All modern gas boilers are equipped with electronics. For normal operation of the equipment, a control board is required. If malfunctions occur, the automation gives a signal and an error code is indicated on the screen of the gas boiler. The operating instructions for the gas boiler describe the causes of errors. Let's look at the most popular error e01 in Baxi gas boilers in this article. In our store you can buy gas equipment.

Resetting error e01 in a Baxi gas boiler

Before you start troubleshooting the problem yourself, you should study the instructions for use and recommendations from the manufacturer. If you are not confident in your abilities, it is better to contact a qualified specialist.

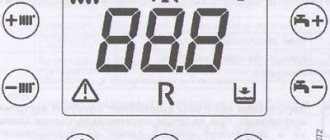

This error is serious and does not allow the equipment to continue operating without its elimination. You need to reset the error by pressing and holding the R button for a few seconds. After this, the gas boiler should be started as usual.

Automation

Automation for boiler equipment is very diverse. Some of it is preinstalled by the manufacturer. This category includes all sensors and electronic devices that ensure the safe operation of equipment.

The simplest example is a sensor that monitors the normal gas supply. When the gas is turned off, the sensor is triggered and the boiler automatically turns off. Restart will occur after the gas supply is restored.

Systems that ensure operational safety also include:

Boiler structure

- Frost protection (starts to work if the outside temperature is below 5 degrees).

- Protection against blocking of circulation pumping equipment.

- Protection against blocking of the three-way mixing valve in case of long-term equipment downtime.

- Protection against scale formation in the heat exchanger and boiler.

- Overheat protection.

- Voltage protection in the electrical network.

- Control of stray flames.

- Combustion and draft control.

- Coolant pressure control.

In addition to the pre-installed automatic systems, you can install additional electronics:

- Outdoor temperature sensor.

- Room temperature sensor.

- Thermostat.

- Electronic thermostat.

- Remote panels.

- Weather dependent sensors.

- Elements for remote control.

- Water quality sensors, etc.

Boiler Baxi mainfour 240 f error e01

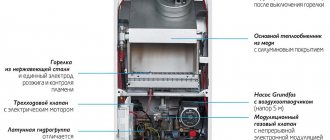

This model of gas boiler includes a fourth-generation bithermal heat exchanger. The difference between this unit and the 24 brand boiler is the white display panel.

The Baxi mainfour 240 f gas boiler is single-circuit, which is equipped with a fan for forced removal of combustion products. The equipment of these elements is indicated by the letter F.

The operating principle and ignition scheme of this model are the same as those of other Baxi gas boilers. If error e01 occurs, you should follow all the recommendations that we will discuss in this article.

A little more about electricity

In addition to the need for grounding, there are other nuances when connecting boilers:

Baxi luna 3 comfort 240 fi

- Gas boiler equipment ensures stable operation in the range of 170-250 V. When the voltage drops, the boiler turns off, and when the voltage rises, the varistor burns out.

- The sinusoid in the power supply must be free of interference. Such devices do not tolerate power surges well. Experts recommend connecting additional voltage stabilizers. You should not use UPS for installation of gas heating appliances.

- The connection must have a separate machine.

- For phase-dependent models, it is important to ensure that zero and phase match.

Boiler Baxi Eco Four 24 f error e01

The Baxi Eco Four 24 f heating boiler is a double-circuit turbocharged boiler with a closed combustion chamber. One can highlight the difference from the previous model - a second plate heat exchanger for heating water.

The main cause of the boiler ignition error may be a malfunction of the electronic board. For an accurate diagnosis, you must contact a qualified specialist.

In this model, the ignition element is located on the board, and it is difficult to independently identify the cause of the error. The eco four and main four electronic boards can be replaced and customized for a specific model using parameter settings in configuration mode.

You can buy spare parts for Baxi gas boilers from us.

Briefly about the main thing

Baksi gas boilers do an excellent job of heating a home and last a long time if used correctly. Errors e01, e03, e10 that occur can often be corrected independently without the help of a service specialist. In some cases, it is necessary to increase the pressure in the heating circuit, in others, to check the serviceability of the power supply. Self-checking the sensors and electrodes will also help determine the cause of the error. Knowing the mechanics of the boiler’s functioning, you can easily eliminate the malfunction that has arisen.

Why does error e01 occur in a Baxi gas boiler?

Most often, this error indicates a failure to ignite the burner of the heating equipment. This signal comes from the flame control sensor. This element is an electrode that detects the presence of a flame and stops the operation of the gas unit if the combustion of the main burner is incomplete or gas supply interruptions occur.

Let's look at the main reasons for the error:

- No signal or poor signal contact with the flame control sensor.

- There is no gas supply to the system or insufficient pressure.

- The flame control sensor has failed. May occur due to breakdown or contamination.

