Installing a heating system for a large country house or apartment is a complex and expensive task. You will first need to carry out all the necessary calculations, then purchase the main element - the boiler.

The modern market offers Russian consumers products from different brands, which produce dozens of models that differ in type of design, technical characteristics and other parameters. The Italian plant also presents its product - the Baxi gas boiler, which has a number of advantages.

Failure protection

For stable operation of Baxi equipment you must:

- provide protection against power surges;

- perform grounding;

- install mechanical filters on water and gas so that there are no particles in the system that could harm its operation.

Installation, connection, configuration and maintenance must be carried out by specialists. For any issues related to the operation of the equipment, consumers should contact certified service centers. This, firstly, will allow you to take advantage of the warranty, and secondly, it will prevent mistakes that are made when performing technical work yourself. The manufacturer warns that stable operation is impossible without proper installation.

User manual

The operation of boilers has no specific requirements or conditions. The user only needs attention, periodic maintenance, and timely response to errors . They are displayed on the display and indicate that a fault has occurred.

Often the occurrence of an error is a consequence of a random signal or a power surge, so the boiler is usually rebooted and started again. All repair work must be carried out by service center employees.

It is not recommended to carry out such activities on your own, since the result may be opposite to the owner’s expectations.

Download instructions

You can download the instructions here.

Advantages

The company produces floor and wall devices of two types - turbocharged and atmospheric. Double-circuit modifications of the mounted type have been adapted to Russian conditions. Even when the gas pressure drops to 5 bar, they continue to function normally. Advantages:

- Self-diagnosis - information about problems is displayed on the display.

- Weather-dependent automation – parameters are adjusted depending on the weather.

- There are quality certificates and permits.

- Maintainability - breakdowns can be easily repaired.

- Affordable price – 25,000-50,000 rubles.

- Attractive appearance – the models are ergonomic and easily fit into modern interiors.

- Automatic operation and adjustment save fuel.

- The electronics quickly respond to changes in operating conditions, making adjustments to the operation.

- Electronic flame modulation – the set temperature is maintained.

- The elements of the hydraulic unit are made of composite materials and are therefore durable.

- Overheat protection.

- There are control panels - portable and built-in.

- For instant water supply – built-in boiler

The technical characteristics of Baxi gas heaters and the level of reliability have determined their place in the Russian market - Italian equipment is chosen by both ordinary consumers and specialists in the field of heating engineering.

Recommendations before purchasing

Heating boilers are technically complex devices; in order for the equipment to serve for a long time, you need to know how to handle it correctly. Each model is supplied with an instruction manual, which provides recommendations for installation and safe operation.

The Baxi brand produces several lines of boilers, and in order not to overpay, first of all you should decide on the required power and volume of heated water. If pressure drops occur in the system, this must be taken into account, not to mention other operational features.

For example, there is no point in buying an expensive and high-power unit for heating a small house. For such cases, the Baxi ECO Four model is suitable. If you need a small but powerful unit, you should pay attention to the Nuvola 3.

During the selection process, you need to pay attention to the following criteria:

- Power. To do this, you need to know the area of your home and divide this figure by 10.

- Energy dependence. More expensive models do not depend on the availability of electricity. Of course, the issue with the supply of electric current can be solved by installing an uninterruptible power supply.

- Availability of heated water. Then you need to buy a dual-circuit unit.

- Boiler type according to installation location. Floor and wall mounted units are available.

- Heat exchanger material. To increase the service life, it is better to purchase a boiler with elements made of copper or stainless steel. There are also cast iron heat exchangers, but they are quite fragile and heavy, but they have excellent corrosion resistance.

- Type of heating system. Centralized or autonomous.

- Compliance of the chimney and combustion chamber.

You can deal with these issues yourself, but if you lack knowledge and experience, it is recommended to contact a specialist who will take into account all possible nuances. Buying a Baxi gas boiler is not a problem if you know which model is needed.

Possible problems and malfunctions

So far, no ideal technology has been invented in the world that would not fail. If the Baxi boiler does not work as before, this may indicate some kind of malfunction. As a rule, minor problems are solved on their own, because taking the boiler to a service center is not an easy task. If the skills are not enough, it is better to immediately call a specialist to your home.

List of frequently encountered problems and ways to solve them:

- The flame power in the burner has decreased. Most often, this situation occurs when the pressure in the system is incorrectly set. Another reason is that the gas valve modulator or diode bridge is broken. To get rid of this problem, you need to correctly configure all system parameters, following the instructions supplied with the boiler, or replace damaged components.

- Turning off the boiler immediately after starting. The problem occurs when the pressure in the gas pipeline is low. This can be solved by adjusting the gas pressure downward to 5 mbar.

- The coolant is not heating well. You need to check the pressure parameters on the gas valve. Most often, this problem occurs if the min and max values are incorrect.

