Sections of the article:

Connecting an electric boiler: calculating the cable and load

The transition to electric heating is most often associated with the installation and connection of an electric boiler. Many, of course, are heated by fireplaces. But when upgrading an existing water heating system, you cannot do without installing an electric boiler.

And if you decide to install a heating boiler yourself and then connect it to a 220 or 380 Volt network, then you must at least have the necessary knowledge for this. What do you need to know to properly connect an electric boiler to the network? How to calculate the cable cross-section for connecting an electric boiler?

Boiler selection

The choice of boiler unit for heat supply is made according to thermal power, electrical network parameters and the principle of the heating element. The price of the heating set depends on the last parameter. Such electric units have increased functionality - all models are equipped with block automation with a temperature controller.

Modern modifications of electric boilers are implemented with various peripheral devices - weather-sensitive sensors, room thermostats and GSM modules for adjusting the indoor temperature at a distance from a mobile phone via the Internet.

The level of assembly of block units is very high, which allows you to install such heating with your own hands. The only exception is the installation and adjustment of power supply lines to the unit, which must be performed by certified specialists.

For example, for a house with a total area of 150 m2, the boiler power will be required: 150x1.2x0.1= 18 kW.

Operating rules

Despite the fact that an electric boiler is rightfully considered one of the safest, do not neglect compliance with safety precautions during operation. This is especially true when it comes to connectivity.

- The connection is made directly to the meter through network circuit breakers. The protection ensures safe shutdown of the heater in the event of a short circuit and sudden voltage drops.

- Proper grounding is mandatory. The manufacturer's instructions contain a diagram, failure to comply with which will result in a waiver of warranty obligations.

Advantages of Erdo electric boilers

- To buy and install an electric boiler for heating, you do not need to build a chimney or choose a place to store solid fuel in a private house.

- There is no need to specially equip the room to install the unit.

- There is no need to install additional equipment for gas control.

That is, installing such equipment does not create unexpected costs or additional problems. The electric heating boiler is a popular unit. Because Erdo electric boilers are environmentally friendly. The device runs on electricity, which means there is no open flame. Oxygen from the air is not wasted on combustion, and therefore no ventilation is required.

Experts will help you make the right choice. Moreover, the website has a large assortment of Erdo electric boilers, thanks to which it will not be difficult to buy an electric boiler. It should also be noted that all products are certified, and each device comes with a quality guarantee.

Types of three-phase heaters

The three-phase boiler is characterized by increased productivity, quiet operation and compact size.

Homemade induction heater

Most often used for heat and hot water supply systems in country houses. Double-circuit models are especially popular. It is recommended to install in combination with other heaters.

Available in two types:

- Electrode. The advantage of such a boiler is the high heating rate of the coolant.

- Induction. This is the most innovative type. Provides low specific energy consumption. The disadvantages include the large mass and relatively high price of the equipment. Such units are not produced with high power. To expand it, the method of cascading installation of three heaters at once is used, in which each boiler is connected to a separate phase.

Boilers with heating elements are also produced, but their popularity in private households is declining. Heating elements have to be cleaned and replaced frequently.

How to connect an electric boiler

Modern electric boilers are very popular because they are very easy to install and configure. They do not require the construction of a smoke exhaust system or exhaust ventilation, or the presence of a separate room to house the boiler.

Typical modifications of electric boilers already contain all the necessary components and functional units: network pump, expansion tank, thermostat, safety group.

Therefore, connecting an electric boiler is very simple, since you will need to connect a minimum number of in-house utility networks and you will not have to select an expansion tank.

Calculation of heating costs

As mentioned above, an electric three-phase boiler is economically more expensive than its gas and solid fuel counterparts. Electricity is becoming more expensive by leaps and bounds.

Electric boiler wiring diagram

Calculate consumption for a month or heating season in the following way:

- Considering that the efficiency of most units is close to 100%, it is believed that to obtain a kilowatt of thermal energy, 1.03 kW of electrical energy will be required;

- the area of the house is divided by 10 and multiplied by this indicator;

- multiply the resulting value by the cost of one kW/h. (it varies in different regions), then by 24 (the number of operating hours per day) and the number of days in a month or heating season.

