After gas supply to a private home, the next task, as a rule, is the installation of gas equipment.

Requirements for installing a gas boiler

Many apartment owners also refuse central heating and prefer the autonomous option, wanting to save money and turn on and off the heating of the premises when they see fit. But in order for such heating to be safe and efficient, it is necessary to comply with the requirements for installing a gas boiler.

In the organizations that control gas supply, the necessary documents are drawn up and agreed upon both for connecting the gas main to the house and for installing heating units.

Documentation for boiler installation

One of the rather unpleasant procedures when installing a heating boiler that runs on gas is the collection and execution of a voluminous package of documents. Many, faced with this process, soon rush to abandon this idea.

Before starting installation, you will have to spend a lot of time agreeing

Basic requirements and standards can be found in the document “Gas distribution systems”, included in SNiP 42-01-2002. In addition to this, it would be nice to study a document that is no longer working, but contains a large amount of information that will also be useful - this is “Gas Supply” SNiP 2.04.08-87. Additionally, you will have to familiarize yourself with the standards given in related documents that talk about boiler systems, ventilation systems, heating, sewerage, water supply, construction safety, sound insulation, fire safety, etc.

Standard design 903-1-217.85 Boiler house block with 4 Universal-6M solid fuel boilers.

Boiler room block with 4 “Universal-6M” solid fuel boilers.

For this project there is

Documentation in electronic form

What is a project passport?

A project passport is a brief description of a typical project presented on several A4 sheets. The number of sheets varies from 1 to 15 (usually 2-4.)

Attention ! The project passport is not a typical project. Purchasing a standard project passport is necessary to familiarize yourself with a summary of the project. Almost 95% of projects are calculated in 1984 prices

An approximate translation based on coefficients is possible. To calculate, you need to buy a project passport and convert it to current prices

Almost 95% of projects are calculated in 1984 prices. An approximate translation based on coefficients is possible. To calculate, you need to buy a project passport and convert it to current prices

We provide a calculation - “Certificate on the estimated cost of a capital construction project”

The cost of this service is 1200 rubles.

to provide a certificate of the estimated cost of a capital construction project

*Fields are required

Images

To complete the procedure for purchasing a standard project passport, you must click on the “Download passport”

and save the file with the PDF extension in any place convenient for you.

To complete the procedure for purchasing a standard project kit, you must click on the “Download kit”

and save the file with the PDF extension in any place convenient for you.

VTsIS Foundation, 2000-2018

Coordination of boiler installation

You need to go through several authorities to obtain approval for the installation of a gas-fired boiler. Doing it yourself, without approval, the installation process will be illegal and unsafe, and not only for the home owner, but also for the other residents of the house if the boiler is installed in a high-rise building.

Specifications

To connect a private house or apartment to the gas supply, you will have to obtain technical conditions from the gas supply organization that permit this procedure. To do this, a statement is written to the controlling organization. It must indicate the approximate demand for gas volume per hour. The registration procedure lasts seven to fourteen days. Upon successful completion of this event, a document will be issued - technical conditions for the installation of equipment operating on gas fuel. This is a permit for preparatory construction and installation work.

Project

Having the technical specifications in hand, you can proceed to the second step - developing design documentation. The gas supply project includes plans for laying a gas supply pipe from the boiler installation site to the central gas pipeline.

The project will also indicate sections of the gas pipeline crossing the site

If the home is located in the private sector, and the pipeline must cross the land, then a diagram of the gas pipe on the site is also drawn up, indicating the location of its entry into the wall of the house. The project is developed by engineers licensed for such activities, based on the provisions of the GOS.

Coordination with the gas supply organization

The completed project is submitted for approval to the organization that controls gas supply in the applicant’s area of residence. Project approval takes from seven to one hundred days, depending on the volume and complexity of the document. The following materials regarding the heating device are attached to the project:

- examination of the boiler’s compliance with all requirements necessary to ensure normal operation and safety;

- technical passport of the device;

- certificates of compliance with technical and sanitary-hygienic requirements;

- operating instructions.

All documents specified in the list are prepared by the manufacturer and must necessarily accompany any product of this type. They are transferred by the seller to the buyer when purchasing the device - special attention should be paid to this.

If the project was rejected for the first time, the applicant is given a document indicating the reasons for the refusal and a list detailing all the problems of the project that require correction.

If the project is approved, it is certified by the signature and seal of the responsible person. This document is the final permission to install the heating device.

Cost of specialist work

Prices for a full replacement, paperwork and commissioning work depend on the type and model of the boiler, region and company providing the services. In Moscow and the Moscow region it is about 8-22 thousand rubles, for St. Petersburg – 6-15 thousand rubles, for the regions – 4.5-12 thousand rubles. About half of the cost is for dismantling the old and installing a new boiler unit, almost half is for commissioning.