- Modulation has failed. The valve will need to be replaced.

- Temperature sensors have incorrect values. Old elements are replaced with new ones.

- Insufficient water heating for DHW. The malfunction may be caused by incomplete opening or a broken three-way valve. To make sure of this, you need to wait until the system has completely cooled down. Next, the valve closes and the boiler switches on to DHW mode. If the element is faulty, the heating system will heat up.

- During ignition, “popping” noises are heard. This situation arises for two reasons: there is insufficient pressure in the system or the distance between the gas supply and the igniter has changed. The situation is solved by adjusting the gap size, the optimal value is from 4 to 5 mm. To perform this work, remove the boiler cover and the damper behind which the igniter is located. Next, the screw holding the electrode is removed and carefully bent.

- The temperature of the liquid in the circuit has decreased. As a rule, this happens due to clogged filters. This means they will need to be cleaned. Sometimes the cause may be radiators or damaged pipes. It is necessary to prevent freezing and clogging of the system.

These problems arise most often, but, as practice shows, you can cope with them on your own. Of course, this will require certain skills. Baksi boilers are fully automated and have a self-diagnosis system. Therefore, during operation, the device display may display corresponding icons and error numbers indicating a particular malfunction.

Types of Baksi boilers

The manufacturer produces several lines of gas heaters, each of which has options for any circumstances and financial capabilities. The devices are classified according to their functionality:

- Single-circuit - for heating only.

- Double-circuit - heat and provide hot water.

Two in one - economical and compact. The separate approach also has its adherents - it is more reliable and durable.

By installation method:

- Wall-mounted. Low power. Compact - the size allows you to install them in a kitchen cabinet. Hangs on the wall.

- Floor-standing. Heavy and powerful. If the first ones are usually installed in apartments, then these ones are intended for private houses that require high heating output from the equipment.

According to the method of smoke removal:

- With an open combustion chamber. It is often called a chimney. To remove combustion products, draft is needed - it is created in a long gas duct.

- With a closed camera. It is called turbocharged. The draft here is pumped by a fan. Combustion products are discharged through a coaxial chimney passing through the wall. The burner is supplied with outside air.

Based on the operating principle:

- Convection. The fire heats the coolant, but some of the heat is lost. Such devices are simpler.

- Condensation. There is an additional heat exchanger - hot gas condenses on it and the coolant receives additional heating. The efficiency of such devices is higher. If you compare how much convection and condensation versions cost, the former are definitely cheaper, but they also have lower efficiency.

Also distinguished:

- Non-volatile. Not connected to the mains.

- Energy dependent. Connected to the mains. Such devices are more advanced and functional. But we have to provide backup power in case of a power outage.

How to choose and what to pay attention to?

When choosing a model, you should pay attention to such characteristics as:

- heat exchanger material - affects the service life of the device;

- volatility – volatile boilers require uninterruptible power supply;

- design of the combustion chamber - when the chamber is open, a chimney is required in the house;

- thermal power - determined by the square footage of the room;

- type of unit - if there is a need for large quantities of hot water, you should give preference to dual-circuit options.

Range

Baxi gas heaters are presented in lines that combine modifications with similar features. Models included in the line may differ in thermal performance and other characteristics. Series of wall modifications:

- Eco Four is a dual-circuit version. Two heat exchangers. Copper hydraulic tubes.

- Main – with bithermic heat exchanger.

- Eco Compact – similar to Eco Four, but more compact.

- Four Tech - also repeats Eco Four, but the tubes are plastic, not copper - so their price is lower.

- Luna - dual-circuit, except modification 3 1.310Fi.

- Nuvola - built-in boiler. There are atmospheric and turbocharged ones.

The estimated cost of single-circuit models is 27,000-47,000 rubles. Double-circuit atmospheric - 27,000-37,000, and double-circuit turbocharged - 35,000 - 40,000 rubles.

Floor-standing versions are presented more modestly. The most popular line is SLIM. All with cast iron radiator. Power range - from 22 to 107 kW.

Condensing boiler is a new generation of gas equipment. Models - Power Ht45—150 / Ht230—650 with stainless steel/silumin heat exchangers. These are the best devices from - they have great power, they can be connected in cascades.

Briefly about the company

Baxi is a brand originally from Italy that has been producing heating and hot water equipment for 50 years. The company offers users a wide range of its products: classic wall-mounted and condensing gas boilers, floor-standing units with cast iron heat exchanger, electric water heaters. These are modern, high-quality and reliable products that meet all regulatory requirements.

At the moment, the company produces about half a million units of gas boilers in one year, including the popular series: Luna, Main, Slim. Since 1993, when the company received the ISO 9001 quality certificate, its products have received high ratings from consumers.

