Home / Solid fuel boilers

Back

Published: 05/27/2019

Reading time: 4 min

0

619

In modern conditions, solid fuel boilers (SFC) have become very popular due to their independence from communications and high efficiency. Manufacturers of Russian brands have also carved out a niche for themselves in a series of heating equipment, offering the most profitable solutions.

The presented models are distinguished by their ability to perform their functions in harsh climatic zones. They are easy to maintain and easy to install, without requiring the involvement of qualified specialists.

The simplicity of long-burning solid fuel boilers made in Russia is the key to high reliability. In order to understand the assortment on the market, it is suggested to consider the models with the highest ratings.

- 1 TTK “DRAGON”

- 2 TTK "Prometheus"

- 3 TTK "Ochag"

- 4 TTK "Zota"

- 5 TTK "Dymok"

- 6 TTK "Siberia"

TTC "DRAGON"

Dragon is one of the leading developments of Russian heating equipment. Production is established in the city of Tchaikovsky, which is located in the Perm region. Service centers providing warranty service are located in all regions of the Russian Federation. The superiority of this brand's equipment is colorfully illustrated by its technical characteristics.

- The power range of models on the market varies from 10 to 100 kW per hour. This variety allows you to choose a unit both for use in the private sector and for industrial areas. For enterprises with workshop premises with excessively large volumes, boilers with a power of 200 to 300 kW are being developed.

- Heating boilers of this brand have record performance in terms of efficiency, which ranges from 88 to 94%, depending on the type of fuel.

- The duration of fuel combustion after one filling is 8 hours, which allows you to comfortably use the unit in any weather without any extra effort.

- To create Dragon boilers, heat-resistant steel is used, this significantly improves performance, and also increases reliability and guarantees the durability of heating equipment.

DRAGON boilers are suitable for operation on any available fuel. Plus, the installations are equipped with pellet burners, which allows you to sell pellets, as well as fuel granules.

TTC "Prometheus"

The next well-known manufacturer representing Russian solid fuel boilers is Boilers of this brand have excellent reviews from consumers. The power of the presented units of this brand allows you to heat rooms with a volume of up to 450 m2.

The main fuel for which these installations are oriented is coal, but they can also operate on other types of solid fuel; Prometheus solid fuel boilers use wood especially economically.

One of the distinctive characteristics of this brand of heating devices is their relatively small dimensions, and most of the boilers are distinguished by their energy independence.

The following advantages can be highlighted:

- dimensional loading chamber;

- long battery life;

- anti-corrosion coating of installations significantly extends their service life;

- independence from power grids.

The combustion process in Prometheus boilers uses an unusual technology. The burners of this system are located around a heat exchanger, which allows for increased efficiency and increased heat transfer. In addition, to increase the profitability of the equipment, a high level of thermal insulation of the housing was used.

An increase in fuel combustion time is facilitated by the reverse combustion principle. The flame of the combustion chamber moves from top to bottom, increasing the duration and productivity of combustion, and the air supply to the firebox is controlled by a metal damper.

Prometheus boilers are best suited for coal firing. Their body is made of heat-resistant steel, capable of withstanding heating up to 1800°.

One of the attractive features of such installations is their low cost, which is several times lower than their German counterparts.

Device Features

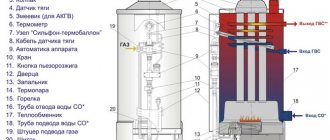

Solid fuel boilers have such functional systems as:

- temperature control;

- smoke removal;

- coolant turnover;

- firebox

The supplied fuel burns in the firebox. This causes its walls to heat up and transfer high temperature to the water circulating through the water jacket. There are pyrolysis and classic boilers. In classic ones, the fuel simply burns, releasing gas. In pyrolysis, fuel and released gas are burned in different systems. This increases power, efficiency and reduces chimney requirements.

However, pyrolysis equipment is demanding on the level of fuel moisture - no more than 20%. The owner of the boiler must have a supply of firewood at all times, which has been drying for at least a year.

The firebox has double walls. The coolant is poured between these walls. As a rule, water is used. Sometimes water is mixed with antifreeze. Such equipment is most common in central Russia.

After the coolant has heated up, it passes into the heat pipe. The water then passes through the pipes, heating the room, and returns to the boiler. To speed up the circulation of the carrier, special pumps are used. Smoke removal equipment looks like pipes with a heat insulator extending from the boiler to the street. In some models they are equipped with forced ventilation systems.

