The water heating system is designed for the entire home or individual rooms.

To install it, radiators are completely or partially installed in the floor covering, which is heated by the circulation of heated water.

This is done by specialists who are helped by a program for calculating a warm water floor.

The parameters of the kitchen, dining room, living rooms, toilet, hallway/corridor, attic and balcony are entered there.

Such software also requests other characteristics that help make efficient and ergonomic home heating.

Calculation using special programs

The existence of such programs slightly simplifies the process of choosing the design of warm water floors.

How should you work with them? First, the program fills in all the data about the room and the intended product material for the circuit that you decide to use. The program will automatically give you the required pipe length and pitch.

At this stage, the following parameters are determined:

- The required length of the entire circuit.

- Correct distribution of thermal energy over the entire floor surface.

- Limits of the maximum thermal load that the system can provide.

Advice. If for some reason you need to increase the pipeline pitch, then at the same time you should take care of increasing the temperature of the coolant. The acceptable pitch is 5–60 cm; most often, pipes are laid in steps of 15–30 cm, using both variable and constant pitch.

Online calculator

From this publication you learned about the different types of installation of underfloor heating. About how they differ and in what cases it is better to use one or another option. We also told you how to calculate the length of underfloor heating pipes. We hope that the article was useful to you. Don't forget to share it with your friends!

Do you want to get help from a master, a specialist in this field? Go to the professional search portal. This is a completely free service where you will find a professional who will solve your problem. You do not pay for posting an ad, views, or choosing a contractor. If you are a master of your craft, then register on Pro and receive a flow of clients. Your profit is just one click away!

Installation of water heated floor pipes and pouring screed

How to install a mixing unit for a heated floor with your own hands

Basically, heated floors are installed using special fastening profiles, which are secured to the floor with dowels and screws. They have sockets for securing pipes. With their help, it is much easier to maintain the pitch distance between the turns of the pipe.

Tip: To secure it, it is enough to use plastic ties that press the pipe to the reinforcing mesh

It is important not to tighten the pipe too tightly; it is better to keep the tie loop free.

Pipes are most often supplied in the form of coils. Do not pull the pipe out of the coil, turn by turn. It is necessary to unwind it gradually as it is laid and secured to the floor. All bends are made carefully in compliance with the minimum possible radius limit. Most often, for polyethylene pipes this radius is equal to 5 diameters.

If you compress a polyethylene pipe too much, a whitish stripe may appear on the bend. This means that the material began to sharply stretch and a crease formed. Unfortunately, such defects cannot be installed in a heated floor system due to the increasing risk of a breakthrough in this place.

The ends of the pipes that are supplied to the collector are, if necessary, laid through the walls and enclosed in insulation made of foamed polyethylene. To connect the pipes to the manifold, either a Eurocone system or a compression fitting is used.

If this is your first time encountering polypropylene pipes, we recommend reading about their welding and installation.

There are several schemes for laying underfloor heating pipes. You can choose the right one based on your needs

Along with other factors, it is worth paying attention to the arrangement of furniture and plans for rearranging it.

When the installation of underfloor heating is completed, a mandatory high-pressure system check is performed. To do this, water is poured into the pipes and a pressure of 5-6 bar is applied for 24 hours. If no leaks or significant expansions are noticed on the pipes, then you can begin pouring the concrete screed. Filling is carried out at connected operating pressure in the pipes. Only after 28 days can we consider that the screed is ready and begin further work on installing the floor covering.

Important nuances of forming a heated floor screed

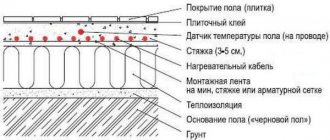

There are some peculiarities in the formation of screeds over water-heated floors. This is due to the principle of heat distribution in its thickness and the floor covering used.

- If the heated floor is laid under the tiles, then you should make a screed about 3-5 cm thick, or distribute the pipes at intervals of 10-15 cm. Otherwise, the heat from the pipes will not properly warm the space between them, and this phenomenon will appear like a "thermal zebra". In this case, the alternation of warm and cold stripes will be quite clearly felt by the foot.

