The need to install a ventilation system applies not only to the rooms in which residents spend most of their time - bedrooms, living rooms, kitchens - but also to non-residential premises. Ventilation is especially necessary if heating equipment is installed in utility rooms and boiler rooms.

Both for the safe life of people and for the trouble-free operation of a heat-producing unit, a well-organized air exchange system is required. You will learn everything about how ventilation for a gas boiler in a private house should be arranged from the article we presented.

We will tell you what you need to consider at the preliminary stage. We will explain what should be done before installing ventilation ducts, what rules to follow during the installation of the system. This information may be useful if you want to do some of the work yourself, without involving specialists.

Types of ventilation systems

Ventilation for rooms with gas heating equipment, as for other objects, is of two types: natural and forced. The installation of natural and forced ventilation is permitted and regulated by current regulations.

Natural ventilation of boiler rooms

Natural ventilation ensures the ventilation of the room using multi-format pipes and pre-made holes in the walls, ceiling or floor. In fact, natural ventilation works thanks to pressure differences.

It allows the design of vertical and horizontal bends. In accordance with the requirements of SNiPs, the system can have horizontal sections up to 8 m long, but it is better to make them no more than 2 m long. In this case, designing no more than three is allowed.

The design of large horizontal sections of the exhaust system is not a gross violation, but the speed of air flow through them is quite low, which makes normal ventilation difficult

Most often, exhaust vents are located above the boiler. Natural ventilation does not require the use of special supply and exhaust equipment.

Calculation of air exchange for natural ventilation in a boiler room with a gas boiler is quite simple: you need to add 5 degrees for external air temperatures and 18 degrees for internal air temperatures. The ventilation operation is checked subject to the specified temperature difference.

When accepting a natural exhaust system, calculations are made to determine whether it will work in the summer. If not, then you will have to design forced ventilation, because... According to standards, the hood must operate year-round.

Forced ventilation system

Forced (artificial) ventilation is a whole automated system with an exhaust duct and the installation of fans and air conditioners.

The power of this engineering structure can be adjusted using programs or mechanisms (depending on the characteristics of the equipment). Moreover, it is better to design an automatic control system that will start when the boiler is turned on and turn off when the fuel is completely burned out.

However, it is completely dependent on electricity supply. When installing an artificial hood, it is recommended to install an additional generator. If possible, it is better to use a combined exhaust system, in which automated devices are activated only when natural ventilation cannot cope with air exchange.

Diameter of flow hole in ventilation systems

According to the standards, natural and artificial ventilation differ in the diameter of the vent (in another way it is called the inlet opening) to ensure normal draft and standard speed of air movement in the ventilation ducts. Although the diameter can also be calculated based on the cubic capacity of the room.

When choosing pipes of a certain diameter for ventilation systems, you need to take into account the effect of the grilles and information on gas consumption, which is indicated in the gas equipment passport

For natural ventilation, the value should be: 30 cm2 cross-sectional area of the inlet opening per 1 kW of gas boiler power. For forced ventilation of a gas boiler room, according to standards, the cross-sectional area can be smaller - 8 cm2.

Which system is better: natural or forced?

Even if natural ventilation works well, it is always better to use forced exhaust. Drilling a hole into the street and inserting a fan there will cost 5-10 thousand rubles.

A forced system is much safer than a fanless system for the following reasons:

- the operation of natural ventilation depends on the weather: the stronger the wind, the better the hood works, and vice versa (if there is no wind, air exchange may stop altogether);

- the frequency of air exchange is unknown, is not regulated and is not maintained at the required level;

- natural ventilation will not provide much air exchange (relevant if the boiler room is large, and if a powerful boiler is used - for a large country house).

The fan will do a better job of removing air if an emergency occurs (gas leakage). If the ventilation is natural, then if a gas leaks, it may not be completely removed and may accumulate in the room, which can lead to poisoning or an explosion.

How to do it yourself?

Schemes and calculations

Natural ventilation scheme:

- The air supply is located opposite the hood.