Water machines require careful attention to temperature. To avoid an accident, you need to make sure that the water does not boil. Fuel combustion can be stopped by reducing the intensity. To protect the system, cooling-type heat exchangers are used. Water is supplied to them directly from the water supply. In case of water supply interruption, you need to have a spare container of cold water. To shut off the flow of overheated water, a special shut-off valve is used.

TTC "Ochag"

Models of this equipment represent products. “Ochag” boilers are designed to heat rooms with a heated area of up to 250 m2. The installations of this manufacturer assume the use of mixed types of fuel for operation.

For this reason, gas burners are included in the boilers. In addition, the company offers dual-circuit versions with a power of 6 - 32 kW. This feature allowed a fairly new company on the heating equipment market to quickly find its supporters among consumers.

TTC "Zota"

These Russian-made solid fuel boilers are manufactured in Krasnoyarsk. The “Dymok” and “Zota mix” models received the most positive ratings due to their efficiency and quality of workmanship.

The latest development, these boilers are made from heat-resistant steel plates. The power of the new Zota boilers allows heating even medium-sized industrial premises.

Their distinctive features are:

- two ways of supplying solid fuel materials;

- Efficiency equal to 70%;

- equipped with automatic controllers that allow you to monitor both combustion temperature and power;

- high efficiency;

- Various fuel options are acceptable.

These advantages allow boilers of this brand to confidently occupy a position in the domestic market, attracting consumers with reliability and affordable prices.

Advantages of Russian-made units

The heating appliance market is filled with products from various manufacturers.

Advantages of Russian boilers:

- availability;

- durability;

- maintainability;

- competitiveness.

Russian manufacturers seriously study the consumer market, constantly improving their products to suit the specific climatic conditions of our country.

The range of the best manufacturers of solid fuel long-burning boilers made in Russia and their prices are presented below.

TTC "Dymok"

Long-burning solid fuel boilers, which are also produced at the Krasnoyarsk plant, deserve special attention. Boilers in this line are manufactured in a wide range and are capable of heating both residential buildings and industrial areas.

Household appliances of this model are equipped with a hob, which adds additional advantages to everyday life. The design of the Dymok boilers allows the majority of the heat to be directed to the heating medium, which significantly increases the efficiency.

The combustion chamber has large dimensions, accommodating firewood up to 50 cm long. Adaptation to harsh climatic zones and attractively low cost make this model one of the most attractive in this brand.

Parameters for choosing a solid fuel boiler

Efficiency

Power is valuable as a parameter only in relation to efficiency, and in this case it fluctuates widely and depends on the type of unit and combustion material.

1. Traditional devices have an efficiency of about 80%,

2. pyrolysis – approximately 90%,

3. long burning – about 85%.

Type of fuel

The type of fuel is of great importance, and it can be very diverse:

1. Coal;

2. Pellets;

3. Briquettes;

4. Firewood;

5. Coke;

6. Peat.

When burning fuel, ash is formed, which needs to be cleaned: from coal - every day; from wood - weekly; from briquette - monthly.

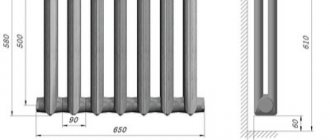

Heat exchangers of products are:

1. Cast iron;

2. Steel;

3. Copper.

Purpose

The devices are:

1. Single-circuit - designed exclusively for a heating system with the ability to connect an indirect heating boiler;

2. Double-circuit - designed for heating and hot water supply.

Electricity dependence

Devices are also divided according to the criterion of dependence on electricity. Models that operate without electronics, are loaded manually, and circulate water without a pump are considered autonomous.

TTC "Siberia"

Solid fuel heating boilers called “Siberia” are also produced in Russia. The products are equipped with a hob, which makes them attractive for everyday use.

The power of such boilers reaches 30 kW, they are able to operate on:

- firewood;

- coal;

- briquettes.

Some models are equipped with an additional circuit that allows hot water supply. The boiler body, made of heat-resistant steel, has an anti-corrosion coating, which protects it from rust and mechanical stress. The spacious combustion chamber allows you to store firewood up to 60 cm long.

This equipment attracts consumers with its low cost. However, it has some disadvantages; it requires frequent removal of slag formations and independent control of the combustion mode in order to avoid attenuation or overheating of the coolant.