Automatic gas boiler AGV-80

AGV-80 devices are automatic gas boilers, which are designed for local water heating of residential premises with an area of up to 60 m2 and for supplying hot water to an apartment (bath, washbasin, kitchen).

Technical characteristics of AGV-80 boilers

Water reserve in the tank, l – 80

Nominal heat load of the burner, kcal/hour – 6000

Gas consumption by burner (with a calorific value of 8000-9000 kcal/nm3 and specific gravity of 0.73 kg/nm3), nm3/hour – 0.7

Consumption of liquefied gas by a burner with a calorific value of 21000-22000 kcal/Nm3 – 0.28

Nominal gas pressure in front of the device, mm water. Art. – 130

Maximum water pressure in the water supply system, kgf/cm2 – 6

Setting interval for water heating temperature in the tank, C – 40-90

Water heating time from 20 to 900, min. – 75

Permissible minimum vacuum value in the chimney, mm water. Art. – 0.1

Efficiency – 0.8

Diameters of holes in nozzles, mm:

– burners (natural gas) – 2.4 – burners (liquefied gas) – 1.4 – igniter (natural gas) – 0.5 – igniter (liquefied gas) – 0.25

Overall dimensions, mm:

– diameter – 410 – height – 1560

Total weight, kg – 85

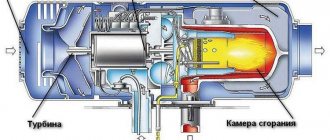

The AGV-80 automatic gas boiler consists of the following main components (Fig. 1): a galvanized welded tank, a casing, a combustion device (base) with a burner, a gas tap, a thermostat, a magnetic gas valve, a filter, an igniter, a thermocouple, a safety valve and a draft breaker .

Rice. 1. Diagram of the AGV-80 gas boiler

1 – traction breaker; 2 – thermometer coupling; 3 – stabilizer; 4 – filter; 5 – magnetic valve, 6 – thermostat; 7 – gas valve; 8 – igniter; 9 – thermocouple; 10 – air vent; 11 – gas burner; 12 – fitting for cold water supply; 13 – tank; 14 – thermal insulation; 15 – casing; 16 – hot water outlet pipe to apartment wiring; 17 – safety valve

The thermostat is a two-position device (positions “open” - “closed”) and is designed to automatically regulate water temperature.

The thermostat valve opens and closes automatically when the temperature of the water in the tank changes by lengthening or shortening the brass tube of the thermostat.

The tube is located inside the tank in water and has a large linear elongation with temperature changes. Inside the tube, in a sleeve on a thread, a rod made of Invar (an alloy of iron and nickel) is attached, which has a very low linear elongation.

The free end of the rod presses on a system of levers with a spring connected to the thermostat valve.

Rice. 2. Scheme of operation of the thermostat

1 – changeover lever; 2 – valve spring; 3 – glass; 4 – gasket; 5 – valve sleeve; 6 – valve; 7 – valve seat; 8 – Invar rod: 9 – bushing; 10 – tube; 11 – nut; 12 – gasket; 13 – spring, 14 – washer; 15 – sealing ring; 16 – body; 17 – figured lever; 18 – flip spring.

The thermostat has a special scale and a pointer knob, by moving which you can set the thermostat to a temperature from 40 to 90°C.

This temperature change is caused by a change in the length of the free end of the rod when screwing it into the bushing of the brass tube (Fig. 2).

If the AGV-80 gas boiler is set to a water heating temperature of 90°C, the pointer knob is opposite the “HOR” scale. To lower the temperature setting, you need to move the pointer knob to the extreme position against “COOL”.

To increase (lower) the temperature of the water in the tank, you need to use a screwdriver to unscrew the screw connecting the pointer handle to the rod and move it to the lowest (upper) position; Re-fasten the pointer handle with the screw and move it to the extreme upper (lower) position.

A thermocouple of the THK type is designed to create an electric current arising from the heating of the hoarse free end by the igniter flame.

The igniter is designed to heat the thermocouple and ignite the burner. The pilot flame does not go out until the gas is turned off (Fig. 3).

