A furnished balcony is a surprisingly cozy place. An additional room in an apartment or house will not hurt anyone. This means it should be comfortable and warm there even in cold winter. Modern repair technologies allow you to make your balcony warm and stylish with your own hands. Warm floors on the balcony under laminate are gaining popularity. The walls and the floor will have to be insulated.

Before installing a heating system, you need to take into account certain nuances and understand the features of using certain floor heating systems on a balcony under laminate.

Features of laying heated floors on loggias and balconies

Having decided in favor of underfloor heating, you need to choose the appropriate type. Modern systems, known as “warm floors,” are divided into three types:

- Mermen.

- Electrical.

- Infrared.

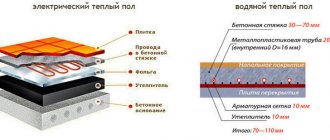

When choosing a floor, they evaluate the features and complexity of installation, the conditions of the balcony room, installation costs, and economic feasibility during operation. All types of warm foundations have common characteristics. Each of them requires the installation of a thermal insulation layer, a high-quality screed and a decorative floor covering on the loggia.

Installation of water floors

The water heated floor circuit is a coil of a tube in which hot water or antifreeze circulates. The system is connected to central heating or a heating boiler. In the latter case, an expansion tank and an automated distribution unit are required.

Water-heated floors are characterized by high heat transfer. However, it is not suitable for installation on balconies in high-rise apartment buildings, since connection to a common heating system is prohibited in them due to possible emergency situations. In general, it is not recommended to install warm water pipes on any classic balconies. This type of flooring is only suitable for insulated loggias in private houses, the slab of which can withstand the additional weight of a circuit filled with coolant, and can be connected to an autonomous boiler.

The costs for water heated floors on the balcony are one-time - when installing it. However, installation is classified as complex. Difficulties also arise when adjusting the temperature during operation.

Electric floor installation

The basis of an electric heated floor is a circuit made of cable or special mats connected to the electrical network. The use of such heating elements for heating a balcony is considered beneficial. It is much more convenient to make a warm floor from cable mats than from loose cable, but they are more expensive.

Air bubbles do not accumulate inside the finished warm structure, so the shelf life of the system is quite long. Electric heated floors work through a thermoregulatory sensor, which makes it easier to control the temperature. In financial terms, installation of this type of floor falls into the budget category. Another advantage is the rapid detection of defects during operation and their elimination.

Despite all the positive aspects, the operation of an electric floor requires electricity, which means additional monetary costs for this resource during the heating season. In addition, the system is a source of electromagnetic radiation. Although this minus matters if the balcony is used as a living space.

Connecting infrared floors

To construct an infrared heated floor, a thin fabric is used, into the structure of which conductors and strips of graphite are mounted. The material is covered with polyester film on top. The principle of operation of the element is to generate infrared rays.

IR film is flexible, so it freely bends around any protrusions and depressions. The ease of installation is due to other advantages of infrared flooring. It does not require a screed or adhesive base. A stapler is enough for fixing. The warm floor in the form of an IR canvas is very easy to dismantle if necessary.

The disadvantage of a warm infrared base is the high price of the material. But considering that the balcony area is small, and the heating method is quite effective, IR film for the floor is in demand. The cost of electricity that powers the system can also be considered a disadvantage. But the amounts of money are not too large.

Sometimes there are recommendations to do without floor insulation if IR film is used. Since this heater works on the principle of radiating energy upward. However, if for a number of reasons such floors are disconnected from power, their surface will become icy. Therefore, ideally, you should not abandon the installation of a traditional thermal insulation layer.

How can you heat a balcony?

You can heat the room that we equip on the balcony using:

- central heating outlet;

- heated floor equipment;

- installation of an infrared heater;

- the presence of an electric heater;

- placement of oil batteries.

Briefly about central heating

Heating a balcony using central heating is a very profitable way for the long term. It is seduced by reliability and proven over the years. But it also has disadvantages. Heat will only be supplied at the beginning of the heating season. In addition, this method entails quite a lot of hassle, since its equipment requires permission from the BTI.

