The lifespan of any furnace depends on how you use it. It is especially important to fire the stove according to the rules. Many people think that this is easy to do: throw in some wood, light it with paper, and that’s enough. But in practice, improper kindling can not only shorten the life of the structure, but also provoke a fire hazard.

In this article, I will tell you not only how to properly light a stove, but also what problems you may encounter when lighting and how to fix them.

How can you heat a brick oven?

The efficiency of a furnace structure largely depends on the quality of the fuel supplied. Even not the best designs will heat rooms better than a properly built stove in which garbage is burned. Therefore, use the type of fuel for which the furnace structure was designed.

A wood stove must be fueled with wood. If it is planned to use another type of fuel, the structure must be designed accordingly. For example, a coal stove differs from a classic stove in a more developed smoke circulation network. During their passage, the flue gases manage to transfer a sufficient amount of thermal energy to the walls of the structure, and the heat does not immediately go into the chimney along with the combustion products.

The following fuel is also used for brick stoves:

- Coal, hard or brown. This fuel has maximum heat transfer with minimal consumption, and is characterized by long and uniform combustion. When it burns in a stove, the temperature is much higher than from firewood. Therefore, the walls of the fireboxes in such structures are made much thicker and must be lined with refractory bricks. It has a number of disadvantages - coal dust is very corrosive and harmful to health. Fuel is sold in tons, which is not always convenient when the stove is used infrequently. In addition, without the same firewood, it will not be possible to light coal.

Furnace fuel

- Euro firewood or fuel briquettes. There are two types: RUF, formed by pressing wood chips and sawdust under pressure and glued together with a natural composition. Pini-kei, the same briquettes, but fired at the last stage of production, which makes them resistant to moisture and ensures long-term storage. Fuel briquettes burn for a long time (3-4 times slower than ordinary firewood) and heat the walls of the stove well. But they produce little external heat, so it is better not to use them in a fireplace. High-quality briquettes are quite expensive, but cheap briquettes crumble and do not produce long, slow combustion with a long heat release.

- Peat briquettes consisting of peat and sawdust. When burned, such material does not emit toxic substances, does not spark during combustion, and is easy to store as it takes up little space. Forms a small volume of ash (it can be used as a mineral fertilizer due to the increased content of potassium and phosphorus). Among the disadvantages, the most significant are low heat transfer and increased soot deposition.

- Pellets are cylindrical granules of wood waste of the same size. They are most effective when burned in a special boiler, but can also be used in a wood stove. Environmentally friendly fuel with a minimum content of ash substances, high dryness and high density, which transfers heat well, but is expensive.

Despite the fairly large selection of fuel types, firewood remains the most popular option.

We start with competent laying of firewood

It is necessary to carefully prepare the stove mechanism for the heating procedure.

In standard industrial furnace models, you need to work using three main components - a combustion chamber, a specialized smoke and burning system, equipped with a blower and a device for storing ash from firewood - an ash pan. It must be thoroughly cleaned of any remaining ash remaining from the time of the previous kindling - an excessive amount of this substance will interfere with the access of air to the stove. This will significantly slow down the ignition process. In most stoves, the ash pan is a small compartment, so cleaning it will not take much time and effort from the stove maker. After completing the preparation, you can proceed to the next stage - laying firewood.

When it comes to how to properly fire a wood-burning stove, working with the chimney and blower systems plays an important role.

- Before starting work, open both channels to fill the combustion chamber with oxygen.

- While interacting with the smoke exhaust duct, open the shaft damper leading from the combustion chamber to the roof outlet.

- Prepare the required amount of fuel to start work, as well as to complete the entire heating process.

- The initial mass of firewood for kindling should be at least one third of the total volume of the stove chamber.

- Only good quality firewood must be used.

Examples of loading firewood:

Example 1

Example 2

Example 3

The first ignition is a responsible event. You should not try to light a stove with raw wood - all material for heating the stove must be easily and quickly flammable. Otherwise, there is a risk of wasting a huge amount of it, but not achieving the desired goal - to light the stove so that it is warm.

It is necessary to ensure that the base of the combustion material is well dried. At first, it is good to lay thinner wood logs first. It is possible to use various auxiliary means - dry paper from old books or newspapers, well-dried tree bark before starting work.

How to properly heat a stove with wood

The stove structure will properly perform its function for a long time if, when firing it, you adhere to several rules regarding both the quality of the firewood and the features of the process.

Kindling the stove

What kind of wood to heat the stove with?

“Proper” firewood has good flammability and heat transfer, burns almost completely and produces little smoke. These properties depend on the type of wood and the degree of drying.

For the main firebox, hardwood with dense wood is chosen. Birch and oak are considered the best; ash, alder, linden and acacia burn well. Fruit trees are also considered suitable for heating, but it is still better to use them for a fireplace, smokehouse or classic Russian stoves. When burned, such firewood gives a pleasant subtle aroma.