Fig. 3. Diagram of a thermocouple, igniter and connecting them to a magnetic valve

1 – burner; 2 – igniter; 3 – thermocouple contact washer; 4 – contact washer of the magnetic valve; 5 – button.

Rice. 4. Magnetic gas valve diagram

1 – wires; 2.6 – valve plates; 3,4 – valves; 5 – spring; 7 – rod; 8 – body; 9 – membrane; 10 – cap; 11 – core; 12 – anchor.

The magnetic valve is an automatic safety device for gas boilers AGV-80, which serves to completely stop the gas supply to the burner and igniter when the latter goes out.

Its operating principle is based on the fact that the core winding, receiving a certain electric current from a heated thermocouple, magnetizes the core, which attracts the armature.

The armature is connected through a rod and rod to valves, which are held in an intermediate position, opening the passage of gas from the network to the burner and igniter (Fig. 4).

When the magnetic valve is turned on, the upper valve is pressed against the seat, gas flows to the igniter. In the non-working position, the lower valve is pressed against the lower seat under the action of a spring and closes the gas access to the igniter and burner (Fig. 5).

The safety valve consists of a body with a membrane between two gaskets. The membrane is a special plate made of copper foil 0.03 - 0.035 mm thick, in the middle of which the hole is filled with a low-melting alloy.

When the pressure in the tank is above 6 kgf/cm2 or the water temperature is up to 105°, the membrane breaks through and the water passes through the signal tube.

Rice. 5. Magnetic gas valve diagram

1 – union nut; 2 – contact washers; 3 – plug; 4 – gasket; 5 – conical washer; 6 – core base; 7 – button.

Rice. 6. Safety valve diagram

1 – intermediate ring; 2 – membrane; 3 – washer; 4 – pipe; 5 – tank; 6 – casing; 7 – top cover; 8 – casing cover; 9 – body; 10 – gasket.

For the Soviet generation, the abbreviation AGV was associated with any gas boiler. AGV is also a trademark for the production of gas equipment. At that time, AGV-120 and AGV-80 were boilers, the most affordable of gas equipment for heating a private home. The low efficiency of such boilers did not particularly bother anyone, since the price of natural gas was more than affordable. The primitive automation with which those heating systems were equipped failed quickly, but the boiler could do without it. The external pipes for distribution along the walls also didn’t bother me much ─ they didn’t think about the design, and the boilers coped well with the main function - providing heat. When installing a heating system with an AGV boiler with pipes of a smaller diameter, there is a risk of air “bubbles” appearing, slowing down the circulation of water.

Rules for installation and operation

Installation and installation

Factory-made devices are allowed for installation at consumers' premises if they have a passport. Before installing the water heater, check by external inspection that all parts are complete and intact. The gas valve should move smoothly and turn with light hand effort.

When installing the AGV-80, all conditions must be met to ensure normal and safe operation of the device.

Such conditions are: - appropriate premises for installing the water heater; — correct connection of the water heater to the chimney or gas pipeline. Installation of water heaters in residential buildings is allowed only if there is a chimney with combustion products discharged from the AGV-80 into it. Gas water heaters can be installed in bathrooms and kitchens of residential buildings. The temperature of the rooms in which water heaters are installed must be at least 0°C.

For the requirements for premises, see “Safety Rules in the Gas Industry” of Gosgortekhnadzor. When connecting the device to a chimney, fire safety requirements must be met in accordance with SNiP Sh-G, P-62 of the USSR State Construction Committee. The cross-sectional area of the chimney should not be less than that of the gas apparatus pipe connected to the chimney.

Work on the installation of AGV-80, a heating or hot water supply system must be carried out according to a project developed by the consumer (according to current rules and regulations), approved by the local Gorgaz.

Starting and regulation

Before starting, check that the water heater and heating system are filled with water; this is monitored by the appearance of water from the signal pipe. Then close the valve on the water supply and, after checking, start it.

