Today, gas heating is still the cheapest. Therefore, if there is a main gas pipeline and technical capabilities nearby, it makes sense to install a double-circuit gas boiler. Why dual circuit? Because one device will provide both heat and hot water.

The wall-mounted double-circuit gas boiler has the dimensions of a small cabinet

When choosing a double-circuit boiler, be sure to pay attention to several parameters:

- installation method: floor-wall;

- power;

- type of combustion chamber (open, closed);

- type of heat exchanger and material from which it is made;

- set of service functions.

There are many other points, but these are the main ones. Without them, it is impossible to choose a double-circuit gas boiler; we will talk about them further. First of all, let’s get acquainted with the structure of this equipment and the principle of its operation. Then all the stages of choosing a gas boiler for a house, apartment or cottage will be clear.

Floor-standing gas boiler and storage boiler nearby

Structure and main differences

A gas boiler consists of three main modules - a burner, a heat exchanger, and automatic control. The burner is located in the combustion chamber, above it there is a heat exchanger in which the coolant is heated. The entire process is controlled by automation. It ensures safety and changes the operating modes of the equipment.

Boiler with a closed combustion chamber (turbocharged)

Types of heat exchangers

A double-circuit boiler is distinguished by the fact that it can heat both water for heating and water supply. This must be done separately, because special heat exchangers are needed. There are two types:

- Double heat exchanger. It consists of two separate modules - primary and plate. In the primary, the coolant from the heating system is heated, in the secondary - plate - water for domestic needs. The primary heat exchanger is a tube with fins, the secondary is a set of plates. They are located in different parts of the boiler - primary at the top, plate at the bottom, but they are connected to each other so they can be read as a single part.

- Bithermal heat exchanger. It consists of two metal tubes of different diameters inserted into one another. In the inner tube, water is heated for hot water supply, in the outer tube - for the heating system.

The structure of a double-circuit gas boiler

A system with a dual heat exchanger is more reliable. Since heating is a closed system and the coolant circulates in a circle, little scale is formed. When heating water for hot water supply, the situation is the opposite - running water heats up, which means there is a lot of scale. This part of the heat exchanger periodically requires repair or replacement. If in a dual heat exchanger it is possible to replace only the part that heats water for domestic needs, then in a bithermal heat exchanger there is no separation; you have to change the entire device, and this is much more expensive. There is one more point: a double-circuit gas boiler with a double heat exchanger works normally for heating, but with a bithermic the situation is different - it does not work at all.

Heat exchanger material

The choice of a double-circuit gas boiler can also be influenced by the material from which the heat exchanger is made. It could be:

- Stainless steel. A good option in terms of durability, but it has rather low heat transfer, which reduces the efficiency of the boiler. However, the price of such a heat exchanger is high.

- Cink Steel. This is the cheapest type of heat exchanger, but also the most short-lived.

- Copper. An excellent option for heat transfer (boilers have high efficiency) and durability, but the price is high. But this scares few people - it outweighs the opportunity to pay less for gas during operation. It is for this reason that most good double-circuit gas boilers are equipped with a copper heat exchanger.

This is what the primary heat exchanger looks like in gas wall-mounted boilers

Choosing a double-circuit gas boiler based on this parameter is not so difficult. Copper seems to be the best option. Not without its drawbacks - high chemical activity and low melting point - but they have long learned to compensate for them. The boiler automation ensures that there is no overheating. Chemical activity is neutralized by using chemically neutral materials in the heating system - using polymer pipes - polypropylene or cross-linked polyethylene.

Types of burners for gas boilers

In wall-mounted double-circuit gas boilers, atmospheric gas burners are installed. According to the method of controlling the flame, they are:

- Single stage. The burner either burns or it doesn’t. There are no intermediate provisions. To maintain the required heating mode, the burner either lights up or goes out. Not the best working algorithm.

- Two-stage. There are two operating modes - at 100% power and at 50-60%. The automation itself regulates the required power. Such burners are more economical and allow you to maintain the temperature more accurately. By reducing the number of on/off switches.