Remember: under no circumstances should you install additional radiators on the balcony and connect them to central heating. This is primarily due to the fact that due to an unauthorized connection, your neighbors will not receive enough heat. But if your application was reviewed and approved by the BTI, then you can safely install a heated floor on the balcony from central heating:

- To begin with, experts advise covering the part of the wall where the battery will be located with foil. It will become a heat reflector. This way the room will warm up better, and the heat will not escape to the street.

- After this, it is necessary to call a specialist from the organization that supplies heat to shut off the common riser.

- Then holes are drilled in the wall for the pipes. Instead of pipes, experts advise using a plastic-aluminum hose. Then a tee with a valve is mounted on it.

- Next, heating batteries are installed. To do this, you need to fix two brackets on the wall that will hold the radiators at the top, and one bracket at the bottom to hold the battery at the bottom.

Only after all this work is completed are the batteries connected to the central heating

Particular attention must be paid to ensure that no air pockets form in the system.

Warm floors are a great alternative

A more economical option is to install heated floors, since their installation will cost less. They are electric and water. The principle of operation is simple: the air heats up and the top rises. Thanks to this, the desired temperature is maintained in the room.

Installing a water floor on the balcony

Installation of a water floor

- First, you need to insert tees on the supply and return lines when the pipe replacement work is carried out. And also be sure to install shut-off valves (valves) so that it is possible, if necessary, to shut off the supply of warm water.

- Next, a concrete screed is laid on the floor. Its base must be leveled.

- After this, the insulating material is laid.

- Now begins the laying of plastic pipes, which are the basis of the heated floor. They are placed like a snake. The bend should be small. The distance between the pipes is insignificant.

- Next, connect the plastic pipes to the hot water supply system.

- The final stage is laying the concrete screed on the base.

We pour the screed onto the installed water floor on the balcony

For concrete screed, you can use various materials: special building mixtures or ordinary cement mortar (an old proven method).

When laying a water floor, you need to remember several mandatory rules to follow:

- If the main floor is tile or laminate, then the thickness of the screed should be small.

- For a water floor, it is necessary to purchase only high-quality materials with a long service life, since troubleshooting will then cost a significant amount.

- The “warm floor” system is installed from a single pipe. There should be no joints under the screed. Therefore, before purchasing materials, take careful measurements.

- Protect the ends of the pipes to prevent blockages.

- It is imperative to glaze the balcony on which it is planned to install heated floors.

- After completing all work, you must wait several days until all concrete mixtures have completely dried. Under no circumstances should you use a direct heat source to the underfloor heating system to speed up the drying process. But be sure to regularly ventilate the room to remove excess moisture that will form during drying.

Heating connection

The heated floor is installed, the screed is completely dry, now you can connect to the central heating and check the result of the installation. If your central heating system is already running, all you need to do to get your floor working is open the valves. A few minutes - and you can feel a pleasant warmth under your feet.

What should be the insulation?

A balcony is a structure that protrudes beyond the load-bearing walls and has no support underneath. All enclosing surfaces are thin and freeze in winter. GOST allows a maximum operating load of only 200 kg/m2.

What to consider when installing balcony insulation:

- moisture resistance of thermal insulation in the area of contact with atmospheric moisture;

- a lot of construction and finishing materials.

The construction market has all the necessary goods to install balcony insulation with your own hands. The floor is the coldest contact surface, so you should pay special attention to it.

Important! The warm floor is installed after glazing and insulation of the perimeter of the walls and ceiling, but before finishing.

DIY cable floor installation

Installation of cable heated floors

- The first step is to remove the previous floor and remove all small debris.

- Then lay the “bottom” floor - a leveling base for the future screed. Lay a layer of thermal insulation between the balcony slab and the “bottom” floor so that all the heat remains inside the room and does not go to the neighbors. The base is lined with a waterproofing material (for example, polyethylene) so that the heat insulator is not saturated with condensate moisture, which reduces the effectiveness of its functions.

- Wooden beams are laid across the balcony at intervals of about half a meter and attached to the concrete base with anchors. Longitudinal logs are placed on these transverse boards and secured with self-tapping screws. As a rule, three logs are enough for a standard balcony. The base for leveling should be the highest point of one of the outer lags. The rest of the boards are leveled to the level of the base using mounting wedges. All voids between wooden beams and joists are filled with heat-insulating material (for example, mineral wool).