When putting the water heater into operation, it is necessary to: a) open the gas valve on the gas pipeline; b) open the combustion door and with your left hand bring a lit match to the igniter; c) press the magnetic gas valve button all the way and simultaneously light the igniter. The button must be kept pressed all the way for one minute, without releasing pressure on it; d) after one minute, release the magnetic gas valve button and slowly open the gas burner tap. If the burner does not light up and the igniter goes out, re-ignition can be done no earlier than two minutes later and only after the firebox has been ventilated; e) when starting the water heater, check the presence of draft in the chimney. During normal draft, the flame of a match brought to the draft breaker cap will be drawn under the cap. If there is no draft and the flame is knocked out of the firebox, the water heater cannot be used.

When the water heats up to the required temperature, the gas supply automatically stops and the burner goes out. When the water temperature in the water heater drops (as a result of water withdrawal and replenishment with cold water or heat loss during heating), the thermostat resumes the gas supply to the burner and it lights up from the pilot flame.

Terms of use

In order to avoid accidents and accidents, it is strictly prohibited: Persons unfamiliar with the rules for using the water heater to put it into operation. Troubleshoot the water heater and adjust it yourself. Make repairs or make any design changes to the water heater, gas pipeline or heating system; Hang any objects on gas or water pipes. If there is a problem with the operation of the water heater, you should close the gas valves at the water heater and on the wall in front of the water heater and then call a representative of the Gorgaz trust.

Immediately report: poor draft in the chimney and malfunction of the heating system to the building manager; about the smell of gas - the emergency service of the Gorgaz trust; about a malfunction of the water heater or gas supply - to the Gorgaz trust.

When operating the AGV-80 for heating (see Fig., an expansion tank equipped with a signal pipe must be installed in the system.

an expansion tank equipped with a signal pipe must be installed in the system.

When operating the AGV-80 for hot water supply, it is necessary to: Always keep the hot water tap fully open. The water valve supplying the water heater should be closed as soon as the tank is full and water comes out of the hot tap. To draw heated water, open the water valve slightly so that hot water flows out of the hot tap without pressure. When the hot water intake is completed, the water valve must be closed. The temperature of the water supplied by the hot water supply device should be no more than 70°C.

AGV boiler

During their entire operation, these boilers were modernized twice (brands AOGV and AOKGV), but the new models inherited the disadvantages of the old ones - low efficiency, unreliable automation, inability to control the air thermostat.

And yet, AGV boilers have confidently occupied their niche in the market, thanks to many advantages:

- Affordable price (relative to imported models).

- Economical.

- Safe operation and reliable design.

- Independence from electricity.

- Possibility of equipping with automation.

- Use of different installation options (wall and floor models). AGV boilers

- Easy to maintain.

Design and parameters of AGV

The main element of the AGV boiler is the tank. Through it, heated water enters the heating system of the house. When gas burns, the flame tube heats up - a heat exchanger built into the tank (can be compared to a samovar). The flame tube transfers heat to the water in the tank. It has a connection with the chimney, through which combustion products escape. The automatic device is connected to a valve that turns on the gas supply. In this way, the temperature of the coolant in the heating tank is maintained.

The heating network is assembled from the following elements:

- expansion tank;

- pipeline (upstream);

- radiators;

- distribution line (upper);

- return line.

Heated water, since it is lighter than cold water, rises through the pipeline, enters the radiators, cools, returns to the return line, again ending up in the heating tank. The movement of water in the system creates a difference in the height of the heating tank and the radiator, where heat transfer occurs.

AGV boiler structure

This type of heating system is called thermosiphon, gravity, gravity. Water circulates naturally in the system, forming a closed circuit. When the system is in operation, the coolant heats up and increases in volume. Excess water flows into an expansion tank mounted at the highest point of the line. Through the overflow tube, excess water from the tank flows back into the network. Due to the water from the tank, the losses of the coolant that are in the system are compensated, and since the expansion tank communicates with the atmosphere, the pressure in it is equalized.

The main burner AGV-80 was made of cast iron, later it was made of steel

The main indicator of heating equipment is power. However, another parameter is encrypted in the name of the model - the tank volume, which is 80 liters.