- On phase-dependent models, the power supply may not be connected correctly.

- Insufficient air for normal combustion. For example, the intake pipe is clogged or there is no draft.

- Control board faulty.

If 3 unsuccessful starts occur, the boiler is blocked. In order to restore operation, you must hold the R button for several seconds.

You can find some possible causes of the error yourself. For example, the presence of contamination and air access, contact with the sensor. If after eliminating the error the error appears again, it is recommended to contact a specialist.

Error e03. Checking chimneys.

First of all, it is necessary to carry out a visual inspection of the chimneys.

It happens that the head of a coaxial chimney at the outlet can be equipped with a fine mesh to prevent the entry of large objects. In winter, when conditions are created for the formation of frost and this mesh is covered with frost so that air intake completely stops. The formation of ice or icicles is not a rare occurrence; ideally, when designing the boiler installation site, even the wind rose of a particular region should be taken into account.

If we are talking about the summer period, then the reason for the “narrowing” of chimneys may be spiders making webs or birds making nests. Here, I think everything is clear.

Carefully inspect the intake pipe and the air outlet pipe, if there are no obstacles there, you can proceed to consider the following possible causes of error e03 baxi.

Incorrect gas boiler power connection error e01

In any Baxi gas boiler, it is necessary to observe the polarity of the phase and zero connections. If the equipment was connected incorrectly, error e01 will appear. To check, you should turn the connection plug over or check the corresponding connectors on the board. The first option is the simplest.

Do not forget about grounding the gas boiler. In accordance with the PUE standards, all metal elements must be grounded. If the work is performed incorrectly, problems with electronics may occur.

Check what

Settings

If error E99 is displayed after replacing the boiler EP, the corresponding adjustments have not been made in the menu. The procedure for the Baxi model is described in the instructions.

Electrical network parameters

The manufacturer guarantees trouble-free operation of the Baxi boiler, provided that the requirements of the PUE are met and the voltage corresponds to the value specified in the unit passport (~230V). Error E99 is triggered by internal board failures in areas with intensive development, in houses whose power supply is supplied through an outdated substation that is not designed for the increased load. When connecting the Baxi boiler to an autonomous source, the network parameters must be monitored. If a diesel or gasoline installation produces voltage with U and f that do not correspond to standard values, incorrect operation of the board and errors E97–99 are inevitable.

Advice

Problems with incorrect functioning of the power supply in the city electrical network are eliminated by connecting the Baksi boiler through a UPS. The unit, in addition to voltage stability, guarantees reliable operation of Baxi in autonomous mode even in the event of a line failure. For owners of suburban properties - a rational solution.

Tips

The presence of potential where, by definition, it should not be, causes malfunctions in the electronic board, error e99. The reasons for the appearance on the metal parts of the boiler are different: a nearby power line or other source of EM radiation, wear of the insulation of the power cable. Testing the equipment is simple and is done using an indicator screwdriver. The LED indicates the presence of voltage at U = 55 (±5) V, causing an internal ED problem and error e99.

Interference also appears when the Baksi boiler is not properly grounded. It is organized according to the PUE, and there is a corresponding section in the instructions for the unit. Violation of the rules is the cause of electronic failures and error e99.

one dielectric coupling

Signal line

We are talking about the gas valve/electronic board circuit. Contact failure, breakage, melted insulation leading to a short circuit are the causes of error e99. A visual inspection of the insides of the Baxi boiler is not enough: the condition of the connector is assessed. Burnt contacts and oxides can be easily eliminated on your own. In practice, it is enough to undock and connect 3-4 times, and code 99 disappears.

Oxidation of contacts in a Baxi boilerMalfunction of the flame control sensor in the Baxi gas boiler

Some manufacturers recommend changing the igniter. But this is not necessary in all cases. The igniter may need to be replaced depending on gas quality, air pollution and conditions of use.

It is necessary to inspect and clean the electrode if necessary. This can be done with an alcohol solution, and then check the gap relative to the burner body and the correct position in accordance with the instructions. Each Baxi gas boiler model may have different requirements.

The flame control function is performed by the ignition electrode. The main function of the gas boiler safety system is flame control. It is necessary to automatically shut off the gas if the flame on the burner goes out. The operating instructions indicate the required gap that needs to be set.

The flame monitoring function consists of recording a small current that flows through the electrode during combustion. Since the flame structure contains an air gap, if the gap is small, the flame will not be registered, and, consequently, an accident will occur when the gas boiler operates at a certain power.

The electrode cannot be bent, as in most cases it breaks off.

