The range of construction products is growing every year. Modern materials are appearing on the market that make construction stages easier and increase worker productivity. Consumers tend to use pipelines with a long service life when planning internal systems in their homes. Plastic internal communications branches have become a suitable alternative that meets consumer needs. How to solder plastic pipes?

Another advantage of such technologies is the ability to independently repair or replace water supply and heating networks. How to solder plastic pipes for water supply?

Basic working methods

Considering that the quality of the connecting seam largely depends on the contact area, different connection methods are used for pipes of different diameters.

Soldering of polypropylene pipes is possible:

- using a coupling (another connecting element). Suitable for products with a diameter of up to 63 mm, as well as thin-walled ones;

- directly, with a butt seam - for large-diameter, thick-walled models.

In both cases, a tight connection is ensured by the diffusion of heated plastic.

To operate, a special heating device is used to increase the temperature of the plastic to the desired level.

Important: the second installation option requires significant professional skills and, as a rule, is used only in production. At home, the coupling (fitting) soldering method is used.

The main principles of the process are shown in the master class.

Soldering of polyethylene bags

A bag sealer is a special type of equipment that is used to solder film and finished plastic bags, and also to produce bags from any film material and polymers with the addition of polypropylene.

Today, the modern market offers various types of devices, which can be equipped with pulsed or constant heating, be tabletop or floor-standing, have a pedal drive, and be automatic or manual.

So, for example, to package products with a short shelf life, you can use a device that is equipped with a function that allows you to stamp a date on plastic film.

Equipment used

The main condition for tight and high-quality fastening of pipeline sections is simultaneous heating to the same temperature, the so-called polyfusion welding. Alternate heating is unacceptable, since the cooling time of the plastic to the temperature at which molecular diffusion stops is 6...15 seconds.

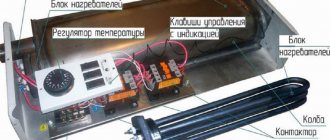

Accordingly, a special welding machine with paired heating nozzles is used for the work. Its “folk” name is “iron for welding,” obviously due to the similarity of shape. The device is also often called a soldering iron.

Heating in this apparatus is transferred from the mandrel to nozzles selected according to the nominal diameter of the pipe.

In industrial conditions, they use floor-standing rather than table-top welding machines.

Since large diameter pipes have a corresponding weight, special mounting devices are also used to hold them in the desired position during welding. Also, this device should make it possible to move the product exactly along the axis for proper joining of heated fragments.

In addition, the work requires tools for marking and cutting polypropylene pipes.

Ordinary scissors or a hacksaw do not provide such a precise and even cut, so it is better not to use them.

For large diameter pipes, a different type of cutter is used - with a movable cutting wheel.

In order for the pipe to fit better into the fitting, it must be chamfered. This can be done manually, but it is more convenient to use a bevel remover.

For products with a small diameter, you can use a manual model.

The reinforcing layer is cleaned using a shaver or trimmer.

Properties of polypropylene

One of the many materials from the family of plastics - polypropylene - is a product of the polymerization of two gases: ethylene and propylene, mixed in a certain proportion.

The result is granules, from which various products are produced by extrusion. Water supply products are made from PPR plastic with the following characteristics:

- operating temperature range from -10 to +90 degrees;

- plastic melting begins at 149 degrees;

- nominal pressure from 1.5 to 2.5 atmospheres.

The given parameters are suitable for cold water supply, but the need for a wider range of characteristics is obvious. Therefore, certain technological methods are being taken to strengthen them.

One of them is to reinforce the walls with fiberglass or aluminum. To do this, a layer of fiberglass or aluminum foil is placed on top of the finished pipe, and then another layer of polypropylene is applied.

This design makes it possible to obtain polypropylene pipes suitable even for use in heating and hot water supply systems.

The fundamental way to reinforce polypropylene products is to install a metal layer. For this, aluminum foil in the form of a strip is used.

It is wound along a helical line onto the workpiece along a layer of glue, and a second adhesive layer is applied on top of the metal foil. The outer shell is made of the same polypropylene.

Such products are suitable for use in water supply systems with high pressure up to 6 atmospheres.

Features of pipes taken into account during installation

To choose the right method for soldering plastic pipes, it is necessary to take into account not only their diameter, but also the wall thickness. Therefore, before starting work, it is necessary to clarify the actual wall thickness of the selected product using markings and measurements (for verification).

For normal operation, it is necessary to clarify the data in the regulatory document according to the marking.

In general, technical data for pressure pipes made of thermoplastics is standardized by GOST R 52134-2003. However, each production has its own nuances, and for foreign manufacturers this standard does not work at all. Therefore, it is better to clarify the permissible temperature range (operating and emergency), they should not exceed the soldering temperature.

Next, according to the information received, it is necessary to clarify the heating duration when welding prepared plastic pipes and the heating temperature, as well as the cooling time of the parts.