Important technical characteristics include:

- The heating time of water in the tank is 60-70 minutes.

- The temperature range of the liquid is 40-90°C.

- Efficiency is 80%, in modern versions it is higher - up to 85%.

- Thermal power - 7 kW (and heating output - 5.7 kW). The heated area is small: even with minimal heat loss, it is 60 m². Therefore, the boiler is suitable for small country houses or city apartments that cannot be connected to central heating.

Gas consumption is small, but given the low (compared to modern boilers) efficiency, this characteristic is unimportant. Despite the spacious tank, the model does not take up much space. With a height of 1560 mm and a diameter of 410 mm, it is easy to find a suitable area for the device. The total weight of the equipment is 85 kg.

AGV heating: what it is and how it works

Over the past decades, new modifications of devices have appeared; the popularity of modernized AGVs has become less than in the last century, but they are still widely used as autonomous heating systems for houses. The boiler is connected to batteries. It provides the house with heat and, if desired, can be used for hot water supply.

The appearance of the first AGV models was not aesthetically pleasing, but they did an excellent job of heating small houses

Operating principle of AGV heating

The operating principle of the device is very simple: the gas heats the heat exchanger, which in turn transfers thermal energy to the water in the container. Combustion products are discharged outside through the chimney. The heating system consists of pipes, an upper distribution line, a return line and an expansion tank.

Water circulation occurs naturally due to differences in altitude and temperature. Warmer water rises to the top, enters the radiators, where it is cooled, after which it descends and returns to the AGV.

To compensate for the difference in the volumes of warm and cold water, an expansion tank is needed. The excess flows out of it through a special overflow tube.

This avoids excess pressure in the heating system.

Automation and security

The AGV is equipped with simple automation that opens the gas supply valve. The automation is triggered when the water temperature in the tank drops below a preset level or the pressure in the pipes decreases, the burner goes out, and the chimney becomes clogged.

The AGV-80 model has a simple safety system, thanks to which water is drained if the membrane breaks. This is not very convenient, because... in such cases, the valve must be completely replaced. In the AGV-120 the problem is eliminated: the device is equipped with a special cylinder with a bellows temperature regulator.

The modernized model is more convenient than the previous one, since it allows you to regulate the water temperature; the AGV-80 does not have this option.

AGV design diagram

Design Features

The main elements of the boiler are:

- galvanized tank with a volume of 80 liters, the walls of which are not subject to corrosion;

- heat exchanger - a flame tube equipped with a heat flow extension and passing through the center of the tank;

- the main burner that ensures the operation of the coolant;

- devices for ensuring automatic safety (thermocouple, solenoid valve, igniter, draft sensor, thermostat);

- valve for supplying gas to the burner.

The boiler design includes thermal insulation of a galvanized tank. Mineral wool is used for these purposes.

The solenoid valve controls the flame. The part consists of gas and electromagnetic parts, between which a membrane is placed. The thermocouple is a soldered structure made of metal wires chromel and copel.

If the required temperature is maintained at the junction of dissimilar conductors that are connected in series, then a closed circuit with thermoelectric current is obtained. The work is based on the Seebeck effect: a thermocouple heated during gas combustion creates an electric current. The latter ensures the operation of the automatic protective component.

More complex modern modifications of boilers are also produced:

- AOGV - single-circuit models intended only for heating;

- AKGV are combined devices that allow you to additionally obtain hot water.

Despite the fact that many details have been improved, both models are practically no different in design from their predecessor.

AOGV uses a complex thermoregulation system to control temperature, which includes special sensors and valves. As soon as the indicator reaches a predetermined value, automatic devices are activated and the gas supply is stopped.

The system operates from an electric current created using a thermocouple. Expensive versions of AOGV use thermostats that give a warning signal for the owner to adjust the temperature. The AKGV boiler is equipped with the same sensors for convenience and safety.

⇐ PreviousPage 7 of 10Next ⇒

The solenoid valve is the basis of the automatic safety system, which ensures that the gas supply is stopped when the igniter goes out. There is also an automatic system that ensures that the gas supply is stopped if the draft in the chimney is disrupted.