Double-circuit gas boiler with modulating burner is the most economical

If we talk about the optimal choice, then these are modulating burners. They not only allow you to maintain the heating temperature accurately, but also heat the water exactly to the specified parameters. If you want to choose an economical double-circuit gas boiler, it must have a modulating burner.

Automation

Automation is a must in gas boilers - it ensures safety and switches operating modes. There are three main parameters that are constantly monitored:

- presence of draft in the chimney;

- gas pressure;

- flame control.

These are key points that simply need to be monitored. If at least one of these parameters is not normal, the boiler does not turn on. In addition, there is an extensive list of additional functions:

- Maintaining a stable temperature. There are two types of automation: one controls the temperature of the coolant, the second controls the air in the room. More comfortable conditions are created by controlling the air - the weather changes, but regardless of this, the set mode is maintained in the room.

This is the remote control from which all parameters are set

These are the functions that are common, but there are also specific ones: the ability to connect (and control) solar panels, underfloor heating systems. There is weather-compensating automatic control. In this case, there are remote sensors that are installed on the street. Based on their data, the operation of the boiler is adjusted.

Ferroli Diva gas boiler control panel

All these functions are embedded in the microprocessor, which controls everything. Of all the automation systems, the average user only encounters a remote thermostat, which can be installed in any room and based on the readings of which the temperature can be adjusted (another additional feature). Basically, all interaction with the boiler and its automation is limited to a small panel. All necessary information is displayed on the screen. There are also buttons with which you change modes and set the temperature.

Installation method

Depending on the installation method, gas boilers can be floor-mounted or wall-mounted. Wall-mounted - compact installations, the size of a small kitchen cabinet. They do not require equipment in a separate room and can be installed in the kitchen or other suitable room. The maximum power of a wall-mounted gas boiler is 30-35 kW. This is usually enough to heat rooms with a total area of 250-350 square meters. m.

Floor-standing gas boilers are more powerful and, accordingly, have larger sizes and weight. There are models that can be installed in a living space, while others require a dedicated room - a boiler room. Installation requirements are prescribed by each manufacturer separately, but usually the distance from the top of the boiler to the ceiling, the volume of the room and the presence of ventilation are specified.

Wall-mounted gas boilers are larger in size and weight, but this is due to their higher power

Regardless of the type, a certified project is required to install gas boilers. The diagram must include a gas meter, so if it is not there, you will need to purchase one. Connection work must be carried out by a company that has a license for this type of activity. Only in this case will the boiler be put into operation.

Selecting a double-circuit gas boiler based on installation method is simple. If there is enough power, they usually take a wall-mounted version, if not, a floor-mounted one.

Gas stove in the bathhouse

In bathhouses with gas mains, the use of a gas stove has become popular. It has practically replaced wood heating in bathhouses. Due to the fact that the gas stove has absolutely no waste after combustion, neither the chimney nor the heating box is clogged with debris, it does not require special care.

Construction of a gas stove for a bath

A gas furnace can be domestic, heating or heating. For a sauna, a brick heating stove with an atmospheric burner is usually used. As a rule, a brick stove takes longer to heat up than a metal stove, but it retains heat for a long time, while a metal stove cools down quickly.

It happens that preference is given to a metal gas stove because it looks more compact than a brick or stone stove. In such cases, it is faced with brick.

The gas burner can be inflatable or atmospheric. An inflatable burner uses electricity to operate, which is not very economical. An atmospheric burner is the most economical, because it works thanks to the air entering the plenum. The opening for the burner should have the following dimensions: width - 350-450 mm, height - 470-550 mm in height.

The principle of operation of a gas stove for a bath

A gas stove includes a thermostat, a gas chamber, a chimney and a system for automatically stopping the fuel supply in case of extinguishing. The operating principle of a gas stove is based on mixing air and gas, which you can independently regulate using the door through which the burner is cleaned.

It is important to know that natural gas has less heat output than propane. A gas cylinder of five cubic meters, which is placed in a specially designed container, can heat an area of up to 200 sq.m. during the heating season.