- Chipboard sheets are laid on the logs. This material should not be replaced with plywood or anything else; it is ideal for a balcony - it is resistant to fluctuations in humidity and temperature. The seams between the sheets are filled with polyurethane foam.

- The heat cable is fixed to the chipboard. It is mounted with a “snake”, the distance between the turns is called the laying pitch. For a standard balcony it is 10 cm. This value must be taken responsibly, because if the step is too large, the floor will partially warm up. The cable is fixed to a special mounting tape, which is fixed in advance to the chipboard. Now you can connect the thermostat (for the balcony it is installed externally) and check the heating system to eliminate any shortcomings.

- The final layer is filled with screed - the thickness is about 5 cm. It is not recommended to use reinforcing mesh and make the screed layer thicker, so as not to burden the balcony structure.

- After five days, when the concrete has completely dried, the flooring can be laid.

Installation video instructions

It is much easier to install another type of electric heated floor with your own hands - heating mats.

Installation of heating mats

First you need to decide on the location of the heaters themselves.

Then everything follows the same scheme: thermal insulation, “bottom” floor, heating mats according to a given scheme, connection to the power supply system and the mandatory test. The advantage is that a concrete screed is not needed; the floor covering is laid directly on the heating elements. This version of a warm floor is well suited for tiles, which are mounted with special glue. After the glue has dried (usually 20 days), you can begin to operate the heating system.

Preparing the premises

Before installing the infrared floor, the room must be carefully prepared. Naturally, you need to remove all furniture and other things that will interfere with your work with the surface. But that's not all.

You can get the maximum effect from the new system only if the heat remains in the room and does not escape from it to the street. Of course, if in your region the weather is consistently warm, and only sometimes (for example, at night) it gets cool, then you can heat the floor even on an open, unglazed balcony. Your feet won't get cold, but your body will still be warm.

But what happens if everyone in your city wears warm jackets for most of the year? When the next frost sets in, the heat from the loggia will slip outside, the heating system will be forced to work continuously, and most of your energy costs will go, in fact, to insulating the street, but the room will still be cool. Agree, this is not a very bright prospect.

Installation of a water floor on the balcony

A warm floor on a balcony is a wonderful opportunity to make this room more convenient and comfortable, to create the most optimal conditions for the life and hobbies of home owners.

This article will discuss all the features and nuances of such a process as installing a heated floor on a balcony.

Which underfloor heating option is suitable for a balcony?

The best option, according to experts, is a water floor. Hydronic floor heating is one of the most popular heating systems; its popularity is due to its high availability and efficiency.

And installing such a warm floor on a balcony will not be difficult if you follow the instructions given below.

What are the steps involved in installing a warm water floor on a balcony?

Surface preparation. The floor must be cleaned of dirt, dust and construction debris such as crushed stone. If there are visible irregularities, they must be eliminated using a new sand-cement screed. Make markings on the cleaned surface: mark the areas between which you will draw so-called expansion joints.

Insulation. Before laying a water floor, it is necessary to provide thermal insulation (otherwise the heat will go down). The thickness of the heat insulator material is usually from 30 to 150 mm. Choose the strongest thermal insulator for a water floor. Examples of such heat insulators include polystyrene foam and polystyrene foam. If you choose a poor thermal insulator, the heating efficiency will be reduced to almost zero. This is especially true for a water floor, since in most cases it is under this room that there is a layer of cold air and free space.

We install the pipeline fastening elements. The next step is to install special fasteners for the pipeline. This design should hold the pipeline and ensure the stability of the system as a whole. Reinforcing mesh can be used as fastenings. In this case, the diameter of the reinforcement should be 4-5 mm, and the cells should be 150 mm in size. Sometimes in practice the double reinforcement technique is used. Thus, the mesh can be placed both under and above the pipes. This guarantees increased reliability of the water floor system, in which the likelihood of its deformation is reduced to zero.

Collector installation. Before starting the pipeline installation, you need to install the manifold and the underfloor heating control group. The choice of system control system depends entirely on the type of heated floor. The control is installed on the wall or in a special cabinet.