When it is triggered, the gas supply to the igniter first stops, and then the solenoid valve closes. This principle of automatic operation is called “with gas removal from the igniter.”

The solenoid valve works together with the thermocouple.

Gas path of the boiler

The boiler design includes a fan that forces combustion air into the boiler furnace forcibly. The pressure created is sufficient for the combustion products to be forced through the heat exchanger, leaving through the chimney. This is a closed type of firebox. Here the volume of air is as close as possible to the ideal volume, due to this the amount of heat going into the flue is minimal.

Some boilers involve creating the draft necessary for combustion using a chimney. This is a type of boiler with open fireboxes; it makes the design somewhat cheaper. But when there is no fan in the boiler, the efficiency indicator decreases, and the requirements for the pipe increase. For example, for boilers with a fan, the chimney can be routed vertically through the wall, but for a boiler with an open firebox this is not possible.

What are the requirements for installing a gas boiler, see here.

Floor-standing boiler OAGV (Lux non-volatile)

By using the energy of the gases escaping through the coaxial chimney, it is possible to supply already heated air into the boiler. If the air temperature in the combustion furnace is increased, this is beneficial for the process itself: ignition improves, the torch burns evenly, without prolonging the combustion, this ensures better heat removal.

In reality, the increase in temperature for this reason is not too noticeable if cold air comes from the street. But overall efficiency indicators increase, since savings are achieved by heating the air that enters the house ─ the boiler sucks air from the room and exhausts it through the chimney.

Advantages and disadvantages

AGV heating using boilers of this type can significantly increase the comfort of living. Like any technology, they have their own set of advantages and disadvantages.

- Energy independence. The boiler does not require a connection to electrical networks; it will work all the time as long as there is gas in the pipe.

- Simplicity. Pipe, burner, tank. Operation is possible by unqualified personnel, which reduces its cost.

- Optimal efficiency - at higher values, condensate will flow through the pipe, at lower values, heating costs will increase.

- Relatively small in size.

- Acceptable price.

- Outdated design.

- Condensation of moisture from the atmospheric air on the bottom mirror of the boiler and a leak, which can extinguish the burner. The effect is observed until the coolant reaches a temperature of 25-30 0 C.

- To completely interrupt the gas supply, the thermocouple must cool down. This takes up to a minute, which can be fatal in an accident.

- Ergonomics are not very good - pipelines and controls are open. It is difficult to coordinate the boiler with the interior design.

- To ignite the burner, you need to handle an open flame, which in itself is dangerous.

Automation

You can choose a budget option aimed at reducing gas in the absence of owners. This mode avoids the danger of the system defrosting in cold weather.

A modern AGV boiler is equipped with many sensors providing a high degree of automation

Sensors on the boiler allow you to notice malfunctions and accurately determine the system that has failed so that you can promptly fix the problem. The AGV automation controls the shutdown of the gas supply if the chimney draft is disrupted, when the gas pressure drops, or when the pilot flame goes out.

Types of heat exchangers

The main heat exchanger of the boiler can be made of different materials:

- A stainless steel heat exchanger is used in wall-mounted boilers.

- The steel heat exchanger is designed for economy class boilers.

- A cast iron heat exchanger is used in floor-standing boilers.

- The steel heat exchanger belongs to the low price segment, but its performance characteristics are appropriate. Heat exchanger made of stainless steel or cast iron occupy equal positions. Moreover, the latter option has good heat capacity, and the first has a more advanced design and manufacturability, which determines their floor or wall location.

New generation of AGV

The AGV manufacturer was in no hurry to discontinue its popular boilers due to obvious advantages. However, technical progress also affected this equipment: during modernization, significant changes appeared in their design:

- Unreliable glass thermometers have been replaced with durable Italian ones.

- The new systems are equipped with automatic equipment from the American company Honeywell.

- To turn on the device, a piezo lighter is used with the handle.

- New coating technology has improved the appearance of the boiler.

Boiler AGV 80 technical characteristics are impressive

What is the difference between AGV and AOGV

AGV boilers from the city of Zhukovsky can be considered the same technical rarity as UAZ cars. Moreover, they are similar in reliability and ease of operation.

