Installing a gas boiler allows you to forget about cold water in radiators and taps. Double-circuit models are capable of simultaneously operating for heating and hot water supply (DHW) of a room. But what to do if the boiler does not heat the water? If you encounter a similar problem, our recommendations will help you find the cause and fix the problem yourself.

Operating principle of the boiler

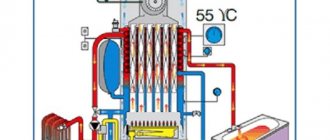

To understand the causes of the breakdown, you need to understand how the boiler works. Double-circuit devices “Ariston”, “Baksi” and other models have several blocks. In the gas unit, ignition and combustion take place, the water unit is responsible for the water supply and pressure in the line. The smoke exhaust unit removes combustion products to the street.

As soon as you start the boiler, the pump is activated, which pumps water into the system. The gas valve opens. The liquid circulates through the tubes of the heat exchanger, and the burner evenly heats its body. Sensors control the heating process. As soon as the temperature reaches the set temperature, the gas supply is turned off and heating stops.

When the temperature begins to decrease, the sensors will send a signal to the control module - the heating cycle will start again.

When the mixer is opened, the flow sensor is activated. It signals the board to switch the three-way valve to DHW heating. When the mixer closes, the valve switches to the heating system. Some models are equipped with a “quick start” mode. Then the valve periodically switches, heating both the first and second heat exchangers.

How does a boiler work?

To understand the situation more clearly, you need to understand the principle of operation of the boiler. Double-circuit gas wall-mounted boilers such as Baksi or Ariston consist of several components. In the gas part, the incoming fuel is burned, the water part ensures the supply of heated water from the heat exchangers to the heating system, and the smoke removal part is responsible for removing combustion products outside the home.

Depending on the user settings, temperature sensors adjust the water heating mode. A sensor on the return pipeline turns off the boiler, depending on the achievement of the required temperature set for the return. However, the system pump does not stop running until the heat exchanger temperature drops.

This is provided to prevent the water from boiling in it. As soon as the coolant cools down to the maximum level, the electronics will send a signal to turn on water pumping and the gas valve. The whole process will start again. When you open the tap in the mixer in a double-circuit boiler, a flow sensor reacts, which informs the electronics about the need to switch the three-way valve to the mode of heating water for DHW.

When the hot water tap is turned off, it returns to heating mode. Some manufacturers provide heating for both heat exchangers during periodic switching.

Why the boiler does not heat well and does not reach temperature

No hot water? For what reasons does the equipment not work? Sometimes it's a matter of external factors. Let's take a closer look.

The device works, but does not heat or heats poorly

Airlock. Check to see if air has accumulated in the batteries. Use taps to remove excess air. If you don't have an air vent on your radiators, then you need to install one. By adjusting its tap, you can release the accumulated air in the system.

Also inspect the valve for blockages. Most often it becomes clogged with scale.

Clogged radiators . After cooling, drain the water from the pipes. If it is very dirty, run it through the batteries until it comes out clean.

Incorrect connection . If there is no hot flow, make sure that the diameter of the pipes corresponds to those stated in the instructions. Are the hoses connected correctly and the shut-off valves installed?

Low pressure in the line . It is not enough to open the valve and ignite the burner. Add water.

Scale accumulation in the heat exchanger. You may notice that the equipment takes a long time to heat up the liquid, and the batteries heat up slightly. Clean the radiator tubes from deposits. To do this, it is better to remove the unit, but this cannot be done in all models. Therefore, remove the casing and disconnect the device from gas and water. Connect the tubes from the pump to the heat exchanger and circulate the cleaning liquid through the system. Special products can be selected in the store. Then rinse the parts with running water.

Adding reagents to the coolant fluid helps reduce the formation of salts on parts.

When purchasing, it is important to pay attention to the brand and model of the boiler. For example, Electrolux, Arderia, Ariston, Buderus prohibit the use of the reagent. It is recommended to install cleaning filters or use distilled water.

