The appearance on the market of solid fuel boilers with automatic feeding has greatly simplified the lives of many consumers for whom gas or electric heating is not available. The development of production has led to the creation of many models for various purposes. Knowledge about the structure, operating principles and types of automatic units will help you choose the most suitable and profitable option.

Types of boilers and burners

Boilers with automatic fuel supply operate on coal or biomass (pellets, oat grains, sunflower husks, wood chips, etc.). Among coal boilers, the most popular boilers are those using “eco-pea” coal as fuel (coal granules with a diameter of 5-25 mm).

To burn fuel in boilers, burners are used: retort, tray or flare. 85% of installed coal boilers with automatic feed operate on retort or tray burners - we will consider these solutions.

How to choose

When choosing a specific model of coal boiler for a residential building, several factors should be taken into account: thermal power and size of the heated area, type of combustion, type of heat exchanger - cast iron or steel, energy independence, safety, efficiency, weight of the unit and its price.

Direct long burning or pyrolysis

In order to compare boiler units by type of combustion: long burning or pyrolysis, compare the main operating parameters of coal boilers:

- Efficiency: Long-term combustion - from 75 to 85%, pyrolysis - from 85 to 92%.

- Possibility of autonomous operation: long burning - yes, pyrolysis - yes.

- Energy independence: long burning - yes, pyrolysis - yes.

- Permissible fuel humidity: long burning - from 30%, pyrolysis - up to 15%.

- Acceptable fraction: long burning - up to 50 mm, pyrolysis - from 25 mm.

Thus, today it is possible to draw the main conclusion - it is simply not possible to burn fuel more efficiently than in an automatic pyrolysis solid fuel boiler using coal and wood.

Heat exchanger material

The type of material from which the body of a coal boiler is made is the main factor that determines the durability and maintainability of the heating system:

- Steel is a relatively light metal that can withstand changes in pressure and temperature. Its disadvantages include susceptibility to corrosion processes and burnout in the zone of maximum temperatures.

- Cast iron is the most durable material and is used in all powerful units. However, it does not withstand shock and temperature changes well. In addition, if fistulas form in the walls, it will not be possible to weld them, as in steel products.

Modern boilers, using the positive qualities of both metals, are produced in a steel body and with a cast iron combustion chamber.

Single-circuit or double-circuit

Single-circuit or double-circuit are available, either only for heating, as in the first option, or, respectively, for heating and hot water supply - in the second.

In this case, double-circuit boilers operate on the principle of switching hot flue gases to the DHW circuit when the valve on the mixer is opened. Coal units have a fairly pronounced low inertia, so it is practically possible to regulate the heating medium between the circuits only in pyrolysis devices.

Therefore, for many options for coal boilers, the preferred hot water supply scheme remains, organized through an additionally installed indirect heating boiler. In this case, the efficiency of the heat supply system is significantly increased by reducing the temperature of the exhaust gas.

Minimum required power and heated area

In order to determine the approximate thermal power, use a practical formula depending on the heated area of the room:

Mk = Pd x 0.1 where:

- Mk - design power of the boiler, kW;

- Pd - area of the house, m2.

- 0.1 - specific power indicator per 1 m2 of area (W/m2).

This calculation does not take into account many more important parameters of the house, for example, such as the level of thermal insulation, glazing area, roof structure and climatic region of residence.

These calculations are complex and can only be performed by special design organizations or using software packages.

Therefore, in everyday life, an approximate calculation is carried out, which is carried out according to the principle “from small to large” - the power is set for each room separately, and then the result is summed up. This approach also allows you to determine the number of metering devices required for each room.

Another difference for coal boilers in this calculation method, which will need to be taken into account when selecting equipment. The power according to the formula takes into account the calorific value of standard coal, which in reality is much worse, so an adjustment of 20% is made to accurately determine the coal consumption in a solid fuel boiler.

Efficiency

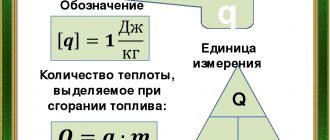

Efficiency - represents the ratio of the volume of fuel consumed to the volume of thermal energy generated by a coal boiler. This is the most important indicator of equipment efficiency and fuel use.