Foundation for a gas furnace

Before you make a gas oven with your own hands, you need to create a foundation.

We build the foundation of a gas bath stove in the following sequence:

Construction of a gas stove for a bath

The stove should be located so that it can heat not only the steam room, but also the relaxation room.

The procedure for making a gas stove for a bath looks like this:

Combustion chamber type

The gas burner is located in the combustion chamber. There are two types - open (atmospheric) and closed (with a turbine, forced). A double-circuit gas boiler with an open combustion chamber can only be installed in rooms with good ventilation. During operation, the oxygen necessary for combustion is taken from the room, and combustion products are discharged into the chimney with good draft. Therefore, a good air flow and a properly functioning exhaust ventilation duct are necessary.

Gas boilers come with open and closed combustion chambers

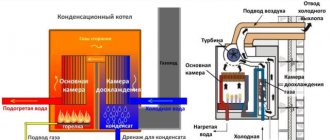

Gas boilers with a closed combustion chamber are distinguished by the fact that at the chamber outlet there is a coaxial chimney (pipe within a pipe) equipped with a fan. The chimney is taken out into the street, or into the wall near the boiler. Through one pipe, air is taken in from the street, through the second, combustion products are removed, their movement is ensured by a fan-turbine.

Which combustion chamber is better? A boiler with a closed combustion chamber operates more stably - air enters directly into the combustion zone. But there is also a disadvantage to this: with a side wind, the air flow can be so strong that it blows out the burner and the boiler turns off. The second disadvantage of this solution is freezing and the formation of ice in winter. Well, the third drawback is that such a boiler only works when there is electricity - without a turbine it turns off. Well, there is another small minus - the turbine is not silent. It’s almost inaudible, but it’s “almost.” Apparently for these reasons, if possible (a working ventilation duct), boilers with an open combustion chamber are installed. After all, ensuring a constant flow of air is much easier.

Choice

What are the characteristics of gas stoves intended for baths?

Stones

The traditional stove for a Russian bath - a heater - is distinguished by a large number of round stones placed in a tray. The tray is located above the firebox and, after lighting the stove, heats up quite quickly; the stones heat up to temperatures of 200 degrees or more.

They perform a dual function:

Gas heater Ermak.

If you are a fan of the Russian bathhouse, a heater is your obvious choice. If you want to use a sauna with high temperatures and minimal humidity, you don't need stones. Heat accumulation in the case of gas, you understand, is of no value.

Water tank location

It may be located in the stove body or around the chimney. In the first case, the heat source for heating water is the burner flame, in the second - combustion products. In the author’s humble opinion, the second option is preferable: the tank additionally cools the combustion products, increasing the efficiency of the device.

Gas stoves

If you use bottled gas, a stove that combines two types of fuel would be an excellent solution for you. When the cylinder runs out, you can light the stove with wood.

Burner

Often it is purchased separately.

What should you pay attention to when purchasing?

Domestic burner Teplofor.

Boiler power

One of the key points in choosing a heating boiler is determining the required power. If we approach this with full responsibility, it is necessary to consider the heat loss of each room, if we are talking about an apartment or a building as a whole, if the boiler is selected for heating a private house. The calculations take into account the materials of the walls, their thickness, the area of windows and doors, the degree of their insulation, the presence/absence of an unheated room below/above, the type of roof and roofing material. Geographical location and a whole bunch of other factors are taken into account.

Such a calculation can be ordered from a specialized organization (at least in GorGaz or a design bureau), if desired, you can do it yourself, or you can take the path of least resistance - calculate based on average standards.

Where does the heat leave the house?

Based on the results of all calculations, a standard was derived: heating 10 square meters of area requires 1 kW of heating power. This standard is suitable for rooms with ceilings of 2.5 m, with walls with an average degree of thermal insulation. If your room falls into this category, divide the total area that needs to be heated by 10. You get the required boiler power. Then you can make adjustments - increase or decrease the resulting figure depending on real conditions. It is necessary to increase the power of the heating boiler in the following cases:

- The walls are made of material with high thermal conductivity and are not insulated. Brick and concrete fall into this category for sure, the rest - depending on the circumstances. If you are choosing a boiler for an apartment, you need to add power if the apartment is corner. For “internal” ones, heat loss through them is not so terrible.