- Under laminate, linoleum, etc. It is advisable to form a thinner screed. For strength, in this case, another reinforcing mesh is used on top of the heated floor. This will reduce the heat path from the pipes to the flooring surface. Also, a layer of thermal insulation is not placed under the laminate, because it will only worsen the efficiency of the heated floor.

You can turn on the water heated floor heating at the first hint of the onset of autumn cold. The initial warm-up may take several days, after which the system will already maintain the required temperature. The greater inertia of water heated floors can also play a good role, even if for some reason the boiler is not able to heat the water for some time, the system will continue to transfer heat to the premises for a long time. In addition, you can keep the underfloor heating system at low power throughout the year, turning off most of the circuits and leaving only the part that heats the rooms where the flooring is made of ceramic tiles or self-leveling floors (hallway, bathroom, etc.), because even In hot weather, such coatings feel cold.

Radiant radiant floor heating

A sense of well-being is one of the most important things to consider when installing heating.

Of great importance is the development of technology that has been observed in recent years in the field of environmental comfort, and especially in the sector of heating and control systems: a new generation of radiant floor heating has been developed thanks to the low temperature of the water in the system, which has led to significant energy savings.

Radiant floor heating has been around for a very long time, but it only gained final popularity after improvements in certain factors, such as insulation, spatial control systems and synthetic pipes, which completely replaced iron and copper pipes.

With the development of control systems and electronic control, it was possible to change the technical concept and eliminate sources of faults. With this improvement, the radiant floor heating system has been rebuilt and given the opportunity to take its rightful place in a modern installation.

This modern technology has allowed us to eliminate excessively high temperatures in the floor, which caused poor circulation and swelling of the legs.

Thermal comfort

With countless studies on heating systems, it has been proven that radiant floor heating system, which uses modern technology, provides comfort and coziness to the human body higher than conventional heating systems. A comfortable feeling is achieved due to a constant temperature, which is distributed throughout the entire area of the heated room.

Traditional heating scheme It is known that the speed of hot air and, above all, cold air and the excess of uneven temperature distribution, increase the feeling of poor thermal comfort of individuals and, therefore, the burden of their health. This completely eliminates air currents that cause strong and harmful temperature fluctuations in our body.

If the radiant surface is made of flooring, this system can keep the air temperature lower while maintaining the same feeling of comfort. The lower air temperature, in addition to improving its quality, eliminates the feeling of difficulty that sometimes arises when we enter an overheated environment. Heating imbalance

For large surfaces with low temperatures, air draft is practically removed and the air in the environment is less dry. This system can create a natural coziness and thus avoid heat leakage and high temperature changes, as occurs with traditional heating systems. Research has shown that people like warmth near their feet and bother them around their heads.

Advantages of an underfloor heating system

The low surface temperature significantly limits the flow of dust and prevents the classic dark streaks on walls, thereby eliminating the need for new wall painting: it removes the so-called chimney effect, which is associated with air that, when in contact with a very warm surface, such as the surface of a radiator, quickly rises and falls again and settles on the cold surface.

The benefits of a radiant underfloor heating system bring great relief to people who suffer from allergies and have health problems with the respiratory tract - asthma, allergies, etc.

This is comfort for the whole family, including pets such as dogs and cats.

Underfloor heating system components

The underfloor heating system consists of thermal insulation panels, known as system boards, which serve for quick and precise installation of pipes and have a thermal and sound insulating function.

To install an underfloor heating system, we recommend using pipes (PEXb, PEX/Al/PEX), whose feature is durability and prevent phenomena such as decoration and corrosion.

The heated floors are controlled by a thermostatic controller, which controls the distribution performance according to actual needs and responds to climate changes, ensuring a high level of comfort at low operating costs.

In addition, there are central distributors and three-way mixing valves, thermoelectric heads, which are actuated by a thermostat and which control the temperature in the rooms and are located on the distribution combs. All these varieties are placed in a distribution cabinet so as not to disturb the aesthetic character of the room.