In theory, for a house of 100 square meters with a cost of 3.2 rubles per kilowatt and round-the-clock operation per month, approximately 26 thousand rubles will be required for heating. In practice, this amount should be reduced by approximately half - the boiler does not always work around the clock. The costs will be even lower for an apartment.

The video shows the installation procedure:

The material from which the house is built, the type of floors, the type of windows and doors, and the quality of insulation have a great influence. It is not possible to take everything into account. Therefore, only practice will show how expensive the boiler will be.

Types of electric boilers:

Electric boilers EVPM Compact

Equipped with a built-in control panel designed to regulate and maintain the heating temperature of the coolant. The pipes intended for connecting the water heater to the heating system in Compact boilers are made in one version - they are perpendicular to each other (the supply pipe is vertical, the return pipe is horizontal). The device body has vertical stiffening ribs. The heating element heating block for Compact series boilers is similar to the heating element block for boilers of previous model series. Low cost and ease of installation are the distinctive features of this model.

Choosing a brand of electric boiler

Today, buying a three-phase boiler for heating does not seem problematic. There are a great many manufacturers and versions.

The choice is not easy to make. Be sure to pay attention to available features and warranties. Customer trust was formed under the influence of subjective and objective factors. The most popular brands today are produced in Germany, the Czech Republic, Spain and Switzerland.

German samples Bosch Wespe Heizung and Swiss STS are distinguished by high performance, but also by the same high price.

Wall-mounted units of the Bosch Tronic 5000 H series are used in various heating systems, including in conjunction with battery tanks. These are heating element type boilers. There are three of them installed.

Bosch Tronic 5000H

The heaters are single-circuit, suitable for supplying hot water using an indirect heating tank. The efficiency declared by the manufacturer is 99%. They provide water heating up to +90 degrees, four-stage power and temperature adjustment using a room regulator.

Slovakian Protherm boilers are distinguished by no less functionality and performance at an adequate cost. The same equipment is supplied by the Czech company Dakon - the Protherm 18K model, like the German ones described above, is equipped with a steel heat exchanger and automation, providing even greater capabilities with the same efficiency. The boiler has the function of remote control of power supply from the tariff meter.

Russia produces products that are not inferior in quality, but are more affordable. Since 2010, the SAVITR company (part of NPK VETROSTAR) has been producing double-circuit boilers of the Ultra series with weather-dependent automation and remote control with a GSM module. According to reviews, the quality and reliability are the highest.

Russian manufacturers have extensive service networks, which is important.

How to connect the boiler to the electrical network

Before connecting the boiler equipment to the electrical network, it is necessary to carry out a thorough check of its technical condition.

If problem areas are detected, it will be necessary to carry out repair work; if it is not possible to increase the power supply of the existing line, the reconstruction of the in-house electrical networks is carried out with the involvement of certified specialists.

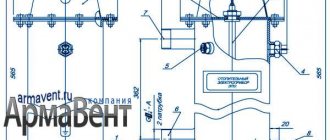

Schemes for connecting an electric boiler to the network

Copper electrical wiring is used for connection; the cross-section of the wires is calculated in accordance with the data provided by the manufacturer in the instructions for the boiler equipment.

Connection to an external cable is made using specialized terminals located at the bottom of the boiler. Typically, a grounding terminal with a copper bolt is also located in this location.

When installing an electric boiler, it is essential to implement a grounding system. In this case, it is necessary to ensure that the contact between the device body and the copper bolt is strong.

A control device for adjusting the temperature schedule must be connected to the circuit. In order to protect electrical equipment from voltage surges, it is necessary to install an RCD.

Connection diagram for a single-phase boiler at 220

The 220 V power supply line of the boiler unit is protected by a differential circuit breaker made of one module, a protection unit made of an RCD with a circuit breaker.

Grounding must be connected to the boiler body. The heating element in such an electric boiler is designed exclusively for 220V, therefore, a phase is connected to one of its ends, and zero to the other.

To connect the unit to the 220 power supply network, it is necessary to lay a three-core cable and select the required cross-section and automatic protection ratings for it to ensure reliable power supply to the boiler. When choosing, proceed from the thermal power of the electric boiler.