- The windows have a large area and do not provide airtightness (old wooden frames).

- If the ceilings in the room are higher than 2.7 m.

- If in a private house the attic is not heated and poorly insulated.

- If the apartment is on the first or last floor.

The design power is reduced if the walls, roof, and floor are well insulated and energy-saving double-glazed windows are installed on the windows. The resulting figure will be the required boiler power. When searching for a suitable model, make sure that the maximum power of the unit is not less than your figure.

Double-circuit gas boilers: manufacturers

Having decided on the technical characteristics, all that remains is to find a suitable model and choose a manufacturer. This is not at all easy - there are many companies on the market, prices vary considerably. As usual, there are three segments - expensive, mid-priced and cheap.

Expensive ones are products from European manufacturers:

- Italian gas boilers - Ferroli, Beretta, Ariston, Baxi.

- The German ones are not inferior to them in quality: Viessmann (Weissmann), Wolf (Wolf), Vaillant (Vialant).

- Korean Navien (Navien) are worthy competition to the leaders.

This equipment works reliably and without failures, but only under certain conditions. The first is a stable power supply, without significant deviations in frequency and voltage. Our networks lack stability, so a voltage stabilizer is needed, preferably an electronic one. The second condition for normal operation is a certain gas pressure in the line. Most German and Italian gas boilers operate if the gas pressure is 2 atm or more. The exception is the Ariston and Navien boilers.

Manufacturers of double-circuit gas boilers number in the dozens

Russian-made wall-mounted double-circuit gas boilers - Danko, Protherm - have proven themselves well on the market. They have approximately the same functionality as the “Europeans”, but react less sharply to deviations in the power supply and operate at low gas pressure. What is not pleasing is the Russian “service”.

There are also Bosch boilers. The company itself is German, but there are factories in Russia, so it’s not easy to determine the geographical location of these boilers - some are produced in Russia, some at other factories in other countries. Bosh campaign specialists have developed a new boiler model adapted to our conditions - Gaz 6000 W.

Gas is one of the most popular types of fuel, which has one of the most optimal efficiency and price ratios. These days, more than half of the installed heating equipment runs on gas. The market offers a wide range of products, which is difficult even for a professional to choose from.

The selected model of gas boiler must be as reliable as possible and fully satisfy the needs of the buyer. Before purchasing, you need to answer several questions regarding the type of equipment you are purchasing, power, functionality, desired level of comfort, etc.

Advantages and disadvantages

Let's try to evaluate gas against the background of traditional fuel for a bath - firewood.

Advantages

The chart allows you to compare costs when using different types of fuel.

Flaws

Perhaps, after listing the advantages of the solution, the reader was filled with delight and adoration for gas equipment.

Let's try to take off his rose-colored glasses.

Selecting the type of boiler

The first question that needs to be resolved is which of the proposed types of boilers is most suitable. Equipment is conventionally divided into two categories:

The most widespread are mounted models, characterized by simple installation, minimal operational requirements and relatively low cost. They are perfect for heating systems of a medium-sized cottage.

If we talk about cost, installation of heating with a wall-mounted boiler costs a modest 700-1000 USD. e. The equipment that is necessary for the operation of the system is provided by the manufacturer in the kit. During the installation process, all that remains is to supply cold water and remove heated water.

Advice. Wall-mounted gas boilers can be installed in any room, for example, in the hallway or corridor. Installation of a floor-standing boiler is recommended in a separate boiler room.

Floor-standing gas boilers are more expensive. Unlike wall-mounted models, they require additional equipment, the purchase of which will increase costs. Thus, installation of floor-standing models costs from 1500 USD. e.

Advice. It is recommended to carry out regular inspections of floor-standing gas boiler equipment every 3-4 years. For mounted models, it is carried out once every 1-2 heating seasons.