The heat regulation, which is implemented separately for each circuit, allows us to control the temperature in each room at any time, which definitely exceeds the limits of older heating circuits.

Operating underfloor heating

In winter, the water entering the heating line is between 30 ° C and 40 ° C. The temperature from the piping system in the floor takes the underlay layer and then the floor, the surface of which reaches a temperature of 25 to 29 ° C. The heated floor radiates heat in a radiant manner , which is very convenient and economical.

How to lay a heated floor cable, determining the pitch

Thermostat for water heated floors

If we are talking about a heating cable, then there is no need to be tricky with the “snail” - in this case, just lay it like a snake, maintaining the selected step. But choosing the distance between two heating wires on the floor is not easy.

The laying pitch is the distance between the underfloor heating pipes or the turns of the heating cable. It may be the same throughout the entire circuit. Sometimes in those areas where more heat is required (along external walls, for example), the installation step is deliberately made smaller.

How to calculate the step? If floor heating will serve only for comfort (there are also radiators), then, without much pain, you can choose a step for laying the heated floor cable in the range of 20-30 cm. If tiles will be laid on top, then it is better to take a step of 20 cm - it is heat-intensive and To keep your feet warm, you need to heat it up more. Laminate or linoleum cannot tolerate high temperatures; they can only be heated to 26-27°C. Therefore, here you choose a step of 25-30 cm. In general, when laying a cable floor, the distance between the turns of the cable also depends on the power of the heating cable. More powerful heaters are used for tiles, and less efficient ones for laminate and linoleum.

Basic “snake” installation schemes and some heating cable options

If floor heating is planned as the main heating, at least an approximate calculation is necessary. Just a few simple steps:

- Calculate the heated area. This is the total area of the room minus those places where heating is not needed: under furniture and appliances. There are two reasons for this. First: not all cables can withstand blocking (when something is placed on them). Second: there is absolutely no need to heat a cabinet or, say, a washing machine.

- Do you know the heat loss in this room? If you don’t know, they can be calculated, look in the article “”. You need a method for calculating heat loss by room volume and adjusting the results.

- Now you can determine how much thermal power should be removed from each “square” of heated area to replenish all heat losses. To do this, divide the heat loss by the heated area.

- If you have already purchased the cable, you know its thermal power (it is in the passport data). If you don’t know or haven’t bought the cable yet, find it on the manufacturer’s website. Now count how many meters you need to place on one square of area. To do this, divide the figure found in the previous paragraph - the required power per heated “square” - by the power of the cable. You get the length that needs to be laid on one square of heated area. Usually it is 4-6 meters. Depending on the obtained value, you determine the laying step of the heated floor cable. For example, you need to lay 4 meters. This means that the laying step is 20 cm.

Take the length of the cable for a heated floor not “butt-to-tail”, but with a margin of 10-15% - for losses when turning.

Is it possible to lay a heated floor with a snake?

When laying with a snake, the greatest heat losses are observed due to the fact that heated water is supplied only from one side and loses all energy when it reaches the end of the circuit.

You can observe a hot floor at one end of the room and a gradual decrease in temperature as you move away from the coolant mixing unit.

Another disadvantage of laying using the snake method is the difficulty of installation:

- firstly, installation requires good experience and relevant knowledge;

- secondly, in the case of laying a water circuit, the pipes bend only 180 degrees. Because of this, a step of 200 mm is made (while the step of the snail starts from 10 mm). Of course, you can make rings at the ends of the loop and avoid a large investment, but this is a very complex process.

The temperature difference in such a system can be reduced by making a double snake (also called a “meander”). But this will not solve the issue of the complexity of installing the water floor circuit.

Options for laying heated floors - snake and double snake

The best option would be to combine a snake with another styling method. In this way, the energy distribution can be made more uniform and the temperature difference will not be so noticeable.