It would be correct if the cable, RCD and circuit breakers are selected with a reserve, so that in the future, when it is necessary to replace the boiler, there is a reserve for the electrical load with a more powerful model.

Connection diagram for a three-phase electric boiler to the power grid 380

Electric boilers, which are most often used for heating homes, do not have very high power - up to 15.0 kW, since energy regulations no longer allow them. Such installations can be equipped with heating elements manufactured for 220 V.

They are connected to a 380 V network by a “star” with a common “0”. For example, three heating elements of 6 kW each create a total load of 18 kW. With this connection, the operation of any heating element is allowed, regardless of the adjacent one, that is, a choice of power of 6, 12 and 18 kW is allowed. If the heating elements are supplied at 380 V, then they are connected between the phases in a “triangle”.

It is prohibited to deviate from the electrical diagrams designed by the manufacturer for a specific boiler model. If heating elements are installed for 220V with a 3-phase connection, change the circuit to a “triangle”, otherwise they will simply burn out.

The RCD compares the strength of the current flowing through it in phases. These data in a properly functioning system will be approximately the same. But when damage occurs or a person touches the current-carrying surface, a current leakage will occur from a certain phase and a current differential will arise between the wires. In the event of such a disruption in the network, the relay will turn off the network in a very short time.

The circuit breaker operates when the specified current strength in the circuit increases. For example, in case of a short phase-to-phase circuit. In this option, the RCD will not work, since the current strengths in the phases will become the same. But limit current protection will turn off the circuit and prevent fire of electrical appliances and wires.

To summarize, it can be noted that the installation of modern electric boilers for heating individual houses is not difficult, since they are equipped with a full set of auxiliary boiler equipment.

The owner will need to carefully follow all the recommendations of the manufacturer and invite an electrician if reconstruction of the home electrical network is required.

Why do you need boiler piping?

The unit comes with compounds, their task is to increase the electrical conductivity of the liquid.

If their design is mechanically damaged for any reason, a circuit break is created for the flow of current, which will leave a dangerous phase potential on the housing. Expensive sensors can detect not only the presence of water flow, but also its speed. These boilers have high energy consumption up to 15 kW.

Thus, in terms of safe use, direct heating boilers are significantly inferior.

Choosing a boiler Calculate the area of your home. Economical Electric boiler is the source of the most expensive heat among all modern boilers for autonomous heating.

Optimal temperature distribution. Schematic diagram of the electric boiler wiring According to the installation diagram of the electric boiler, it is necessary to provide a heating grounding system. Buffer containers with a capacity of 1 ton of liquid are used.

Best product

How is buffer capacity used?... First of all, inspect the terminals of the heating element; most likely, the manufacturer has already prepared the contacts for a specific circuit. The power is adjusted in steps by turning on one or several 1.5 kW or 2 kW heaters at once. To do this, use a pipe of the appropriate length and two fittings. Modern electric boilers operate in automatic mode, so owners do not have to constantly adjust it.

In order for home heating to be highly efficient, it is necessary to use powerful equipment that consumes a significant amount of electricity. Read more: "Electric boiler: electricity consumption - economical calculations." Connecting an electric boiler - electrical and hydraulic circuits Connecting an electric boiler - electrical and hydraulic circuits Electric boilers are now installed quite often. Equipment is being improved at a slow pace. Types of electric boilers Heating element boilers - heating elements are used as a heating element and are considered the most common.

It is necessary to start only if these conditions are met: There are no leaks, all components in the system have been checked. With pipes the situation becomes more complicated. This process occurs in the expansion tank; there are no other open sections of the circuit. Heating the garage with an electric boiler

How to connect the boiler to the electrical network

Before connecting the boiler equipment to the electrical network, it is necessary to carry out a thorough check of its technical condition.

If problem areas are detected, it will be necessary to carry out repair work; if it is not possible to increase the power supply of the existing line, the reconstruction of the in-house electrical networks is carried out with the involvement of certified specialists.

Copper electrical wiring is used for connection; the cross-section of the wires is calculated in accordance with the data provided by the manufacturer in the instructions for the boiler equipment.

Connection to an external cable is made using specialized terminals located at the bottom of the boiler. Typically, a grounding terminal with a copper bolt is also located in this location.

