When choosing heating devices to supply the house with hot water and heating, the homeowner is guided, first of all, by considerations of the appropriateness of the device in a particular case. It is necessary to calculate the economic issue - how much the equipment, its installation, and maintenance will cost. It is important and technically justified to choose a boiler so that its performance is sufficient to solve the main problem, and at the same time you do not have to overpay for unnecessary options and excess power. In some cases, it is convenient to use a system where the energy carrier is natural wood. Especially in those areas where there is no gas supply line or there are power outages.

Wood boiler for home heating Source anatomycharty.com

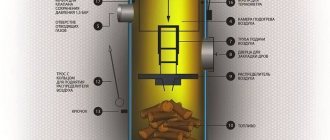

Wood boiler design

Such boilers have in their design:

- Fireboxes, in one of which the wood is burned, and in the second the actual afterburning process takes place, for which a fireclay brick lining is provided. Thus, the temperature in it remains unchanged for a long time, reaching up to eight hundred degrees.

- Automation, which allows them to function as an autonomous station, regulating both air flow and temperature. If the boiler is of a simple design, then this function is performed by a coil, allowing the coolant to circulate unhindered;

- Taps through which radiators for heating are connected;

- A broken-type chimney capable of accumulating heat from gases;

- Many models are equipped with a loading chamber.

Autonomously, such a device can function from eight to twelve hours. Some manufacturers produce units that continue to operate for several days from one refill.

Heat regulation

The presence of a buffer tank (heat accumulator) in the system plays an important role in heat absorption. This device allows you to smooth out peak heat release during intense fuel combustion. All the heat absorbed by it is returned to the heating system after the fill burns out. One of the important advantages of a boiler in conjunction with a heat accumulator is that this process can be automated. The hydraulic separator (hydraulic arrow) allows you to separate the boiler circuit from the heating circuit and supply the latter with exactly as much heat as is needed to maintain a comfortable temperature in the rooms. Of course, this causes a slight increase in the cost of the heating system.

Furnaces also have temperature control capabilities, but they are much more modest. Heat dissipation can be adjusted in much smaller ranges and only manually. Many stoves have a long-burning function, where the wood smolders for several hours. However, the subsequent filling must be burned intensively so that soot and tar deposits do not accumulate in the chimney. In any case, fuel combustion in the stove will be accompanied by temperature fluctuations in the rooms. And each stove owner will have to develop a fuel filling schedule and experimentally determine the optimal positions of the dampers. Although production models are the same, the volumetric heating value of firewood can vary greatly.

Thus, the boiler provides a more balanced microclimate in the house.

Criterias of choice

Knowing some of the differences between domestic models and foreign designs, as well as the amount the consumer expects, will help you choose the right wood-burning boiler with a water circuit.

Thus, it will be necessary to take into account:

- Country of manufacture;

- Design features;

- Productivity.

If the power of the unit is calculated correctly, then it can easily provide heat to areas of up to five hundred square meters. If we consider that one kilowatt is consumed per ten square meters, then for a specific area it will not be difficult to calculate the power indicator, adding from twenty to fifteen percent.

Basically, the formulas are calculated for the middle latitudes of the Russian climate, when the height of the room does not exceed two and seven meters. By using an online calculator, you can easily make a similar calculation for rooms that have a more complex configuration.

What are the benefits of brick ovens?

The good old stoves are still popular in the private sector and are not losing ground. What’s interesting: many home owners are abandoning modern heating devices in favor of these very voluminous structures, and for good reason. Brick stoves have a lot of advantages:

- They are completely autonomous and energy independent; the house will not be left without heat in any case, even if the electricity is turned off;

- The stoves have high efficiency, heat up well and retain heat for a long time;

- They are easy to use and can be beautifully decorated with tiles;

- If the stove design has a hob, then you can cook food on it: boil, stew and bake;

- The presence of stove heat creates a more comfortable environment in the house;

- The heat from the stove will not dry out or overheat the air in the room;

- If desired, you can install a water container in the stove masonry, hot water from which can also be used for heating and for various household needs;

- The stove structure can be easily repaired by replacing worn-out bricks with new ones.

But stove heating also has many disadvantages:

- The stove takes a long time to heat up and also takes a long time to gain heat;

- All maintenance will be done entirely manually;

- Only a specialist, of whom there are few, can build a furnace structure and re-arrange it if repairs are required, and their work is expensive;

- The manufacture of such a structure is made only from high-quality expensive bricks;

- Even the smallest stove structure will take up quite a large volume in the house;

- Any brick oven is heavy and requires the construction of a foundation for it;

- The presence of stove heating creates a risk of fire in the house;

- Sudden heating of the firebox can lead to cracks in the bricks and costly repairs.