Pipeline installation. The most optimal options for laying underfloor heating pipes are the “Snake” or “Spiral” scheme. The pitch of the pipes should be smaller closer to the walls and wider in the center of the room. The maximum pipe pitch can be 30 cm, and loops should be made no further than 10 cm. This must be done for high pressure in the system and good heat transfer from the floor. Installing a warm water floor also involves connecting to a heat source, as well as conducting hydraulic tests. The tightness is checked for at least 24 hours. Otherwise, you may face a lot of troubles in the future.

Screed layer. Next, a concrete screed is made, which must be prepared in advance. The minimum layer thickness is 3 cm. To increase thermal conductivity, special substances – plasticizers – must be added to concrete. The screed is poured only at the moment when the system is under pressure. This pressure must be maintained throughout the curing time of the screed. And this is from 28 to 35 days

It is important to maintain pressure so that a breakdown does not occur when trying to put the water floor system into operation and, as a result, redo all the work performed.

Flooring. Once the concrete screed has dried, you can begin laying the finishing layer, for example, tiles. Instead of tiles, you can use any other floor covering - a water floor does not impose restrictions on the covering; the choice of a specific floor covering for a balcony depends only on the preferences of its owner.

Water heated floors are the best solution for heating a balcony. Only thanks to this system can you ensure maximum comfort in the room.

https://youtube.com/watch?v=GPDTFtvh-Go

With all this, installing a warm water floor on a balcony will not take much time and effort - all the steps from preparing the base to laying the finishing layer are quite simple and can be done independently.

And the last drop in the sea of advantages of a water floor is, perhaps, its cost. A warm water floor is quite affordable in all respects.

Kinds

The design and operating mechanism of underfloor heating may vary. It may be a cable type - consisting of one wire or a mother-type version, or maybe a completely unusual, infrared (in the form of a film) version. Let's try to understand on what basis a choice should be made.

See below for more details.

Cable heating system

It is characterized by its simple design and does not require additional installations. It looks like a longitudinal cord. Warming is carried out thanks to electricity passing through the wire. This type of heating has its advantages:

- low power consumption;

- safety and security of materials. Thanks to the strong protection of the cable itself, for example, the coating of the tie on one side, and the location of the wire in the insulation layer, oxidation is almost impossible;

- The heating system is very easy to operate and adjust.

7 photos

Mats

The design has the shape of a canvas, 40-50 centimeters in size. A thin heating wire is fixed to a glass-metal mesh - this serves as a convenient form for installation. The benefits include:

- safety – floor heating mats are the safest design. When using them, the heating system fully complies with safety measures;

- saving space. The height of the floor practically does not increase - together with all the insulation, the floor rises only 1.7 cm;

- easy installation. The balcony has different shapes and the floor is sometimes unique. The mats can be easily cut and deformed into complex parts, leaving the functional part intact. The wire with this design is always protected.

Infrared floor

The option of a warm infrared floor is an interesting alternative to classic types of heating. Installation is expensive, but on the other hand it is chosen very often. And that's why:

- saving electricity consumption. Due to the unique heating system, electricity is not dissipated through the wires, but is accumulated in the system itself, giving maximum heat to the space, consuming minimum energy;

- easy operation system. The system can be turned on immediately after installation - the design is as simple as possible to use;

- fast heating. You can regulate not only the temperature in the room, but also its heating time. Usually 10-20 minutes is enough.

Water floor

Such a system is fundamentally different from an electric one - it is based on water heating. It has the form of a cable that is laid in a “snake” around the entire perimeter. The installation of water structures is least often chosen because it can leak and become deformed. If it breaks, it is necessary to disassemble the insulation structures to the base - this is expensive. Although, along with this, the water floor system has exceptional advantages:

- saving. The heating system does not consume electricity;

- safety. With this design, all safety measures are observed. There will be no fire threat;

- long and high-quality heating of the room. This function is due to the fact that water retains heat longer than electrical wiring.

Thermal mats

This is probably the most suitable electric heated floor under linoleum that can be laid on the balcony. Its advantages compared to the previous solution are as follows:

- There is no need for a screed here. The mats are laid on the surface in a layer of tile adhesive used for installing tiles and porcelain tiles. Therefore, the layer will be only one to two centimeters.