Dimensions of components

When calculating the required amount of material, you should take into account not only the dimensions of the siding, but also the dimensions of its components. Basically they are the same as the panel, but the sizes of some elements may differ. For example, the length of the “G-trim” strip for most brands corresponds to the size of the siding. The finishing material “Doke” does not comply with accepted principles. In this case, the “J - trim” strip is only 3050 cm. Based on these individual features inherent in some elements, we can say that the characteristics below are considered common to all vinyl siding. It is recommended to check specific dimensions with the supplier or see the technical description of the official manufacturer.

- External corners – 3.05 m;

- Internal corners – 3.05 m;

- Starting bars – 3.66 m;

- Finishing bars – 3.66 m;

- Connecting strips – 3.05 m;

- G-trim planks - 3.66 m;

- Window trim strips – 3.66 m;

- Hanging strips – 3.66 m;

- Near-window strips (slopes) – 3.05 m;

- Soffits – 3.66 m.

As mentioned earlier, the general technical characteristics are average for all types and sizes of vinyl siding, therefore, in order to more accurately calculate the required number of components, it is recommended to check the dimensions of a specific manufacturer ahead of time. This is necessary in order not to make a mistake in the calculation, since when purchasing excess material there will be no one to blame. You can only hope that the seller will accept the excess back, but this is not practiced in all stores.

Advice from the “façade designer”

You should not purchase products from a little-known brand at an inexpensive price. This may be due to the low quality of the product. Often the thickness of cheap vinyl siding is so small that there are through holes in the panel, which renders it unusable.

Thanks to a wide selection of color shades and various sizes and textures, vinyl siding can satisfy almost any design solution for facade finishing.

Control board fault error e01 Baxi

If all checks have been made and the cause has not been identified, then it is necessary to diagnose and then repair the gas boiler board. In Baxi equipment, the board contains modules and an ignition unit, which are responsible for modulating the flame. If these elements fail, error e01 will appear. For diagnostics, it is recommended to consult a specialist.

If the cause of error e01 is a malfunction of the electronic board, then you need to contact a service center, where experienced specialists will perform all the work in accordance with safety standards and regulations.

In our online store you can buy a Baksi gas boiler.

Valve clicks

Gas valve clicks can be observed for various reasons - from a weak contact on the relay, to a difference in gas pressure in the main line and the boiler valve system. In each case, solving the problem requires its own actions.

Restore the gas valve relay contact group, adjust the minimum and maximum gas pressure, check the inlet reducer setting. All this work must be carried out by specialists from the service center; it is extremely dangerous to interfere with the operation of gas equipment on your own .

Decoding

The Baksi manufacturer's instructions speak about error e04 in general terms: lack of ignition or frequent flame failure, but there is only one recommendation.

Error e04 on the Baxi boiler control panel

Its presence and the stability of the combustion process are monitored by an ionization sensor (current). Knowing that the boiler’s operation is blocked after 3 unsuccessful ignition attempts or six short-term flame failures, it becomes clear that it is impossible to unambiguously diagnose the reason for the appearance of this fault code. To reduce the time required to restore the functioning of the heating unit, this procedure is recommended.

Step 1

Restarting the Baxi boiler: by pressing (holding for at least 2 seconds) the R button on the control panel. If error e04 is caused by a random factor (power failure or other), it will disappear.

Reset error e04 on the Baxi boiler control panel using the reset button

Step 2

Checking the burner operation. When starting the Baksi boiler, characteristic clicks are heard as a spark jumps between the ignition electrodes. If the ionization sensor detects a current whose value is 6 times lower than the operating one, the control module generates an emergency stop error with code e04. The flame is easy to see through the viewing window. Its instability, small tongues, and uncharacteristic shade are regarded by the boiler automation as a violation of the combustion process and gives a command to activate the protection.

The baxi boiler works like a fireplace.

Step 3

Checking the ionization (flame) sensor. Baksi boilers are reliable heating installations, and the vast majority of problems that arise are not related to the equipment, but to external factors or incorrect user actions during operation.

Baxi boiler ionization sensor

Electronics

The heart of the boiler is complex electronics. It is this that ensures the normal operation of the device and will turn it off in the event of a malfunction. The automation will report problems to the owner by displaying an error code. These alphanumeric codes are essentially a description of the problem. They talk about what is broken in the operation of the unit and how the situation can be corrected.

Before talking about the most common error codes, it is worth recalling that independent intervention and repair attempts are not the best solution. Correcting problems without the intervention of a specialist is permissible only within the limits limited by the manufacturer’s instructions.

The advantage of domestic speakers

There are many types of faults, so it is easier to find domestically produced parts. Therefore, speakers made in Russia, such as Neva, are in great demand.

And the newer model “Neva 4511” consumes even less gas and is completely silent.

A gas water heater called “Oasis” is in demand, which can operate at low pressure and is protected from scale.

It is also equipped with a safety system that blocks operation if the column overheats.