Initially, gas boilers AGV-120 and AGV-80 were produced. The number in the abbreviation is the volume of water in liters. It characterizes the power of the boiler, which is convenient for the average user, since the number coincides with the maximum possible heated area.

Modern gas boilers AOGV (the abbreviation stands for “Gas Water Heating Unit”) are more efficient devices, the power of which ranges from 11.6 to 29 kW. The number in their model index indicates precisely this parameter, and to determine the possible heated area it must be multiplied by 10. Their design has undergone slight changes. For example, the flame tube is made cone-shaped and divided into three sections (number 3 in the index), which made it possible to increase the efficiency of the device from 0.8 to 0.9. In addition, some models are equipped with an additional water circuit (water heater) used for hot water supply. Its presence is indicated by the letter “K” in the index - AKGV.

For user convenience and expanded choice, boilers are available in three types of equipment:

- Economy - all fittings and automation are made in Russia.

- Station wagon - imported automation is used in the most critical units.

- Comfort - all fittings and automatic devices are made in Italy.

Table. Technical characteristics of AOGV boilers produced by Zhukovsky Machine-Building Plant

Installation option for AGV in a private house

A room is allocated for the unit in the lower part of the building. The ascending section of the pipeline needs insulation. The reverse part should not be insulated.

The AGV boiler should be installed in a separate room (AGV 80 boiler)

The pipeline for the return part of the network is laid at the floor level of the rooms. If you lay it over door jambs, this can contribute to “airing” of the system.

Two-inch pipes in a home network are not entirely aesthetically pleasing, but when trying to replace them with pipes of a different diameter, one must take into account that as the diameter of the pipe decreases, the hydrodynamic resistance increases, weakening the water pressure in the system and the efficiency of the boiler.

AGV boiler connection diagram

During installation, the pipeline is installed with a slope of 1 cm for each meter of its length. This technique prevents the appearance of air locks in the system, improves water circulation and makes it possible to drain water from the system.

Precautionary measures:

- If the water temperature in the system drops to +50 degrees, abundant condensation appears, which can even extinguish the burner.

- When mixed with combustion products, condensate releases nitric and sulfuric acids, causing corrosion of equipment.

- As the temperature of the coolant in the system drops to +50 degrees, its circulation in the system stops completely.

- If the boiler is not used in winter, the water from the system must be drained, however, this option significantly increases corrosion.

- You can use hot water without heating the entire system; to do this, use a tap that shuts off the circulation in the heating system. And if you connect the forward and return lines, the turnover is maintained.

Criteria for selecting AGV boilers

When analyzing the options, it is necessary to take into account the characteristics of the boiler and the features of the room:

- The area of the house that needs heating.

- Climatic zone.

- The probability of heat loss associated with the use of specific materials during the construction of a building.

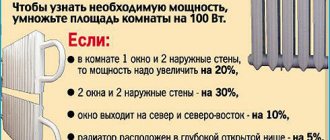

- The choice of power for the AGV boiler is determined by the heating area. Standard power values ─ 35 kW, 29 kW, 23.2 kW, 17.4 kW, 16 kW - 11.6 kW, etc. Calculation of power for your boiler: for 1 kW of AGV power there are 10 sq. m of room area.

The AGV boiler in the heating system is the main component, therefore the choice of the AGV model will be decisive

If the house is located in a region with harsh winters or is built from materials with large heat losses, then 25% of the power is added to the calculated power of the AGV.

Until recently, the most popular AGV boilers were the AGV-120 and AGV-80 models, the technical characteristics of which can be compared in the table. They use the gravitational principle of water circulation. They are produced in two types:

- Single-circuit (used for heating).

- Double-circuit (additional function - hot water supply).