Tile 6.0

Connecting a heated floor to a thermostat

Specialized program for laying out tiles and wallpaper. There are three versions: Home for home use, Profi - for professionals, Profi+Render - professional with extended functionality. Tile 6.0 Home is suitable for creating your own design, but it is not free - 1000 rubles per month of use. All of them can be purchased on the campaign website tile3D.com. Naturally, there are hacked copies, but it’s difficult to say how safe it is to download them.

Program for laying out tiles in 3D Tile 6.0

The program in its current version is good: even the stripped-down home version allows you to create three-dimensional projects (3D) and receive calculations for the necessary materials (in addition to whole and cut tiles, it calculates the amount of glue and grout for joints). What else can she do:

- Take into account door and window openings, columns, arches and other curved surfaces.

- It is possible to add new tiles to the directory and save them for future use.

- Tiles can be installed and moved at any angle.

- You can add three-dimensional images of other objects (bathtub, shower, etc.) by specifying their coordinates.

- The program calculates tiles and consumables, but in the “home” version you cannot print them, but you can copy them from the screen or take a screenshot and print them as an image, not a table.

In addition, you can change the degree of illumination, shine and relief of the tile. All these settings can be made for each individual object. What’s also good is that the site has educational videos on how to use the program, where the creation of a project is described step by step. Working in the program is easy, the interface is clear, and you can master it the first time. One of the disadvantages of the home version is that you cannot get a scan along the walls, which is completely inconvenient. In general, the program is good, but not free.

VALTEC.PRG.3.1.3. Program for thermal and hydraulic calculations

The VALTEC.PRG program is publicly available and makes it possible to calculate water radiator, floor and wall heating, determine the heat demand of premises, the required flow of cold and hot water, the volume of sewage, and obtain hydraulic calculations of the internal heating and water supply networks of the facility. In addition, the user has a conveniently arranged selection of reference materials at his disposal. Thanks to its clear interface, you can master the program even without having the qualifications of a design engineer. The program meets the requirements of Russian regulatory documents governing the design and installation of engineering systems (certificate of conformity).

- Difference between version 3.1.3 and version 3.1.2:

- added module for calculating pipe capacity;

- amendments have been made to the module for calculating water demand according to SNiP - it is possible to continue the calculation if the probability is more than one (insufficient number of devices);

- the “Pipes” reference table has been expanded;

- The User's Guide has been updated.

Training videos:

Calculation of heat loss of a cottage. Part 1 Calculation of heat loss in a cottage. Part 2 Calculation of underfloor heating Part 1 Calculation of underfloor heating Part 2

Selection of materials and necessary devices

Before making a heated floor with your own hands, you should decide on the composition of the equipment and all elements of the system and calculate the materials.

The composition and design of a warm water floor includes the following elements:

- Water heating boiler;

- Pressure pump (may be included in the boiler);

- Ball valves at the boiler inlet;

- Distribution pipes;

- A manifold with a system for setting and adjusting heated floors;

- Pipes for laying on the floor surface;

- Various fittings for laying the main route from the boiler and connecting underfloor heating pipes to the collector.

The pipe material for water heated floors can be either polypropylene or cross-linked polyethylene. It is better to choose polypropylene pipes with glass fiber reinforcement, since polypropylene itself has a significant linear expansion when heated. Polyethylene pipes are less susceptible to expansion. It is the latter that are most widespread in the layout of surface heating systems.

Pipes with a diameter of 16-20 mm are used. It is necessary that the pipe can withstand temperatures up to 95 degrees and a pressure of 10 Bar. It is not necessary to chase expensive options with oxygen protection and additional layers. Especially if the main goal is to reduce the overall costs of installing heated floors.

The collector is a pipe with a number of branches (splitter). It is necessary to connect several underfloor heating circuits to one main warm water supply line and return, cooled water intake. In this case, two splitters are used, which are installed in a special manifold cabinet. One is for distributing hot water, and the second is for collecting return, cooled water. It is within the manifold that all the necessary elements for setting up heated floors are located: valves, flow regulators, air vents and emergency drain systems.

Which type of styling is better, advantages and disadvantages

Each type of installation has its own positive and negative sides, and is recommended for different models of heated floors.