Please note that the required paperwork process is not always included in replacement services.

Gas boilersInstructionsBoilers

Installation restrictions

For safety reasons, appliances operating on gas fuel are prohibited from being installed in the following premises:

- in which there are no ventilation systems;

- in dormitories (rooms);

- in bathrooms;

- in the corridors and on the balcony;

- in basements;

- on the ground floor;

- on flammable wall surfaces.

One important clarification regarding installation on the ground floor and basement: installation is only permissible in a private single-apartment house, i.e. if the house is not divided into several owners.

Requirements for installation of units

When installing a gas boiler, the homeowner must strictly adhere to a number of regulatory rules:

- the boiler is installed in such a way that there is free access to it from any side;

- the size of the entrance door to the boiler room where the device is installed cannot be less than 80 centimeters wide;

- the area of the boiler room or other room cannot be less than four square meters;

- the boiler room must have a window with an area of at least 30 cm² per 10 m³ of volume - to provide lighting in any situation;

- the ceiling in this room must have a height of at least two and a half meters;

- water must be supplied to the boiler room;

- a grounding loop is mandatory if the operation of the boiler is related to the consumption of electricity;

- boiler room walls must be plastered;

- the chimney must have a cross-section corresponding to the power of the unit.

Having considered the requirements presented, we can conclude that a kitchen can be a fairly good room for installing a wall-mounted boiler, if it is not possible to install a boiler room. There it can be placed next to the gas stove.

Compact wall-mounted boiler can fit even in the kitchen

An additional advantage of installing a boiler in the kitchen is that it meets all the above requirements - ventilation, gas supply, adequate room area, cold water supply. In addition, by installing a boiler there, you can save a lot on pipes and keep more than one wall intact.

A floor-standing boiler, which has massive dimensions and a power of 150 kW, must be installed in a separate room - the boiler room. It should be taken into account that a device with a power of up to 60 kW can be installed in a room with a volume of at least 27 m³, which means it can be installed in the kitchen.

For flooring it is better to allocate a separate room

But you need to know that floor-standing boilers are quite noisy, so if you plan to install the unit in an apartment, it is better to choose a wall-mounted option.

If the boiler is hung or installed against a wall made of flammable material, it must be protected with a heat-resistant insulator, for example, special plasterboard or asbestos sheet will do.

Boiler connection

There are several options for connecting a boiler to a gas boiler.

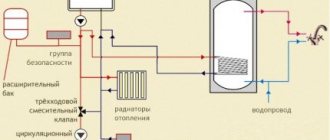

Connecting the boiler via a three-way valve

The valve is placed on the battery. And a pipe is run from it to the container, where it enters the pipe. The refrigerant pipe leaving is directed to the battery with a “return”. We also recommend connecting the outlet pipe to the pipe.

When connecting wall-mounted gas boilers, the valve is controlled by the boiler itself. And in floor-standing models, you can connect a thermostat to the valve for direct control.

Connecting the boiler through an additional pump.

Priority is given to water supply. Two pumps are used. The thermostat is placed on the tank, it also signals a drop in degrees, the pump turns off and the tank pump starts. Don't forget to install the valves.

Boiler installation

Installation of any gas equipment is carried out by a gas technician; independent installation is strictly prohibited. The manufacturer attaches the boiler installation diagram to the documentation of the heating device, and it will be useful to the installer.

Equipping a boiler room at home will require the intervention of experienced specialists

- When installing the unit in a boiler room, you need to arrange the floors correctly. They must be made of non-flammable material and have a water drain. It is necessary to extract coolant from the heating circuit in case of an emergency.

- Installation of gas equipment is not carried out at sub-zero temperatures; it must be at least five degrees Celsius. But it is also unsafe to install equipment at too high a temperature, so it should not exceed 35 degrees.

- A level mark is made on the wall for the bracket, on which the boiler will then be hung.

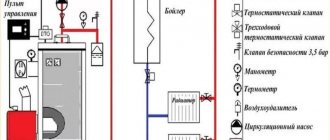

- If a dual-circuit gas appliance is installed, then a strainer is placed on the return pipe. It is necessary to ensure that the heat exchanger remains clean for a long time. Ball valves are installed on both sides of the filter and on the boiler pipes.

- When connecting the boiler to the gas supply line, a gas meter, a special gas tap, a gas alarm and a thermal shut-off valve are installed in front of it.

- The socket into which the boiler will be connected, if it is volatile, must be grounded.

- When the boiler pipes are connected to the water supply and gas supply, the system must be filled with water. This is done slowly so that the air in the future coolant does not stagnate - it will have the opportunity to leave the circuit through the air outlet devices. During the period of filling the system, the boiler must be disconnected from the power supply.