Antifreeze can be applied to Baxi, Beretta, Vailant, Proterm, Celtic, and Korea Star models. But a separate reagent is produced for each manufacturer.

Filter clogged . Another reason for poor battery warm-up. The mesh filter becomes clogged with small debris, so it is periodically removed and cleaned under running water. If the part is severely clogged or worn, it is better to replace it.

Incorrect adjustment . Check the set values on the panel. The temperature may be set too low, so the gas is not heating the hot water.

Problems with the operation of the circulation pump . Overheating, the pump turns off when hot water is turned on. Its power may not be enough for normal circulation. Adjust settings.

The battery design is not suitable for your equipment . Each design has its own permeability and heat transfer. An incorrect choice leads to a decrease in heating due to the permeability of the system.

Failure to comply with the slope of the highway . The problem is typical for systems with natural circulation, which is ensured by compliance with installation standards. According to the documents, the slope of the pipes for each linear meter must be at least 10 mm. No slope - no heating. The coolant stagnates, the batteries remain cold.

Possible nuances

Today there are many gas wall-mounted boilers from various manufacturers on the market. The principle of operation of the units for all models is essentially the same, but each brand has its own nuances that may be related to the causes of malfunctions and, as a result, poor water heating.

- "Ariston" is an Italian brand that is distinguished by its reliability. The brand’s boilers are adapted to domestic utilities and operating conditions. The most common cause of malfunctions is hard water, which contributes to the formation of blockages in the heat exchanger and circulation pump.

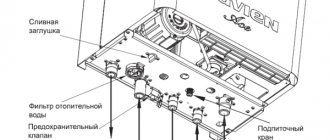

- "Navien" - Korean autonomous gas boilers. They are easy to use and effective. A special feature of the modification is the presence of two heat exchangers and the absence of a control panel on the body. The reason why the Navien boiler does not heat hot water well may be a stop in the operation of the equipment. This is due to the air pressure sensor, which, in the presence of reverse draft in the smoke exhaust unit, sends a signal to the control board, which causes the gas supply valve to the burner to close.

- "Vailant." German quality is fully reflected in the units under this brand. Since the device is of European origin, its heat exchangers most often suffer, becoming clogged due to the poor quality of the conductive heat fluid.

- “Baksi” is another representative of Italian manufacturers of autonomous heating equipment. He has simple and reliable boilers. The main reason why the Baksi does not heat the water, as noted by specialists servicing such units, is a manufacturing defect, which is sometimes found in this model line - a South Korean manufacturer. He provided a certain algorithm for controlling heating equipment. Incorrect settings may be the answer to the question of why the boiler stopped heating water.

- Proterm is a subsidiary of the German company. When operating these boilers, you need to monitor the quality of the heat-conducting fluid and use cleaning filters to prevent clogging of the heat exchanger.

- “Buderus” is another “German” in the domestic market of autonomous heating equipment, which has proven itself on the positive side. Like all Europeans, malfunctions can be caused by the formation of limescale inside the heat exchange system, as well as clogging of the working fluid flow sensor.

What kind of breakdowns can occur in a Navien gas boiler?

Most often, consumers choose a Navien double-circuit gas boiler; its faults are displayed on the display. Many users on the forums are interested in what error codes mean and how to fix problems.

As practice shows, the occurrence of malfunctions is mainly associated with improper installation and operation of units, as well as with voltage surges and the use of low-quality coolant.

Navien floor-standing gas boilers - pros, cons and model range

Floor-standing single-circuit gas heating boilers - what is important to pay attention to

The manufacturer has provided the following fault codes for Navien gas boilers:

- 01E – system overheating;

- 02E – lack of coolant or the flow sensor circuit is broken;

- 03E – no flame signal;

- 04E – short circuit of the flame sensor circuit or false message about the presence of fire;

- 05E – temperature sensor circuit connection failure;

- 06E – temperature sensor circuit short circuit;

- 07E – connection failure of the DHW temperature sensor;

- 08E – short circuit of the DHW sensor;

- 09E – malfunction of the coaxial chimney fan;

- 10E – failures in the combustion product removal system;

- 13E – short circuit of the heating system flow sensor;

- 27E – malfunction of the APS sensor circuit;

- 15E – malfunction of the control board.