It depends on the thermal design and the use of innovative technologies in the boiler design. In EU countries, due to strict environmental protection requirements, the installation of new devices with an efficiency below 90% is not allowed. High-tech condensing domestic boilers today operate with an efficiency of 100-105%.

Retort burners

Retort burners consist of a cast iron elbow (retort) and a cast iron grate burner in which the fuel burns. Some burners are equipped with a "ring gear" whose rotation stirs the fuel, breaks down the coking slag, and distributes the fuel throughout the retort tray.

Thanks to the 90-degree bend, the burner is installed in the middle of the combustion chamber, so the side walls of the boiler are heated evenly and do not overheat. The design increases the path to the fuel hopper and reduces the likelihood of fuel fire in the feeder.

Another advantage is low sensitivity to deposits arising in the hearth itself: incoming portions of fresh fuel automatically dump unburnt or sintered fuel into the boiler ash pan.

There is also a downside - bending the knee complicates the supply and combustion of fuel, which eventually settles at the bend. Sediment and carbon deposits build up, reducing the "throat" for fuel movement on its way to the top of the burner. This results in increased resistance of the auger feeder, premature wear of the auger and breakage of the pin (shear bolt) protecting the auger feeder.

Varieties

Automatic coal boilers are grouped into 4 basic types: traditional, pyrolysis, pellet and long-burning. Certain models combine different design options, for example, in a traditional boiler unit I install a pellet burner.

Long-burning coal boilers

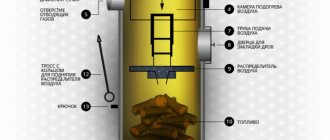

Boilers operating on the principle of long combustion are otherwise called “top combustion”. They are distinguished by a long period of work on the first coal load.

In such designs there is no ash pan or grate; moreover, the bottom of the device is completely solid, and therefore combustion of fuel in the lower part is categorically unacceptable. The combustion chamber has a cylindrical shape. Air is supplied from above, strictly in the center.

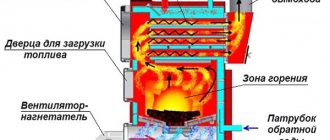

Fuel combustion process

In order to organize such an air supply scheme, an air distributor is installed in the firebox, which has the ability to move down along with the fuel during the combustion process.

The air continuously approaches exactly the upper combustible layer, where hydrocarbons are partially oxidized, that is, the process of pyrolysis occurs. Products containing ash particles fly up into the combustion space. They are separated from the primary combustion zone by a thick metal disk mounted on a dynamic air-blowing tube.

In this secondary combustion chamber, atmospheric air enters the pyrolysis gas, volatile combustible substances burn, releasing heat, which is supplied to the heat exchanger, which heats the coolant for the heating system.

Pyrolysis coal boilers

Another very popular option for a coal unit is a pyrolysis or gas generator. The pyrolysis process has long been used in many industrial applications in the pharmaceutical and petroleum industries.

In coal-fired boilers, pyrolysis involves the slow thermal decomposition of coal under oxygen deficiency. In this case, pyrolysis flammable gases are released from the fuel, which penetrate through special passages in the loading chamber into the secondary chamber, into which the calculated volume of air is supplied by a fan.

Volatile gas substances ignite and burn completely, ensuring efficient operation of the device with the highest efficiency for coal boilers - 92%.

Bunker automatic boilers

Modern autonomous coal boilers, operating in automatic mode, are controlled using a controller and a screw fuel supply mechanism. The boiler system is equipped with forced air supply and smoke removal.

To keep heating surfaces and smoke channels clean, a stationary self-cleaning device is installed. Coal boiler houses equipped with such units do not require a large number of maintenance personnel due to the high level of automation of the combustion process.

Boiler with coal bunker

Operating principle of automatic coal boilers:

- When the unit starts, the screw fuel supply starts.

- The first share of coal is ignited by electroplasma.

- As combustion proceeds, a fresh portion of fuel enters the combustion chamber. The increase in unit productivity is regulated by the speed of the screw conveyor.

- Simultaneously with the screw fuel supply, a dosed air supply into the combustion chamber is turned on.

- The controller determines the rate of air intake, thereby regulating the intensity of the combustion process.

- Automatic grates dump ash residues into the ash box.

- Soot cleaning is carried out by special springs installed inside the channels.

Tray burners

Tray burners are a tray made of steel or cast iron into which an auger supplies fuel.