If we consider the “snake” option, it has many turns, so when used in water heating systems, a difference in the heating level at the inlet and outlet is possible. In addition, as the coolant moves through the pipes, it loses its degree - the further it is from the heat source, the colder the surface will be.

The "Snail" scheme is more productive. Heating is uniform, as hot zones alternate with cool ones.

The process of heat loss is minimized, but it is more difficult to install the heating element using this method. In addition, with this installation there are no sharp turns of the heater, that is, the cable or pipeline does not bend, so the distance between the branches can be made smaller.

The combined scheme is suitable when it is necessary to zoning a room. For example, use a “snake” at the entrance, and a hotter “snail” in the middle of the room.

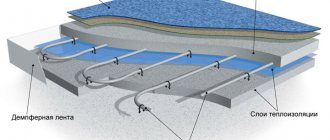

Installation of water heated floor

Before installing a heated floor, it is necessary to prepare the base for it

. The surface where the floor will be laid must be level, and the total number of unevennesses over the entire surface area should not exceed ±5 mm.

The pipes are laid on special fastening profiles, which in turn are secured to the floor using screws and dowels

. These profiles have sockets where pipes are fixed. Thanks to these sockets, it is much easier to maintain the pitch between turns of the pipe.

If, due to strong compression of a polyethylene pipe, a whitish strip is formed, then it is best not to lay such a pipe in a heated floor system, since it increases the risk of a breakthrough in this place. The pipes that are supplied to the collector are connected either by a Eurocone system,

or a compression fitting.

After installing a water heated floor, it is checked under high pressure.

This is done in this way: water is poured into the pipes and a pressure of 5-6 bar is applied, such testing lasts for 24 hours.

Concrete screed can only be poured if no leaks or expansions are found on the pipes. Filling must be carried out at connected operating pressure

. It will be possible to install the floor covering only after 28 days; it is after this time that the concrete screed is considered ready for further use.

Water-based heated floors with adjustable heating are increasingly used as a solution to the issue of heating a room. During renovation or construction, a closed-loop piping system can be installed under the finishing floor covering.

Thus, a comfortable temperature is ensured inside the room, regardless of work, if any. The exact amount of materials that will be required for the work can only be determined by a correct calculation of the water heated floor. To do it correctly, you will need to familiarize yourself with the details of this work.

Layout

Tubes must be laid using existing methods. The most effective, but difficult to install, is the “spiral”. It ensures uniform heat distribution due to the fact that the inlet part of the tube lies next to the outlet, unlike the “snake”.

Before laying the pipe, you need to lay down insulation, then cover it with film. This is followed by reinforcement with metal mesh and the installation itself, followed by concreting and laying the floor covering. When laying, maintain a distance from the walls of at least 20 cm.

Calculation of the length of the circuit and heating boiler

Using the collected data, you must first calculate the power of the circulation pump, electric or gas boiler. Also, these indicators are taken into account when calculating the pipe pitch during installation. Today, you can use 5 types of material to construct a heated floor circuit:

Working in Multiplaner CAD

- Corrugated stainless steel pipes. This material has effective heat transfer.

- Copper. They also have high performance, but at the same time they are much more expensive.

- Pipes made of cross-linked polyethylene. They are distinguished by good quality at an affordable price.

- Metal-plastic products. The most popular material, combining low cost and high quality.

The type of pipes used is also taken into account when calculating the heated floor, because each material has its own characteristics and thermal conductivity coefficient. For example, copper pipes have high heat transfer and operation, but due to the high cost of the material, not everyone can afford them.

Initial data

Before purchasing materials, you need to determine the following parameters:

- Room area. The wider it is, the more pipes will be needed.

- Characteristics of the room , i.e. desired temperature, wall materials and window design. This also affects the length of the pipes (if the house is located in a cold area, more dense installation is required).

- Type of flooring , i.e. what it is planned to be made of. The thicker it is, the higher the required degree of heating.

- Calculate the required power of the boiler, pump and pipe diameter .