Also, taking into account the increase in wall thickness with an increase in the nominal outer diameter, the table determines the width of the welded belt - that is, the length of the heated section. It must be the same for pipe and fitting, since diffusion (interpenetration of material particles at the molecular level) is required over the entire joined area. You can determine the width of the welded belt (the depth of insertion of the pipe into the coupling) and the size of the chamfer using the table.

Maximum insertion depth (actual width of the welded belt) without stripping.

Based on data on the type of plastic, the required heating level of the welding machine, or more precisely, the heating elements - paired nozzles, is set.

In some cases, the soldering temperature of polypropylene pipes is not 200...220 degrees Celsius, but about 260 degrees; this must be clarified with the manufacturer or seller.

Tips for choosing and using a pipe soldering iron

When choosing a pipe soldering iron, you should take into account its technical parameters:

- power. Powerful devices are needed for welding large-diameter pipes; for domestic systems, in which the diameter of the products does not exceed 50 mm, you can purchase a device with a power of 0.6 - 0.8 kW;

- quality of coating of nozzles and technology of their use. The products to be welded can be easily removed from Teflon-coated nozzles, so it is advisable to choose a soldering iron equipped with just such nozzles. In addition, you should pay attention to the possibility of heating not only one, but two or three nozzles at the same time. This will significantly speed up the work;

- type of temperature controller. The soldering iron can be equipped with an electronic, capillary or bimetallic thermostat. It is better to choose a model with an electronic temperature controller, since the other two have too large a discrepancy between the set and actual heating temperature of the products.

How to solder polypropylene pipes

Let's look at the process using the example of creating a water supply system in an apartment.

Important: make sure that the elements being welded have the same temperature and geometry! Violation of the correctness of the circle, uneven heating of the fragments will lead to poor quality of soldering.

For this, products with nominal diameters of 20...63 mm are used, so a hand tool will be sufficient:

- machine for manual welding of polypropylene pipes with Teflon nozzles 14...63 mm;

- manual chamfer (the principles of working with it are shown in the video);

- for reinforced pipes (PP25), a shaver will also be required to strip the outer layer;

- cutter of any suitable type;

- tape measure and marker for marking;

- degreasing composition for treating surfaces to be welded (acetone, ethyl or isopropyl alcohol, chlorethylene, trichloroethane);

- hard tarpaulin rags for cleaning heating elements.

How to weld and prepare polypropylene pipes:

- a welding machine is installed, heating nozzles are selected. Before use, they must be wiped to remove remnants of previous soldering and degreased, just like the communication parts themselves;

- pipeline sections for soldering are marked and cut to the required length;

- chamfer the pipe;

- indicate the width of the welding belt - the section that will be included in the fitting. Important - it is necessary to push the pipe into the mounting hole of the fitting until it stops. Otherwise, a gap remains between the connected pipes, which has a bad effect on the further operation of the pipeline. If it is necessary to connect parts in a certain position (for example, to obtain a right angle between two already partially assembled sections), marks are also placed for correct mating;

- for reinforced pipes, remove the top layer exactly to the width of the welding belt;

- turn on the heating apparatus. Depending on the room temperature, this will take 10...15 minutes (so you can first turn on the soldering iron, and then follow steps 2...5). The welding temperature is set to 260 degrees, wait until the green indicator of the soldering iron turns on - this means that optimal heating has been achieved;

- install the pipe and fitting on the heated nozzles. The heating duration is selected according to the diameter of the product and wall thickness;

- the heated parts are smoothly removed from the nozzles and connected at the same time. It is necessary to push the pipe into the fitting without twisting or sharp jolts;

- maintain the required initial soldering time and leave the connected elements until they cool completely (2...15 minutes).

Important: when heated, polypropylene pipes release toxins! It is necessary to ensure high-quality ventilation of the room, without directing the air flow directly to the heating area - the parts may heat up unevenly.

Figure 4 shows how the pipeline fragments look in cross-section after soldering small-diameter polypropylene pipes with your own hands - there are no visible seams or heterogeneity of the material.

Health protection and working conditions

When carrying out work related to heating heating main joints, we follow safety rules to prevent injuries and burns:

- We solder using special protective gloves.

- We monitor the cleanliness of the floor in the room. Dirt will negatively affect the quality of welding and the appearance of the entire structure.

- The soldering iron is installed on a flat horizontal surface.

- It is necessary to start working after the device has completely warmed up and after the readiness indicator has turned off.

- We do not turn off the electrical outlet during the entire installation.

Soldering plastic pipes with your own hands is not difficult. The soldering process does not require professional skills or experience. Anyone can install life support networks in their own home. The mandatory composition of the required tool includes only a soldering device. The remaining auxiliary tools can be replaced with improvised means, a pipe cutter - with a sharp knife. A pipeline made of polyethylene structures and PVC is a reliable, durable and environmentally friendly system for supplying water and heating.

Nuances of work: how to solder plastic pipes without problems

The above instructions describe the general provisions for welding polypropylene pipes. But there are interesting points that can confuse an inexperienced master.