- The adhesive mixture dries much faster than cement, which will ensure quick commissioning of the system.

- The load on the floor increases insignificantly and the solution can be applied anywhere.

- The raising of the floor surface will be insignificant and comparable to a layer of simple leveling mixture.

The swearing system also has disadvantages, but they are not particularly critical. For example, the mats themselves are quite fragile and can be accidentally damaged during installation. The second disadvantage is the cessation of heat transfer immediately after turning off the electricity. The adhesive layer is not able to accumulate heat. The last drawback is the most important - such a system costs much more than a heating cable.

Description of fabric

Felt is a super dense and durable fabric. It is obtained by felting the fluff of hares, goats, and rabbits. Fur waste is often used for this.

Sometimes felt is made together with chemical soft fibers. This fabric can be either smooth or pile.

Collector system

The collector is a stainless steel comb with thermostats and flow meters. Designed to distribute water through pipes and maintain a certain temperature of the coolant.

The temperature of the water floor heat source should be no more than 40 degrees . The set temperature is maintained by thermostats. These devices are:

- electronic;

- mechanical.

Electronic thermostats are programmed to maintain the desired water temperature throughout the entire system. Using mechanical devices, you can manually change the temperature of the heat source.

The water collector is installed in a special niche hollowed out in the wall or in a collector cabinet.

Infrared heated floors

When connected to an electrical outlet, such a floor emits long infrared rays and negatively charged ions. Since all heat is infrared in nature, it can be said that the indication of “infrared” is simply a marketing ploy by manufacturers. The principle of heating is no different from other types of heated floors - they heat the floor covering, and from it the air.

Air ionization is undoubtedly useful. Ions kill fungus, the air becomes cleaner. The only problem is that the entire beneficial effect will be limited to the floor covering. It simply will not let the ions go further.

Manufacturers recommend installing infrared floors under carpet, tile, laminate and wood. But we want to warn you - due to constant heating, the last two coatings may dry out.

Advantages of infrared heated floors

Comparison of three heating systems: cable, infrared floors and radiator

Infrared heated floors are in many ways better than cable ones:

- they heat the air more evenly across the entire height of the room. Near the ceiling it will be +20°C, while cable and water floors warm the top of the room to +15°C

- The thermal conductivity of infrared floors is slightly higher than that of water and cable floors. The heat from the first is transferred by 90% to the floor covering, and only 10% can go to the neighbors below

- infrared floor saves 20% energy compared to cable floors

- heating to the set temperature occurs twice as fast as other floors

- heat transfer does not decrease over time. With proper use, the floor can work like new for many years.

- electrical contacts have a parallel connection circuit. This means that if one section fails, the rest will work without noticeable heat loss

- infrared floor is safe to use. It does not burn, does not freeze, and does not give an electric shock. Electromagnetic radiation is less than that of cable floors - the latter emit it throughout the entire volume of the balcony, and in infrared the current flows only along the edges

- To install such a floor, you do not need permission from the authorities. It is convenient to use in apartment buildings with centralized heating, since installing a water floor there is prohibited by law

- Install easily and quickly in a few hours

- if necessary, they can be collected and spread in a new place

Disadvantages of infrared heated floors

The connection diagram for a warm film floor is not simple

Infrared floors also have disadvantages:

- Difficult to connect electricity. If you cannot connect the contact correctly, you will have to throw it away. And there are a limited number of them included

- film manufacturers assure that it can be laid even on uneven floors

However, it is not. The floor needs to be well leveled so that, again, the contacts are not damaged.

Types of infrared heated floors

There are two types of infrared floors - film, which are rolls of thin film, and mats made from heating rods.

Rod infrared floor

These are carbon rods that are connected to each other at both ends by black connecting wires.

Unlike film floors, the core floor must be filled with screed. But spreading it out is also easy—roll it out and you’re done. In addition, you won’t have to level the slab as carefully as you would with film.

Film floor

It comes with heating strips and fully heated.

In films with heating strips, individual strips placed between polyurethane layers are heated. Depending on the material of the heating element, such films are divided into bimetallic and carbon (carbon).