Pipe system design software

New calculation program Aquatherm Project UA

The AquathermProjectUA software package for designing internal engineering systems contains:

1. The Aqua-therm 4 HCR program allows you to edit plans and layouts of any central radiator heating system in a one- or two-pipe system, as well as floor and wall heating systems. Also covers refrigeration systems. The graphic editor allows you to independently draw a building diagram using scanned construction drawings or using a more beneficial solution for the designer - importing construction drawings from dwg, dxf files, with recognition of walls and rooms. Projections and developments with plotted system and calculation results can also be exported in these formats. The program performs complex thermal and hydraulic calculations and automatically creates a complete bill of materials.

2. The Aquathermheat&energy 4 program is used to calculate the heat loss of a building and seasonal energy consumption. The program determines the balance of ventilation air in rooms and calculates the air temperature in unheated rooms. The program reads the building structure from the drawing recorded by the Aqua-therm 4 HCR program, due to which the structure loaded from a dwg or dxf file, or drawn in the graphic editor of the Aqua-therm program, only requires the addition of data such as wall structure, ventilation data and etc. This innovative solution significantly reduces the amount of labor required to perform heat loss calculations, and also ensures that the data in both applications is fully consistent (the data is stored in a single file that is shared between both programs).

3. The Aquatherm-san 4 TS program is used for designing internal water supply and sewerage systems. Equipped with a graphic editor that allows you to quickly draw a plan and layout of the system and supplement the data. Performs hydraulic and thermal calculations and automatically creates a complete bill of materials. In calculations of the circulation network, the so-called thermal method, which complies with the requirements of the DVGW and DBN of Ukraine. Projections and developments with the system and calculation results plotted can also be exported in dwg, dxf formats.

The program is designed to determine the thermal power of the heating system, select heating devices, calculate the hydraulic diagram of the heating system and pipes for heated floors and to calculate water pipes for hot and cold water supply. The AquathermIntegraCAD program uses many solutions that speed up and facilitate work on the project. The most important of them: - graphical process of data entry using drawings in AutoCAD; — presentation of calculation results on diagrams and floor plans in dwg and pdf formats; — a multi-window environment that allows you to simultaneously view many types of data, calculation results, etc.; — simple collaboration with a printer, plotter, with the function of previewing pages before printing; — error diagnosis, as well as the function of automatically searching for them on the diagram;

— quick access to catalogs of data on pipes, heating devices and fittings.

Simple programs for beginners

Easy to use programs with which you can make calculations.

"Snail"

The program provides accelerated planning and saves money. The floor layout using the “snail” method is done in a spiral with a step of 30 cm.

you can follow the link.

It is necessary to calculate the heating power based on the floor area. Almost 10 W are spent on 1 m².

Pros and cons of the Snail program:

drawing on a grid created for a new project;

the ability to create the necessary nodes, loops, rooms with calculation of the area of the room;

calculation of the amount of metal or plastic substrate;

displaying the resulting circuit on the screen and printing.

the demo version works without registration, but has limited functionality;

To expand the capabilities, the user must undergo authorization and receive a special key;

the software does not work without the Internet;

does styling according to only one option.

OVPlan

Convenient and simple service with constant updating of modules and databases.

on the official site.

Advantages and disadvantages of the OVPlan program:

a large number of functions if the user goes through a simple and free registration on the developer’s website;

The heating system plan is first drawn in AutoCAD and then transferred to the OVPlan diagram. As a result, you can get a detailed project;

displaying diagrams and specifications on screen and printer;

lack of rigid connection to radiators, pipelines, pumps and boilers, although the fittings should only be Oventrop;

rewriting local resistance coefficients for each section with determination of percentages.

you need to download only from the manufacturer’s website, otherwise the software will not be updated

Calculation and distribution of pipes

For each room, the calculation of the length of the pipe and the pitch of its installation must be made separately. Calculations of water heated floors can be performed using specialized programs or using the services of design organizations. It is very difficult to independently calculate the required power for each circuit; a lot of parameters and nuances are taken into account. If you make a mistake in the calculations, this can negate the entire operation of the system or lead to unpleasant consequences, including: insufficient water circulation, the appearance of a “thermal zebra” when warm and cold areas alternate across the floor, uneven heating of the floor and the formation of leakage points heat.