The main advantage of tray burners is their omnivorous nature. The burner burns most types of fuel and fuel mixtures available on the market. Fuel is supplied to the hearth only in a horizontal direction and over a shorter distance compared to a retort burner. The resistance of the feeder during operation of the auger in this case is minimal. At the same time, the short distance of fuel movement and horizontal supply increase the likelihood of fuel backfiring towards the fuel bunker. Therefore, for such structures, additional protection against backfire (fire extinguishing group) is organized.

Another disadvantage is the sensitivity to the formation of sintered substances and deposits in the burner. Deposits accumulate at the end of the burner tray and are more difficult to remove automatically - they will only be removed when the next portion of fuel is fed into the burner.

Video

Additional recommendations for choosing the appropriate model are available in the video.

Evgeniy Afanasyev chief editor

Author of publication December 27, 2018

Did you like the article? Save so you don't lose!

The most modern and cost-effective are automatic solid fuel boilers. This, of course, affects the initial price of such devices, but ultimately leads to the desired economic and operational result.

The purpose of automatic solid fuel boilers is: maximum autonomy (independence) of operation with the lowest possible fuel consumption. And here everything is natural: the more responsibilities are transferred to automatic control, the more accurately and consistently each of its nodes works. Which ultimately translates into savings in fuel and maintenance time, as well as a general reduction in labor costs when it comes to maintenance personnel.

Reverse heat flow to the bunker (fire)

A rare but familiar accident to manufacturers is the reverse flow of heat to the bunker. In 9 cases out of 10, the situation arises due to the negligence of the boiler user himself. Also, a reverse flow of heat occurs when the safety pin breaks, after which the auger stops rotating.

If the bunker is tightly closed, the fan is running, and nothing prevents the movement of flue gases from the boiler into the chimney, even if the auger does not rotate, there is nothing to fear.

Reverse heat flow (fire) is a rare phenomenon in boilers with automatic fuel supply. However, boiler manufacturers equip supply systems with two safety stages to eliminate such a possibility in principle.

The first stage is a temperature sensor, installed on the fuel supply pipe: if the temperature exceeds the set one, the sensor signals the boiler controller to solve the problem. The controller begins to continuously circulate fuel through the pipe until the sensor temperature returns to normal. The continuous supply interval in Galmet boilers is 10 minutes.

If the problem remains, the thermostatic valve is activated - water is supplied from the emergency tank into the pipe and eliminates the fire in the feeder pipe.

One of the causes of fuel fire in the tank is backdraft, which occurs if the bunker is left open or closed incorrectly. To prevent this from happening, some manufacturers equip the fuel tank lid with a limit switch. When the hopper lid is not closed tightly, the sensor is triggered and gives a warning signal. If measures are not taken, the controller will stop the boiler.

DeOnis-I › Blog › Homemade mine boiler for all types of fuel

In the process of transforming the dacha into a country cottage, the need for high-quality heating arose.

Gas runs along the perimeter of SNT and will be connected later, but for now there is no money for this. You will have to heat with wood, coal and pellets. Another task for the boiler is the disposal of combustible waste. First, wood scraps and then household scraps. The boiler is planned to be installed in a separate boiler room located on the site. So to speak, “household block”.

I surfed the forums and realized that the most effective is a mine boiler with afterburning. The main advantage is the automatic gravity supply of coal into the combustion chamber. After considering various options, I settled on Cooper Carbo, but not everything went smoothly for him either. If you fill it with coal, then you won’t be able to put the garbage in, and it’s still somewhat unclear what to do if the boiler goes out and it’s full of coal... How to relight it, shake it out, light it, and fill it with coal again?

I had to think about my cauldron with blackjack and I send****... Perhaps, of course, I won’t collect it, but the task is interesting and why not train my brain.

The side walls are planned to be double so that the volume of liquid is maximum. And you don’t want the walls of the boiler to be too hot. Plus, if something happens, the boiler will flood with coolant. Hot water in the house is supplied through a heat accumulator - a boiler.

Air supply through a throttle for installing an automation drive.

The second choke is planned on the side of the boiler to supply additional air for afterburning.

Garbage is loaded on top of the coals, this will allow the most complete decomposition of harmful substances.

I think I’ll draw a boiler and order the sheets to be cut at a company and weld it myself.