If some error codes appear, only a service center specialist will help solve the problem. However, you can try to fix certain problems yourself without involving a technician.

What to do if the aspirated air leaks?

For the Atmo model range with an open (atmospheric) burner, the primary heat exchanger is made of copper.

The appearance of a leak is almost always associated with its destruction. Purchasing a new heat exchanger is not an easy and expensive task, so most often the issue is solved by soldering the fistula .

To carry out repairs, you should contact a technician from the service center, since this requires a qualified specialist who can dismantle the unit, find the fistula that has arisen, solder it properly, simultaneously rinse the heat exchanger and install it in place without damage.

The work is complex and requires the participation of a trained person.

What problems can you fix yourself?

Let's look at the malfunctions of Navien gas boilers and how to fix them yourself.

The reasons for the appearance of error 01 are a blockage in the heat exchanger or a decrease in the volume of liquid in the system, or failure of the circulation pump. To resolve this issue, it is recommended to do the following:

- check the pump and coil for short circuits;

- bleed excess air from the heating system, if any;

- Check the pump impeller for damage.

Error 02 is usually accompanied by the following malfunctions: warm water first flows out of the hot water supply, and then cold water flows in; on the remote control, the water temperature rises sharply to a maximum, and then quickly drops. The heating works fine. The cause of this problem may be:

- lack of coolant;

- airiness of the system;

- the circulation pump cannot work fully;

- the flow sensor is not functioning;

- the distribution valve is closed.

You can troubleshoot the problem as follows:

- adjust the pressure;

- expel excess air from the system;

- open the distribution valve.

Most often, the cause of this error is air locks in the hot water system. Water entering the circuit is heated to the required temperature, but when air enters the heat exchanger it sharply increases to critical levels, which causes a malfunction with code 02.

error 03 appears in a gas boiler this may indicate that the flame sensor is clogged or its wiring is broken. The situation can be corrected by adjusting the wires or cleaning the sensor from adhering deposits. Fine-grained sandpaper removes dirt well.

What happens when hot water is turned on at one point of intake

The double-circuit boiler is set to maintain a certain temperature in the hot water supply circuit. When you turn on hot water at one of the points:

- For some time, cold water continues to flow from the tap, which was standing in the pipe before it was opened,

- the boiler heats up, and a certain time is required for it to reach the set temperature,

- after a few seconds, the heated water enters the pipe and begins to move to the intake point,

- a few more seconds are needed for the hot water to reach the point of intake,

- an additional few seconds are necessary due to the fact that the incoming water seems too hot to the consumer, and he adjusts the water supply with the mixer.

Thus, at least a few seconds pass from the moment the hot water tap opens until the water supply starts at a comfortable temperature. The further the water intake point is from the boiler, the longer this period of time.

All this time, the user cannot fully use the water and it will be that the boiler does not heat hot water normally. He waits until water arrives at a comfortable temperature. Meanwhile, water at a temperature that is not comfortable for the user simply goes down the drain.

Unproductive water consumption can range from several liters to tens of liters, depending on how far the water intake point is from the boiler.

Doesn't start for a long time

The boiler is started when certain conditions are reached. If the temperature or pressure of water (OB, DHW) is within the specified range, heating will not start until it cools down .

A possible cause may also be partial clogging of the water filter, which slows down the flow and changes the circulation mode. It may be difficult for the circulation pump to operate if it is clogged with lime deposits or small debris.