- Before starting the boiler, be sure to check the gas pipe connections for gas leaks. This is very simple to do - you need to knock off a thick foam from any detergent and apply it to the connecting elements using a sponge. If there is a leak, then a soap bubble will certainly inflate, and if the pipe is connected tightly, the foam will gradually settle. Only after all these manipulations can you start the system by connecting it to the power supply.

Heating connection

Flow-through boilers can be portable or stationary.

The instructions for the equipment will help you avoid mistakes and position the pipes correctly. The circuit may be different, determined by the model and manufacturer.

If the heating system is already in use, then before connecting the gas boiler, you need to drain it and rinse everything. And check if antifreeze can be used with your equipment.

Gas boiler connection diagram directly

For a single-circuit boiler

When connecting a gas boiler, the circulation pump is placed on the reverse side. Taps are needed to separate the system and the boiler without draining the coolant. Plus, change the filter, which saves the equipment from clogging, and it must be placed in front of the equipment on the horizontal part of the pipe.

The refrigerant pipe from the boiler is connected to the boiler pipe with a tap. The same taps should be on the remaining pipes. They are needed during draining and repairs.

Ventilation

It is very important to ensure that the room where the gas appliance is installed has good ventilation.

Supply and exhaust ventilation is a prerequisite for any boiler room

- The kitchen area in a multi-storey building is equipped with a common building ventilation system, so there will be no problems with it. When installing the device in a boiler room, a ventilation duct is installed in the ceiling of the room and vented outside.

- Supply ventilation can be installed in the door by making a hole and installing a ventilation grille.

- Special standards have been defined for ventilation inlets. So, for one kW of device power, the grille must have a size of no less than 8-10 cm² (air intake from outside the house) and no less than 30 square meters. cm (air intake from inside - from other rooms).

Electrical connection

Connecting a gas boiler to electricity

There are two ways to connect a gas boiler to the network:

- Plug into the socket.

- Cable with three cores.

The choice is determined by the equipment model. But you always need to work through local protection. Connect to the panel. And don't forget to ground. It would be great if there were stabilizers or backup sources if the plugs suddenly went out.

The circuit breaker must be located next to the equipment. In any case, there must be a local outlet. And she must eat through a machine.

Building a ground connection on a gas pipeline or battery is prohibited! According to gas service standards, the resistance does not exceed 10 ohms.

Chimney

Particular attention to the correct organization of the chimney

Correct installation of the chimney is no less important than the ventilation system. The chimney can be made of a metal sandwich pipe that is discharged through the roof of the boiler room (or through the wall) and rises along the wall from the outside to the roof.

Convenient and reliable sandwich pipes

Or maybe coaxial, coming out through the wall and having a small size. Each of them is established according to certain rules.

- Combustion products should not enter the room, which means that the smoke exhaust duct must be gas-tight.

- The diameter of the chimney should not be less than the diameter of the pipe leaving the boiler. The ratios for boiler power have been established - the homeowner will definitely be familiarized with these figures when drawing up project documentation.

- The head of the metal pipe must rise above the roof no lower than its ridge - this will ensure normal removal of gas combustion products and prevent backdraft.

- When the chimney is brought out through the wall, a hole is made for it, the pipe is connected to the boiler and taken out into the street. If gaps have formed in the opening between the wall and the chimney, they must be sealed hermetically. This coaxial type flue duct is suitable for a boiler with low or medium power, and is usually used for wall-mounted models.

The head of a coaxial chimney in a wooden house

Two big differences

The boilers mentioned above are the extremes of a huge variety of models of gas water heating devices. They are available for self-installation. Any other gas heating boiler requires professional work for installation. However, every cloud has a silver lining - specialized companies also take on the preparation of the premises and the preparation of documents. But why can you install only the “tips of scissors” yourself?

Simple water heater

The simplest boiler is really very simple: a gas burner, a heat exchanger - that's all. It is enough to connect water and gas to it, vent the exhaust into the chimney - and you can use it. If the papers have already been completed; otherwise - an inevitable large fine.

Home boiler room

A double-circuit boiler with a boiler and full automation is so “smart” that installing it is as easy as the simplest one. Automation is important not only for simplicity: a complete system with a double thermostat and a microprocessor monitors the temperature in the house and outside, according to a given program, reduces heating to a minimum according to sanitary standards when no one is at home (for example, when everyone is at work). The gas consumption of such a boiler is 30-70% less than with manual or semi-automatic adjustment, and the savings are greater the more severe the weather.

But such a home boiler room has a serious drawback: if you find yourself in a natural disaster zone and the power supply is disrupted, the automation “stalls” and the boiler goes into the mode of minimal heating of the room. Therefore, such a boiler requires additional costs for guaranteed power supply. It is not difficult to provide it yourself, see below.