When installing an electric boiler, it is essential to implement a grounding system. In this case, it is necessary to ensure that the contact between the device body and the copper bolt is strong.

A control device for adjusting the temperature schedule must be connected to the circuit. In order to protect electrical equipment from voltage surges, it is necessary to install an RCD.

Connection diagram for a single-phase boiler at 220

The 220 V power supply line of the boiler unit is protected by a differential circuit breaker made of one module, a protection unit made of an RCD with a circuit breaker.

Grounding must be connected to the boiler body. The heating element in such an electric boiler is designed exclusively for 220V, therefore, a phase is connected to one of its ends, and zero to the other.

To connect the unit to the 220 power supply network, it is necessary to lay a three-core cable and select the required cross-section and automatic protection ratings for it to ensure reliable power supply to the boiler. When choosing, proceed from the thermal power of the electric boiler.

Connection diagram for a three-phase electric boiler to the power grid 380

Electric boilers, which are most often used for heating homes, do not have very high power - up to 15.0 kW, since energy regulations no longer allow them. Such installations can be equipped with heating elements manufactured for 220 V.

They are connected to a 380 V network by a “star” with a common “0”. For example, three heating elements of 6 kW each create a total load of 18 kW. With this connection, the operation of any heating element is allowed, regardless of the adjacent one, that is, a choice of power of 6, 12 and 18 kW is allowed. If the heating elements are supplied at 380 V, then they are connected between the phases in a “triangle”.

The RCD compares the strength of the current flowing through it in phases. These data in a properly functioning system will be approximately the same. But when damage occurs or a person touches the current-carrying surface, a current leakage will occur from a certain phase and a current differential will arise between the wires. In the event of such a disruption in the network, the relay will turn off the network in a very short time.

The circuit breaker operates when the specified current strength in the circuit increases. For example, in case of a short phase-to-phase circuit. In this option, the RCD will not work, since the current strengths in the phases will become the same. But limit current protection will turn off the circuit and prevent fire of electrical appliances and wires.

To summarize, it can be noted that the installation of modern electric boilers for heating individual houses is not difficult, since they are equipped with a full set of auxiliary boiler equipment.

The owner will need to carefully follow all the recommendations of the manufacturer and invite an electrician if reconstruction of the home electrical network is required.

About company

"Resurs - ElectroKotel" has been an actively developing company producing climate control equipment for more than ten years. During this period of time, we were able to establish ourselves as a proven, reliable and responsible supplier of electric boilers for heating a private home, as well as components for heating boilers throughout Russia and in neighboring countries.

"Resurs - ElectroKotel" is a manufacturer of single-circuit electric boilers EVPM for heating systems of residential, industrial buildings and other types of buildings with an open or closed heating system, operating with an electrical voltage of 220 W or 380 W (single-phase and three-phase). Our boilers are used both separately and together in a system with other heating boilers (gas, solid fuel boilers).

We bring to your attention heating boilers of various power kW (3 kW – 96 kW). A wide range of power characteristics will certainly help solve the problems of heating rooms of various sizes and purposes. For home, cottage, garage, industrial, residential premises, greenhouses, baths, and other buildings.

In addition to electric boilers, please pay attention to electric heaters, heat guns of various modifications and capacities, automation (control panels), heating elements and much more.

Excellent quality and guarantee, ease of installation and use of our products,

affordable price and delivery of goods throughout Russia by any transport company or mail - these are our advantages!

An electric heating boiler occupies a special place among other heaters because it is operated without the need to replenish fuel reserves. Gas, which also does not have to be stored, is not available everywhere, unlike electricity.

Simplicity and ease of connection ensured the widest distribution of electric heaters. It is installed in apartments and country houses. It is found in northern and southern latitudes. These are mainly 220 volt units, since the required power in this case does not exceed 12 kW.

A more powerful electric heating boiler is three-phase and requires connection to a 380 V network.