What happens when hot water is turned on simultaneously at two points of intake

The scheme becomes more complicated if, while using hot water at one point of intake, it becomes necessary to turn it on at another point, for example: when the shower is turned on in the bathroom, it becomes necessary to wash your hands in the toilet washbasin. In this case:

- the rate of hot water use increases sharply, its consumption increases,

- weak pressure of hot water appears;

- the flow of cold water into the boiler increases,

- a drop in the temperature of the boiler heat exchanger leads to the fact that the water temperature at the first intake point ceases to be comfortable,

- a few seconds are required to turn on the boiler automation for heating,

- a few more seconds for both users at two points of collection to be able to use water at a comfortable temperature.

All this time, both users cannot fully use hot water. It arrives intermittently. The unproductive consumption of water, which goes uselessly into the sewer system, increases sharply.

Ways to solve the problem

The problem can be solved in ways that require significant investment, for example:

- using an indirect heating boiler together with a boiler,

- purchasing a new boiler with a built-in boiler.

However, there is a less expensive, but very productive method - inserting an electric storage heater into the hot water supply circuit. Moreover, for this purpose, any standard heater with a volume of 30 liters is quite suitable, regardless of the manufacturer.

Use a water heater

A water heater embedded in the hot water supply circuit acts as a buffer tank. Its purpose is to equalize the temperature of hot water and smooth out possible temperature surges. The storage water heater and the gas boiler heater are set to the same operating temperature.

Even if the hot water taps are turned on simultaneously at different points of its intake, all users will initially receive water from the storage tank. The time spent waiting for a comfortable water temperature is reduced. Unproductive water consumption is reduced.

Turning the hot water supply on and off at any point of intake causes a temperature difference in the water leaving the gas boiler. However, this water enters the lower part of the water heater, and when it leaves the upper part, the temperature jump is completely smoothed out.

Connecting the water heater through a ball valve allows you to switch to a conventional gas boiler operating system at any time, which can ensure uninterrupted hot water supply in the event of a water heater failure.

Using a bypass jumper with a tap in close proximity to the boiler allows you to exclude the boiler from the hot water supply system. If the boiler is under maintenance, using the existing water heater will ensure uninterrupted operation of the hot water supply system.

Recommendations for operation and repair

- To ensure that the equipment operates for a long time and productively, you can install a voltage stabilizer, filters (gas and water), a magnetic or polyphosphate water converter, etc.

- The gas boiler must be installed strictly in accordance with the requirements specified in the passport.

- To eliminate the causes of malfunctions, you must carefully study the instructions and act according to them.

Use an expansion tank

In winter, when the boiler's heating circuit is activated, any activation of hot water results in the heating circuit being turned off so that the hot water supply circuit can turn on. In the summer, when the boiler's heating circuit is not activated, each turn on of the hot water leads to the gas boiler turning on.

Often the user opens the hot water tap to simply rinse his hands. The boiler turns on or switches, hot water flows through the pipes. But the user may simply not wait for it, washing his hands with cold water.

Meanwhile, frequent and useless turning on and switching of the boiler “eats up” its operating life. A possible solution is to install a small expansion tank. It is installed in front of the water heater. If there is such a tank, for the first time after turning on the tap, hot water enters the pipe exclusively from the water heater due to the increase in pressure in the tank. Thus, in case of short-term use of hot water, there is no need to turn on and switch the boiler.

It is recommended to use a tank designed for hot water supply. Using a tank intended for heating will cause an odor because its membrane is made of rubber.

Use a recirculation pump

The best option is that the water heater is located in close proximity to the hot water intake points. The closer it is, the faster the hot water enters the tap, the more efficiently it is used. If this option for installing a water heater is not possible, then it is recommended to install a recirculation pump.

The pump is installed in the section between the water heater and the hot water intake points, ensuring the slow movement of hot water through the pipes. In addition, if you install a heated towel rail in this section, it will perform its direct function at any time of the year, regardless of the operation of the heating circuit of the boiler.