Coniferous wood burns well. But it smokes a lot, burns out quickly and produces a lot of soot due to the high resin content. In addition, it does not provide good heat, so it is better to use it for ignition.

Whatever firewood you use, it must be well dried. Otherwise, the steam released during combustion will condense on the walls of the smoke channels, which leads to a decrease in the efficiency of the furnace. This is also one of the most common factors leading to its premature failure.

Based on the moisture level, firewood can be divided into several categories:

- Freshly cut firewood with a humidity of 50% or more is considered raw. Such fuel will not burn so much as smolder, and will not produce a high temperature. Most likely, there will be big problems with kindling, and moisture from the wood can cause an air lock to form in the chimney.

- Wet firewood is already dried wood (usually outdoors), with a humidity of up to 30%. Such logs can be considered conditionally dry. They can be used to light a stove, but it is best to bring them into a warm room to give the fuel a chance to dry out.

- Dry firewood has a moisture content of 8-15%. This is the best option for a firebox.

Firewood burning in the stove

It is better to buy firewood from wood harvested in winter. They initially contain less moisture and dry faster than summer ones.

You can quickly dry the firewood in order to easily light the stove in the house as follows:

- If the logs have already been dried, but have become wet due to snow or rain, they must be brought into a warm room in advance, where they will dry to a satisfactory condition. That is why many stove makers advise constantly keeping a supply of firewood in the house for several fireboxes.

- Raw wood, immediately after harvesting, must be chopped to the required size. The finished dies are placed under a canopy to dry in the summer, and next to a heating structure in the winter. If you need to quickly dry the firewood, you can place it above the stove, but comply with all fire safety rules. Wood should not be allowed to come into contact with very hot parts of the structure.

So that in winter you don’t have to think about how to dry the logs, store the wood indoors or at least under a canopy. It’s best to make a special woodshed, well protected from precipitation and covered with high-quality roofing material.

Preparing the oven

Before heating the stove with wood, you need to make sure that the structure is in order. This is especially important for structures that have not been used for a long time. Besides:

- Prepare everything you need for the fire, bring in firewood and kindling.

- Clean the firebox and remove ash from the ash chamber so that air can flow freely to the fuel.

- Check the draft in the oven. Open the chimney damper, bring the burning paper to the slightly open firebox opening. If there is a draft in the chamber, then everything is in order.

If, when checking the stove, smoke does not go into the chimney, but into the room, immediately extinguish the flame. And until the cause of the lack of draft is eliminated, do not light the stove!

If you have glass smoking near the stove door...

In any oven there are times when glass smokes. This often happens during kindling, when the stove is still cold or the air lock has not been “broken.” The combustion temperature is not yet high, and there is a lot, a lot of unburnt gases, smoke, which does not have time to escape and can swirl around the glass of the door.

Glass blowing measures do not always help, although we try to make fireboxes with glass ventilation. It may be trivial to have damp firewood (among other things).

What to do in such a situation?

Just try for the first 15-30 minutes of the fire, while the wood is burning, open the fire door 0.5-1 centimeter, this is enough to cut off the smoke from the glass. This will also provide additional oxygen for lighting the stove. With this calculation, you can open the blower a little less.

Stages of kindling

For kindling, take birch bark, wood chips and shavings from dry firewood. Lighting the stove with flammable and explosive substances is prohibited!

The prepared kindling is placed on pre-crumpled paper, and several logs are placed on top. When filling for the first time, the fuel chamber does not need to be filled to the limit; it should be filled to a third of its height. If you immediately load the firebox, it will be difficult for the stove to reach operating mode. In addition, the height of the stack depends on the quality of the firewood. The damper the logs, the lower their layer should be.

Firewood for the stove

As soon as the kindling flares up, close the fuel door and fully open the ash chamber. We wait until the bookmark burns out.

We stack the first main portion of firewood tightly, over the entire area of the grate, so that at least 100 mm remains to the top of the fuel chamber. We regulate combustion by partially closing/opening the valve and the ash door:

- Normally, the flame should be straw-colored.

- If the fire turns red and soot appears, you need to increase the access of fresh air (i.e. open the valve or ash door).

- The flame becomes almost white and the stove begins to hum - the draft is excessive, you need to cover the vent.

The main batches of firewood should be laid as tightly as possible to ⅔ of the volume of the firebox, so as not to unnecessarily open and cool the firebox. If one load is not enough, subsequent bookmarks are performed after the first one has completely sunk.

There may be several floods, but it is worth remembering that a brick stove “does not like” overheating. And a long time of heating will ruin it. Therefore, do not make more than two bookmarks.

The firebox is considered complete if the flame completely disappears in the chamber. However, you should not close the valve or view if there are still smoldering coals in the stove. This is life-threatening! You must first wait until they burn out completely and only then close the chimney.