- The air is exhausted through an exhaust pipe, the beginning of which is on the ceiling, and the end is above the roof ridge. If the ventilation system is located on the wall, then this should be done as close to the ceiling as possible.

Mechanical ventilation scheme:

- The pipe with the fan must be discharged either through the roof to the street or through the wall outside the house.

- The air duct exits into the existing ventilation shaft with a fan.

During the heating season, it is recommended not to turn off the exhaust fan, leaving it to run on a regular basis.

Calculation of ventilation for a boiler room with a gas boiler is carried out taking into account the area of the room, the frequency of air exchange, and the number of family members regularly living in the house. Using these parameters, you can calculate the required hood cross-section for a gas boiler.

Attention Formula for calculating the amount of air exchange:

L (boiler power, kW/h) = N (air renewal rate) × S (room parameters) × H (boiler room ceiling height, m).

Attention Formula for calculating the number of family members:

L (boiler power, kW/h) = N (number of family members) × Lн (minimum air consumption per person, m³/h).

Generally accepted minimum air consumption standards per person:

- sleep – 20 m³/h;

- rest – 40 m³/h;

- vigorous activity – 60 m³/h.

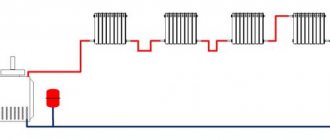

Boiler room ventilation diagram:

Materials and tools

Basic materials and tools:

- Hammer or drill with a crown attachment.

- Saw for processing pipes.

- Tools for marking - ruler, pencil.

- Air ducts and adapters for them.

- Protective grilles.

- Adapter with check valve.

- Protective sleeves for slabs.

- Self-tapping screws, dowels, mounting clamps.

- Sealant or polyurethane foam.

- Hacksaw.

- Protective equipment: gloves, glasses.

Installation

Installation of natural ventilation:

- The installation location is outlined. The necessary calculations are made, a diagram or drawing is created.

- A pipe is applied to the wall, its dimensions are noted.

- A perforator is used to make a through hole with a slope of 60 degrees outward to drain the condensate (with exhaust ventilation, the slope is not made, the pipe is installed evenly).

- A pipe with insulation and a grille on the outside is inserted into the finished through hole.

- A housing with a check valve is attached to a part of the pipe inside the house and the wall with dowels (how to make a check valve for ventilation with your own hands?).

Installation of forced ventilation:

- A through hole is made in the wall with a slope towards the street. It is recommended to use a hammer drill or a drill with a diamond bit.

- A pipe is installed in the hole.

- The gaps between the wall and the pipe are filled with sealant or foamed.

- A duct fan is installed.

- Electrical wiring is laid and connected.

- The rest of the equipment is installed - filters, sensors, sound absorber.

- Grates are attached to both sides of the pipe.

separate article

Organization of air outflow and inflow

The ventilation diameter is selected based on the boiler power.

The pipe diameter is determined based on the boiler power. For a 30 kW boiler, a size of no more than 20 cm is provided. Too high or low arrangement of the holes leads to slower air exchange. If the chimney outlet is located below the roof ridge, a cold flow will flow through the outlet, and combustion products will not be removed.

The chimney can be equipped with:

- horizontally;

- with lift and bend;

- vertically into the ceiling with a bend;

- vertically directly through the roof.

A yellow burner flame and a large volume of soot indicate insufficient oxygen levels, so you need to use a fan for the supply system.

Air duct materials in gas boiler houses

Properly selected material for the air duct ensures longer operation of ventilation.

In accordance with current standards, the following can be used as a material for organizing the ventilation of rooms with gas equipment:

- brick;

- ceramics;

- asbestos;

- galvanized and stainless steel.

It is not advisable to use plastic for air ducts, because... this reduces the fire resistance of structures. Some regulations (for example, paragraph 7.11 of SNiP 41-01-2003) indicate that air ducts can be partially made of flammable materials.

When using plastic elements, you must remember that the presence of flammable elements in the structure will complicate the commissioning of boiler equipment and its acceptance by gas service employeesRegardless of what material is used, all ventilation ducts passing through cold areas must be insulated. In these places, draft may decrease, condensation may form, and the ventilation duct of a boiler room with a gas boiler may freeze and stop performing its functions. That is why it is better to stretch pipes along a warm circuit, eliminating the possibility of them freezing.

Brick exhaust ducts

Brick is not durable because... due to temperature changes, condensation forms on its surface, leading to the destruction of the material. If brickwork is taken as the material for the shaft, then the chimney is assembled from single-circuit galvanized metal pipes, the thickness of which depends on the temperature of the gases emitted.

Ceramic ventilation pipes

Air ducts made of ceramics are universal, easy to use and durable. The principle of their assembly is similar to the technology for constructing ceramic chimneys. Due to their high gas density, they are resistant to severe pollution of various types and aggressive chemical environments.

But in such hoods it is necessary to install condensate drains, because... ceramics absorb moisture well. Structurally, such a hood consists of 3 layers:

- ceramic inner layer;

- middle insulating layer of stone and mineral wool;

- outer expanded clay concrete shell.

This ventilation system cannot have more than three elbows. A drip and inspection are installed at the bottom of the ceramic chimney.

Steel air ducts

Steel exhaust ducts are convenient and practical.

A metal chimney in a gas boiler room can have a rectangular or round shape in cross-section, but in this case the width of one side should not exceed the width of the other by 2 times

When installing a steel ventilation system, you must adhere to the following recommendations:

- The collection of segments is carried out using the “pipe to pipe” method.

- Wall brackets are attached in increments of no more than 150 cm.

- The length of horizontal segments should be no more than 2 m, if the system does not provide forced draft.

According to standards, the thickness of steel walls should be at least 0.5-0.6 mm. The temperature of the gas produced by boilers is 400-450 C, which is why thin-walled metal pipes can quickly burn out.

Installation features according to SNIP

In the absence of specific recommendations in the documents attached to the boiler, it is worth using SNIP standards, according to which:

- Installation of gas boilers is only possible on walls made of non-combustible materials. The distance from the gas boiler to the wall must exceed 2 cm.

- If the walls are still subject to combustion, they must be protected with fireproof material. The most common options are a layer of asbestos with a metal sheet, plaster over 3 cm thick, ceramic tiles or mineral wool cardboard.

- On the sides, the distance from the boiler to the wall must be at least 10 cm. If the walls are made of flammable materials, this distance increases to 25 cm.

- A gas boiler can only be installed on a substrate made of non-combustible material. In the case of wooden coverings, special supports are made from tiles or bricks, which provide the necessary fire resistance. The base for floor-standing devices must be at least 10 cm wider than the dimensions of the boiler itself.

Types of ventilation systems for gas boilers

For rooms with gas units in private houses, the following types of ventilation systems are installed:

- Natural and mechanical;

- Exhaust, supply and combined, based on their purpose;

- Ducted or ductless according to design features.

If ventilation is installed in a boiler room where a gas boiler with an open combustion chamber is installed, the following points are taken into account:

- the presence of a ventilation shaft to remove carbon monoxide to the street;

- installation of a general exhaust ventilation system;

- the presence of supply ventilation, which draws air masses from the street into the boiler room (take into account cracks and gaps in windows and doorways).

When choosing a boiler for heating a house, you should correctly calculate its power in order to justify the cost of installing ventilation. The amount of oxygen supplied must correspond to the needs of the unit so that the flame in the burner does not produce soot. If this is not taken into account, a layer of soot will quickly form on the heat exchanger and the boiler efficiency will drop. When calculating the required air flow, the volume of the boiler room should be taken into account.

The requirements for the exhaust of a gas boiler in a private house are mandatory; compliance with them will guarantee the safe operation of the equipment.

If there is not enough air flow in the boiler room, the volume of oxygen decreases and reverse draft may occur. As a result, carbon monoxide will be released into the room. This is especially dangerous when the heating unit is installed in the kitchen area. When oxygen is absorbed, a harmful atmosphere in the room will lead to residents showing signs of oxygen starvation: pain and stinging in the eyes, lacrimation, dizziness. This means that the air duct for a gas boiler in a private house does not fulfill its purpose.

We calculate the air duct so as not to make mistakes

As already mentioned, a complete replacement of the air in the room where the boiler is installed should be done in a maximum of 20 minutes. It is this requirement that obliges us to calculate the minimum ventilation cross-section before starting installation or even design. There is a constant ceiling height at which ventilation is considered optimal. This value is equal to six meters. If the value is lower, a correction factor is used.

Let's calculate it using an example.

The room where the boiler is installed has dimensions of three by four meters with a ceiling height of 3.5 m. We calculate the volume - 3x4x3.5 = 42 cubic meters. m

We determine the correction factor using the formula: k=(6-h) *0.25+3

We get: (6-3.5) *0.25+3=3.6

We will find the estimated volume of air required for safety by multiplying the actual volume of the room by a correction factor of 3.6 * 42 = 151.2 cubic meters

Now we come to the last calculation. The cross-sectional area of the air duct is calculated as the ratio of the calculated volume to the product of air flow velocity and time. Moreover, speed and time must be in the same units. Taking the minimum air speed as 1 m/s and knowing that there are 3600 seconds in an hour, we get: 151.2/3600 = 0.042 sq. m

When using a round pipe, the formula for converting area to diameter is: D=2√S/π, where

D is the required diameter;

S – found cross-sectional area;

π is a constant approximately equal to 3.14; As a result, we get:

2√0.042/3.14=0.231m

The nearest larger diameter from the range of pipes for ventilation is 250 mm. It is he who will be the solution to our problem.

Of course, you can avoid these calculations if you use tables or the services of professionals, but this, as they say, is at the discretion of the person for whom the hood for a gas boiler is being built in a private house.

What about the height above the roof?

If the ventilation comes out vertically above the roof of the house, the question about its position would be quite logical. The following parameters will be relevant here:

- Level relative to the ridge;

- Removal from the chimney;

- Level above the roof.

Let's designate the coordinates based on construction standards, the experience of professionals and the elementary laws of physics. A hood for a gas boiler in a private house, or rather its outlet pipe, must:

- Rise at least 50 cm above the roof ridge if the chimney is at least 1.5 meters away and at the same distance where the parapet is located.

- Be level with the ridge or higher than it if the chimney is located from one and a half to three meters from both the ridge and the parapet

- Be below a line drawn from the ridge of the roof at an angle of 10 degrees, if the height of the chimney is higher than three meters from the top edge of the roof.

- In the case of a flat roof, the requirements for the hood are simple - be at least half a meter above it.

On a note

The height of the hood can be adjusted if there is a large and high wind vane on the chimney - decorative protection from precipitation or birds.

A hood for a gas boiler in a private house, despite being quite complex, can easily be installed, as they say, with your own hands

Simple calculations, accuracy and attention when working - this is what will add comfort, safety and aesthetic appeal to your home

Natural circulation in a room with a gas boiler

It is necessary to install a polypropylene pipe into the vent. If the heating equipment has a power of 30 kW, then the pipe is suitable with a diameter of Ø15 cm. A metal mesh protects the entrance from the outside. To prevent foreign odors and debris from entering the room, a valve is installed inside the pipe.

Combustion products go directly into the exhaust pipe installed above the heating equipment. The supply air pipe is designed to bring fresh air into the combustion chamber, so this air duct is installed immediately behind the firebox. The efficiency of natural ventilation in a boiler room directly depends on weather conditions. And according to the standards, the air in such a room must be renewed 3 times every 1 hour.

It is impossible to calculate the air exchange rates for this ventilation system. In practice, it often happens when, for natural ventilation, a hole is made through a wall with a diameter of 150 mm, a ventilation pipe is inserted into the hole, it is protected from the outside with a mesh, and a check valve is mounted on the other side. From a financial point of view, this option is quite inexpensive, and the performance is very good.

Types of ventilation for operation of gas heating equipment

Convection can be natural or forced. Spontaneous air flow is ensured by the presence of windows, vents, doorways and an exhaust duct, the outlet of which is mounted in the room with the boiler.

The natural ventilation system consists of an air duct that connects the outlets from the kitchen, boiler room and bathroom to a pipe on the roof. The width of the box is not calculated, but selected according to SNiPs, because For an accurate calculation, it is necessary to take into account the direction and speed of the wind, atmospheric pressure and other parameters. With a boiler power of 30 kW, an air duct with a width of 150 mm will be required, with a boiler power of 100 kW - 230 mm.

The hood is mounted directly above the device, and the pipeline is mounted behind the fuel chamber.

To calculate the blower parameters, you need to multiply the volume of the room by the loss and air change coefficients. The cost of resistance during the passage of the chimney is about 40%, therefore, with room parameters of 4x2x2.2 m, the fan power should be at least 74 m³/h.

Requirements for the premises for installing a gas boiler

Comprehensive information on the correct preparation of the premises is contained in one of the above documents. Among other things, there are regulations on the dimensions of the boiler room, the arrangement of the entrance door, the height of the ceiling and other important parameters (see key requirements below).

It is immediately worth noting that if the maximum thermal power of a gas boiler is more than 30 kW, then it is necessary to allocate a separate room for its installation. Models with lower capacity and with a corresponding location of the outlet under the chimney can be installed, for example, in a kitchen area. Installing a gas boiler in a bathroom is strictly prohibited.

It cannot be installed in the bathroom, as well as in rooms that are considered residential. As an alternative, it is possible to install a boiler room in a separate building. At the same time, their own standards are taken into account, about which there is information below.

A boiler room in a private house can be equipped at the ground floor level, in the attic (not recommended) or simply in a room specially equipped for these tasks.

In accordance with the rules for installing a gas boiler in a private house, it must be equipped taking into account the following criteria:

- Area of at least 4 m2.

- One room is designed for no more than two units of heating equipment.

- The free volume is taken from 15 m3. For models with low productivity (up to 30 kW), this figure can be reduced by 2 m2.

- From the floor to the ceiling there should be 2.2 m (not less).

- The boiler is installed so that the distance from it to the front door is at least 1 m; It is recommended to install the unit near the wall, which is located opposite the doorway.

- At least 1.3 m of free space must be left on the front side of the boiler for setting up, diagnosing and repairing the unit.

- The width of the entrance door is taken around 0.8 m; It is desirable that it opens outwards.

- The room is provided with a window with an outward opening window for emergency ventilation of the room; its area must be no less than 0.5 m2;

- Surface finishing should not be made from materials prone to overheating or fire.

- A separate power supply line is introduced into the boiler room to connect lighting, a pump and a boiler (if it is volatile) with its own circuit breaker and, if possible, an RCD.

Particular attention should be paid to the arrangement of the floor. It must have a solid base in the form of a rough screed with reinforcement, as well as a finishing coating made of absolutely non-combustible materials (ceramics, stone, concrete)

To make it easier to position the boiler, the floors are made strictly level.

On a curved surface, installation of the boiler may be difficult or impossible due to insufficient reach of the adjustable legs. It is prohibited to place third-party objects under them to level the unit. If the boiler is installed unevenly, it may not operate correctly, with increased noise and vibration.

To fill the water heating system and replenish it during operation, it is necessary to introduce a cold water supply into the boiler room. To drain the system during equipment maintenance or repair, a sewer point is installed in the room.

There are special requirements for the chimney and air exchange in the boiler room of a private house, therefore this issue is considered in a separate subsection below.

If the premises for installing a gas boiler are equipped in a building separate from a private house, then the following requirements are imposed on it:

- your foundation;

- concrete base;

- presence of forced ventilation;

- doors must open outward;

- the dimensions of the boiler room are calculated according to the above standards;

- no more than two gas boilers are allowed to be installed in the same boiler room;

- the presence of a properly equipped chimney;

- it must be provided with free access for cleaning and other operations;

- for powering individual lighting and heating equipment, a separate input with a circuit breaker of appropriate power is provided;

- The water supply must be organized so that the main does not freeze during the cold season.

Mini-boiler room mounted near the house.

The floors, walls and ceilings of a separately equipped boiler room must also be made and finished with materials that meet the class of non-flammable and heat-resistant.

More about multilayer pipes

If you have prioritized the sandwich pipe option, we suggest using a few practical tips:

- The pitch of pipe fastenings to the wall should be in the range from 100 to 150 cm;

- The number of inspection wells must provide full access to all sections of the pipe;

- It is advisable not to allow horizontal sections of ventilation pipes and chimneys longer than one meter. Otherwise, you will have to install forced draft (fan).

Ceramic hood for gas boiler

Another option for the material from which the hood for a boiler in a private house is made is a ceramic pipe. The advantages here include environmental friendliness and durability. In this case, pipes made of this material are not used as a whole. You will still need organic or polymer insulation, and stone, metal, brick and something else as a decorative layer. In this case, condensate drains will also be needed, which will add cost to the already expensive material. Before this, we considered options when the hood for a gas boiler in a private house and the chimney existed separately. However, there is an option for a coaxial pipe that allows you to combine two processes and two purposes into one.

The essence of this invention is to place a pipe designed to remove volatile combustion products in one housing with a pipe providing clean air. There are several advantages at once:

- The exhaust gases, moving through the inner pipe, are cooled by air coming from outside. This not only increases the efficiency of the boiler, but also reduces the aggression on the surface of the entire chimney.

- The second advantage of a coaxial pipe is its compactness. Saving space never hurts, but lower labor costs when installing one pipe - instead of two - will have a noticeable impact on the budget.

One significant drawback follows from the design feature - the system does not provide horizontal sections. This means that, having made a decision in favor of “two in one”, you need to be prepared for some costs for laying a pipe to the detriment of the adopted plan (move the kitchen, boiler room or put up with a pipeline that is sticking out itself).

Coaxial chimney as a ventilation element

Due to their design, coaxial chimneys are justifiably popular. They are assembled according to the “pipe in pipe” scheme, which allows you to perform two functions necessary for gas equipment at once: removing combustion products to the outside and supplying air to ensure the combustion process.

Coaxial chimneys are divided into two types: horizontally and vertically located. The first ones are installed in the wall, the second ones are brought out through the ceiling into the attic, then onto the roof. The vertical gas exhaust system is longer, more expensive, more difficult to install and requires the installation of a condensate collector.

The only disadvantage of the equipment is the risk of condensate freezing on the external part vented outside. The problem can be solved by insulating the pipe with mineral wool or other heat-insulating material, although this will not help in cold weatherTo combat ice, the end of the pipe is equipped with a lattice cap.

Several rules for the correct installation of a coaxial chimney:

- It is recommended to install the pipe outlet at a height of 2 m above the ground.

- The distance from the pipe to the window located on top is at least 1 m.

- A condensate collector is not necessary if the pipe is installed at an angle of 3-12° towards the street.

- It is prohibited to route the main line into an adjacent room.

If there is a gas pipe near the chimney outlet, the distance between them should be 0.2 m or more.

The standard set of horizontal equipment consists of a pipe, an elbow for connecting to the boiler, adapters, decorative overlays, crimp rings, and mounting bolts.

An example of installing a horizontal coaxial chimney that goes out through a wall:

The installation of a horizontal coaxial chimney is considered the easiest to implement, and is therefore recommended for self-installation. At the end of the work, the boiler is put into operation and the tightness of the connected pipe is checked.

Installation of supply ventilation

Supply ventilation is required in order not only to allow air from the street to enter, but also to filter it, cool it or warm it, depending on the situation.

Low-power equipment is installed in apartments and private houses. This system works quietly and creates comfortable living conditions. Modern air ducts fit well into the interior.

The simplest way to organize this system is to install a supply fan.

This is done according to a scheme similar to the installation of an exhaust ventilation device.

When should you invite specialists?

When arranging ventilation ducts in a private house, you can go in two ways:

- invite specialists who will complete everything turnkey;

- deal with all the issues yourself, completing the work on your own.

Each option is appropriate for specific conditions. All design options for the ventilation duct system can be divided into traditional and the latest ready-made systems. In the first case, you need to select equipment based on calculations. Here we must not forget about the smallest details that will be useful when assembling the system.

Secondly, we are talking about a comprehensive solution from a specific manufacturer. For example, the German Selfwind ventilation system, which is purchased as a ready-made kit for a certain area of the house. All components required for assembly have been selected. The system itself resembles a collector heating system, only many tubes surround the entire house from the inside.

These flexible plastic ducts with a diameter of 75 mm or 50 mm are pulled together into a manifold. They are poured with a concrete screed on the floor, and those areas that run like a circulatory system throughout the house are skillfully masked by the designers.

In the future, this technology provides an ideal microclimate in each room with the ability to regulate humidity, temperature and other parameters

If you choose such a complex ventilation system, which costs several thousand dollars for a country house with an area of 800 m2 or more, then there is no point in saving on installation. And it will take a lot of time to arrange such ventilation.

When building a house with your own hands “from scratch,” laying out ventilation shafts from bricks and providing holes for installing supply valves is not difficult. In the future, all areas of the natural ventilation system are equipped with special valves and, if necessary, hoods. This option is relevant for houses with an area of up to 250-300 m2.

Complex and expensive polymer ventilation duct systems are equipped with all the necessary parts for installation

Natural and forced ventilation of the boiler room

According to the method of updating the air space, natural and artificial (or forced) ventilation are distinguished.

Natural ventilation operates without the use of fans; its effectiveness is determined solely by natural draft, and, consequently, weather conditions. The draft force is influenced by two aspects: the height of the exhaust column and the temperature difference between the room and the street. In this case, the air temperature outside must be lower than that indoors. If this condition is not met, reverse draft occurs and ventilation of the boiler room is not ensured.

Forced ventilation involves the installation of additional exhaust fans.

Usually these types are combined into one boiler room exhaust system. When calculating it, it is important to take into account that the volume of air drawn outside must be equal to that pumped into the room. To ensure this condition is met, check valves are installed.

Types of ventilation for gas boilers

There are two ways to ventilate a gas boiler room - natural and artificial.

To ensure natural ventilation, it is necessary to make a hole in the wall opposite the boiler and lay an air duct with a diameter of 15 cm or higher through the hole, in accordance with the size and capacity of the installation. The flow of air masses is regulated by a valve in the pipe. Thanks to the natural supply of air from the street to the gas boiler, the combustion process is supported. However, the air in the room itself is not renewed.

Supply ventilation in a boiler room is the easiest to install and use, but it has significant disadvantages:

- The system can only be used for boilers with low power;

- The process of air intake cannot be controlled;

- Additional ventilation is required in a room with a gas boiler - gaps between doors and walls, windows, etc.

A more functional option for powerful gas boilers is forced ventilation, which is distinguished by the installation of artificial air exhaust. To do this, one or more fans are installed inside the chimney pipe, depending on the power of the gas boiler, the number of turns of the pipe and its diameter.

Automation of boiler room ventilation

To increase the safety of residents, boiler room ventilation can be automated.

For this:

- Choose a fan with a control panel or wall-mounted speed controller, a performance reserve (the larger the reserve, the better) and several speeds. The remote control must be secured at the entrance to the boiler room. If the concentration of carbon or natural monoxide suddenly increases in the room, you can turn on the maximum exhaust speed remotely. Fans with remote control are on average 10-20% more expensive than “regular” ones.

- Install a gas analyzer in the boiler room - a device that measures the gas concentration and gives a signal when it is exceeded. The average cost of a simple household model is 3000-6000 rubles.

- Choose boilers with safety features: a flame control sensor and a draft control sensor. They will automatically turn off the boiler if the burners go out or if the draft in the chimney is too low. In the middle and high price categories, these sensors are installed on almost all models.

To ensure safety, it is better to follow all the rules.

How to arrange ventilation in a chicken coop: a review of schemes for poultry houses of different sizes

How to arrange ventilation in a pigsty: rules and diagrams

Related Posts

Requirements for ventilation for a gas boiler in a private house

For the efficient and safe operation of a gas boiler, you must comply with the requirements for its installation.

First of all, for high-power devices, a separate room - a boiler room - is required.

It must be isolated precisely because of the inability of ventilation to remove exhaust air from residential premises, as well as because of the explosiveness of the fuel. This primarily applies to large private houses, which are heated by floor-standing boilers equipped with an open combustion chamber.

Attention! Using the basement as a boiler room if the boiler runs on liquefied gas is unacceptable. The boiler room is located in a separate building, since liquefied gas has a high specific gravity and in case of a leak it accumulates and creates a threat of explosion

According to SNiP 2.04.05. II-35, such premises must be equipped with a ventilation system. Ventilation is facilitated by opening windows and a separate, constantly open vent - also listed in the list of requirements. The ventilation duct should be located at the top of the room. It is equipped with an inspection hole for cleaning, since contamination of the air duct can interfere with air exchange. In this case, it is better if the duct ventilation duct is made of non-combustible material.

Photo 1. Diagram of the boiler room in a private house. The arrow indicates the location of the ventilation duct.

For small rooms where low-power wall-mounted gas boilers are installed, ventilation can be installed in utility rooms (bathroom, kitchen). In such devices, a closed combustion chamber operates, and air is supplied and removed through a coaxial (pipe-in-pipe) air duct, which is separately discharged to the street through the wall.

What do SNiPs say?

The installation of smoke ducts for gas boilers is regulated by SNiP 2.04.05-91, as well as DBN V.2.5-20-2001

- One boiler - one chimney. Combining, installing tees, etc. is prohibited.

- Combustion products must be periodically cleaned out; for this purpose, pockets with a depth of 250 mm are equipped.

- The height of the pipe is at least 5 meters.

- The elevation of pipes above the roof must be arranged taking into account.

- The diameter of the chimney pipe must be no less than the diameter of the pipe outlet of the boiler itself.

- The system is checked and cleaned annually before the heating season.

If you comply with all requirements during installation work, you can be sure that the gas service specialists will not have any questions for you. On cold winter evenings, your family will be warm and safe.

To learn how to choose and install a chimney correctly, watch the video:

https://youtube.com/watch?v=yKKaZneQDa0

Why do you need an air circulation system?

In such a small and sealed boiler room, very effective ventilation is needed; there are most likely dimensional violations here

Despite the development of high-tech gas boiler equipment, the number of poisonings and deaths from carbon monoxide is high. General weakness and headache are the least a person can feel. Ignoring generally accepted standards reduces the performance of heating equipment. Only with a continuous air supply is normal operation of the boiler ensured, and if there is a lack of oxygen, the fuel does not burn completely. This means that heat generation will be minimal.

It is necessary to understand that if, even at the initial stages of designing a building in the scheme, the boiler room is located separately from the house, the air that circulates in the room will be used by the boiler. When installing non-plastic doors and windows, there will be enough air in the boiler room. When installing modern plastic windows and doors, fresh air will not circulate from the street. When the boiler is running, it discharges the air, which means that the power of the equipment will decrease. There is a high probability that carbon monoxide will enter the boiler room

This example confirms the importance of a ventilation system in any room

Date: September 25, 2022

Principle of operation

The principle of operation of ducted supply ventilation

The equipment is an installation of exhaust or supply ventilation for processing air flows and supplying it to the boiler room. The device is a component of the heating system and is often connected to a central pipe. The air comes directly from the street or through the air ducts. A complex system consists of metal boxes or pipes, between which functional devices are mounted. External elements are protected from atmospheric action.

Working elements of the system:

- A fan with a two-phase electric motor supplies air to the boiler room or to the common air duct.

- Filters purify the air using coarse types or the method of electrostatic sedimentation. Coarse elements are placed in front of thin filters, protect them from damage and are easily replaced.

- Heating or cooling devices change the temperature of the incoming stream. Heat pumps, electric heaters or evaporators are used.

Balancing devices, shock absorption and sound insulation in the system eliminate vibration and reduce sound during operation. The vibrations are isolated and damped by obstacles, and the fan is placed on spring supports.