This is the first draft for now. I'm thinking about assembling coolant-washed pipes in the heat exchanger shafts.

An idea arose to assemble heat exchangers on pipes. This assembly technology will avoid both sharp corners and eliminate welding inside the shaft.

The ends of the pipes are welded into the walls and open into the coolant jacket.

All parts of the boiler, with the exception of dampers, ash pan grates and two ash storage boxes, cannot heat up above the coolant temperature.

In the future, I plan to introduce a liquid fuel or gas burner into the boiler to ignite the boiler automatically.

Source

What to do to avoid fire?

- Ensure constant boiler draft, hermetically seal the fuel tank and monitor the condition of the fuel tank lid gasket.

- Check the cleanliness of the channel and the air mixer chamber: dust or ash enters the mixing chamber through the blowing nozzles and over time clogs the air supply channel of the fan - as a result, the fuel burns unevenly and the efficiency of the boiler decreases.

- Adjust the fuel supply parameters; if the supply speed is slower than necessary and the air supply to the burner is incorrectly configured, more intense fuel combustion occurs. The result is that combustion begins to move down the burner and goes into the fuel supply pipe.

- The burner metal also heats up and heats the feed tube, resulting in a false alarm indicating reverse heat flow. To avoid false alarms, install a special non-flammable gasket separating the burner and the pipe - the gasket will not allow the temperature of the heated burner to be transferred to the feeder pipe.

Water jacket

The principle of operation of a solid fuel boiler implies the presence of double walls in its firebox: in the interval between them they are filled with coolant. This design is called a water jacket. As the fuel burns, the liquid in the water jacket heats up. This leads to the appearance of heat flows that lift the hot coolant to the upper part of the container. From here, hot water flows into the heat pipe. After the liquid passes through the entire heating circuit and gives off heat to the home, it returns back in a cooled state. For these purposes it has a lower pipe.

To speed up the circulation of water inside the heating system, special pumps are installed on some solid fuel boilers. However, most models are produced for open heating systems. This refers to schemes where the coolant moves not due to a running pump, but due to a slight slope of the pipeline. This is explained by the simplicity, reliability and efficiency of inertial systems. In addition, they are completely independent of the availability of electrical energy. Thanks to this, they can be used in remote areas deprived of the benefits of civilization.

Smoke from the fuel tank.

There is a simple “at-home” way to check the quality of smoke removal from the boiler: open the boiler door - if adjusted correctly, smoke does not come out, even if all doors are open.

If exhaust gases (smoke) come out of the fuel tank, this is a sign of insufficient chimney draft. This happens when the boiler chimney or the incoming combustion air mixer is clogged. The second reason is incorrect boiler control settings or a simply unsuccessful boiler design.

Another note: when adding fuel to the firebox, make sure that the burner is at rest (the fan is turned off and does not create excess pressure in the boiler).

Broken pin (shear bolt): causes.

A common reason for the boiler to stop working is the pin (shear bolt) that connects the engine to the auger breaks. Below are possible reasons for this failure:

- Fuel of non-recommended fraction

- Foreign bodies in fuel (bolt, stone, pieces of wire)

- Deposits (carbon deposits) in a retort-type burner - carbon deposits reduce the diameter of the channel for fuel supply to the burner and increase the resistance of the screw. The problem is easily identified: when carbon deposits are deposited on the retort elbow, the “crunching” sound when fuel is supplied to the burner becomes louder. Once a year, before the start of the heating season, clean the fuel supply elbow to the burner. If the boiler runs on pellets, it is better to repeat the procedure during the season - when using pellets, carbon deposits form faster.

- Damage to the auger. Over time, the auger turns wear out mechanically or are destroyed by sulfur contained in the fuel. In places of wear, the auger does not move fuel but grinds it. Sawdust or coal chips accumulate in the feed tube, increasing the resistance of the auger. The wear rate of the auger depends on the humidity of the fuel used, the sulfur content in the fuel and the location of the boiler room (in a damp basement and without ventilation, the service life of the equipment is reduced).

