the section, m.

The diameter is calculated using the formula.

Expansion tank calculation

To calculate an expansion tank for a closed heating system, it is necessary to find out how much the volume of liquid increases when it is heated from room temperature +20 ºС to operating temperature, which is in the range of 50-80 ºС. This task is also not an easy one, but it can be solved in another way.

It is considered quite correct to take the volume of the tank as a tenth of the total amount of water in the system, including radiators and the water jacket of the boiler. Therefore, we open the equipment passports again and find in them the capacity of 1 section of the battery and the boiler tank.

Next, the calculation of the volume of coolant in the heating system is carried out according to a simple scheme: the cross-sectional area of a pipe of each diameter is calculated and multiplied by its length. The obtained values are summed up, passport data is added to them, and then a tenth of the result is taken. That is, if there are 150 liters of water in the entire system, then the capacity of the expansion tank should be 15 liters.

Steam heating networks

This heating network is designed for a heat supply system using coolant in the form of steam.

The differences between this scheme and the previous one are caused by temperature indicators and environmental pressure. Structurally, these networks are characterized by a shorter length; in large cities they usually include only main lines, i.e. from the source to the central heating point. They are not used as intra-district and intra-house networks, except at small industrial sites.

The schematic diagram is carried out in the same order as with water coolant. At the sections, all network parameters are indicated for each branch; data is taken from a summary table of maximum hourly heat consumption, with step-by-step summation of consumption indicators from the end consumer to the source.

The geometric dimensions of pipelines are established based on the results of hydraulic calculations, which are performed in accordance with state norms and regulations, and in particular SNiP. The determining value is the pressure loss of the gas-condensate medium from the heat supply source to the consumer. With a greater pressure loss and a smaller distance between them, the speed of movement will be high, and a smaller diameter of the steam line will be required. The diameter is selected according to special tables, based on the parameters of the coolant. The data is then entered into pivot tables.

Hydraulic linkage

Balancing pressure drops in the heating system is carried out using control and shut-off valves.

Hydraulic linking of the system is carried out on the basis of:

- design load (coolant mass flow);

- data from pipe manufacturers on dynamic resistance;

- the number of local resistances in the area under consideration;

- technical characteristics of fittings.

Installation characteristics - pressure drop, fastening, flow capacity - are set for each valve. They are used to determine the coefficients of coolant flow into each riser, and then into each device.

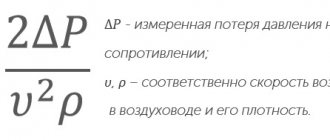

Pressure loss is directly proportional to the square of the coolant flow rate and is measured in kg/h, where

S is the product of dynamic specific pressure, expressed in Pa/(kg/h), and the reduced coefficient for local resistance of the section (ξpr).

The given coefficient ξpr is the sum of all local resistances of the system.

Coolant for condensate network

The calculation for such a heating network differs significantly from the previous ones, since condensate simultaneously exists in two states - in steam and in water. This ratio changes as it moves towards the consumer, i.e. the steam becomes more and more wet and eventually turns completely into a liquid. Therefore, calculations for pipes for each of these media are different and are taken into account by other standards, in particular SNiP 2.04.02-84.

The procedure for calculating condensate pipelines:

The design features of this type of network significantly affect the quality of measurements, since the pipelines for this type of coolant are made of black steel; sections of the network after the network pumps, due to air leaks, quickly corrode from excess oxygen, after which low-quality condensate with iron oxides is formed, which causes metal corrosion. Therefore, it is recommended to install stainless steel pipelines in this area. Although the final choice will be made after completion of the feasibility study of the heating network.

Calculation of hydraulics of the heating system

We will need data from thermal calculations of the premises and an axonometric diagram.

Axonometric diagram

Enter your data into this table:

| No. of settlement area | Thermal load | Length |

| write down | write down | write down |

Step 1: count the diameter of the pipes

Economically justified results of thermal calculations are used as initial data:

1a. The optimal difference between hot (tg) and cooled (tо) coolant for a two-pipe system is 20º

- Δtco=tg- to=90º-70º=20ºС

1b. Coolant flow G, kg/hour - for a one-pipe system.

2. The optimal speed of coolant movement is ν 0.3-0.7 m/s.

The smaller the internal diameter of the pipes, the higher the speed. Reaching 0.6 m/s, the movement of water begins to be accompanied by noise in the system.