Safety regulations

A brick oven is a fire hazardous structure. Therefore, when operating it, first of all, it is necessary to adhere to fire safety rules. There should be no flammable substances or materials near the structure. When opening the oven, make sure that no coals fall out.

The stove is a fire hazard

The second danger is the formation of a significant amount of carbon monoxide when burning fuel. That's why:

- do not operate the structure if there is no traction;

- light the stove long before bedtime and do not leave it running unattended at night;

- do not close the valve until the coals have completely burned out;

- if the structure has not been used for a long time, first inspect it for cracks through which carbon monoxide can enter the room.

In addition, a furnace is a structure with an increased risk of injury, and it is easy to get burned on the heated elements (furnace doors, cast iron stoves, side surfaces of individual structures). When working, be careful and keep children away from the structure.

Step-by-step instructions for lighting and organizing the operation of a solid fuel stove

The first steps towards obtaining heat by operating solid fuel stoves are taken long before the onset of the cold season. The preparation and storage of material is carried out in such a way that it is convenient to “dosage” and transfer it to the room when the time comes.

A woodpile can become an original design element for a personal plot. Source pinterest.ru

How to light a stove after a long break

After a long period of inactivity, the stove usually heats up very reluctantly and does not go into operating mode for a long time. There are several reasons for this condition:

- the structure became damp due to high humidity in the house;

- the pipe is frozen;

- an air lock has formed in the chimney;

- the chimney is clogged with debris.

All these problems lead to a decrease or complete loss of draft, which negatively affects the operation of the furnace. Therefore, before heating the stove, you need to carry out preparatory measures.

Burning stove in the house

You can restore the functionality of the furnace structure in the following ways:

- Eliminate the difference in air temperature in the room and inside the pipe. The method will only be effective if the house is initially warm. Open the furnace door of the stove and the entrance door of the room so that the resulting draft provokes the movement of air masses from the firebox into the chimney and further into the street.

- Warm up the chimney. This helps to break through the air lock formed due to high humidity, temperature or pressure changes. To do this, several newspapers or sheets of paper are placed in the chimney cleaning door and set on fire. After a couple of minutes, the hot air will push out the cold air and a draft will appear.

- You can also heat the chimney from the firebox. Open the air damper and the blower door and burn several batches of paper in the firebox. If the flame tends inward, towards the chimney, the desired effect is achieved.

If all of the above methods did not help, most likely a blockage of soot or icy snow has formed in the chimney, or a bird has built a nest (this is rare, but it does happen). Soot build-ups often appear when the stove is burned incorrectly, for example, with wood with a high resin content. They can be removed by cleaning the chimney.

An ice jam forms in winter. This happens if the stove has not been used for a long time (for example, if it is installed in a country house). The kurzhak is usually located quite deep in the pipe, on the border of a warm and cold room, where it is difficult to reach. Therefore, it is quite difficult to get rid of it. You can try to carefully break through the ice plug with a heavy object smaller than the diameter of the pipe. However, this will only help if there is not much snow accumulated inside. In other cases, you will have to wait until spring when the ice melts naturally.

Some “craftsmen” suggest getting rid of this problem by using boiling water with dissolved table salt, heating the iron chimney with a blowtorch or welding transformer. There are even those who suggest pouring antifreeze or gasoline into the pipe.

I do not recommend using such advice, as this can damage the stove and subsequently result in costly repairs.

To avoid encountering such problems during rare use of the stove, do not forget to regularly inspect the chimney for clogging, the appearance of soot and traces of soot, and be sure to clean the smoke channel.

Useful tips

- When lighting a stove that has not been used for a long time, it is recommended to carry out the ignition process very carefully, gradually and slowly

- Use wood that has been dry for at least a year

- Before lighting, inspect the heating device and chimney for cracks, deformation, and soot.

- It is not recommended to use gasoline and other flammable liquids for ignition, as they can damage the heating product and produce an unpleasant odor.

- Follow the stove manufacturer's recommendations for use, fuel type and size.

- It is recommended to finish the heating process several hours before bedtime.

- Carry out chimney maintenance twice a year - at the end and beginning of each heating season

- When installing and assembling the stove and chimney, use the services of professionals

How to avoid getting burned by the stove in your home

After the wood burns out, quite a lot of coals remain. They can smolder for quite a long time, while carbon dioxide is released no less than during combustion. Therefore, at this moment you cannot completely close the chimney damper.

Open chimney damper

On the other hand, if the view is open for too long, the stove will quickly cool down due to heat leakage through the chimney. This problem can be solved by afterburning coals:

- To do this, they are raked onto grates in the middle of the combustion chamber, the combustion door is tightly closed and the damper is half closed. Then open the blower door for free access of air. The coals will smolder on their own.