Comparative table of electric boilers EVPM LLC "ERDO":

| Comparison parameters/boiler name | Aristaeus | NEXT ELECTRON | NEXT 3-12kW | Compact 3-15kW |

| execution type | wall | wall | wall | wall |

| boiler power, kW | 18 | 3-12 | 3-15 | 6-12 |

| number of power stages | 6 | 3 | 3 | 3 |

| area of heated premises max., m2 | 150-180 | 55-120 | 25-120 | 25-150 |

| supply voltage | 380 | 220/380 | 220/380 | 220/380 |

| overheat protection | + | + | + | + |

| remote electronic room temperature sensor | + | + | — | — |

| connecting dimensions of pipes | G 3/4″ | G 1″ | G 1″ | G 1″-G 1 1/4″ |

| a heating element | heating element | Heating element block | Heating element block | Heating element block |

| Control block | electronic | electronic | mechanical | mechanical |

| LCD display | + | + | — | — |

| maintaining coolant temperature | + | + | + | + |

| maintaining ambient temperature | + | + | — | — |

| possibility of changing the location of the supply and return pipes | — | — | + | — |

| automatic air vent | + | — | — | — |

| System defrost protection | + | + | — | — |

| built-in circulation pump | + | — | — | — |

| possibility of connecting a circulation pump | + | + | from 9 kW | — |

| rotation of heating elements | + | + | — | — |

| system pressure control | + | — | — | — |

| self-diagnosis | + | + | — | — |

| Possibility of operation at reduced mains voltage | — | from 90 V | — | — |

| recessed control panel | — | + | + | — |

| implementation of power switching | on display | buttons | keys / automatic switch | keys / automatic switch |

| presence of lighting fixtures | + | + | + | +/- |

| type of emergency thermostat | electronic | electronic | self-returning | with mechanical return |

| emergency overpressure relief valve | + | — | — | — |

Types of electric boilers

Electric boilers are available on the market in a wide variety of products. The differences between them are as follows:

- Number of circuits. Like other types of heaters, an electric boiler can be single- or double-circuit. A single-circuit boiler has a slightly higher output power, since it does not provide for operation with domestic hot water.

- Type of heating element. This can be a heating element, an electrode or an induction coil (inverter).

- Coolant type. Some single-circuit heater models use antifreeze.

- Type of electrical network used (220 or 380 volts) and connection method (single-phase or three-phase).

- Heating method. The boiler is of flow-through or storage type.

To create increased power, greater electrical system performance is required. It is recommended to connect an electric heating boiler with a power of over 12 kW to a 380 V network. To do this, you need to obtain permission and draw a separate line.

If there is insufficient water pressure, it can boil!

Room thermostat and energy saving

To get a more functional option, let’s add here a device for monitoring the air temperature in the room - a room thermostat.

It doesn’t matter to him what the temperature of the boiler water will be; he reacts precisely to the comfortable air temperature in your home. By analogy with the previous elements, mount it in the gap, in front of the working thermostat

The second simplest scheme is ready

By analogy with the previous elements, mount it in the gap, in front of the working thermostat. The second simplest scheme is ready.

But people always strive for more, and in addition to the comfort of electric heating, they always want to save money. Still, with rare exceptions, electric heating is not exactly a cheap thing in our realities.

How to do this by improving the above connection diagram? There is a night rate for this business.

To take full advantage of it, we need a time relay.

It will start electric heating only during a specified period of the day. Place it in the circuit in front of the room thermostat.

However, pay attention to one nuance. If there is such a device in the circuit, a minimum air temperature thermostat must be mounted parallel to it.

During the day, in your absence, the temperature outside can drop sharply. We left at -5C, arrived in the evening - minus 25C outside. Accordingly, your home will become significantly colder.

It will start heating as soon as the temperature in the house drops below the minimum threshold. As a result, it will prevent the house from cooling down and the system from defrosting.

To visually observe whether the sensors are turned on or off at the moment, you can connect a signal light to a common point in front of the microswitches and display it in a visible place.

This is especially useful when the control panel and the boiler itself are located in the basement of the house or in a neighboring outbuilding.

Most factory electric heating boilers are built precisely on such basic control schemes. There is one supply line (phase) that supplies a signal to the coil of the device with power elements, and all additional equipment, sensors and switches are “hung” on this very line, performing protective and monitoring functions.