There is a spark, but no ignition

When this dilemma arises, the following factors appear:

- The valve responsible for the gas supply is closed. Measure - twist it all the way.

- Low water pressure. It may be not only in the main line, but also at the inlet section of the boiler, where the filter may become clogged.

- The water is slightly fixed annuity interest rate heated. Solution: cleaning the heat exchanger (HE). Fastenings on which plaque has accumulated can be cleaned using VD-40, and the radiator can be placed in a basin with a composition based on citric acid. Then heat on the stove for half an hour until the scale disappears completely.

- The burner is clogged. Sometimes a lot of soot and soot appear in the jets. You can get rid of it using a thin copper wire.

If the piezo did not work in the Electrolux geyser or other similar equipment, then you should periodically check it for gas leaks using a soap emulsion. If there are no bubbles, then everything is fine.

Cleaning the primary and secondary heat exchangers

First, you need to remove water from the heating device. There is a tap on the right side of the boiler; if you unscrew it, the liquid will be drained. It would also be a good idea to drain the heating system. For cleaning, a special washing device is used. The pipes are connected to the pipes of the gas boiler. Then the cap on the flushing device is unscrewed, and then the cleaning liquid must be poured inside. After this, you can connect the device to the network.

Cleaning the heat exchanger is a slow process and can take several hours.

During this time, it is necessary to switch the direction of the rinsing fluid. After two to three hours, you should stop cleaning. After this, the tap is opened and the water is drained, and then the hoses are removed. When doing this, you need to be sure that all the liquid has flowed into the device. After all the manipulations, the boiler is reconnected to the heating system. The pipes are filled with coolant. Washing the device parts should dissolve the scale, which will increase the life of the system and optimize its operation.

Similar to the primary one, to clean the secondary heat exchanger, you need to attach a flushing device to the boiler. After connecting it to the network, you need to close the gas tap and move the hot water tap to the open position. Then turn on the cleaning device so that the reagent moves along a short circuit.

To install Baksi gas equipment, you should definitely use the services of gas service workers. They will also help in case of a malfunction in the boiler. Parts of heating devices from this company can also wear out over time, so sooner or later repairs will still be inevitable.

General recommendations

In the table, we tried to collect information about all the errors that their self-diagnosis system can detect. Keep in mind that some of them are specific to a particular equipment model and may not occur on other boilers.

In addition, with the advent of new models of equipment from Baxi and changes in their design, the list of possible errors and their codes may change. Therefore, it is highly recommended to have a user manual written specifically for your model on hand.

The elimination of the vast majority of errors in the operation of boilers should be entrusted only to competent specialists with the appropriate experience and knowledge. Independent intervention in the boiler design can lead to more serious damage to it, as well as to emergency situations.

In general, as practice shows, Baxi boilers are highly maintainable, so any of the errors mentioned above can be eliminated without compromising performance. It is strongly recommended not to delay contacting the service department - the earlier a problem is identified, the easier it is to fix it.

In addition, do not forget to regularly carry out boiler maintenance - this work should also be entrusted to specialists from a specialized organization. The recommended frequency of such maintenance is at least 2 times a year. To more accurately determine the optimal frequency, you need to take into account the intensity of use of the boiler, its technical condition, model, age and other individual parameters.

How to fix the ignition yourself

Self-repair of household appliances or their components is a rather risky undertaking, since the likelihood of aggravating the problem is quite high. It is very difficult to repair the electric ignition of a gas boiler without special knowledge and skills. The device may fail due to contact with water or grease, power surges, or neglect.

The main sign of a device malfunction is the absence of a spark. If there is a spark, but the flame cannot be ignited, it is necessary to clean the contact areas of the burner and candle. If the electric ignition unit is broken, you should check the current-carrying paths and winding resistance. When repairing the ignition, new components may be needed.

Work algorithm

produces metal combustion chambers for its boilers. From the outside, the part is protected by a heat-insulating layer. Just above the chamber there is a copper heat exchanger. When the heated room becomes warmer or colder, the thermostat turns on. Its work is automated. The thermostat sends a signal to turn on the water pump. It begins to pump water by creating a vacuum in the pipes. Then warm water enters the pipeline.

When turned on, the boiler power increases gradually. This happens before the water temperature rises to the required value. Then the heating mode switches to modulation mode. When the coolant cools, the temperature sensor gives a signal to open the inlet valve. This starts the electric ignition, and the water temperature again reaches the desired level.

If the room does not require additional heating, the boiler starts operating in DHW mode. It consists in the fact that cold water enters the secondary circuit through a three-way valve, which, in turn, blocks the heating line. Gas is supplied to the burner using a special valve , and the power of the device gradually increases. When the water is already heated to the desired temperature, its adjustment mode is activated.