When comparing floor-standing and wall-mounted boilers, it is necessary to note the higher level of reliability of models of the first type. The heat exchanger in them is made of cast iron or steel, the heavy weight of which is compensated by resistance to mechanical loads and prolonged exposure to high temperatures.

Selecting the optimal number of circuits

Most models intended for installation in private houses and cottages can be divided into two types according to the number of circuits:

The first ones function extremely simply and are intended exclusively for heating systems. If it is necessary to provide hot water supply in the house, models are purchased that can serve two or more circuits at once.

Advice. When it is necessary to additionally provide hot water to other systems in the house, for example, heated floors, multi-circuit equipment is purchased or modern automation is installed.

Double-circuit gas boilers, which are most widespread, can be divided into two types:

- With built-in boiler

- Flow-through

Boilers with a built-in boiler have one advantage - next to them there is a tank with a capacity of more than 100 liters, in which heated water constantly accumulates. The operation of such equipment allows you to save on fuel, and in the event of a gas shutdown, you can consume the heated liquid for some time. The disadvantages include the need for free space (preferably a separate boiler room) and high starting material costs.

If the need for heated water is small, you can safely use flow-through models. In them, the liquid is heated directly at the moment when it circulates through the circuit.

The main parameter is power

One of the main characteristics that people pay special attention to when choosing a gas heating boiler is its power. The higher this value in the technical documentation, the larger the area the equipment can heat.

The market is very extensive and offers models whose power ranges from a few units to hundreds of kW.

Advice. In order not to make a mistake when choosing equipment, it is recommended to contact a specialist. A qualified technician will quickly select the power based on specific operating conditions.

If you determine the required boiler power yourself, you must proceed from the ratio: 1 kW for every 10 sq. m. In this case, the room should be well insulated, and the height should be less than 3 m. If there is no possibility or desire to insulate the walls of the house, it is recommended to increase the calculated power indicator by 20-30%.

Another pitfall that you will have to face and take into account is the gas pressure in the pipelines. In the technical documentation, manufacturers indicate power, taking into account its nominal value. In reality, the pressure may be lower, especially in remote areas. Consequently, the useful power will be less.

Installation

How to install a gas sauna stove with your own hands?

The instructions are not much different from a wood stove.

A window is left in the wooden wall, which is covered with red brick.

Important: when powered from a cylinder, the cylinder itself must be outside the heating zone (ideally, outside).

Cutting for a chimney in a wooden ceiling.

Condensing boilers

A few words should be mentioned about condensing-type boilers, which can be floor-mounted or wall-mounted. Their main difference from classical models is their high efficiency, which exceeds 100%.

The main disadvantage of such equipment is the high initial costs. For their operation, high-power radiators are required. Warm floors work best with them. Heating must be designed in such a way that the coolant flows to the return with a temperature not exceeding 35-40 degrees.

If we talk about the initial costs, they can reach 3-5 thousand dollars. However, the savings are more than significant. It will be possible to heat a house with an area of 150-200 square meters for a modest 40-50 USD.

Gas heating boilers

If the house has a gas supply, installing this type of heating device will be the most ideal option. A gas boiler has two undeniable advantages: low fuel cost and high efficiency (more than 96%).

Modern gas appliances vary in installation option and can be:

The former are distinguished by their compactness, but at the same time low power. These devices are excellent for heating rooms whose total area does not exceed 100 m2. floor-standing boilers have high power (more than 40 kW). Installation of such equipment is carried out on the floor.

In addition, gas boiler models differ in the type of heat exchanger installed. There are single-circuit, double-circuit and triple-circuit gas appliances. Single-circuit ones are designed exclusively for heating the room. In addition to heating, double-circuit boilers are capable of providing the user with hot water and, most importantly, in sufficient quantity. Thanks to the presence of a third circuit, three-circuit gas boilers are capable of heating water, which is intended to be supplied to the heated floor system.