As you can see, there is nothing complicated or intricate here.

https://youtube.com/watch?v=fw9BUOGXT4Y%3F

Connection and first start-up of a three-phase boiler

They begin to install an electric three-phase heating boiler by calculating the circuit. It is somewhat more complicated than when connecting to a 220 V network, but is present in the passport for the unit. Since you will have to obtain permission to operate the boiler on a 380 V network, it is better to entrust the connection to electrical network workers.

The most important part is connecting the wires. The procedure is indicated in the instructions and is absolutely simple. The main thing is to maintain color and properly ground the unit.

Three-phase connection diagram

It is important to perform the tying correctly. Correct strapping is a guarantee of high-quality operation of the device. This will require a number of components and tools. The work is not difficult for a person who has an understanding of plumbing work.

Water must enter the boiler through the return line. This is done in order to be able to add water while the boiler is operating without causing cavitation processes. A shut-off valve is installed in the supply line, and a filter is installed in the discharge line.

The same taps are needed in the water supply lines to heating and hot water systems.

The boiler is mounted at the lowest point of the system. This will allow you to obtain maximum heating of the heating system elements. The coolant supply pipe to the radiators is installed at the minimum height from them.

A double-circuit heater must be connected so that the coolant in the small circuit is heated to a certain temperature and supplied to the large circuit to the radiators.

After the connections are made, start-up begins. First, remove the front panel and slightly open the return valve so that water begins to flow into the tank.

Control is carried out using a pressure gauge on the device body. The required pressure is limited by the green sector on the device (1.5-2 bar). When the arrow moves to this sector, unscrew the tap on the relief valve (installed in the upper part) and completely bleed off the air. When water flows without bubbles, it is closed. In this case, the pressure in the tank will drop. You should wait until it grows and then bleed the air again.

Electric boiler control unit

Next, proceed directly to the launch. To do this, turn on the gas station. The power light on the device indicator will light up and digital data on the water temperature will appear.

By pressing the arrow buttons (+ and -) you control the amount of kW used and the water pressure in the boiler. The Mode and OK buttons allow you to program the temperature and power consumption in kW.

After setting the set temperature, the pump begins to function and the heating element turns on. All that remains is to close the lid and enjoy quiet and fast operation. Stop the boiler by pressing the button with the minus sign and completely resetting the set temperature.

Electric boilers for heating

In conditions where gas is unavailable and there is no central heating system, the best choice is an electric boiler for heating. In such cases, using an electric boiler is the optimal, environmentally friendly and economical option. This heating equipment is appreciated by consumers.

The growing popularity of Erdo electric boilers is explained by the following advantages:

- Compact parameters that do not require a separate room.

- The devices are easy to use.

- These boilers are the safest of all heating boilers produced.

- Its installation does not require special permission or installation of additional equipment.

The condition that must be adhered to before installing an electric heating boiler is to check the quality of the electrical wiring. This must be done to protect yourself from fire. It is possible to buy an Erdo electric boiler with both the lowest power of 3 kW and 48 kW for large rooms.

- Units with a power of up to 12 kW are Next models. Their appearance has an attractive design. These models are attached to the wall, for example in the kitchen or hallway. A distinctive feature of the devices is the ability to rotate the pipes, both supply and return, during installation work.

- Boilers with higher power from 15 kW have a rectangular body. The front panel has keys for regulating power and turning on the circulation pump, and there is also a thermostat. You can buy an electric boiler in two versions: wall-mounted and floor-mounted.

Which electric boiler should I buy so that it works properly for a long period? The choice depends on the area of the room that needs to be heated. But we should not forget that low-power devices can be connected to 220 V electrical wiring. However, if the power is 9 kW, it is better to connect to a network with a voltage of 380 V. And we should not forget about grounding.

If you buy an electric boiler with a small power reserve, then during operation you can avoid problems caused by voltage drops in the network. To save energy consumption, you should install a power switch.

Advantages of an electric boiler

The electric three-phase boiler is constantly being improved by developers. Wall and floor models are available.

The best representatives of this class receive additional systems and devices that provide multi-stage adjustment, automation of air exhaust and temperature control processes.

An electric three-phase heating boiler can work in conjunction with other types of heaters. Compactness and design are considered an indisputable advantage.