To carry out calculations, the following parameters are required:

- Room dimensions;

- Material of walls, ceilings and thermal insulation;

- Type of thermal insulation for underfloor heating;

- Type of flooring;

- Diameter of pipes in the underfloor heating system and material;

- Boiler power (water temperature).

Using these data, you can determine the required length of the pipe used for the room and the pitch of its installation to achieve the required heat transfer power.

When distributing pipes, you should choose the optimal laying route

It is important to consider that water gradually cools as it passes through the pipes. By the way, this is not a disadvantage, but rather a plus of water heated floors, because heat loss in the room does not occur evenly

When distributing water heated floor pipes in each circuit, a number of rules should be followed:

- It is advisable to start laying pipes from the outer, colder walls of the room;

Important: If the pipe entry into the room is not from the outside wall, then the section of the pipe from the entry to the wall is insulated.

- To gradually reduce the heating of the floor from the outer wall to the inner one, the “snake” laying method is used;

- To uniformly heat the floor in rooms with all internal walls (in the bathroom, wardrobe, etc.), laying in a spiral is used from the edge of the room to the center. The pipe is brought in a spiral to the center with a double pitch between the turns, after which it turns around and unwinds in the opposite direction until it leaves the room and goes to the collector.

In addition to the length and distribution shape of the pipes, their hydraulic resistance should be calculated. It increases with increasing length and every turn. In all circuits connected to the same collector, it is desirable to bring the resistance to the same value. To resolve such situations, it is necessary to divide large circuits with a pipe length of more than a hundred meters into several smaller ones.

For each circuit, a single piece of pipe of the required length is purchased. It is unacceptable to use joints and couplings on pipes that are laid in a screed. So the length calculation and order should be carried out after carefully carried out calculations with thinking through the entire laying route.

Important: Calculations are carried out for each room separately. It is also undesirable to use one circuit to heat several rooms.

To insulate a loggia, veranda, or attic, a separate circuit is laid, not combined with adjacent rooms. Otherwise, most of the heat will go to heating it, and the room will remain cold. Insulation under a heated floor is carried out in the same way as with a floor located on the ground. Otherwise, there are no differences in terms of installing heated floors on the loggia.

Installation Rules

Many people face great difficulties after installing a water heating system. Therefore, before starting work, you should familiarize yourself with the general requirements:

- According to safety rules, it is strictly forbidden to connect a water heating structure to a central heating system.

- Installing additional equipment should strictly comply with all rules. Otherwise, if water or condensate gets on electrical appliances, a short circuit in the wiring can lead to irreparable consequences, including system failure.

It is also impossible to independently connect the system to the common risers of apartment buildings without permission from the relevant authorities. Otherwise, an administrative fine cannot be avoided.

Having familiarized yourself with all the required data that the underfloor heating program will require, it will not be difficult to produce the result. The online calculator has formulas for calculating all parameters, as well as their characteristics. Thanks to which you will use these parameters when installing the system or, using a clear example, you will see the mistakes that you made during preliminary calculations.

AdminAuthor of the article

Did you like the article?

Share with your friends:

ViSoft Premium

This is specialized bathroom design software for professionals. One of the functions is tile layout. The database contains a large number of samples - almost 39 thousand types of tiles from different manufacturers (at the time of writing there were 362). The layout project is developed based on the samples that are in the database; new ones cannot be added.

There is also a Russified version

Here is a summary of the program's capabilities:

- Selected tile samples are automatically placed in the specified area.

- It is possible to view other layout options.

- To create a bathroom interior, you can choose plumbing fixtures from a huge database. In this case, the sets are compiled automatically. If necessary, they can be adjusted.

- During the creation process, the project can be turned in any direction, evaluating the result from different points.

- Take “snapshots” of the results obtained.

There are two operating modes: drawing and sketch. In drawing mode, a black and white image is created, which can later be “filled” with different colors. Sketch mode - immediately with color.