BAXI SpA was founded in 1924 by the Austrian Westen family. The company began producing gas boilers between 1978 and 1984, when it was part of the Zanussi group. Since 2009, the company has been part of the BDR Thermea group, its boiler plant is the center of the holding. The total annual production volume is about half a million wall-mounted units.

Model overview

LUNA 3 Comfort1.240.

Wall-mounted single-circuit. Approximate price 48,000 rubles. Weight 31 kg. 91% efficiency. Heating capacity 9.3-24 kW. Open firebox. There is automatic ignition. “Comfort” models provide a connection to “warm floors”. Copper heat exchanger.

ECO Four 24 F

Dual-circuit. The Ecofor device is a representative of a new generation. Compact. Hangs on the wall. Closed firebox and separate heat exchangers. Heats rooms up to 240 sq.m. There is an LCD display that displays the current parameters. Power 9.3-24 kW. 91.2% efficiency. Almost silent operation. Power consumption – 80 W.

Luna Duo-Tec1.28

Double-circuit turbocharged. Efficiency – 106%. Connection to heated floors. Outside temperature sensor. There is a remote control unit. 28,000 W – heating capacity. Heats up to 210 sq.m.

Nuvola Duo - Tec+

Wall-mounted version. Condensing type. Closed firebox. Can run on liquefied gas. Electronic control. There is an LCD display. Weighs 62 kg. Warm floors mode.

POWER HT 45

Floor-standing condensing type unit. The cost is more than 138,000 rubles. Open firebox. Without DHW. Powerful boilers can be connected in cascades. Width – 45 cm. Power 48.7 kW. Weight 60 kg.

SLIM 2.230i

Floor installation. Open firebox. Weight – 155 kg. Two circuits. 22.1 kW. Heats an area of up to 166 m2. Capacity 13 l/min. The capacity of the expansion tank is 10 l. The price is about 100,000 rubles.

SLIM 2.300 Fi

Powerful floor-standing boiler. Efficiency 90%. Nominal heating output 30 kW. Closed firebox. Heat exchanger – cast iron. Turbocharged gas exhaust. Weighs 184 kg. The cost is about 140,000 rubles. Expansion tank – 10 l. Dimensions (HxWxD) – 85x65x60 cm. There is a circulation pump.

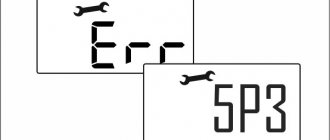

Technical faults and error codes

All failures or breakdowns of boilers are immediately diagnosed by a system of sensors that display an alert in the form of a digital code with the letter “E” (error).

The most common mistakes and owner actions:

- E01 . Keep the burner off. Possible reasons are lack of gas (check the valve), burner nozzles are clogged with soot, problems with the sensor itself.

- E02 . Thermostat overheating. The problem occurs either when the water moves too slowly, or when the heat exchanger is contaminated from the inside with lime deposits.

- E03 . Fan stop. Check it for functionality and replace it if necessary.

- E05 . Failure or short circuit of the air temperature sensor.

- E06 . Failure or short circuit of the DHW temperature sensor.

- E10 . Reduced coolant pressure. The most likely cause is a leak in the heating circuit. This most often occurs when using heated floors, since external radiators signal themselves by the appearance of puddles or streams of hot water.

- E25-26 . Blockage or failure of the circulation pump, failure of the corresponding sensor.

- E35 . False signal about the presence of flame. There may be water on the board, breakdown of the sensor on the case, etc.

- E96 . The power supply voltage is too low.

The full list of errors is much more extensive, so it is recommended to have the user manual included with the boilers at hand. There is no point in learning these codes by heart; it’s easier to look at the list at the right time.

Wiring diagram for Baksi heating systems

The purpose of the strapping is to prevent the device from overheating. Properly executed piping saves resources due to the effective distribution of thermal energy. At the same time, expensive automatic adjustment loses its relevance. There are the following strapping schemes:

- Single-pipe. The coolant rises up, enters the radiator, and leaves it, ending up in the same pipe. After passing through all the radiators, the water returns to the original pipe.

- Two-pipe. The coolant is heated in the boiler. Gas is supplied to the radiator through the supply pipe. The coolant, having cooled, returns through the second pipeline.

- Combined.

Boiler connection

The boiler allows you to stabilize the temperature of the hot water supply and eliminate surges when using the bath or shower. The simplest and cheapest design option is a storage tank into which hot water flows from the boiler.

When it is dispensed from the boiler, the missing volume is immediately refilled from the boiler. The connection is made to the hot water pipe.

It is not advisable to use more complex and expensive options, since their price will be excessive expenses that are not justified by the results obtained.

How to use the self-diagnosis system?

All BAXI modifications are equipped with a self-diagnosis system. The information is displayed on the screen; the user’s task is to decipher the error codes using instructions and take measures to eliminate them. What do the codes mean:

- E01 – no ignition.