3. Design heat flow rate – Q, W.

Expresses the amount of heat (W, J) transferred per second (unit of time τ):

Formula for calculating heat flow rate

4. Estimated density of water: ρ = 971.8 kg/m3 at tav = 80 °C

5. Parameters of sections:

| Plot | Section length, m | Number of devices N, pcs |

| 1 — 2 | 1.78 | 1 |

| 2 — 3 | 2.60 | 1 |

| 3 — 4 | 2.80 | 2 |

| 4 — 5 | 2.80 | 2 |

| 5 — 6 | 2.80 | 4 |

| 6 — 7 | 2.80 | |

| 7 — 8 | 2.20 | |

| 8 — 9 | 6.10 | 1 |

| 9 — 10 | 0.5 | 1 |

| 10 — 11 | 0.5 | 1 |

| 11 — 12 | 0.2 | 1 |

| 12 — 13 | 0.1 | 1 |

| 13 — 14 | 0.3 | 1 |

| 14 — 15 | 1.00 | 1 |

To determine the internal diameter for each section, it is convenient to use a table.

Explanation of abbreviations:

- dependence of the speed of water movement - ν, s

- heat flow - Q, W

- water consumption G, kg/hour from the internal diameter of the pipes

| Ø 8 | Ø 10 | Ø 12 | Ø 15 | Ø 20 | Ø 25 | Ø 50 | ||||||||||||||

| ν | Q | G | v | Q | G | v | Q | G | v | Q | G | v | Q | G | v | Q | G | v | Q | G |

| 0.3 | 1226 | 53 | 0.3 | 1916 | 82 | 0.3 | 2759 | 119 | 0.3 | 4311 | 185 | 0.3 | 7664 | 330 | 0.3 | 11975 | 515 | 0.3 | 47901 | 2060 |

| 0.4 | 1635 | 70 | 0.4 | 2555 | 110 | 0.4 | 3679 | 158 | 0.4 | 5748 | 247 | 0.4 | 10219 | 439 | 0.4 | 15967 | 687 | 0.4 | 63968 | 2746 |

| 0.5 | 2044 | 88 | 0.5 | 3193 | 137 | 0.5 | 4598 | 198 | 0.5 | 7185 | 309 | 0.5 | 12774 | 549 | 0.5 | 19959 | 858 | 0.5 | 79835 | 3433 |

| 0.6 | 2453 | 105 | 0.6 | 3832 | 165 | 0.6 | 5518 | 237 | 0.6 | 8622 | 371 | 0.6 | 15328 | 659 | 0.6 | 23950 | 1030 | 0.6 | 95802 | 4120 |

| 0.7 | 2861 | 123 | 0.7 | 4471 | 192 | 0.7 | 6438 | 277 | 0.7 | 10059 | 433 | 0.7 | 17883 | 769 | 0.7 | 27942 | 1207 | 0.7 | 111768 | 4806 |

Example

Task : select the diameter of the pipe for heating a living room with an area of 18 m², ceiling height 2.7 m.

Project data:

- two-pipe wiring diagram;

- circulation is forced (pump).

Average data:

- power consumption – 1 kW per 30 m³

- thermal power reserve – 20%

Calculation:

- room volume: 18 * 2.7 = 48.6 m³

- power consumption: 48.6 / 30 = 1.62 kW

- reserve in case of frost: 1.62 * 20% = 0.324 kW

- total power: 1.62 + 0.324 = 1.944 kW

We find the closest Q value in the table:

We get the interval of internal diameter: 8-10 mm. Section: 3-4. Section length: 2.8 meters.

Step 2: Calculate Local Resistances

To decide on the pipe material, it is necessary to compare the indicators of their hydraulic resistance in all areas of the heating system.

Factors of resistance:

Heating pipes

- in the pipe itself: roughness;

- place of narrowing/expansion of diameter;

- turn;

- length.

- tee;

The design section is a pipe of constant diameter with a constant water flow corresponding to the design heat balance of the room.

To determine losses, data is taken taking into account the resistance in the control valves:

- pipe length at the design section/l, m;

- pipe diameter of the calculated section/d, mm;

- accepted coolant speed/u, m/s;

- control valve data from the manufacturer;

- reference data:

- friction coefficient/λ;

- friction losses/∆Рl, Pa;

- calculated liquid density/ρ = 971.8 kg/m3;

- Product specifications:

- equivalent pipe roughness/ke mm;

- pipe wall thickness/dн×δ, mm.

For materials with similar ke values, manufacturers provide the value of specific pressure loss R, Pa/m for the entire range of pipes.

To independently determine the specific friction losses/R, Pa/m, it is enough to know the outer d of the pipe, the wall thickness/dн×δ, mm and the water supply speed/W, m/s (or water flow/G, kg/h).