- Incorrect installation of the boiler (the adjustable foot of the fuel tank is used to adjust the height and leveling of the boiler supply system).

| IMPORTANT! When transporting the boiler, do not lift the structure by the screw feeder pipe: if the load is distributed incorrectly, the pipe is deformed and the geometry of the feed system is disrupted. The result: additional noise when the auger rotates, its premature wear and constant pin failures. |

Working principle

The automated type coal heating system uses the working principle of a conveyor. The heating material penetrates the conveyor belt and is fed into the chamber. How the movement mechanism works depends on the temperature of the water in the system. The temperature is recorded by a sensor and transmitted to the microprocessor control unit.

When the temperature drops, the conveyor belt begins its own movement, and fuel is supplied to the chamber. Ash removal is also considered an automatic process.

Models for industrial enterprises can work independently for a month, while domestic boilers have small bunkers and can only work on their own for 2-3 days.

Electronics defects

In the boiler room, in addition to the boiler itself, auxiliary equipment is installed that controls the operation of the system: circulation pumps and hot water pumps, valves and distribution manifolds, safety group electronics. Random errors in the operation of equipment lead to malfunctions of the boiler controller. Factory malfunctions of the equipment are also possible - the manufacturer accepts it as acceptable if for every 1000 products 30-50 controllers work with errors after launch.

When connecting devices, surprises also happen: a short circuit of the triac - transistor of the fuel supply system or fan motor causes continuous operation of the feeder (auger) or fan. If the fan or auger is constantly running, the boiler controller generates an error signal and turns off.

Even if connected incorrectly, it is possible to damage the connector that connects the pump power to the controller. This is unpleasant, but not fatal: in this case, the pump is connected directly to the outlet.

Sometimes a boiler is purchased in advance, and then it waits in the boiler room for installation. The boiler is tightly closed with a bag or film: when temperature changes, condensation forms, including on the controller elements, which then fail. If you purchase the boiler in advance, prepare a suitable storage place - dry and warm with free access of air to the controller.

Application

This kind of equipment is very often used for heating a private home. It is installed in a special way into the system, fulfilling a number of conditions:

- the area of the room with the heat-generating installation must be more than seven meters2, and all living areas of the house must be supplied with air flow;

- floor coverings at home must be non-flammable;

- the boiler should be placed at a distance of 0.5 meters from the walls with a heat generating unit, and a sheet of metal should be placed under it, which will also protect against fire;

- chimneys must contain the required cross-sectional diameter in accordance with the manufacturer's advice;

- It is better to insulate the electric motor and automation systems from any heat.

Likewise, coal boilers are considered an excellent replacement for established heating systems in a private home.

Aging of boiler elements

Check your boiler periodically to ensure safe and trouble-free operation in the upcoming heating season. In boilers with a screw mechanism, the feeder is damaged within 2 years: it is worn out or corroded due to exposure to sulfur and moisture. If the boiler runs on low-sulfur fuel (pellets or oat grains), the corrosion process will be minimal. But when coal is burned, the moisture in the fuel accelerates corrosion of the auger.

By carefully lubricating the connections and rubbing elements of the fuel supply device, it is possible to increase the service life of the feeder up to 10 years. And if you need to remove the auger from the feeder for maintenance or repair, this will be easier to do.

And it’s not only easier, but also safer; without lubrication, the auger “sours.” To dismantle it, you will have to knock the auger out of the mounting hole, risking damage to the gearbox, which costs much more.

Clean the heat exchanger thoroughly after the end of the heating season. During the period when the boiler is not in operation, the boiler heat exchanger must be constantly ventilated: to do this, open the boiler doors and check the flow of fresh air into the boiler room.

The connection between the boiler and the chimney also corrodes and leads to leakage of combustion products (flue gases), reducing the efficiency of the boiler. To avoid leakage of flue gases from the boiler, monitor the quality of the sealing gaskets at the joints.

Once every 2-3 years, replace the fuel supply motor and fan. If this is not possible, disassemble and clean the blades of the fan impeller: dirty blades reduce the quality of the fan, reduce the capacitance of the condenser and cause axial runout of the rotor, which eventually disables the fan.

Service

Maintenance of automatic solid fuel boilers as standard comes down to periodically reloading the fuel hopper, removing the resulting ash from the ash pan, and cleaning the heat exchanger. And depending on the model and power of the boiler, it is performed on average 1-3 times a week.

In an extended modification, some boilers can be equipped with bunkers of increased volume or automatic additional fuel loading systems, an automatic ash removal system, as well as a pneumatic cleaning system for the heat exchanger.