We work on the workbench and locally

Not all components of the future pipeline can be soldered comfortably on a prepared workbench. Of course, maximum work should be carried out there, and the point is not at all in the personal comfort of the master - this way there is less risk of incorrect connection of elements. But sometimes it is necessary to solder parts “in place”, so it is better to mark out the diagram of future communications on the wall, floor or ceiling in advance, and secure the clips that will hold the pipes in the desired position.

We fasten the welding machine

When inserting and removing heated elements, a tabletop “iron” that is not secured in any way will jerk in different directions. This leads to both problems with extracting fragments and burns (when trying to hold the falling apparatus), and its breakdown.

Therefore, it is better to fix the soldering iron on a workbench or desktop in any available way - using a “native” clamp or a clamp added to the design, self-tapping screws, and so on.

Cleaning is required!

One of the striking examples is the joining of products reinforced with aluminum not on the outside, but in the middle of the wall.

To properly solder such polypropylene pipes, it is necessary to strip the aluminum layer - but how to do this if it is between the layers of plastic and not outside?

For this, there is a special trimming tool that allows you to remove aluminum foil precisely between the layers.

The cutting edges, which “scrape out” the foil, are shifted towards the center of the product. Thanks to this, the aluminum is removed, the plastic remains in place - the pipe is ready for welding.

The photo shows what the joint looks like between prepared (right) and unprepared (left) fragments. It is clearly visible that in the first case the adhesion turned out to be dense, in the second the delamination is clearly visible. With short-term use, this defect does not matter, but for pipelines through which hot water is supplied (from a boiler or heating boiler), depressurization and failure of communications is possible.

The diagram demonstrates the consequences of a loose joint between two seemingly welded pipes, delamination of the product and swelling of the outer layer of polypropylene during operation.

Important: fiberglass reinforced pipes do not need to be stripped! This is due to the fact that the welding temperature adopted for polypropylene allows glass fiber to melt to the point of diffusion.

Correct cut

Sometimes users think that cutting the pipe obliquely - at an angle of 45 degrees - can increase the contact area and thereby strengthen the weld. This is actually true, but with this type of pruning problems arise:

- with the alignment of parts - it is difficult to correctly connect the pipe sections inside the coupling, a gap inevitably arises;

- with heating of the welded areas - an oblique cut does not allow the required fragment of the product to be completely placed on the heating element. One edge heats up less, the other more.

The last node is not welded!

This happens if an inexperienced welder inaccurately calculated the lengths and locations of pipeline fragments. When it is not possible to insert a mandrel with nozzles and a coupling between the last two elements to be welded, you can solve the problem differently - weld metal inserts into the elements to be joined.

Such a threaded pair with a union nut allows you to firmly and efficiently fasten two fragments and at the same time weld it in without any problems.

Wouldn't you, priest, chase something cheap...

An attempt to save money when purchasing pipes and fittings is fraught with leaks and swelling of pipes in the future, so it is better to purchase products from trusted manufacturers.

It is also necessary to avoid combining products from different companies - a slight difference in the composition or production technology of goods sometimes leads to critical problems in finished communications.

Other errors

Among the most “popular” errors are often found:

- excessive heating of elements. As a result, the pipe is severely deformed and closes the lumen of the coupling, thereby interfering with the free flow of water in the water supply system;

- refusal to degrease surfaces and/or clean them. In this case, diffusion does not occur over the entire surface; “islands” remain where the plastic has not fused. The result is failure of the connection when the pressure or temperature increases;

- water has not been removed (during the repair of an existing water supply system). This can be done using a rag and a warm (not hot!) stream of air from a household or construction hair dryer;

- loose connection. This happens if the pipe is not completely inserted into the fitting or the diameters do not match.

Another common mistake made by inexperienced craftsmen is not wearing protective gloves. The high heating temperature of polypropylene MUST require hand protection, and it is advisable to use gloves made of natural materials - preferably suede. They do not restrict movement and do not begin to smolder when heated, unlike cotton ones. Rubber and rubberized gloves cannot be used!

Typical mistakes are discussed in more detail in the video “How not to solder polypropylene pipes.”

Alternative to welding

In some cases, for example, in hard-to-reach places in the bathroom or other rooms, it is not possible to carry out welding work. The soldering process can be replaced by gluing the pipe to the fitting using an organic solvent. It has a very strong softening effect, but is also highly volatile.

After lubricating the end of the pipe and the internal cavity of the coupling, the plastic softens for a short period of time, and the connection can be made. Reverse polymerization begins after a few seconds.

However, this method is more suitable for PVC pipes that are less prone to thermoplasticity.

If for some reason this option is not suitable, for pipes NOT UNDER PRESSURE it is permissible to use a supercharged lighter instead of a soldering iron. This connection method is shown in the video tutorial below. It is important to understand: uniform soldering cannot be achieved precisely because of the alternating heating of parts, therefore the technology cannot be used for critical connections.

PE connection methods

There are several types of polyethylene pipe connections.

They are divided into several groups:

- detachable;

- one-piece.

The first allows you to disassemble the finished structure. It is used when disassembly is necessary after use. Metal flanges are used for connections. The most durable connection is considered to be a permanent connection. It is achieved by soldering or welding, which is divided into coupling and butt welding.