To search for hydraulic resistance/ΔP in one section of the network, we substitute the data into the Darcy-Weisbach formula: For steel and polymer pipes (made of polypropylene, polyethylene, fiberglass, etc.), the friction coefficient/λ is most accurately calculated using the Altschul formula: Re - Reynolds number , is found using a simplified formula (Re=v*d/ν) or using an online calculator:

Step 3: hydraulic linkage

To balance pressure differences, you will need shut-off and control valves.

Initial data:

- design load (mass flow of coolant - water or low-freezing liquid for heating systems);

- data from pipe manufacturers on specific dynamic resistance/A, Pa/(kg/h)²;

- technical characteristics of fittings.

- the number of local resistances in the area.

Task : to equalize hydraulic losses in the network.

In the hydraulic calculation, installation characteristics (mounting, pressure drop, flow capacity) are specified for each valve. Based on the resistance characteristics, the coefficients of flow into each riser and then into each device are determined.

Fragment of factory characteristics of a butterfly valve

Let us choose for calculations the method of resistance characteristics S, Pa/(kg/h)².

Pressure loss/∆P, Pa is directly proportional to the square of water flow over the area/G, kg/h: In the physical sense, S is the pressure loss per 1 kg/h of coolant: where:

- ξpr - reduced coefficient for local resistances of the section;

- A - dynamic specific pressure, Pa/(kg/h)².

The specific pressure is considered to be the dynamic pressure that occurs at a mass flow rate of 1 kg/h of coolant in a pipe of a given diameter (information provided by the manufacturer).

Σξ is the term of the coefficients for local resistance in the section.

Reduced coefficient: It sums up all local resistance: With a value: which corresponds to the coefficient of local resistance taking into account losses from hydraulic friction.

Step 4: Determine losses

The hydraulic resistance in the main circulation ring is represented by the sum of the losses of its elements:

- primary circuit/ΔPIк ;

- local systems/ΔPm;

- heat generator/ΔPtg;

- heat exchanger/ΔPto.

The sum of the values gives us the hydraulic resistance of the system/ΔPco:

Design programs

Energy losses due to valves, fittings and bends are caused by localized flow disturbances. Energy loss occurs along a finite and not necessarily short section of the pipeline, however, for hydraulic calculations it is generally accepted that the entire volume of this loss is taken into account at the location of the device. For piping systems with relatively long pipes, it is often the case that the resulting losses will be negligible in relation to the total pressure loss in the pipe.

Pipeline losses are measured using actual experimental data and then analyzed to determine a local loss factor that can be used to calculate fitting losses as it varies with the rate of fluid flow through the device.

Pipe Flow Software products make it easy to determine fitting losses and other losses in pressure drop calculations because they come pre-loaded with a valve database that contains many standard factors for various sized valves and fittings. Within a piping system, a pump is often used to add additional pressure to overcome losses due to friction and other resistance.

The pump performance is determined by the curve. The head produced by the pump varies depending on the flow rate, finding the operating point on the pump performance curve is not always an easy task.

Using the Pipe Flow Expert hydraulic design software, it is quite easy to find the exact operating point on the pump curve, ensuring that flows and pressures are balanced throughout the system, to make accurate piping design decisions.

Online calculations are made in order to select the optimal diameter that provides the best operating parameters, low pressure losses and high speeds of fluid movement, which will ensure good technical and economic indicators of heating networks as a whole.

It minimizes effort and provides higher accuracy. It includes all the necessary reference tables and nomograms. Thus, losses per meter of pipes are assumed to be 81 - 251 Pa/m (8.1 - 25.1 mm water column), which depends on the material of the pipes. The water speed in the system depends on the diameter of the installed pipes and is selected in a specific range. The highest water speed for heating networks is 1.5 m/s. The calculation suggests boundary values of water speed in pipelines with an internal diameter:

Heat generator power

One of the main components of the heating system is the boiler: electric, gas, combined - it doesn’t matter at this stage. Because its main characteristic is important to us - power, that is, the amount of energy per unit of time that will be spent on heating.

The power of the boiler itself is determined by the formula below:

Wboiler = (Sroom*Wshare) / 10,

Where:

- Sroom - the sum of the areas of all rooms that require heating;

- Wdel is the specific power taking into account the climatic conditions of the location (this is why it was necessary to know the climate of the region).

Typically, for different climatic zones we have the following data:

- northern regions - 1.5 - 2 kW/m2;

- central zone - 1 - 1.5 kW/m2;

- southern regions - 0.6 - 1 kW/m2.