Although an electric heater is not as economically profitable as, say, a gas heater, it still has certain advantages:

- An electric boiler takes up less space compared to a solid fuel boiler. It can be installed in any place where there is an electrical network;

- No chimney or additional ventilation is required - this is a direct saving of money and time on maintenance;

- It is not a source of unpleasant odors and carbon monoxide. The boiler is environmentally friendly.

- Makes almost no noise during operation;

- The absence of open flames makes it easier to comply with fire safety measures.

Electric boilers have a high efficiency of at least 96%.

The disadvantage of a three-phase boiler is the need to convert the current to 380 V and the presence of good electrical wiring in the house. Electricity is more expensive than gas, and frequent power surges affect the quality of boiler operation. This also applies to the disadvantages.

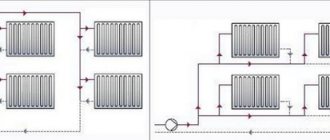

How to connect an electric boiler to a heating system

There are several standard piping schemes, one of which must be selected before connecting the electric boiler to the heating system:

- installation of the unit with piping of the electric pump and expansion tank;

- installation of an electric boiler in a parallel operation scheme with a solid fuel or gas boiler unit;

- connection with a hot water storage tank or an external electric water heater;

- connection of a double-circuit modification of an electric boiler to heating networks and hot water supply;

- connection to an indirect heating boiler.

Typically, modern electric boilers are equipped with all the necessary auxiliary equipment. The safety group protects the unit from high pressure and releases air from a closed water circuit using a membrane expansion tank.

A safety group is installed on a straight section of the supply pipeline, and after it - a ball valve that cuts off the coolant supply. The circulation pump and dirt filter are installed on the return pipeline.

If it is necessary to connect the boiler to an open heating system with natural circulation, then the heating pipes will need to be placed with a slope of 3 mm by 1 pm.

Electric boiler circuits for preparing hot water supply are used in two versions:

- double-circuit design of the boiler, which has two built-in heaters for the heating circuit and DHW;

- single-circuit boiler with external indirect heating water heater.

In the first option, connecting the electric boiler to the heating system is carried out according to the standard scheme. There are practically no difficulties here, the main thing is to correctly install the shut-off valves.

Connection to an indirect heating water heater is made using three-way shut-off valves. Based on a signal from a thermostat integrated into the battery tank, the valve switches the movement of heating water to heat up the DHW circuit or heating system.

DHW loading is a priority: until the water in the tank warms up to a certain temperature, the heating network will not receive thermal energy.

Operating principle of electric boilers

The operating algorithm is simple. First, the coolant is supplied to the expansion tank. It is then heated by electrical energy and then sent into the system.

The design implements the following heating schemes:

- With the help of heating elements. One or two heating elements connected to the network heat the water in the tank, like boilers. A heating element boiler is reliable, provides high efficiency and is relatively inexpensive.

The device of a heating element heater

To increase efficiency, the use of programmers is recommended. These devices provide automated operation depending on the temperature indoors or outdoors. The economic effect of application is up to 30%. Installation is acceptable on your own, but it is better to leave the work to professionals.

- An electrode boiler uses the principle of heating with alternating current passing through water (coolant). Automation protects such a boiler from short circuits, leaks and overheating. These devices are sensitive to water quality.

- An induction type boiler uses the principle of heating due to electromagnetic induction. The heating element is a coil with many turns of insulated wire and a metal rod in the middle. It is placed in a vertical position in a sealed cylindrical housing, into which coolant is supplied through the lower pipe. Power is supplied through terminals installed on the top of the element housing. After heating, it is discharged into the system through the upper pipe. Boilers of this type heat up quickly, which requires monitoring the pressure and the presence of water in the system.

Types of boilers by heater type

Today there are many modifications of units that differ in the connection diagram of the electric boiler, and are classified according to:

- configurations;

- characteristics of thermal conditions;

- design solutions;

- type of heating;

- manufacturing plants;

- cost.

All electric boilers designed for water heat supply, according to the method of heating the coolant, are divided into 3 main categories:

- Heating elements that use tubular electric heating elements.

- Electrode or ionic/electrolysis, operating using the ability of water to heat up when passing alternating current through an electrode.

- Induction, using the properties of ferromagnets to heat up under the influence of induction current.