Gas boilers can have a steel, copper or cast iron heat exchanger installed. Each of them has its own advantages and disadvantages, for example, steel is characterized by high strength, but low resistance to corrosion. On the contrary, a cast iron heat exchanger has high anti-corrosion resistance, but is afraid of mechanical damage. The copper heat exchanger is able to please with its resistance to mechanical damage and increased resistance to corrosion. Depending on the type of boiler, a heat exchanger is installed. Thus, cast iron and steel are installed only in floor-standing heating boilers, and copper, due to its low weight, is installed in wall-mounted gas boilers.

Boilers can have a ventilated or atmospheric burner. The latter are in most cases installed in inexpensive boilers with low power. The combustion chambers in such boilers are of closed and open type.

Models that have a closed chamber have a fan in their design, the task of which is to ensure the forced removal of exhaust gases into a coaxial pipe. Devices with an open camera have a slightly simpler version of operation. Exhaust gases are discharged outside through the chimney naturally, and as for the air that is required for the normal operation of the device, it is taken directly from the room in which the gas boiler is installed.

Ventilated burners are highly efficient. In addition, it is important to note that the design of these burners is very complex, and therefore their cost is an order of magnitude higher than atmospheric type burners. The removal of gases in such devices is carried out exclusively in a forced manner. You can also read the article “What is a condensing gas boiler”.

Choosing a gas boiler for heating a bath

The bathhouse became a part of everyday life and entered the culture of the Russian people back in the days of paganism. And today she continues to enjoy well-deserved love. This is not just a place where you can wash yourself, but also treatment, relaxation and communication. Owners of private houses often think about building their own bathhouse. And the heart of any bathhouse is the heating boiler. Depending on the energy carrier used, boilers come in several types: liquid fuel, solid fuel, electric and gas. If the site is gasified, the obvious choice is in favor of a gas boiler.

Electric heating boilers

It is immediately worth noting that electric boilers have the greatest number of advantages such as:

– quiet operation;

– ease of operation;

– low cost of equipment.

All existing electric boilers are divided into:

The latter in their design have a heating element, the operating period of which is more than 10 thousand hours, after which this element is very easy to replace with a new one.

Electrode boilers require periodic cleaning of the heating element to remove scale formed during operation. In addition, it is worth noting that these devices are relatively inexpensive, which makes them even more popular among users.

It is impossible to answer the question with confidence which type of electric boiler is better, since each of them has both its own advantages and disadvantages. As for the disadvantages, the most important one is the high cost of the fuel used, that is, electricity, which makes it difficult to use it to heat a large house. Electric boilers are an excellent option as an additional source in case the main one, for example, a gas one, fails for some reason.

Gas boiler for a bath: types, advantages, disadvantages, installation rules

Can gas boilers be used for baths? What are they? How justified is the choice of gas equipment? Are there any rules for installing these devices? In this article we will try to answer all these questions.

Let's start, however, with a small clarification. Strictly speaking, gas boilers for baths... are not used. Gas ovens are used.

The photo shows a P20GT sauna stove.

Let us clarify: strictly speaking, most sauna stoves are equipped with a water heating tank; however, it does not participate in the main function of the oven - heating the air in the steam room.

Liquid fuel boilers

These models have many similarities with gas appliances; the only thing that distinguishes the models is the type of fuel used and the type of burner installed. In order to install an oil-fuel boiler, you do not need to obtain a special permit. It is important that this type of boiler is absolutely independent of electricity and gas.

Installation of this type of device requires a special place; in addition, it is necessary to provide a place where the fuel tank will be installed. It should also be noted that during its operation, the boiler smokes very heavily, which is why there is a fairly frequent need to service the device, that is, to clean it from carbon deposits and soot.

Features of gas heating baths

Gas heating of a bath compares favorably with other types. For example, if we compare it with electric heating, the advantages are definitely on the gas side. Firstly, electricity is quite expensive, and with heating the bathhouse, its consumption will increase significantly, especially if your bathhouse is 200 square meters or larger.

Secondly, if it is turned off, the bathhouse will stop heating, the water will have to be drained, otherwise everything will freeze, and there is a risk of damaging the equipment that is in the unheated bathhouse. Gas is much cheaper than electricity, and if there is a gas main, the heating is stable.