- If the design does not have a grate, the remains of burnt firewood can be raked to the stove entrance. In this case, the firebox door must be closed, and the holes in the lower zone of the door must be open. Air is blown through the lower holes.

- If the design of the furnace does not allow you to quickly burn out the fuel and there is no time, small-sized coals can be removed from the combustion area and collected in a metal bucket. The main thing is to close it tightly with a lid and immediately take it outside.

It is unacceptable to extinguish the coals in the firebox with water, this will lead to damage and reduce the service life of the heating device.

Only after complete combustion of the coals can the valve be closed. Following this simple rule will help preserve your health, yours and that of your loved ones. Or maybe even life.

Some nuances of heating

- It is recommended to heat the stove with whole logs after one, or better yet, two batches of small-sized firewood have burned out. It is not recommended to use overly large logs: they form coals that smolder for too long, and most of the thermal energy from them simply goes into the chimney.

- During heating, it is recommended to move and turn the coals in order to get maximum thermal energy from them and optimize air flow.

- When burning wood, you need to make sure that the flame is uniform and all the wood is burning, not just individual ones. To do this, turn over poorly burning logs and use a poker to move them closer to the epicenter of the fire.

Use the advice and recommendations of professionals

Our specialists are always happy to provide competent advice on the best methods for using heating devices, including techniques for lighting stoves. The contacts section contains current information; you can contact us in any way convenient for you. When choosing and purchasing stoves, fireplaces or fireboxes, managers will provide the client with all the necessary information on the correct use of the equipment based on both their knowledge and experience, and the recommendations of a specific manufacturer.

also provides a full range of services for delivery, installation, commissioning and maintenance of heating products and chimney systems.

What types of woodpiles are there?

There are various forms of stacking logs. You can choose the one that is suitable in this particular case.

Woodpiles can look like this:

- In the form of “sheaves”. It is very convenient to store in this form, since you do not need to build a shed or shed for this. In order to lay out a woodpile in a “stack”, you need to find wood of suitable quality that can be stored for a long time and learn how to stack the logs correctly. Such “sheaves” will last for several years and the firewood will retain its properties. Trellis are placed at the base of such a woodpile. You can lay flat stones or bricks as the base. The main thing is to raise the logs above the ground so that they do not get damp. The base is laid out in a circle, the logs inside are placed in random order. This idea is to ensure that the firewood is well ventilated. A pole is installed in the middle, which will hold the entire structure, from bottom to top.

- This styling looks very aesthetically pleasing. If you put wood of different species in such a “sheaf”, the multi-colored structure will decorate any landscape.

- The second way is in the form of a “fungus”. The stacking method is similar to a “stack”; the logs are split in a special way - not in logs, but in short planks. With the help of such a flat shape, the installation of such a “fungus” is easier. If you want to make the “mushroom” symmetrical in shape, you need experience and time. But this option will be a wonderful decoration for your garden plot.

- The woodshed is compact in size with an original roof. Most often, woodpile designs are made simple, without thinking about the aesthetic appearance. And completely in vain. Woodsheds can not only diversify the landscape, but also divide the area into zones. Compact structures are installed in cases where firewood is used from time to time, not as the main fuel.

- Large woodsheds are storage facilities in which you can store a large number of logs, stocking up for several winters ahead. Externally, such warehouses resemble gazebos, there are cracks in the walls for ventilation of the wood, the roof is reliable and should cover the entire woodpile.

- You can put a woodpile right next to the house. A roof of this design protects the path between the building and the woodpile, that is, snow will not get there. Therefore, getting to the firewood in winter will be easy. The firewood is well ventilated and protected from the sun and precipitation. If you stack the logs in this way, you don’t have to worry about them getting damp or rotting. The construction of such a structure is not difficult. You will need to stock up on wooden blocks or metal corners, a chain-link mesh with large cells, and any roofing material. Floors should be laid with simple tiles, such as those used for sidewalks.

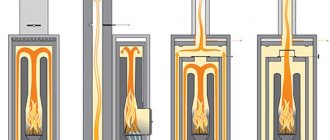

Combustion process

While wood or coal is burning in the firebox, in order to ensure their uniform combustion, it is necessary not only to stir the filling in a timely manner (2-3 stirrings are needed), but also to close the ash door and chimney in a timely manner. If you don’t know exactly how to properly heat a brick oven, aim for 1.5-2.5 hours (depending on the size of the oven itself and the room, as well as the ambient temperature).

Combustion process in a furnace

Unburnt brands and unburned coals are collected during the combustion process on the center of the grate. But large pieces of coal or large unburnt logs will burn out for a very long time and stupidly, since cold air from the ashpit will carry more than 60% of the heat into the chimney . It will be easier to remove them from the firebox and leave them for later storage.

The chimney valve closes only after the blue lights above the coals disappear and a white ash coating appears on top of the burnt-out filling.