Options

Boiler type AGV-80

- Thermal power, kW - 7

- Heating capacity, kW - 5.7

- Tank capacity, cubic meters dm - 80

- Time to heat water up to 90 degrees, min. — 60-70

- Heating temperature range, degrees C – 40-90

- Heated area, sq. m - up to 60

- Efficiency,% - 85

Boiler type AGV-120

- Thermal power, kW - 14

- Heating capacity, kW - 11.3

- Tank capacity, cubic meters dm - 120

- Time to heat water up to 90 degrees, min. — 60-70

- Heating temperature range, degrees C – 10-90

- Heated area, sq. m - 85-100

- Efficiency,% - 85

Today, the outdated gas boiler AGV-120 and AGV-80 has been replaced by new boilers such as AOGV (gas water heating apparatus) and AKGV (complex gas water heating apparatus). The most popular of them are models AOGV-17.4−3 (designed for heating a room with an area of 100-140 sq. m) and AOGV-23.2−1 (designed for heating a room with an area of 140-200 sq. m). The AKGV-23.2−1 unit has the most advanced characteristics, which has the ability to heat a room with an area of 140 - 200 square meters. m, plus hot water supply.

Gas boiler AGV 120

Typically, the consumer chooses dual-circuit models. But with all their advantages (cost-effectiveness, accessibility, two circuits), they have one drawback - the constant availability of a source of electricity.

For consumers with higher incomes, the market offers AGV boilers from well-known world brands:

- BAXI and FERROLI, which are distinguished by their improved design and the ability to set parameters electronically.

- RINNAI ─ Japanese quality and reliability, simplicity and convenient operation.

- ANIERIA ─ are Korean economy-class boilers, characterized by high reliability and affordable prices.

- The listed imported models are distinguished by higher efficiency; they all require a mandatory connection to a source of electricity. In regions where frequent power outages are the norm, this condition may be decisive when choosing an AGV boiler.

Another important criterion for choosing a boiler model is price and maintenance costs. Domestic AGV boilers are several thousand rubles cheaper and their operation costs up to 35% less.

Since gas still remains the most affordable energy resource, heating premises using AGW has not lost its relevance. At the same time, an additional advantage will be the autonomy and relative low cost of operating such equipment. Have a warm winter with AGV!

Old gas heating boilers versus modern models

» Automation and controls » Why and how automation is needed on old-style gas boilers

The newest models of gas boilers are characterized by high power and heating speed. However, their prices are steep, to put it mildly. You can try to use a more economical option and install new automation on the old boiler or fix the old one. The operating principle and automatic design of old-style gas heating boilers will be explained in this article.

- 1 Why do you need gas automation?

- 2 The principle of operation of automation on old-style gas boilers

- 3 Basic elements of automation

- 4 Flame and draft sensors

- 5 The most common automation malfunctions and methods for eliminating them

Why do you need gas automation?

Old-style boilers were manufactured in accordance with the gas parameters and heating system features that were in use several decades ago. These are, for example, models KChM, AOGV. At the same time, their durability allows them to be used for many years to come. But the problem with automation is that quite often it breaks down. In such a situation, there are three options:

- diagnose existing automation and replace the necessary parts;

- equip a reliable and high-quality unit with a modern automatic system;

- buy a new boiler.

The difference, of course, is in the price of the issue, the effort and time of the owner.

Let's consider the cheapest option - troubleshooting gas automation on an old boiler. However, first, let’s figure out why an automatic system is provided in the coolant in general.

Gas automation allows you to regulate and maintain the required level of coolant temperature, and also serves to automatically stop the gas supply in an emergency situation. Installing automation on an old gas boiler will allow you to be sure that if the burner flame goes out, then after a short time the system will work to stop the gas supply without your participation.

Attention! Automation, in addition to regulating and maintaining the temperature at a given level, ensures the safety of using the heating device and allows you to save on heat consumption.

If you want to change the automation, keep in mind that domestic manufacturers produce models that are suitable for almost any old coolant. Imported automation cannot be installed on everything. In addition, when installing foreign automation on old-style gas boilers, not all of its functions may work - the design features of the boiler will not allow it.

On a note! The choice of automation for gas boilers is varied. The most popular is the system from Italian manufacturers, for example, SIT. American automation (Honeywell) holds second place in popularity. There is a large selection of Russian (SABK, "Orion") and Ukrainian, "Iskra", "Plamya", APOK-1).