Features of wood boilers

Currently, there are several groups of similar boilers:

- By the number of circuits. If the design does not have a coil, then it is a single-circuit model. Therefore, additional costs may be required for the purchase and installation of the necessary container. A boiler with two circuit parts is capable of simultaneously heating both the coolant and water used in domestic conditions;

- With different camera locations. Vertical. Firewood is used raw for use, fully implementing the principle in which the lower stacked layer burns. The top part of the firewood is dried at the same time. The horizontal arrangement is intended for loading dry fuel;

- By automation, when the operation is controlled by a damper manually or mechanically;

- With a storage boiler - a separate single-circuit type that allows you to heat both DHW and coolant.

Heating systems for a private home

To create an effective heating system, it is not enough to decide on the heat source, devices and type of heat pipe. Heat engineering is a complex science, it is important to connect everything into a single system and have it work perfectly. Moreover, taking into account several factors:

- lowest installation cost;

- the greatest economic efficiency;

- optimal operating parameters

This concept is implemented by choosing the ideal layout of heat pipes so that: fewer components are needed, this reduces the cost and simplifies installation and subsequent maintenance; The thermal efficiency was ideal in all rooms; for this, all necessary calculations are carried out, taking into account the fact that the coolant is capable of losing thermal energy at a distance, that is, the further away from the heating device, the lower the temperature.

Choosing a scheme is for professionals. Guest workers and fly-by-night companies don’t bother themselves with this, using classic, standard schemes and the principle: “ And so it will do.

».

As a result, extra costs associated with installing a heating system, increased heating costs, constant airing of the system; in some rooms, especially those furthest from the source of thermal energy, it may be simply cold. We are already silent about the quality of installation.

Therefore, the heating engineer must draw up the diagram and bear personal responsibility for it. Such specialists work in, which has been in the heating business since 2000.

Manufacturers recognized as the best

The difficult choice is indicated by the sufficient number of assortments on offer. Many countries produce such products of appropriate quality.

The price of a wood-burning boiler ranges from eight thousand one hundred rubles and varies depending on which country a particular unit was produced in.

If we look at the rating, then:

- The leaders are German-made boilers with full automation and great savings in fuel consumption;

- Boilers from Austria are identical in many respects, including a security system with many levels;

- Czech boilers, where certain brands are extremely popular, due to the ability to work not only on wood;

- Latvian boilers, assessed by Russians in terms of quality and thermal efficiency, which allow them to function for two days from one installation;

- After additional modifications, Russian boilers now have all the necessary indicators, so their popularity has increased greatly in recent years.

Installation

In accordance with the rules and regulations, you can install a wood-burning boiler yourself. Installation, in this case, is carried out on a base that is distinguished by its non-flammable characteristics and durability. And the cladding of the floor and nearby walls must be made entirely of non-combustible materials.

To install the chimney, cutting is used in accordance with fire safety rules. For example, where flammable material is adjacent to the wall surface, it is necessary to lay fire-resistant insulation. Steel sheet is used to cover the entire material.

- The water heating coming from the boiler is connected to specially designed outlets. The instructions indicate a specific pipe for the return and connection of the circuit. If the power exceeds forty kilowatts, then the boiler must be installed in a separate room.

- A boiler that depends on electricity consumption must be connected through a stabilizer device, as well as a source that ensures an uninterrupted power supply.

- Automatic machines must be used with a direct connection from the panel. And if necessary, installation can be done directly in the basement. Only here there should be both adequate ventilation and lighting provided naturally.

To increase the efficiency, you need to heat according to all the rules, and also lay wood only with the required degree of humidity.

Advantages and disadvantages

Before installing a solid fuel boiler in a wooden house with your own hands, you need to familiarize yourself with the strengths and weaknesses of the unit.

The main advantages of the equipment in question include:

- Heating operation when the power is turned off - just open a special tap and let the coolant flow directly.

- Affordable, almost free fuel, especially for people who live near forested areas.

- Easy installation of a wall-mounted boiler in a wooden house.

- Low price of equipment.

In addition to the advantages, the scheme with a solid fuel wood boiler has several disadvantages:

- significant mass of the unit, because cast iron is used for its manufacture;

- a person must constantly monitor the boiler and adjust its operation as necessary, for example when the power is turned off;

- increased fuel consumption, soft wood produces little heat when burned;

- low efficiency, maximum 80%;

- large dimensions of the unit.

Many owners install a wall-mounted gas boiler in a wooden house, but this is only possible in the immediate vicinity of the gas main. Most owners of private country houses use a solid fuel wood boiler to heat their homes. Its installation has its own nuances.