Externally, the two types differ little from each other. However, bimetallic films are not common now because they are less effective. They have aluminum and copper strips.

The hydrocarbon (carbon) floor heats due to carbon strips. The service life of such floors is 15 years. Cost of 1 sq. m. - from 500 to 1000 rubles.

The South Koreans released a solid carbon film in 2011. Its difference is that it does not consist of separate strips, but is a solid carbon layer. The larger the coverage area, the higher the efficiency, that is, heating.

Solid carbon fiber is embedded between layers of polyethylene terephthalate (PET). These layers provide such strength that the film can be cut with a knife, and the heat transfer will remain the same. Therefore, the warranty period for it is 50 years. It is sold in rolls with a width of 50 and 100 cm. The cost is 1 sq. m. m. about 1600 rub.

For balconies, warm film with a power of 180 W and above is suitable. Additionally, you will have to buy: a thermal insulation backing for the film (for example, penophenol or isolon), a thermostat.

Electric models: varieties

There are several options for electrical models of heating systems:

- Cable. The heating element of cable models is a heating cable, which is a heat source, which allows it to transfer heat more efficiently. Comparing a heat cable with water pipes, it can be noted that the cable warms up along its entire length, and the coolant in the pipe cools as it moves away from the heating source. But just like with water pipes, the cable requires pouring a concrete screed and finishing, for which it is better to use laminate.

- Thermal mats. This option is essentially the same heating cable. A distinctive feature of thermal mats is that the user does not have to lay the reinforcing mesh, and then the cable, fixing it to the mesh. Thermal mat is a reinforcing mesh on which the heating cable is already attached. This option, like the previous one, is placed in a concrete screed.

- Infrared. If it is not possible to pour a concrete screed, or there is no desire to wait for it to dry, you can lay the infrared version on the loggia. In this case, the functions of the heater are performed by a film placed on the finished screed, directly under the laminate or tile.

Choosing a thermal floor design

Both water and electric heated floors have their own individual operational characteristics. The general difference is the mounting method. Any heated floor is attached to a specially created heat-insulating surface. A layer of insulation will protect the floor from heat loss. A cement screed is also performed, and after it the floor covering in the form of tiles is laid.

Design diagram of a heated floor under tiles

Water-based heated floors have complex installation and depend on autonomous and central heating. Has high heat loss and is suitable for large loggias. In a small area, such floor heating is not very profitable.

Methods for installing water heated floors under tiles

Technologically, the installation of a water heated floor involves laying two types of screed:

Concrete screed. It looks like a structure where preliminary installation of thermal elements takes place: pipes, cables, heating mats.

Water heated floor under concrete screed

Floor screed. Ready-to-use materials are used, with simple and easy technology. The screed is divided into subtypes: wooden, slatted, polystyrene, modular.

Warm floor on the balcony under tiles on a wooden floor screed.

Water-heated floor on a slatted floor screed.

Modular screed for electric heated floors under tiles

Important: pipe laying in a water heating system on a balcony is usually carried out from the wall to the center. After laying the water heated floor, the elements should be pressure tested

This will help you see and prevent leaks and damage. The pressure in the system should reach 4 bar. And the pressing time is 24 hours

After laying the water heated floor, the elements should be tested. This will help you see and prevent leaks and damage. The pressure in the system should reach 4 bar. And the testing time is 24 hours.

The ideal option for underfloor heating is electric. In order to carry out the installation work yourself and not have to worry about calculating the number of heating cables, it is recommended to use heating mats. This is a specialized fiberglass mesh covering with attached shielded heating sections.

The sections are made by connecting the cold and hot parts. For this purpose, a clampless method was used, which ensures high reliability.

Model options

There are two types of underfloor heating systems.

- Water.

In this case, it is planned to lay pipes, the heating of which is carried out due to the hot coolant circulating inside. In this case, the operation of a heated floor is possible when connected to a central heating system or by installing an autonomous heating boiler. This floor is placed in a concrete screed. Warm water floor for a balcony - Electric.

Its installation involves laying a single- or double-core cable followed by pouring a concrete screed. Electric balcony heating system

To determine which type of heating is better, it is necessary to study in more detail the features of all systems.