Model overview

The AGV 120 gas boiler model differed only in its greater power. It had all the shortcomings of the basic device, so it cannot be called next-generation technology. Not the most successful internal design led to a situation where part of the received thermal energy flew out into the chimney along with combustion products.

It was possible to eliminate this defect independently by changing the firebox design, but such a modification was associated with a certain risk. If the calculation was incorrect, it was possible to achieve an effect where the exhaust gases stopped being released into the atmosphere and remained directly in the room.

In this case, the whole procedure had to be carried out again.

The AGV 23 gas boiler was a more successful modification. It did indeed eliminate some of the shortcomings, making it more ergonomic and easy to use. Among the main improvements it is necessary to note:

- — lower noise level during operation;

- — improved automation, which has become more functional and reliable;

- — by changing the principle of chimney installation, it was possible to slightly increase the level of efficiency and the overall operational efficiency of the unit;

- — the burner received protection from condensation, which in previous models could easily extinguish the flame.

In general, AGV gas heating boilers were a very successful invention for their time. They allowed people to switch from solid fuel systems to more modern and convenient gas analogues.

This was an important step towards the complete abandonment of environmentally harmful heaters. Now solid fuel models in everyday situations are used only in extreme cases.

Most users switched to gas or electric systems.

The price of AGV gas boilers is negotiable. They have been discontinued for a long time, so you can only make a purchase on the secondary market.

The principle of operation of automation on old-style gas boilers

Frequent problems when heating a room with gas boilers are flame attenuation in the burner and gas pollution in the room. This happens for several reasons:

- insufficient draft in the chimney;

- too high or too low pressure in the pipeline through which gas is supplied;

- the flame on the igniter goes out;

- leakage of the pulse system.

When these situations arise, the automation is triggered to stop the gas supply and prevent the room from becoming gas-filled. Therefore, installing high-quality automation on an old gas boiler is basic safety rules when using it to heat a room and heat water.

All automation of any brand and any manufacturer has one operating principle and basic elements. Only their designs will differ. Old automatic machines “Plamya”, “Arbat”, SABC, AGUK and others work according to the following principle.

When the coolant cools below the temperature set by the user, the gas supply sensor is activated. The burner starts heating the water.

After the sensor reaches the user-specified temperature, the gas sensor automatically turns off.

On a note! When using modern automation, it is possible to save heat up to 30%. Old-style automation is non-volatile and does not require electricity. Its adjustment, connection and disconnection are carried out by a person. Commands are transmitted using electromagnetic pulses.

tells how the automation of gas boilers AOGV, KSTG works.

An example of a retro boiler - AGV-80 and modifications

AGV-80, the photo of which is shown above, belongs to the old type of heating boilers. It has one circuit (heating water for domestic needs). Production of the model began in 1939 at the Zhukovsky Machine-Building Plant. The reason for this was the mass gasification in the USSR and the use of gas for heating domestic premises.

The boiler is a cylinder on three legs, in the upper part of which there is a chimney pipe. The cylindrical tank is made of steel, sealed, with a volume of 80 l.

Inside the tank is a flame tube, under the mouth of which an atmospheric burner is installed.

To reduce the speed of heated gases escaping into the pipe and increase the degree of heating of the tank walls, a turbulator is mounted inside the pipe. The efficiency of the device reaches 80%.

Equipment:

- thermometer;

- traction fuse.

When the pressure drops or the maximum water temperature reaches, these devices allow you to shut off the gas supply.

The design of this boiler served as the basis for the company's developers to produce improved models AOGV (for CO) and AKGV (with two circuits), the efficiency of which is up to 89%.

In addition to a similar design, the new generation gas boilers include:

- coil (for supplying water for household needs);

- the flame tube is divided into sections, each of which contains a turbulator;

- traction sensor;

- air regulator;

- automatic start;

- automation unit for regulating boiler operation and temperature.

Construction of the AVG-80 boiler

Basic elements of automation

The main elements of automation for a gas boiler are: