When designing a country cottage, several engineering systems are laid out to provide the owners with the benefits of civilization. The issue that concerns everyone is comfort in their own home, which is difficult to imagine without stable operation of the heating system.

In urban conditions, home heating is carried out in two ways, using central or autonomous (local) heating. For the vast majority of owners of suburban areas, only the second option is available, and all they need to do is choose the optimal method of heating their home. Heating can be carried out in different ways, the most common of which is gas heating of a private house.

We asked specialists from the Miralex store, which offers a wide range of heating boilers, to tell us how to understand the characteristics of boilers.

Gas boilers are easy to operate and maintain Source my-teplo.ru

Features of water heating: system requirements

The dominance of water heating in the private sector is explained by its advantages:

- System reliability. The process is ideally simple and streamlined: water heated from the boiler circulates in the pipes in a closed circuit, gives off heat and returns back.

- Heat capacity (and heat transfer) of water. It is sufficient to heat a residential building efficiently and evenly. Other coolants (including antifreeze) have worse performance.

- Cheap. Water is a cheap and environmentally friendly coolant.

Disadvantages can be considered:

- Expensive pipeline installation.

- Constant consumption of funds for heating the system (and where is it not constant?).

- Thermal inertia. The effect after turning on water heating is not felt immediately (compared to air heating).

- Care. It is necessary to monitor the condition of the system: metal elements are susceptible to corrosion, heating radiators must be kept clean (dust reduces heat transfer).

- Features of functioning. Turning off the heating in the winter can lead to an accident (the water will freeze and burst the pipes). Owners of summer cottages should consider replacing water with antifreeze (or replacing the system).

If water flows from the tap, the system is not aired Source binbank-info.ru

Before the water runs through the pipes, giving off heat and lifting the mood, it must be heated. The heating method (type of heating) is selected based on several criteria:

- Availability of fuel (its price and possibility of uninterrupted receipt).

- System installation costs (cost of labor, equipment and materials).

- Maintenance and repair costs.

Methods for laying heating pipes in the house

Regardless of the pipeline layout, the laying of heating pipes can be open or closed. An open pattern is most often laid out along wall panels, for example, along a baseboard. But the closed one can be performed inside walls and floors. The choice depends on the owner’s requirements for the aesthetics of the room and the skill of the craftsman.

Now, once and for all, without any registrations or SMS, you can click on the active link and continue to enjoy the game and place bets on your favorite team in a convenient mobile application.

Types of fittings and diameter of metal-plastic heating pipes

If the design technology of the heating system is not violated, then the installation method does not affect the performance and reliability of the system.

But there are a number of points to consider:

- The installation technology depends on the pipe material. Steel parts have the property of minimal thermal expansion, therefore it is possible to hide the pipeline in the walls - the risk of rupture and deformation is reduced to zero

- When heated, metal-plastic parts expand more than steel elements. For safe operation, pipes must be protected with metal sleeves with an internal diameter larger than the cross-section of the heating pipe. Insulation allows you to level out the risk of deformation during linear expansion of the pipeline and reduces heat loss.

Open installation is carried out by securing the main line elements to the wall with special clips. Let's look at both installation technologies in more detail.

Hidden gasket

The technology involves hiding pipelines in walls, floors or under the ceiling (in a sheathed structure). The easiest way to create a hidden heating scheme is during the construction or major renovation of a house.

Rules for arranging hidden gaskets:

- integrity of communications - circuits without an abundance of connections are less at risk of leakage;

- areas of detachable connections should be easily accessible for inspection and renovation;

- it is strictly forbidden to hide the contours of old pipes;

- it is necessary to draw up a technical plan for the pipeline so as not to damage the system during subsequent repair work.

Open gasket

The scheme is considered the simplest and most accessible for independent implementation. With this technology, the highway remains visible.

Advantages of open wiring:

Decorative paint, box and contours for heating pipes

- Simplicity, efficiency. The work is completed quickly, there is no need for lengthy preparatory and finishing work.

- Availability. All components remain visible, so if the integrity of the system is compromised, repairs will not be difficult.

- No heat loss. Since the pipeline does not come into contact with the floor or wall structures, the heat is used only to heat the room, without warming up the thickness of the finish.

An open circuit is considered a budget option. Laying is carried out without the use of insulation, insulating materials, adapters, putty and other things.

System components

Before work begins, a project for the future heating system is drawn up. The heating scheme for a private house with a gas boiler takes into account the size and location of the building, on the basis of which the components are selected:

Heat generator

The type of heating system is determined by the selected fuel. Depending on the fuel used, there are:

- Gas boilers. Gas can be obtained centrally or you can create your own storage facility.

- Diesel.

An economical and reliable method of heating is a gas boiler Source sedmoycanal.com

- On solid fuel. The raw materials are coal, firewood, peat, fuel briquettes or pellets (wood fuel pellets).

- Electrical. Electrolysis (electrode), induction devices, as well as boilers with heating elements are used.

- Combined. Popular options are combinations of gas with solid or liquid fuel.

- Universal. The design has several fireboxes for different types of fuel.

Pipes

Installation of gas heating in a private house involves the use of several types of pipes:

- Steel. There are ordinary and galvanized products that are connected both by welding and mechanical (threaded) methods. They can cause an accident (rupture) if the water is allowed to freeze.

- Polymer (plastic). They are not subject to corrosion, are silent, and can withstand frost without problems. Pipes have a significant coefficient of thermal expansion and do not cope well with high temperatures (only metal pipes are suitable for installing a chimney and piping a boiler).

Copper pipes in the heating distribution of a private house with a gas boiler Source vizada.ru

- Metal-plastic. Composite (multilayer) products, reliable and durable. Installation is carried out using fittings.

- Copper. They are not afraid of freezing due to their plasticity, and have high thermal conductivity (higher than that of steel products). Copper pipes are subject to electrochemical corrosion and are also expensive.

Expansion tank

Water has significant thermal expansion (when heated to 90°C, its volume increases by 4%). If in an open (non-sealed) system this is not critical, then in a closed (with forced circulation) it can lead to equipment damage. In order not to spoil the system and compensate for the pressure in the pipes, an expansion tank (hydraulic accumulator) is built into it.

The expansion tank is a sealed steel (sometimes stainless) cylinder consisting of two compartments. A flexible membrane is built between the compartments, separating the hot coolant and the pressure-compressed gas.

Algorithm of operation of the expansion tank Source kvartirnyj-remont.com

Radiators

Manufacturers produce batteries for different heating systems; they differ in the material of manufacture (cast iron, steel, aluminum, bimetallic radiators) and in the number of sections. There are several types of heating radiators:

- Sectional. Old cast iron radiators and modern tubular steel varieties.

- Panel. All-stamped steel, with heating and convection plates, on which the thermal power of the radiator depends.

- Vertical (towel rail).

- Convectors.

- Warm floor systems.

Devices and accessories

The water heating system needs monitoring. For this purpose are intended:

- pressure gauges;

- control and safety valves (shut-off valves and thermostatic valves).

The pressure gauge on the expansion tank controls the pressure in the heating system Source dvamolotka.ru

See also: Catalog of companies that specialize in heating and water supply.

Gas heating: types of supply

There are two ways to supply gas to the house - centralized and autonomous; The choice depends entirely on the location of the property.

- Main gas. Continuous gas supply is more functional and environmentally friendly, but is not without its drawbacks. Gas pipes are usually laid underground, which prolongs operation, but is more expensive. The cost of work is also affected by the distance of the gas pipeline; To approve the connection, it is necessary to prepare and approve a package of documents. Unreasonably long connection times and the high cost of work force us to pay attention to an alternative method of gasification.

- Gas holder. The loud name hides a storage tank for liquefied natural gas. When there is no main gas pipeline nearby, the solution will be a gas holder, whose operating principle resembles a huge lighter and is suitable for any type of boiler. Autonomous gas heating of a country house is a common occurrence in Europe, where a thrifty owner would not even think of stretching a line several kilometers long. A properly selected gas tank (taking into account household fuel consumption) is replenished 2-3 times a year.

Gas holder - autonomous gasification Source distroy.ru

Advantages and disadvantages of gas heating

Using gas for heating has many advantages:

- Price. Gas heating is beneficial due to its better price and efficiency ratio compared to other types of fuel.

- Safety. Thanks to automation, there is no need for constant attention to the process. The work is monitored by sensors; the owners’ task is to regulate the temperature in the house.

- Dimensions. The gas boiler has small dimensions, which allows it to be placed in a small room. A room for storing fuel is not needed (which cannot be said about firewood, coal or diesel fuel).

- Economical. Modern gas boilers are capable of heating large areas; some models (double-circuit) additionally supply hot water.

- Independence. A gas tank allows a household to be independent of utilities.

Economy of gas heating Source otoplenie-gid.ru

- Environmental friendliness. The fuel is stored in a gas holder, the combustion products escape through the chimney (no need to rake out the ash, there is no unpleasant odor).

Heating a house with gas has some negative aspects:

- The installation of boiler equipment operating on natural gas is coordinated with the Gaztekhnadzor service, which is accompanied by the preparation of a project, an agreement and the collection of permitting documents (licenses).

- For safe operation of the system, a separate room with good ventilation, a separate exit to the street and a chimney is required. Automation that monitors gas leaks is also needed. Systems with an open (atmospheric) burner are a potential fire hazard.

- A change in gas pressure in the pipeline can lead to boiler failure. Some models are adapted to such force majeure.

- Some systems require electricity.

A boiler room with an open burner needs a high chimney Source permhistory.ru

Choosing a heating gas boiler

Modern gas-fired heat generating equipment has a variety of automation and is able to operate in several modes. It can be floor or wall mounted.

The second option is more compact, but has power limitations. If the model is chosen for a large private house, then you will have to purchase a powerful floor-mounted unit.

Gas boilers are divided according to the method of execution, type of ignition, energy efficiency, number of circuits and method of removing combustion products

The principle of operation of a gas boiler is extremely simple - the fuel is ignited in the burner using piezoelectric elements or electronic ignition, then as a result of burning the fuel, thermal energy is generated, which is transferred to water through a heat exchanger.

The latter is already used as a coolant in the heating system or consumed in the hot water supply.

In terms of operating efficiency, traditional convection gas boilers are inferior to condensing boilers. The productivity of the former does not exceed 90% of energy consumption. Manufacturers of the latter guarantee 100% efficiency, some models promise 105 and even 110%

The heat exchanger in a gas boiler can be made:

- made of steel (stainless steel);

- copper;

- cast iron

The most common options are made of steel. This metal is cheap and ductile, so cracks from constant heating/cooling appear less frequently.

But steel elements, with constant interaction with water from a gas heating system installed in a country house, quickly begin to corrode.

A cast iron heat exchanger is the most durable, a steel one is cheaper, and a copper one is the most efficient in transferring heat to water

Cast iron is less susceptible to corrosion, but it is quite heavy. Most boiler models with cast iron heat exchangers are floor-standing. It is problematic to mount such heavy and large equipment on the wall.

If you need a compact and extremely lightweight heating unit, then the best option is with a copper coil. However, it is the most expensive among analogues made of other metals.

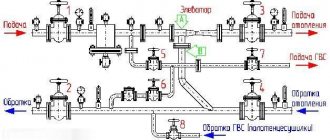

To supply the cottage with heat and hot water, you can choose a scheme with two single-circuit boilers or an option with one double-circuit installation

The piping scheme and the principle of its use depend on the number of circuits in a gas-fired water heating boiler. One heat exchanger was originally intended for organizing a gas heating system in a private house. For hot water supply, it is necessary to install another boiler or immediately select a double-circuit model.

It is best to heat hot water for domestic needs in a storage boiler. Streaming models are less economical. They will spend more gas on heating.

Wall-mounted gas boilers are a fully equipped miniature boiler room. Their design has its own circulation pump, expansion tank and safety group. Most wall-mounted equipment serves two circuits

Which combustion chamber is better?

In order for the gas in the boiler furnace to burn, it needs a constant supply of oxygen. It is taken directly from the boiler room or drawn in from the street. The first option involves natural air flow, and the second – forced air flow using a fan.

Gas boilers are equipped with two types of combustion chambers:

- Closed - oxygen is supplied through the gap between paired pipes of different diameters. Combustion products are discharged through an internal channel.

- Open - air enters the firebox from the room with the heating installation through the supply valve. Combustion products are discharged through a round smoke channel.

The first option is independent of the area of the room. Suitable for rooms of any size. The coaxial type of chimney can be removed from a unit with a closed firebox through a wall or an upper ceiling with a roof.

In the second case, you will have to install a high chimney pipe of 5–6 meters, otherwise the draft to suck the required volumes of oxygen into the combustion chamber will not be enough.

But gas boilers with an atmospheric burner do not require an electrical connection. There is no fan in them, everything happens naturally without forced circulation.

Boilers with closed chambers and forced air injection have a higher efficiency compared to open ones, but they require a constant power supply to operate

It is recommended to install gas water heaters with an open firebox in special rooms with good ventilation. If you install them in living rooms, they will greatly reduce the amount of oxygen in them.

It will no longer be possible to do without a forced ventilation system. And this means additional costs for the installation and subsequent operation of air ventilation equipment.

Characteristics of condensation models

In conventional gas boilers, water vapor generated during gas combustion flies out into the chimney. During the combustion process, little of it is formed, but it still carries a fairly significant amount of thermal energy. To avoid wasting this heat, condensing boilers were developed.

Flue gases in a condensing boiler, before exiting into the chimney, pass through a secondary heat exchanger, where they slightly heat the cold water entering the unit

The operating principle of these installations is based on the fact that when cooled, the exhaust gas vapor transfers heat to water from the return of the heating system. In this case, the temperature of the coolant increases slightly, but the recuperator is quite suitable as an additional source of thermal energy.

Condensed water from the condensing boiler is discharged through a special pipe into the sewer or into a separate container. Here it is worth clearly understanding one nuance - the condensate formed is actually a weakly concentrated acid. Moreover, up to 4–6 liters can leak per hour.

If this liquid is poured into a septic tank, then all the microbes living in it will be destroyed. If there is a treatment station in a country house, condensate from the boiler cannot be drained into the sewer system. With the design of the chimney everything is simpler; just take one that is designed for boilers with a closed chamber.

Design diagrams for heating wiring of a country house

Design features make it possible to divide heating wiring diagrams into types:

- Single- and double-circuit (one- and two-pipe). The scheme depends on the type of boiler; single-circuit is used only for heating, double-circuit is also capable of heating water.

- Passing and dead-end. Types of two-pipe wiring. In the first case, the movement of the hot and cooled flow occurs in the same direction, and the water turnover time for each radiator (and the rate of their heating) is the same. A dead-end scheme involves counter-movement of flows; At the same time, radiators located closer to the boiler heat up faster.

- Vertical and horizontal. Conventional division according to the position of the pipes (risers) supplying water to the radiators. For one-story private houses, a horizontal scheme is used. In dwellings with 2-3 floors, it is used if vertically located tubes do not fit into the design (horizontal ones are easier to hide).

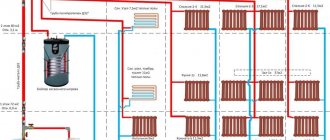

Radiator heating diagram for a two-story house; horizontal two-pipe distribution Source poradnuk.com

Types of boilers

Household gas boilers are very diverse.

according to purpose :

- single-circuit - work only on the heating system;

- double-circuit - have a second heat exchanger and, when switching, heat the water for washing.

Even a powerful double-circuit boiler supplies hot water to only 1 point. If you wash dishes in the kitchen, the water in the shower will most likely be cold.

By type of installation there are:

- floor-standing - the unit is placed on the floor, more precisely, on a pedestal or in a recess, can be very powerful and runs on any type of gas;

- wall-mounted - installed on the wall, compact, lightweight, but run only on natural gas.

Boilers are classified according to their ignition method :

- manual or semi-automatic - gas ignites upon direct contact with a burning match or spark from a piezoelectric element;

- automatic - the boiler is equipped with electric ignition, which automatically turns off the device when the gas pressure drops below critical.

The electric option is somewhat more expensive, but much safer. Here the ignition itself acts as an element of protection.

By design, one- and two-stage boilers are distinguished:

- single-stage – manually controlled, not automated;

- two-stage - allow you to regulate gas consumption, reduce the frequency of switching on/off.

A significant drawback of technological devices is their dependence on electricity. If there are constant power outages in the area or the house is equipped with old wiring, you will have to choose a model with mechanical control.

Schematic diagrams of gas heating

Installing gas heating is a profitable solution for a country house. Gas heating systems are connected according to two principal (suitable not only for gas) schemes:

With natural circulation

They are often called gravity or gravity systems; The operating principle is based on the physical properties of the coolant. Heated water has a lower density than cold water. The return pressure of the cooled liquid (which has passed through the pipes and given off heat) displaces the hot liquid from the boiler. It rises up the heating riser, filling horizontal pipes and radiators.

Installation of heating boilers in a private house Source vashslesar.ru

To ensure that the system works efficiently and the water does not stagnate, the heating pipes are installed with a slope of 3-5°, and the boiler is installed as low as possible (for example, in the basement). The scheme has obvious advantages:

- Simplicity. During installation, it is necessary to fulfill only one condition - to organize the slope of the pipeline.

- Independence. A scheme with a gas heating boiler does not require electricity.

- Silence. The diagram does not include devices (circulation pumps) that create background noise.

- Practicality. The service life is 25-30 years without major repairs.

The heating scheme for a private house with a gas boiler is a single-pipe horizontal water heating system with natural circulation Source rusolymp.ru

There are also disadvantages:

- Contour length limitation. For the system to function effectively, the length of the closed loop should not exceed 30 m, which is only feasible in small houses.

- Service. Gravity-flow structures are prone to clogging; Periodic washing is required.

Video description

About choosing a heating scheme in the following video:

With forced circulation

The circuit includes water pumps that force the water to circulate forcibly. The pump circuit does not limit the use of heating circuits; Top and bottom bottling of coolant, one- and two-pipe circuits are possible. The circulation pump is often installed in front of the boiler and allows you to do without organizing a pipeline slope.

The main condition for a forced circulation circuit is uninterrupted power supply for the entire heating period. The disadvantage of the system is that it becomes airy (usually at the beginning of the heating season).

Comparison of schemes with natural and forced circulation Source yandex.kz

Combined system

Combines the previous types, with its own characteristics:

- The distribution of metal pipes is installed with a slope.

- The pump is connected using a bypass pipe.

If the power grid is intermittent, the house is heated through natural circulation; the pump turns on if you need to quickly warm up the house.

Selection options

The principle of operation of gas boilers is simple: when gas is burned, energy is released, which is accumulated by water and then released in residential areas, heating them. There are several criteria that help evaluate the benefits of a particular gas device model. In addition to the manufacturer and the price of the device, most criteria are interrelated; this makes it possible to conduct a comprehensive assessment.

When designing gas equipment systems for heating a private home, medium-power boilers are often located in utility rooms Source diatec.com.ua

Calculation of gas consumption for heating a house

So, we know the required power of a gas boiler. Now we can calculate how much gas will be needed to heat the entire house, as well as how profitable it will be.

First of all, you need to find out how many cubic meters of gas are consumed per hour. Let's assume that we need a boiler with a power of 26 kW. We multiply the thermal power by one tenth of the gas volume:

26 kW * 0.1 m³ = 2.6 m³/h

Now let’s calculate the consumption per day:

2.6 m³/h * 24 h = 62.4 m³

Then in a month it turns out:

62.4 m³ * 30 d = 1872 m³

Three months of winter and another three months when the boiler operates at half power are counted as a year:

(62.4 m³ * 100 in) + (31.2 m³ * 100 in) = 9360 m³

Now all that remains is to multiply this figure by the cost of gas in your region. So we not only calculated gas consumption, but also found out how much it would cost us to heat the house.

For your convenience, we have developed a calculator to calculate gas consumption for home heating .

But don’t be afraid of such numbers: usually in reality less gas is spent than in mathematical calculations. There are also ways to save gas when heating your home. In short:

- install a gas meter;

- work on insulating your home;

- automate your heating system;

- make the ventilation system work for you;

- reduce the cost of heating water;

- Be sure to maintain your gas equipment.

Using these recommendations together, you will achieve maximum gas savings.

Video description

How to choose a gas boiler in the following video:

Purchasing a gas boiler

When purchasing, you should choose an organization that not only sells boilers and related equipment, but also installs them. This approach allows:

- Receive expert advice not only when purchasing, but also when installing, debugging and operating equipment.

- Be confident in the quality of the boiler and its service (timely delivery of spare parts).

- Be sure that there are no problems with warranty service (which may arise if the installation was carried out by a third-party technician).

Professional installation of gas heating - efficient operation of the system Source yandex.lv

Where to begin

Before you start figuring out how to make gas heating yourself, you need to leave behind naive thoughts about what will happen without gas service employees. Unfortunately, it is impossible to do all the work yourself.

In any case, you will have to involve specialists. But to reduce costs, you can install a lot of things with your own labor.

Why do we rely on gas:

- This is a cheap source of raw materials for combustion and heat transfer to the house. Even firewood is approximately twice as expensive to heat an identical living space;

- The operation of gas implies the absence of soot or combustion products, which is an undoubted advantage in comparison with firewood, coal, and pallets;

- Modern gas systems come with a thermostat - this allows you to regulate the temperature level;

- The equipment does not heat up much as a result of gas combustion. This practically eliminates the possibility of fire in a wooden wall, rafter or beam.

But most of the economic benefits relate to the centralized method of gas supply. Unfortunately, based on cylinders, the cost is expected to increase by 6 - 7 times.

Financial costs are almost comparable to the costs of operating an electric boiler. Therefore, we will not take this option into account.