The layout is simple!

We save material - we save time - we get an accurate layout

User reviews

. I used the program myself and, thanks to it, I performed all the calculations myself, purchased everything and was not disappointed - even in the demo version, I printed the results via a screenshot, wound everything up and everything works - I’m very pleased. Thank you.

Data for calculation

The level of heating depends on the size of the contour laying step.

The step with which the contour is laid is from 100 to 300 mm. The step size controls the heating level. The heat transfer of a heated floor with a small step will be high, and with a large step it will be low. It is not recommended to make a distance between the tubes of more than 300 mm, since the floor will not warm up evenly. The tube itself will not allow less than 100 mm. If it is bent too much, it may break.

Pipe consumption depending on the pitch is presented in the table.

| № | Step | Number of pipes per 1 m2 |

| 1 | 100 mm. | 10 p.m. |

| 2 | 150 mm. | 6.7 p.m. |

| 3 | 200 mm. | 5 p.m. |

| 4 | 250 mm. | 4 p.m. |

| 5 | 300 mm. | 3.4 p.m. |

Heated floor pipes come in different diameters. Depending on the value of this parameter, the length of the entire system is selected.

For pipes with a diameter of 2 cm, the maximum pipe length should not exceed 120 m.

When using pipes of smaller diameter, the maximum permissible footage will be reduced.

Thus, a pipeline with a diameter of 1.6 cm will have a maximum length of only 100 m. Calculation of the length of the pipe for a heated floor must be made taking into account the pitch and cross-section of the pipeline.

Before calculating the coolant water, it is necessary to determine what temperature level in the room will be optimal. It is recommended to calculate the floor surface temperature in the range from 27 to 35°C, depending on the type of coating and the purpose of the room.

So, for parquet or laminate floors, a temperature of 27°C is suitable. When installing tiled flooring in a bathroom or kitchen, you can make the floor temperature about 33°C. It is recommended to lay coatings with the highest temperature of 35°C around the perimeter of external walls. In the living room, the floor temperature should be 29°C.

Calculation of a heated floor is impossible without determining heat loss. This takes into account such parameters as:

- floor height;

- planned floor temperature level;

- climatic parameters of the region of residence;

- dimensions of the perimeter, height and area of the room;

- availability and power of existing heating sources;

- high-quality composition of materials from which the external enclosing structures of the house are made.

You should know that heat transfer from the heating element through the floor screed does not pass without loss, so the coolant should be 10-15 ° C higher than the coating temperature that is ultimately required.

The nuances of laying a heating cable

The heating cable at the base of the heated floor is a universal system, which, depending on the specified power, can be used under any coating. The cable differs from other methods in the ability to change the power for each square meter of the room.

Installation is carried out according to any of the schemes on a concrete base, prepared and leveled. After laying the contour, the system is filled with screed to a depth of 3-5 cm.

A substrate with a heat-reflecting surface is also laid on the concrete base. This is necessary so that the heating does not go down towards the ceiling. A mounting tape is attached to the top.

Reinforcing mesh is used as a basis for fixing the heating cable, especially in cases where it is impossible to attach mounting tapes. Experts recommend making a snake pattern over the entire area of the room, with the exception of places where there will be furniture or carpet.

Fixation is carried out on the mounting tape, and the contour should not intersect in any of its parts. This is important to ensure uniform heating and the absence of excessive heating. The cable ranges from 4 centimeters or more.

Taking into account all the rules, restrictions on use, advantages and disadvantages of possible floor heating systems, the owner makes a decision on choosing the desired scheme and method of its installation.

A water heating system is a complete or partial replacement of radiator heating, which is located under the floor covering. Heating of the room with such a design occurs due to the circulation of warm water along its contours. Thanks to these indicators, this design annually gains popularity among the population. But in order to determine whether the room for installation of such a model is suitable and how much equipment is required, it is worth producing all the data through which the program for calculating a warm water floor can establish this.

But before you begin the calculation process itself, find out what data you will need for this.