Tags: automatic, boiler, sconce, view, choice, switch, house, capacity, grounding, cable, how, design, circuit, installation, power, voltage, nominal, heating, connection, principle, wire, start, work , size, regulator, relay, repair, row, light, network, connection, circuit, ten, type, current, current, triangle, installation, phase, filter, shield, electronic

Replacing the heating element

Replacing the heating element and other elements, as well as diagnostics to determine the cause of the malfunction, is carried out in a passive way when the electrical equipment is disconnected from the external alternating voltage source.

This issue cannot be resolved on your own if you are not an electrician and such work is carried out accordingly if you have knowledge of the regulatory documents of the electrical safety approval group.

So what is the need for these details? — You may ask, if in this or that case there is a malfunction, you can call the electrician directly.

Well, let's put it this way - knowledge of electrical and electrical engineering will not be superfluous for you.

Connecting an electric boiler

Let's consider connecting the EVAN S1-30 electric boiler to a four-wire, three-phase network with a neutral wire.

The fifth PE conductor in the diagram in Fig. 1 is grounding and is connected to the body of the EVAN S1-30 electric boiler. Reading the connection diagram:

The electric boiler is equipped with so-called buses; a network cable with a plug is connected to buses N, A, B, C. From the buses, three phases A, B, C have branching. One branch of phases A, B, C is connected to the first contacts of the heating elements of two blocks.

The second branch from the same four buses is connected through a starter to the second contacts of the heating elements of two blocks.

Here it should be taken into account that for each individual block with heating elements, each individual heating element is connected to phase wires as follows:

Phase A and neutral wire N from the busbars are connected to the control panel. In its combination, the control panel is connected to a voltage of 220 V, the conductors from the control panel are connected:

- with pump;

- with air temperature sensor;

- with thermostat sensor;

- with self-resetting thermal switch.

The control panel consists of electronic elements that are not indicated in the diagram.

For electronic elements, diagnostics are outlined in this blog.

After carrying out repairs to replace one or another electrical part:

- block with heating elements;

- self-resetting thermal switch

and other parts included in the electrical circuit, it is necessary, before connecting the electric boiler to an external source of alternating voltage, to check the electrical circuit of the boiler for resistance. Diagnostics of the resistance in the electrical circuit of this circuit is carried out either with an ohmmeter or a multimeter with the appropriate function.

If, as a result of measuring resistance, the device indicates a zero value, in this example you should reconsider the connections you have made. A zero resistance number indicates a short circuit in the electrical circuit.

Consider the following electrical circuit for two types of boilers EPO-7.5 and EPO-9.45. The electrical circuit shown in Fig. 2 is identical and the difference here is only in the power of electric boilers. Let's follow the connection diagram:

These types of electric boilers are connected to a two-wire, single-phase network. The PE grounding wire is connected to the heating element block and to the body of the electric boiler. The phase wire from the phase bus in this circuit has a branching, one wire with phase potential goes to the control panel and is connected from the control panel to the first contacts of the heating elements,

the second wire with phase potential is supplied through the starter to the electric heating element; also from the starter, the wire with phase potential is connected in series through a switch to the control board. The control board has connections:

- with air temperature sensor;

- with temperature relay of heating elements;

- with thermostat sensor

The neutral wire has a serial connection:

- with starter;

- with control board;

- with the second contacts of heating elements.

The connection diagram for the electric boiler Fig. 3 is intended for a two-wire, single-phase network. The power of electric boilers for this scheme is 5-6 kW.

The phase wire from the bus in a serial connection through the starter is connected to the first contact of the heating element. The neutral wire from the bus is connected to the second contact of the heating element. From the phase and zero buses, power is supplied to the control panel. Remote Control

- with pump;

- with air temperature sensor;

- with thermostat sensor;

- with self-resetting thermal switch.

The PE protective conductor is connected to the body of the electric boiler.

Electric boilers have only minor differences in their electrical circuits.

Current calculation

The RCD is selected taking into account the current strength. We substitute the values using the power formula,

We know two values from the formula - the power of the electric boiler and the voltage. From here we can find the current value.

The result of the current strength is known to you, all that remains is to select a protective shutdown device based on the calculated value of the current strength.