These figures are quite arbitrary, but nevertheless provide a clear numerical answer regarding the influence of the environment on the apartment heating system.

This map shows climate zones with different temperature regimes. The location of the housing relative to the zone determines how much energy needs to be spent on heating a square meter of kWatt of energy (+)

The amount of the apartment area that needs to be heated is equal to the total area of the apartment and is equal, that is, 65.54-1.80-6.03 = 57.71 m2 (minus the balcony). The specific boiler power for the central region with cold winters is 1.4 kW/m2. Thus, in our example, the calculated power of the heating boiler is equivalent to 8.08 kW.

Instrumental geographic information system

GIS Zulu is a geoinformation program for hydraulic calculation of heating networks. The company specializes in research into GIS applications that require visualization of 3D geodata in vectorial and raster versions, topological study and their relationship with semantic databases. Zulu allows you to create different plans and working diagrams, including heat and steam networks using topology, can work with rasters and acquire data from different databases, such as BDE or ADO.

You may be interested in:Industrial reverse osmosis installation: rules, installation instructions, filters and operating principle

The calculations are carried out in close integration with the geographic information system; they are implemented in an extended module version. The network is easily and quickly entered into the GIS using the mouse or using these coordinates. After which a calculation scheme is immediately created. Afterwards, the circuit parameters are set and the start of the process is confirmed. Calculations are used for dead-end and ring heating networks, including network pumping units and throttling devices, powered from one or many sources. Heating calculations can be carried out taking into account leaks from distribution networks and heat losses in heating pipes.

In order to install a special program on a PC, download “Hydraulic calculation of heating networks 3.5.2” on the Internet via torrent.

Structure of definition stages:

Microsoft Excel Developer Tool

Microsoft Excel for hydraulic calculations in heating networks is the most accessible tool for users. Its comprehensive spreadsheet editor can solve many computing problems. However, when performing calculations of thermal systems, special requirements must be met. These can be listed:

- finding the previous section in the direction of movement of the medium;

- calculation of the pipe diameter based on a given conditional indicator and reverse calculation;

- establishing a correction factor for the size of the specific pressure loss based on the data and the equivalent roughness of the pipe material;

- calculating the density of a medium from its temperature.

Of course, the use of Microsoft Excel for hydraulic calculations in heating networks does not make it possible to completely simplify the calculation process, which initially creates relatively large labor costs.

Software for hydromechanical calculations of networks or the GRTS package is a computer application that performs hydromechanical calculations of multi-pipe networks, including a dead-end configuration. The GRTS platform contains formula language functionality that allows you to establish the necessary calculation characteristics and select formulas for the accuracy of their determination. Due to the use of this functionality, the calculator has the opportunity to independently find the computing technology and set the required complexity.

There are two modifications of the GRTS application: 1.0 and 1.1. Upon completion, the user will receive the following results:

- calculation, in which the calculation methodology is carefully described;

- report in tabular form;

- transfer of computational databases to Microsoft Excel;

- piezometric graph;

- coolant temperature graph.

The GRTS 1.1 application is considered the most modern modification and supports the latest standards:

What is hydraulic calculation

This is the third stage in the process of creating a heating network. It is a system of calculations that allows you to determine:

- pipe diameter and capacity;

- local pressure losses in areas;

- hydraulic linkage requirements;

- system-wide pressure losses;

- optimal water consumption.

According to the data obtained, pumps are selected.

For seasonal housing, in the absence of electricity, a heating system with natural coolant circulation is suitable (link to review).

The main goal of hydraulic calculation is to ensure that the calculated costs for the circuit elements match the actual (operating) costs. The amount of coolant entering the radiators must create a thermal balance inside the house, taking into account the external temperatures and those set by the user for each room according to its functional purpose (basement +5, bedroom +18, etc.).

Complex tasks - cost minimization:

- capital – installation of pipes of optimal diameter and quality;

- operational:

- dependence of energy consumption on the hydraulic resistance of the system;

- stability and reliability;

- noiselessness.

Replacing the centralized heat supply mode with an individual one simplifies the calculation method.

For the autonomous mode, 4 methods of hydraulic calculation of the heating system are applicable:

- by specific losses (standard calculation of pipe diameter);

- by lengths reduced to one equivalent;

- according to conductivity and resistance characteristics;

- comparison of dynamic pressures.

The first two methods are used with a constant temperature difference in the network.

The last two will help distribute hot water among the rings of the system if the temperature difference in the network no longer corresponds to the difference in the risers/branches.