- E02 – thermostat activation.

- E03 - no normal traction.

- E05 - the temperature sensor is broken.

- E10 – low water pressure.

- E12 – pressure switch is faulty.

Price range

Double-circuit boilers from Baxi are a large group of series and models of heating units. Among them there are installations of varying power, degree of complexity and configuration . The lower price range is at 30 thousand rubles, and the upper limit is close to 100 thousand rubles.

The cost of the unit itself increases due to additional devices - stabilizer, water filters or softeners, chimney, warranty agreement, delivery and other overhead costs.

NOTE!

Attempts to save money by refusing any additional devices or warranty service can lead to the loss of the boiler.

Device Description

The instructions provide schematic diagrams of the device. Each modification has its own, but the main components are made in the same way. At the top there is a chimney. Directly below the chimney there is a ventilation system. Below it is a heat exchanger. It looks like a radiator or coil. On the left is the temperature sensor and thermostat. In the center is a firebox. There is a burner in it. On the right is the pipe coming from the heat exchanger. The pipe goes into the expansion tank and connects to the pump. On the left is a pipe with a hydraulic relay and a safety valve. From this pipe water flows into the heating system.

What's included

The boiler package includes:

- Primary and secondary heat exchangers.

- Circulation pump.

- Gas burner of closed or open type.

- Fan to supply fresh air to the combustion chamber.

- Expansion tank.

- Three-way valve.

- Gas valve.

- Sensor system.

- Control board.

- Connecting wires and pipes.

Some boiler models have additional elements that provide protection or performance monitoring functions.

IMPORTANT!

The chimney is not included in the boiler package and must be purchased separately.

Reviews

According to users and experts, equipment under the BAXI brand has proven itself to be reliable and durable, easy to maintain, of decent quality and easy to use, with flexible settings, and characterized by almost silent operation. Consumables for repair work are always available in large service centers.

However, despite the intuitiveness and simplicity of the interface, there are a number of parameters that must be set by specialists when putting the equipment into operation. Among other things, the unstable temperature of the hot water supply and the loud bang that accompanies the ignition of the device receive negative feedback.

Features of Baxi products

Baxi is one of the stable brands that has proven itself well in the heating boiler market.

Reference! The brand has existed for more than 100 years, and has been producing thermal equipment for about 50 years. During this period, methods for manufacturing complex structures and components were established.

A wide range of boilers allows you to choose the best model for a private home, office premises, large buildings, apartments.

All heating installations have a basic set of functions:

- Self-diagnosis. Sensors fully monitor the state of device elements in automatic mode.

- Frost protection . When the temperature drops to +5 degrees, the system starts increased circulation.

- Operational temperature control.

Additional functionality includes climate control and advanced regulation.

Temperature adjustment

To increase or decrease the heating agent temperature, there are “+” and “-” buttons to the right and left of the display (on older models there is a special regulator; turning clockwise increases the temperature and vice versa).

If a room thermostat is used, adjustments are made from it, and only limit values are set on the boiler.

When setting the temperature, do not change the parameters in large increments . It is necessary to change the mode smoothly, giving some time to overcome the inertia of the system. This will soften the transition to another mode and extend the life of the boiler.

For which rooms is it best suited?

Double-circuit gas boilers are optimally suited for heating and hot water supply of private houses of the corresponding size. The use of these units in industrial or public buildings is impractical due to inappropriate working conditions and lack of proper maintenance.

Often such boilers are purchased with a view to the future and for the time being operated as single-circuit installations (only for heating premises). This approach is completely justified, since when the opportunity arises, you will only need to connect the appropriate pipelines, and the difference in cost is not too noticeable.

Often, users purchase Baxi Eco Four 24F boilers to organize heating of apartments with a much smaller area than intended by the design, expecting to obtain a large margin of safety.

Expectations are not always met, since abnormal operation is just as harmful to the unit components as overload.

Optimal operating mode

The optimal operating mode of the boiler is described in detail in the user manual.

Its parameters:

- Ambient temperature is 70-75°.

- Water pressure - 0.7-1 mbar.

- Parameters F08 and F10 are adjusted to the minimum and maximum values respectively.

Adjustments are made during commissioning; additional adjustments are made periodically during annual maintenance or after repair work.

Pressure setting

To increase the pressure, a make-up valve is used, and to release the pressure, a drain valve is used.

The optimal value is considered to be a range of 0.7-1 mbar . Usually Baxi boilers independently maintain the desired value, but sometimes failures occur. If there is a constant drop that does not disappear after the system is recharged, then there is an OM leak somewhere.

This could mean either leaking pipes or radiators, underfloor heating systems or other external elements.

Often the problem occurs due to a faulty bleed valve . An abnormal increase in pressure may be due to a malfunction or open make-up valve or damage to the expansion tank membrane.